Mixed conductor composite material LiFePO4-MXy and preparation method thereof

A technology of mixed conductors and composites, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low bulk density, increased irreversible degree of charge and discharge, and low volume specific capacity, so as to improve ionic conductivity and electronic conductivity High efficiency, improved discharge and cycle stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

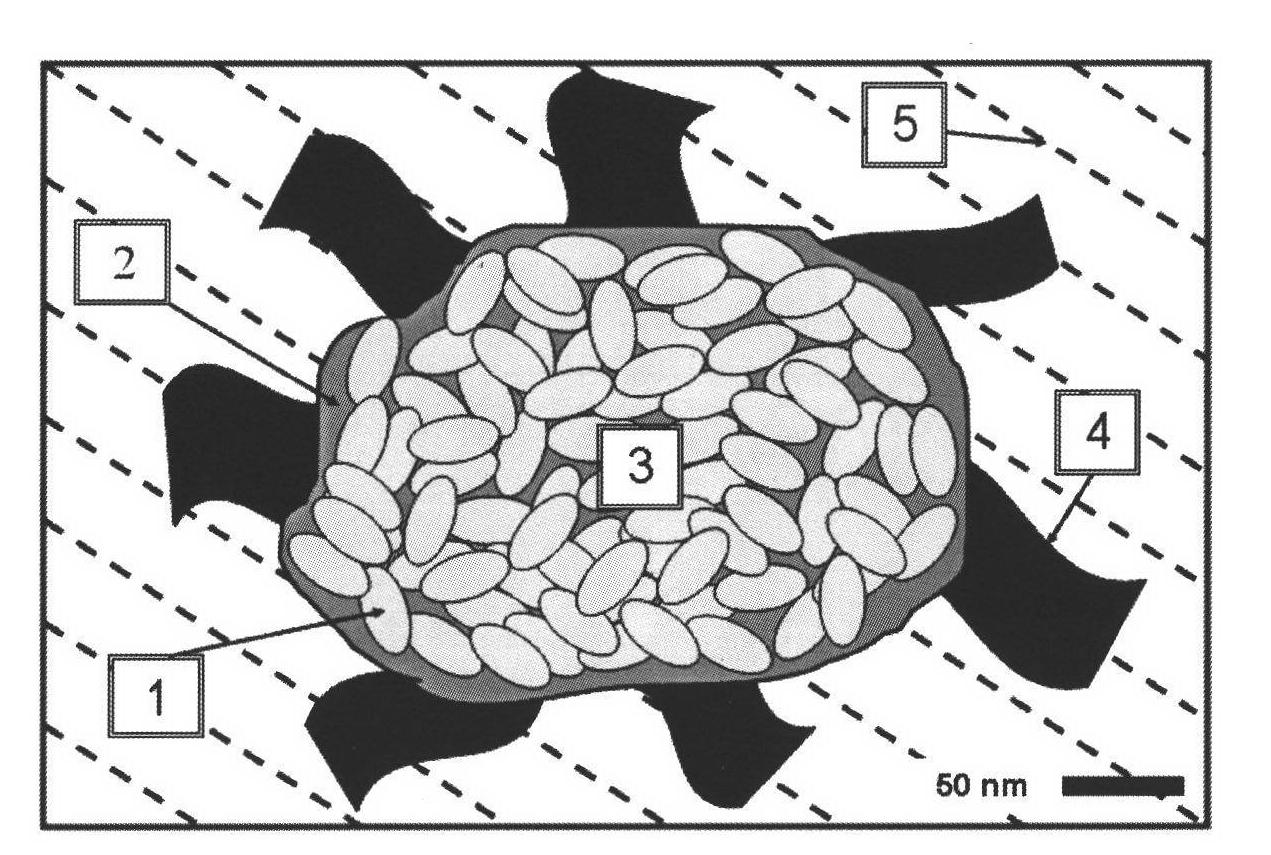

Method used

Image

Examples

Embodiment 1

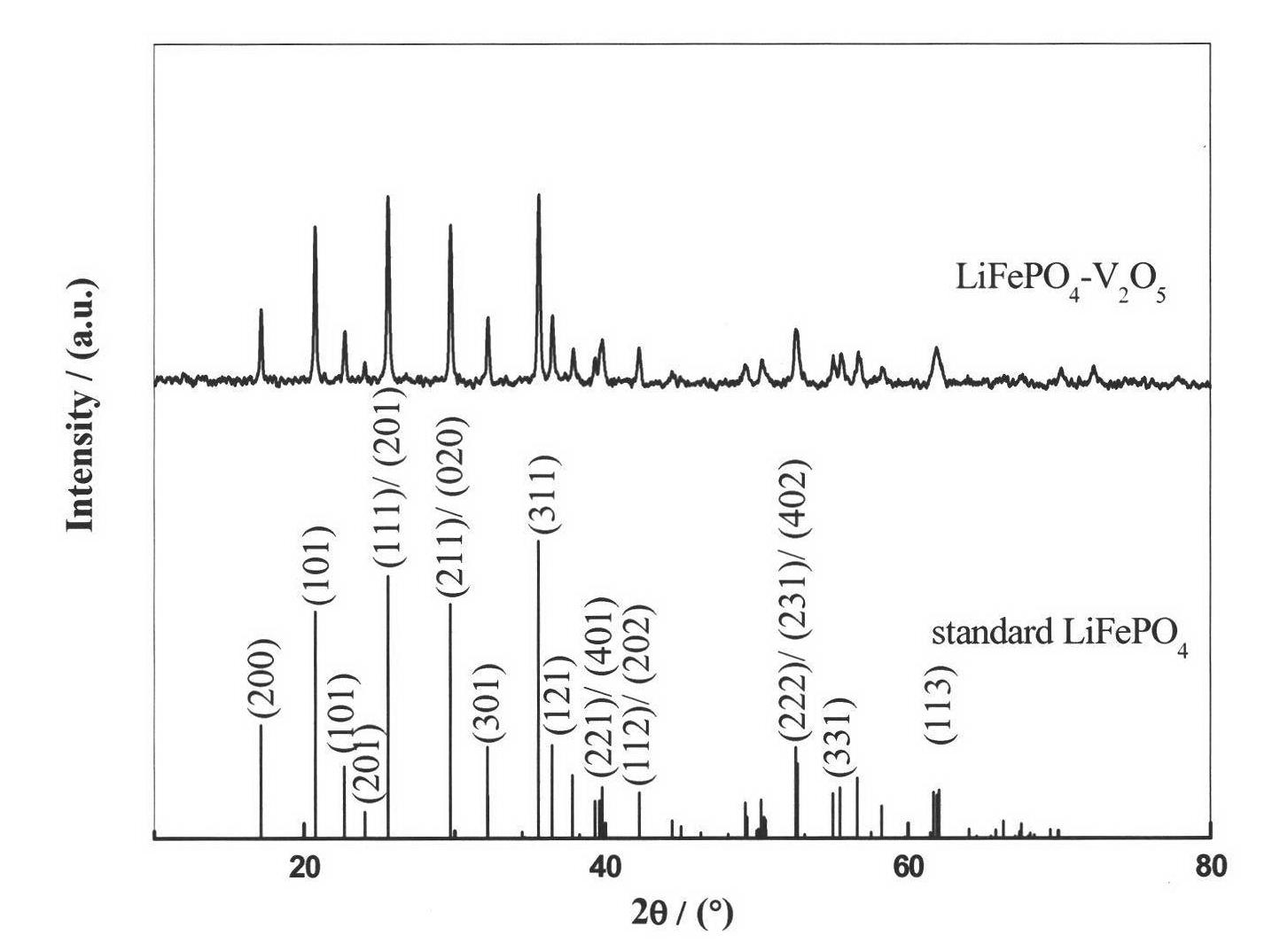

[0031] Weigh FeSO 4 ·7H 2 O 8.34g, NH 4 h 2 PO 4 3.45g and LiOH·H 2 O 1.26g, placed in a ball mill jar, using ethanol as a dispersant, ball milled for 3h, the ball milled slurry was dried at 60°C and then ball milled into powder, placed in Ar / H 2 (Ar accounts for 95V%, H 2 accounted for 5V%) in a high-temperature tube furnace protected by mixed gas at 350° C. for 8 hours, and cooled to room temperature. Then the calcined product was ground, pressed into tablets and granulated, and then placed in Ar / H 2 (Ar accounts for 95V%, H 2 Accounting for 5V%) in a high-temperature tube furnace with a mixed atmosphere, firing at 700°C for 15h. After cooling to room temperature, grinding to obtain LiFePO 4 Cathode material. Then 96wt.% LiFePO 4 and 4wt.% conductive V 2 o 5 The powder was high-energy ball milled for 2 hours, and annealed in a tube furnace in an Ar atmosphere at a temperature of 200 °C for 1 hour to obtain LiFePO 4 -V 2 o 5 Mixed conductor composite (MCM).

...

Embodiment 2

[0036] Weigh FeSO 4 ·7H 2 O 5.56g, NH 4 h 2 PO 4 2.30g and LiOH·H 2 O 0.84g, placed in a ball mill jar, using ethanol as a dispersant, ball milled for 2h, the ball milled slurry was dried at 60°C and then ball milled into powder, placed in Ar / H 2 (Ar accounts for 95V%, H 2 accounted for 5V%) in a high-temperature tube furnace protected by mixed gas at 350° C. for 8 hours, and cooled to room temperature. Then the calcined product was ground, pressed into tablets and granulated, and then placed in Ar / H 2 (Ar accounts for 95V%, H 2 Accounting for 5V%) in a high-temperature tube furnace with a mixed atmosphere, firing at 700°C for 15h. After cooling to room temperature, grinding to obtain LiFePO 4 Cathode material. Then 90wt.% LiFePO 4 and 10wt.% MnO 2 High-energy ball milling for 2 hours, followed by annealing in a tube furnace in an Ar atmosphere at a temperature of 200 °C for 1 hour to obtain LiFePO 4 -MnO 2 Mixed conductor composite (MCM).

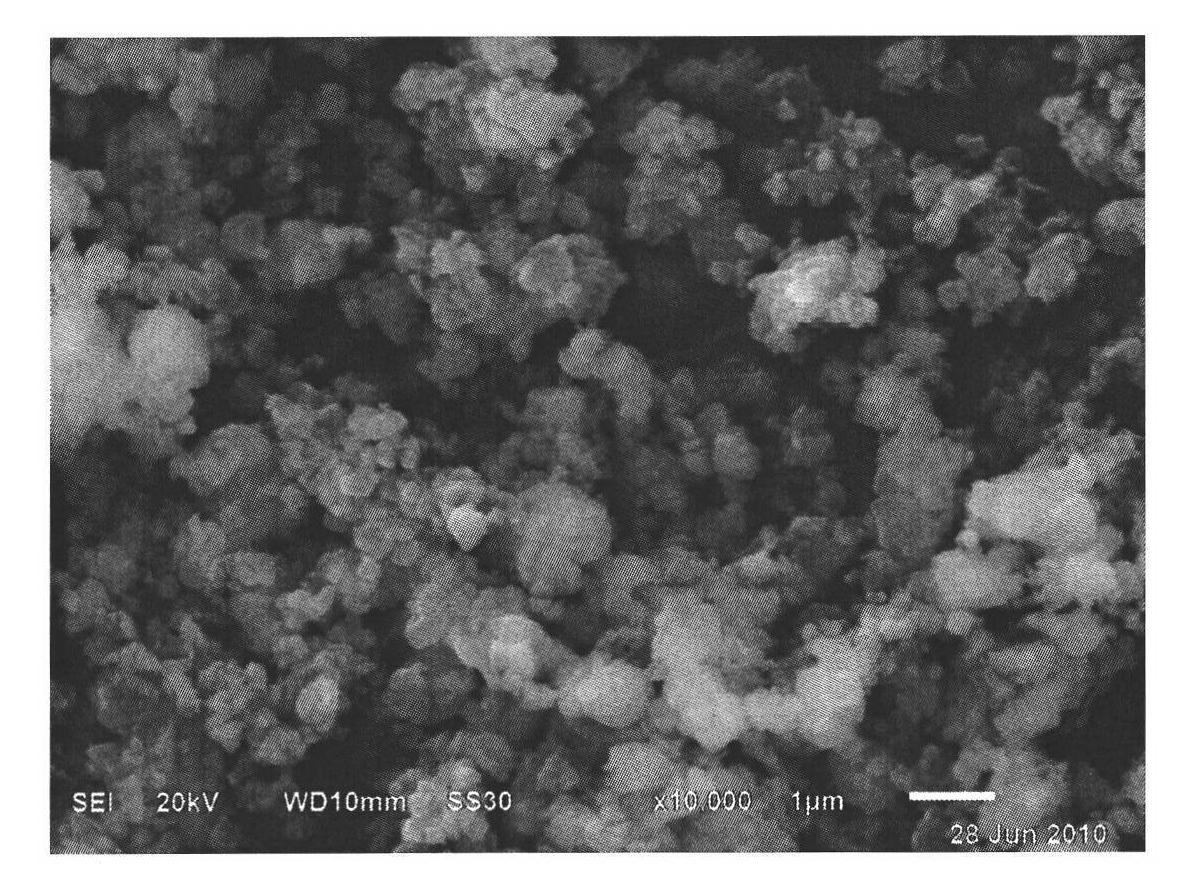

[0037] image 3 for...

Embodiment 3

[0039] Weigh FeSO 4 ·7H 2 O 11.12g, NH 4 h 2 PO 4 4.60g and LiOH·H 2 O 1.68g, placed in a ball mill jar, using ethanol as a dispersant, ball milled for 2h, the ball milled slurry was dried at 60°C and then ball milled into powder, placed in Ar / H 2 (Ar accounts for 95V%, H 2accounted for 5V%) in a high-temperature tube furnace protected by mixed gas at 350° C. for 8 hours, and cooled to room temperature. Then the calcined product was ground, pressed into tablets and granulated, and then placed in Ar / H 2 (Ar accounts for 95V%, H 2 Accounting for 5V%) in a high-temperature tube furnace with a mixed atmosphere, firing at 700°C for 15h. After cooling to room temperature, grinding to obtain LiFePO 4 Cathode material. Then 98wt.% LiFePO 4 and 2wt.% NiO high-energy ball milling for 3h, and annealing in a tube furnace in an Ar atmosphere at a temperature of 300°C for 1h to obtain LiFePO 4 - NiO mixed conductor composite (MCM).

[0040] Conductivity before and after compoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com