Method and apparatus for recovering methane from hydrate near the sea floor

a technology of methane gas and sea floor, which is applied in special mining, sealing/packing, and wellbore/well accessories. it can solve the problems of not disclosing the method of gas hydrate harvesting from the pore spaces of marine sands on the sea floor by fluidizing marine sands, and not disclosing the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

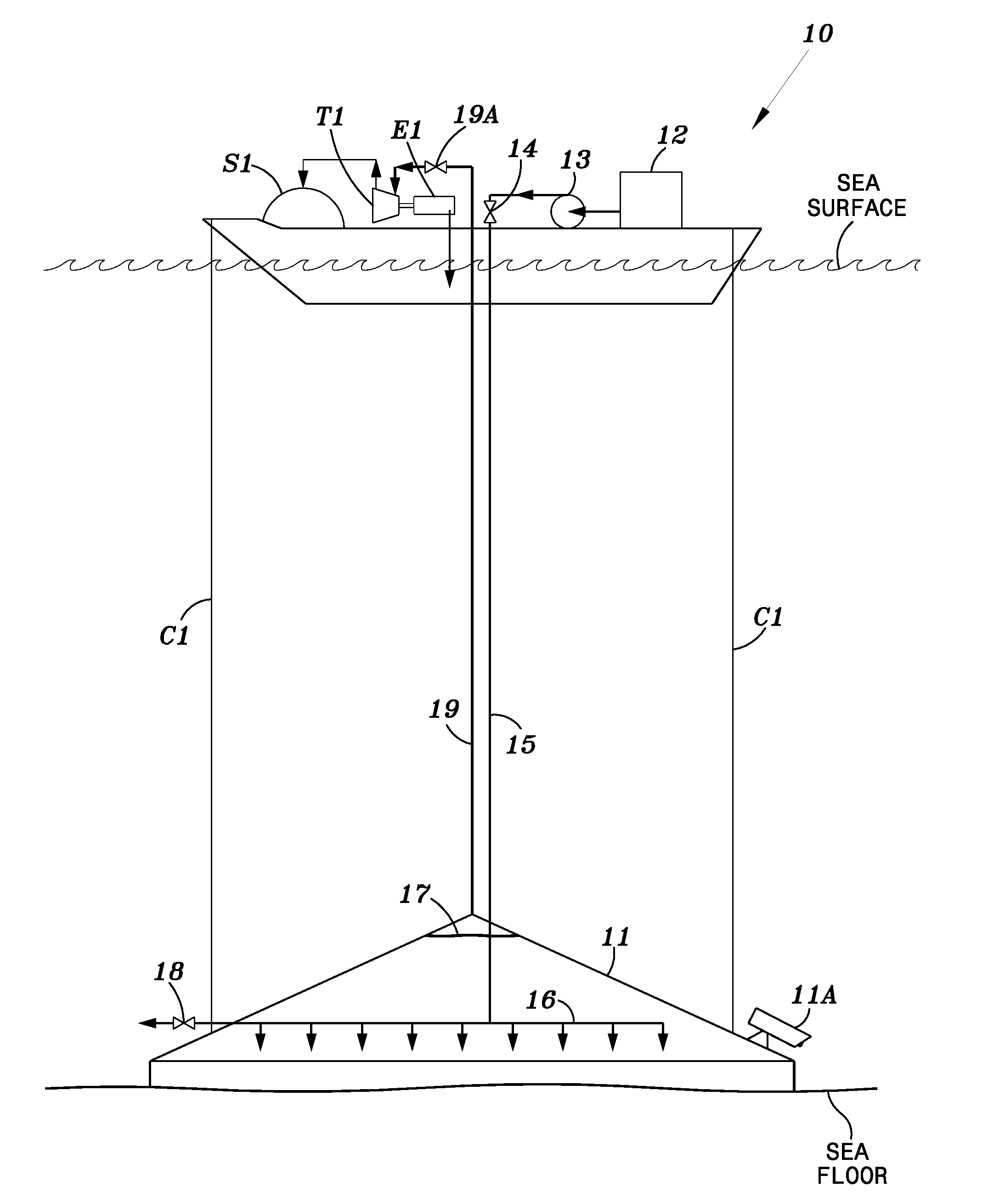

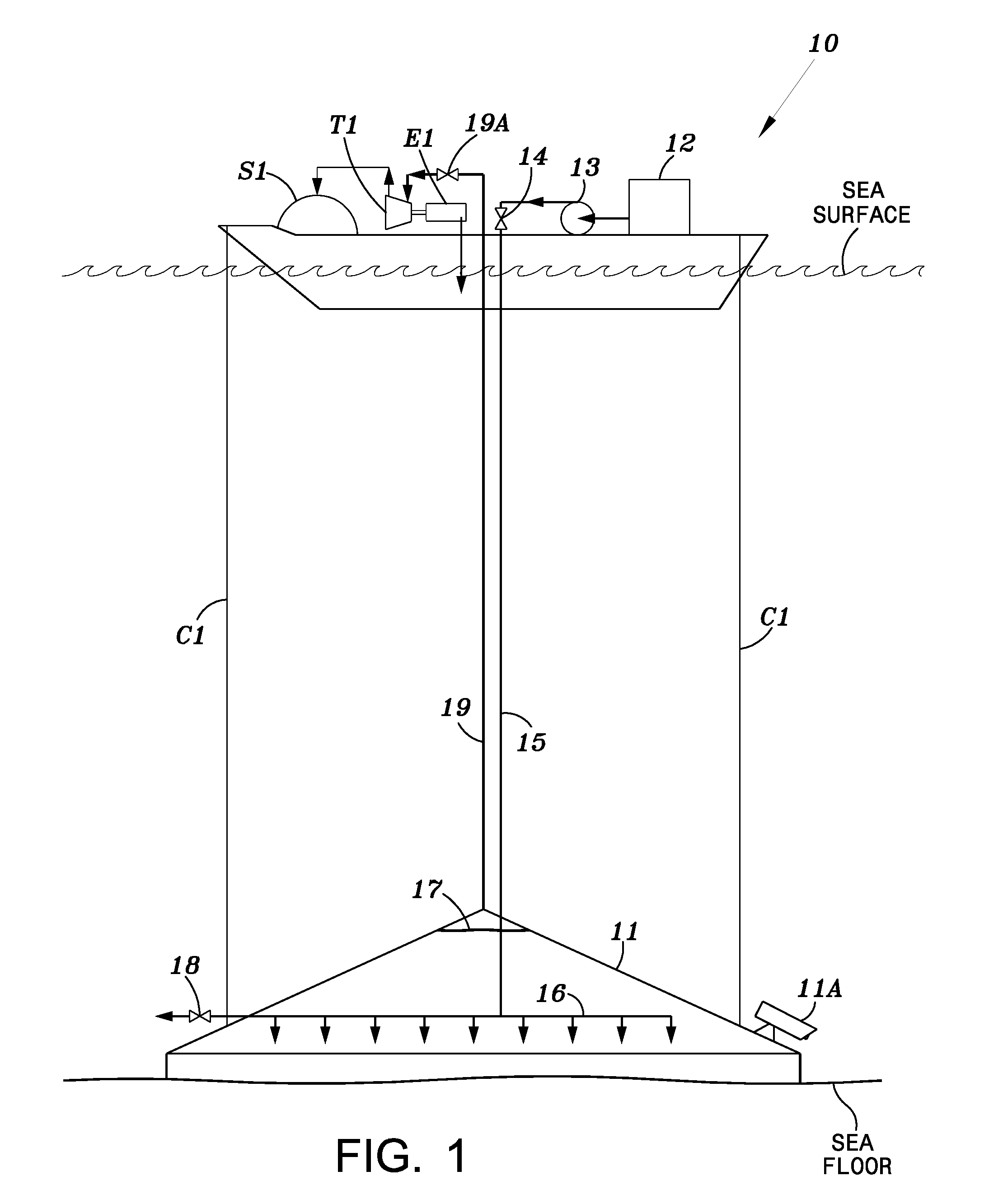

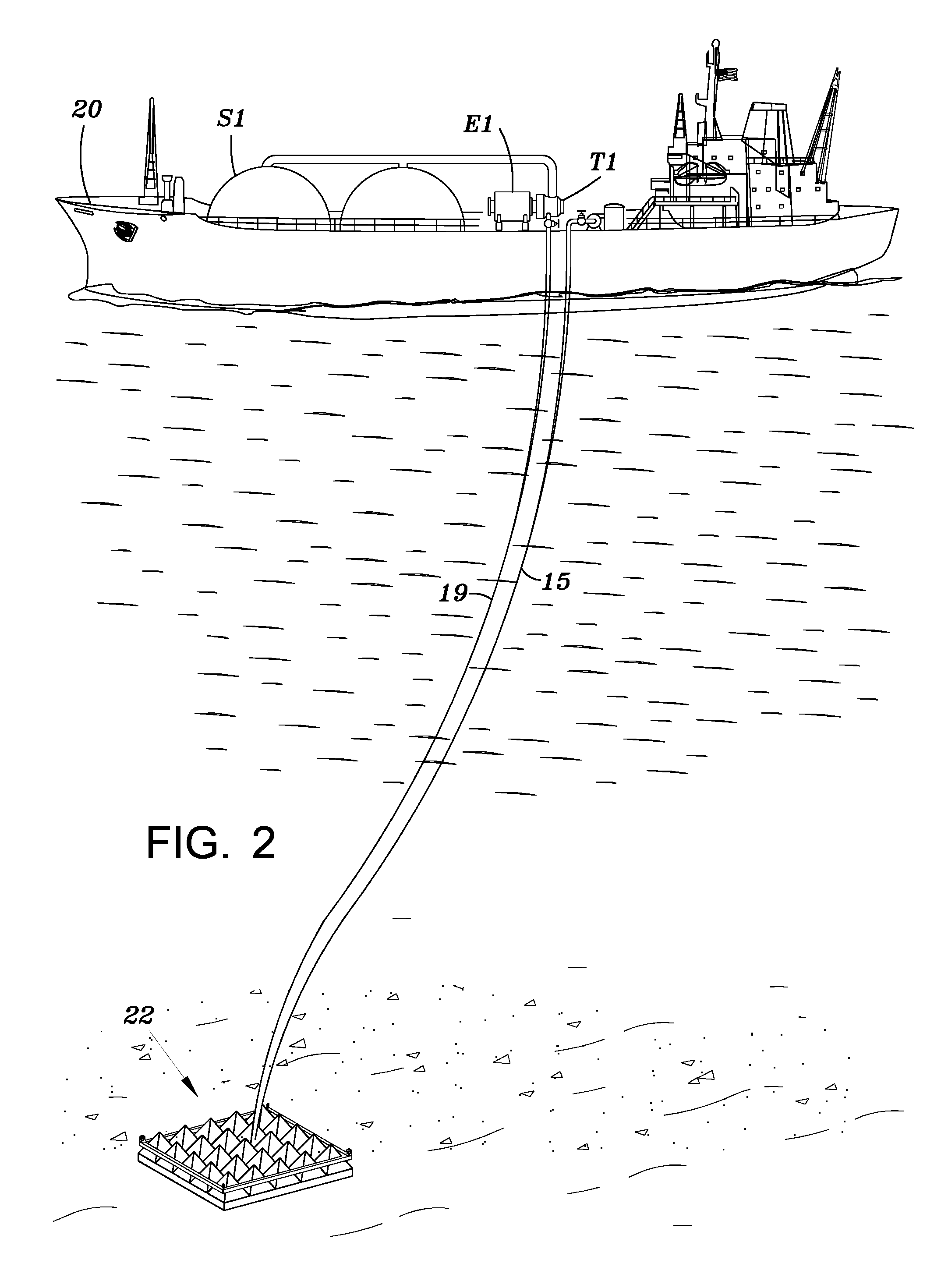

[0021]FIG. 1 illustrates an overview of apparatus 10 used in one embodiment of the process disclosed herein. One or more dome structures 11 are lowered to a depth near the seafloor where hydrate exists. Heater 12 on ship 20 heats seawater and pump 13 pumps the hot seawater through control valve 14 and water pipe 15 to spray header 16. The spray header distributes warm water through spray jet nozzles, preferably evenly spaced and optimized to fluidize the marine silt and sand to release solid gas hydrates located near or on the seafloor. Gas from hydrate collects under dome 11 and migrates to the top to form gas space 17. Gas flows to the surface through gas pipe 19. Valve 19A controls the rate of upward flow of methane gas to control the size of the gas space and to avoid two-phase liquid and gas flow in pipe 19. Cables C1 are used to hoist, lower and move dome 11. Although a ship is illustrated in the figure, any structure at the surface may be used, such as a semi-submersible plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com