System And Method For Natural Gas Liquefaction

a technology of natural gas liquefaction and system, which is applied in the direction of refrigeration and liquifaction, lighting and heating apparatus, solidification, etc., can solve the problems of limited expansion ratio achieved by a single expander, high refrigerant mass flow rate in these processes, and limited performance of lng process, etc., to achieve the effect of improving refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention may be understood more readily by reference to the following detailed description of certain embodiments of the invention.

[0029]Throughout this application, where publications are referenced, the disclosures of these publications are hereby incorporated by reference, in their entireties, into this application in order to more fully describe the state of art to which this invention pertains.

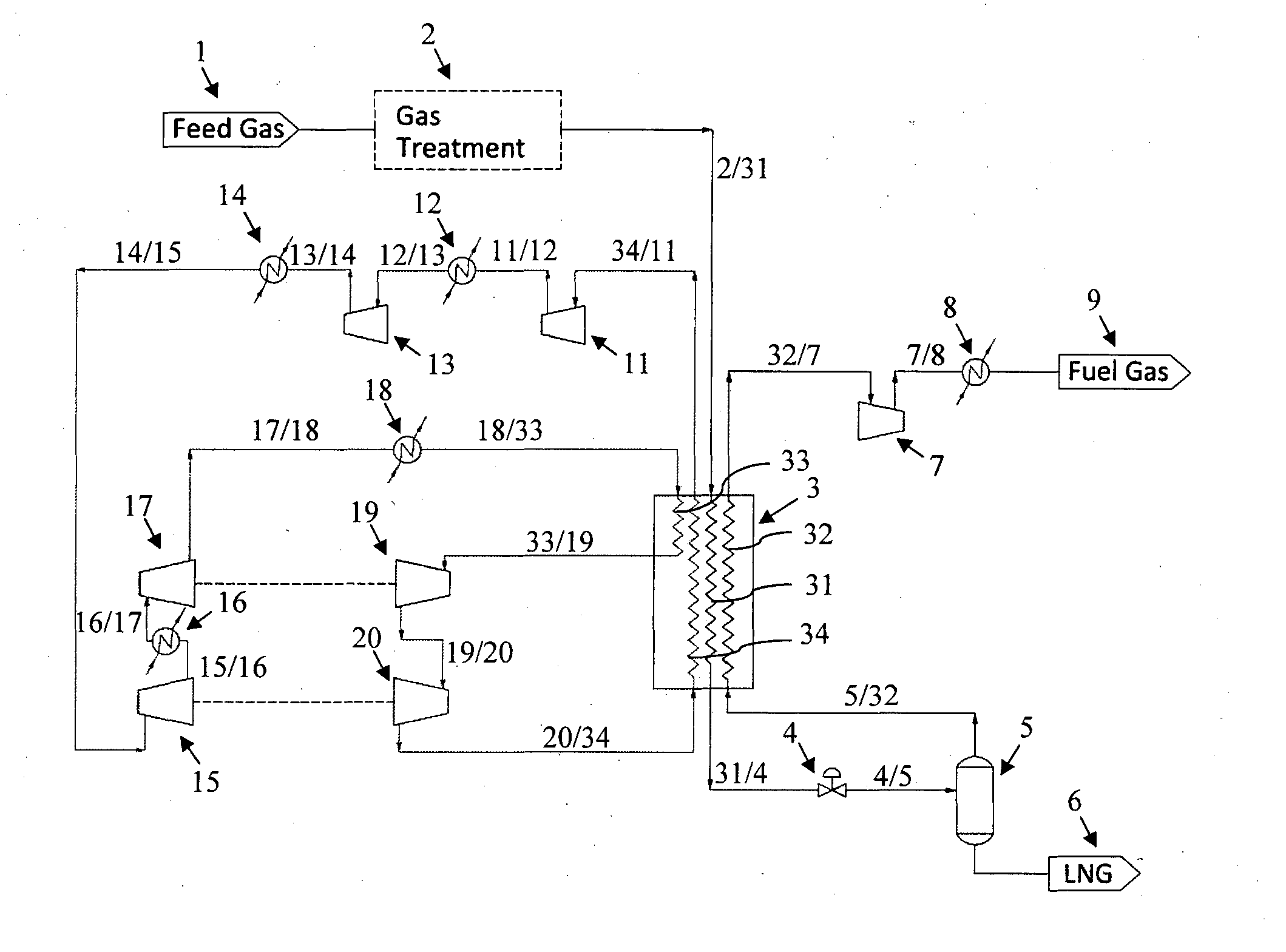

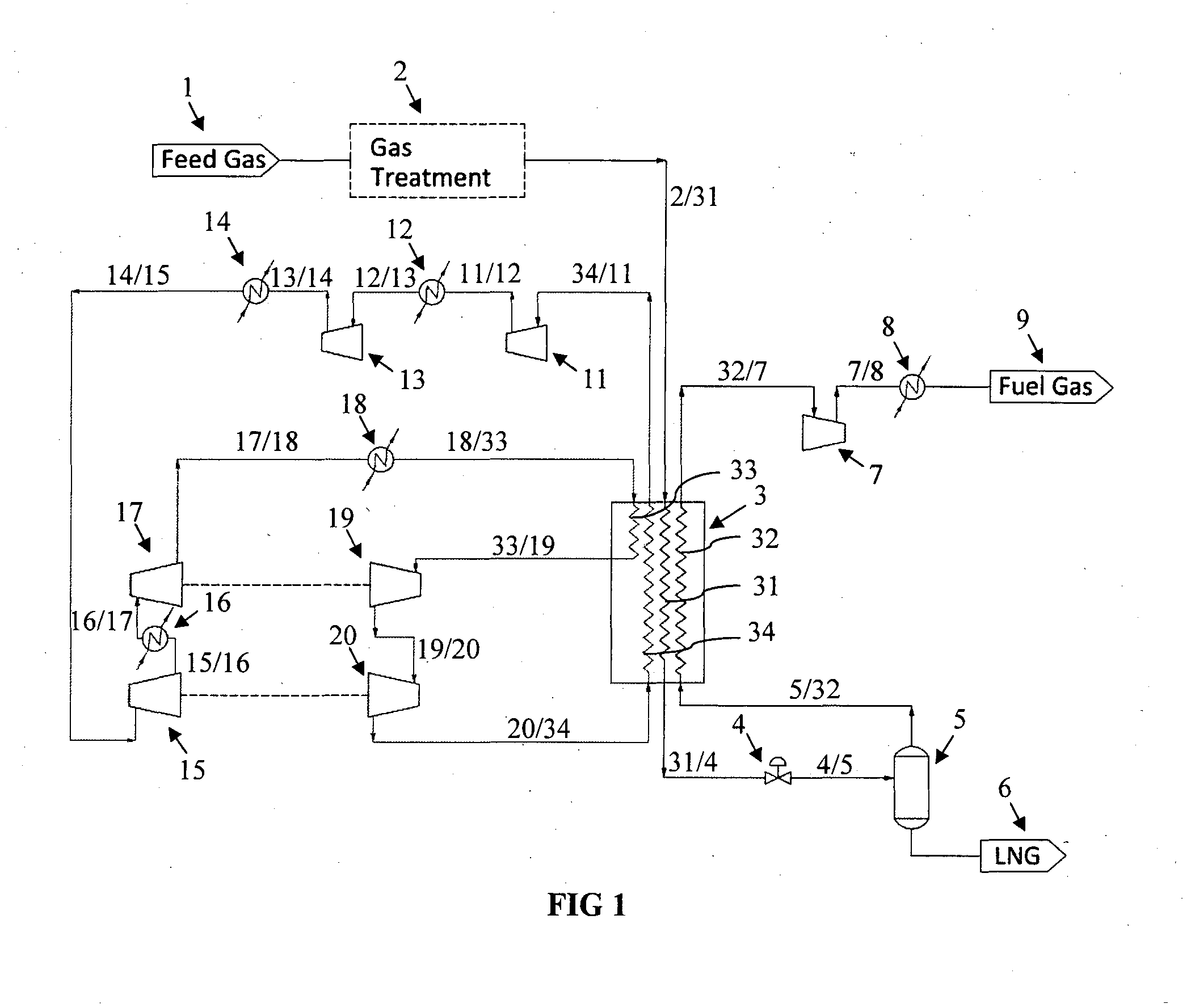

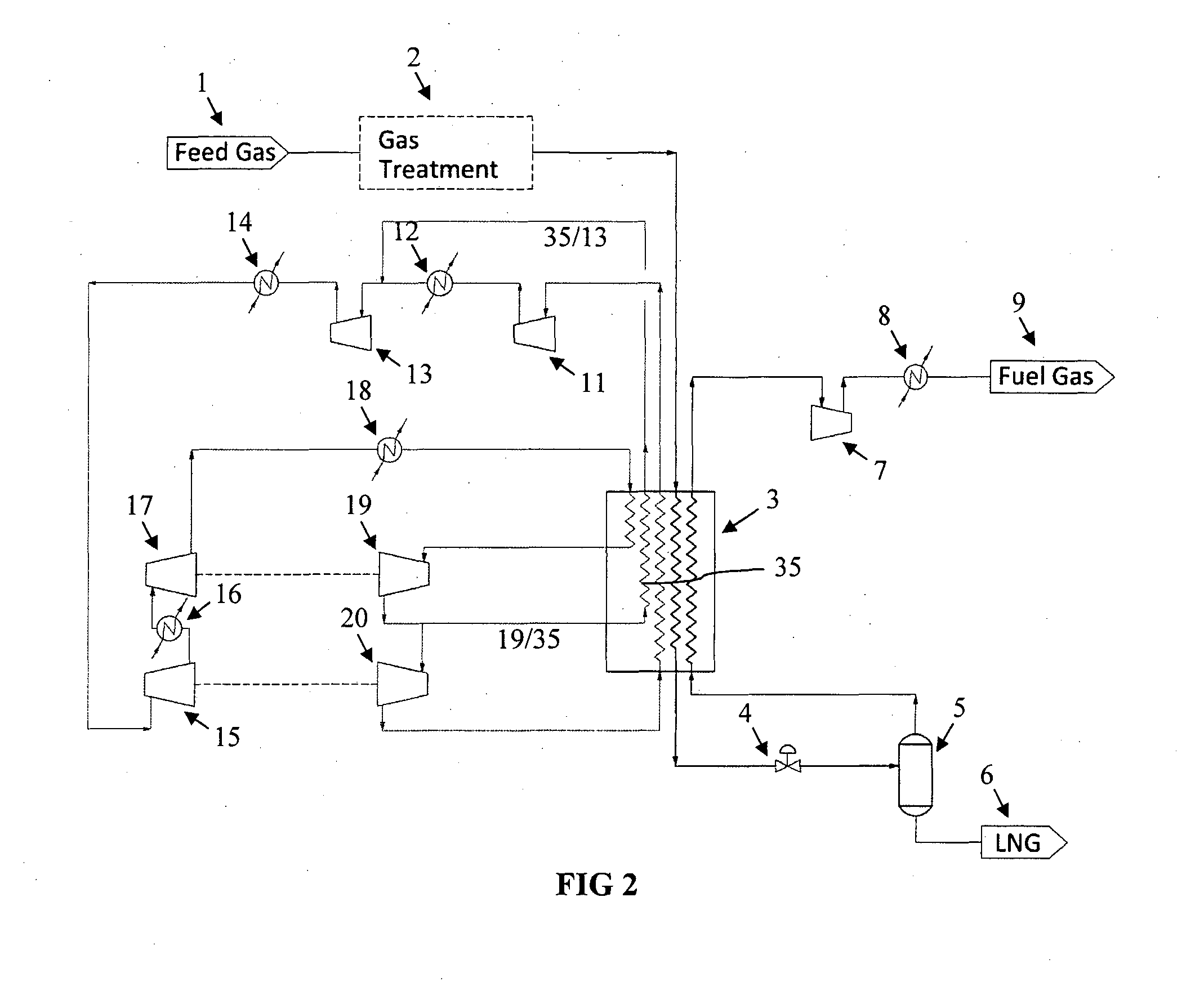

[0030]The present invention provides a system and method to liquefy the natural gas using expander based refrigeration cycle in a simple and efficient way. The system and method uses turboexpanders in series arrangement, resulting in the advantages of simplicity and flexibility, low refrigerant flow rate requirement, low expansion ratio requirement for each expander, and competitive efficiency and power consumption, when compared with the existing prior art processes.

[0031]Referring now to FIG. 1, there is provided an LNG production system in accordance with one embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com