High-pressure compressing solid-liquid separation device of flexible pipe

A solid-liquid separation and high-pressure technology, which is applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of restricting the popularization and use of solid-liquid separation devices, high manufacturing cost, and long axial length of the filter tube unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

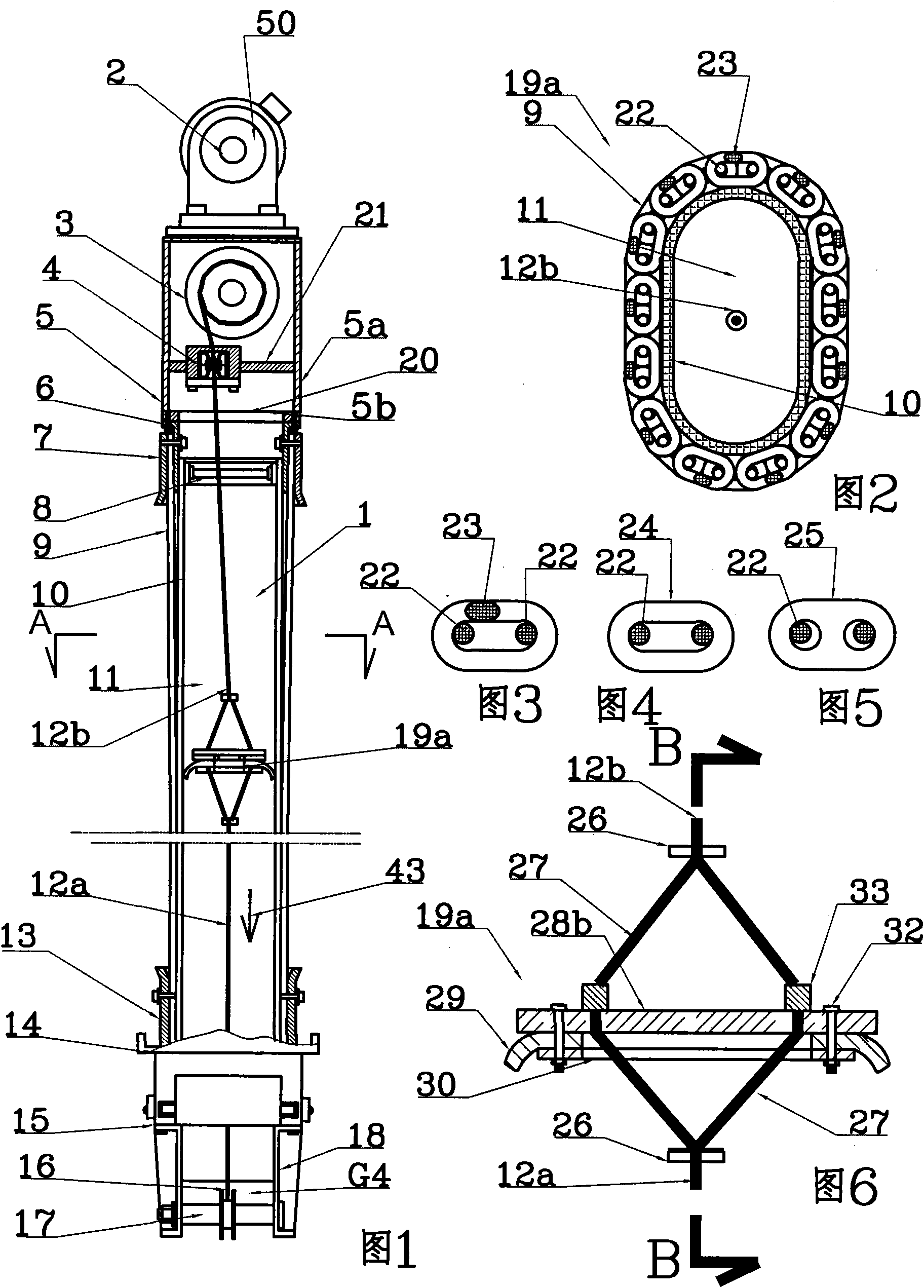

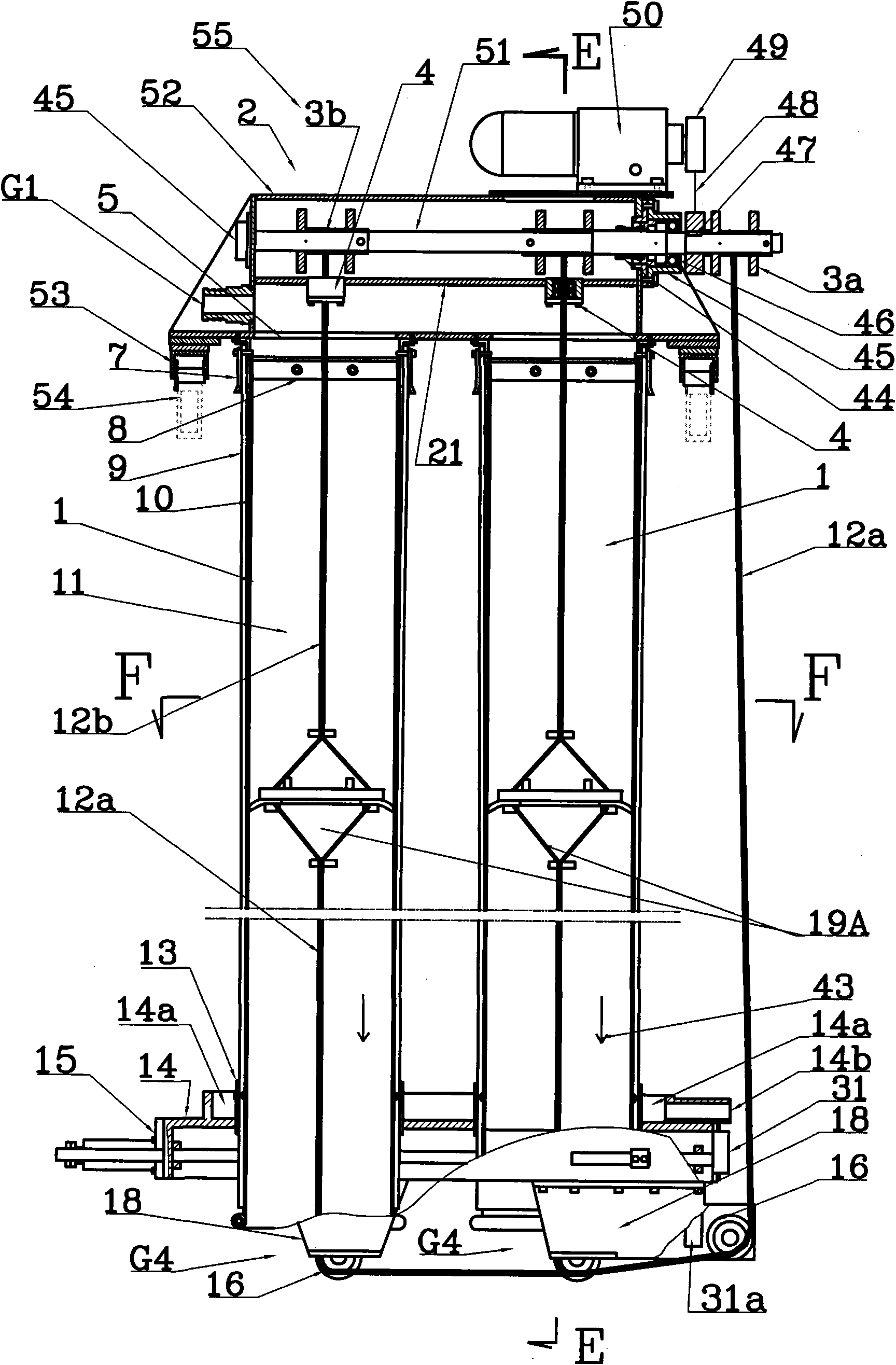

[0062] exist figure 1 , 2, 3, 6, 8, 9, 11, 17 and 18, shows the overall embodiment 1 of the apparatus of the present invention, the filter assembly in this embodiment comprises two A filter elements 55; two A filter elements 55 are arranged in parallel It is arranged on the two frame guide rails 54 of the frame 76 and can be relatively moved along the front and rear direction of the arrangement by the guide wheel assembly 53. The front and rear direction of the arrangement is also the direction of the pressing force of the pressing system; the A filter element 55 includes two filters Tube unit 1, upper flange 5, lower flange 14 and mechanical slag discharge assembly; all filter tube units 1 of A filter element 55 are arranged between upper flange 5 and lower flange 14; all filter elements of A filter element 55 The long axes of the filter pipe unit 1 are all in a central plane, which coincides with the long axis of the center of symmetry of the upper flange 5 and the lower f...

Embodiment 2

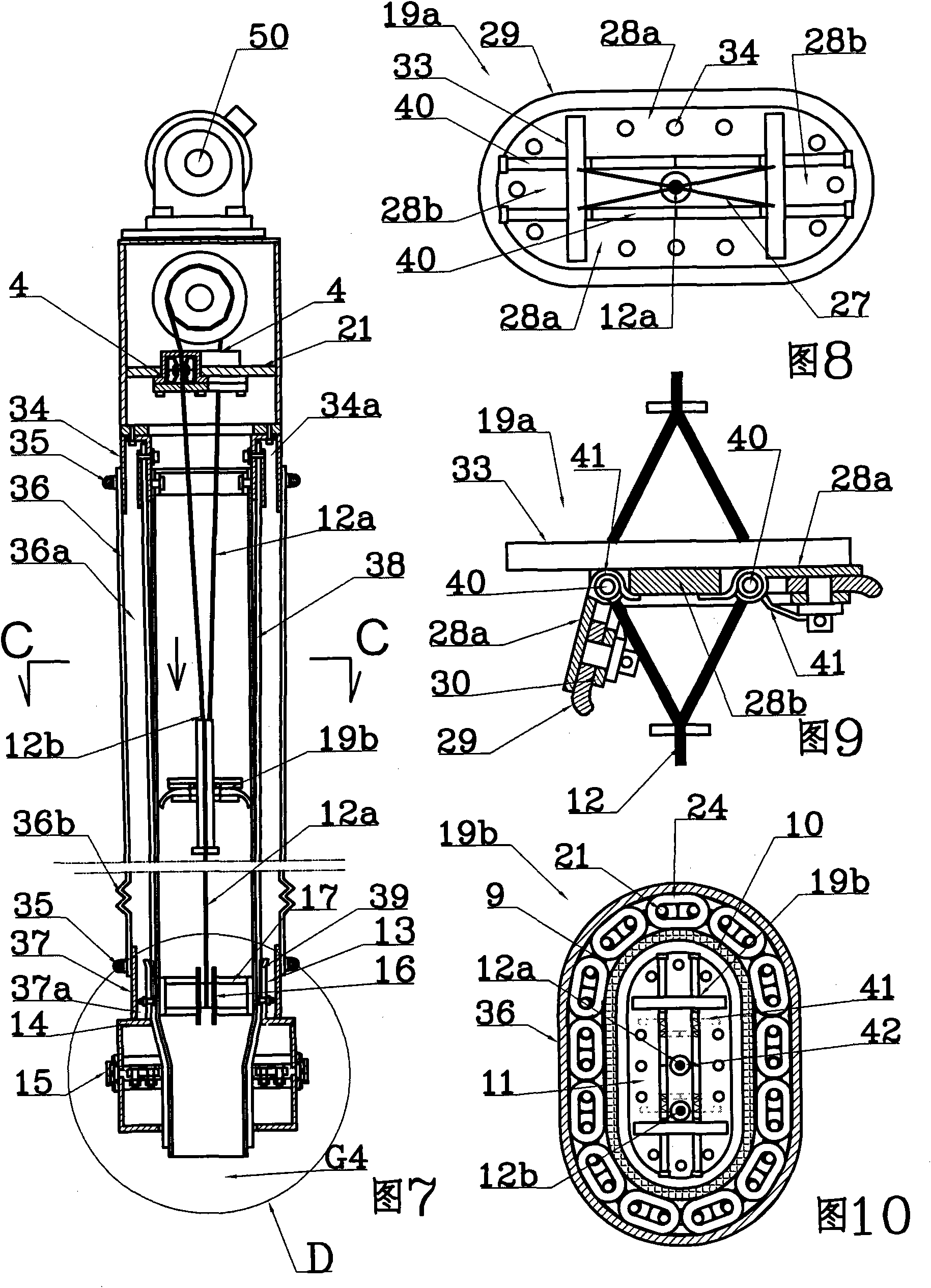

[0066] exist Figure 4 , 7 , 10, 12, 13, 14, 15, 16, 19 and 20, shows the overall embodiment 2 of the equipment of the present invention, the difference between this embodiment and embodiment 1 mainly lies in: the filter tube unit of B filter element 69 Tubular closed membrane 36 is set outside the outermost tubular filtrate of the outermost layer, and tubular closed membrane 36 has shrouded tubular filtrate 9 from the outside, forms annular filtrate collection chamber 36a between tubular closed membrane and tubular filtrate 9, tubular The upper end of the sealing film 36 is connected and sealed to the outer upper branch pipe 26 on the lower end surface of the upper flange 5 with a pipe hoop 35, and the lower end is connected to and sealed on the outer lower branch pipe 37 on the upper end surface of the lower flange 14, so that the horizontal filtrate collecting plate 14a Form the horizontal filtrate collection chamber 37a, the annular filtrate collection chamber 36a of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com