Insulating aerial aluminum alloy cable and preparation method thereof

A technology of aluminum alloy and aluminum alloy monofilament, which is applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of increased costs for changes and transformations, and achieve the goals of increasing current carrying capacity, promoting transformation, and reducing transformation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

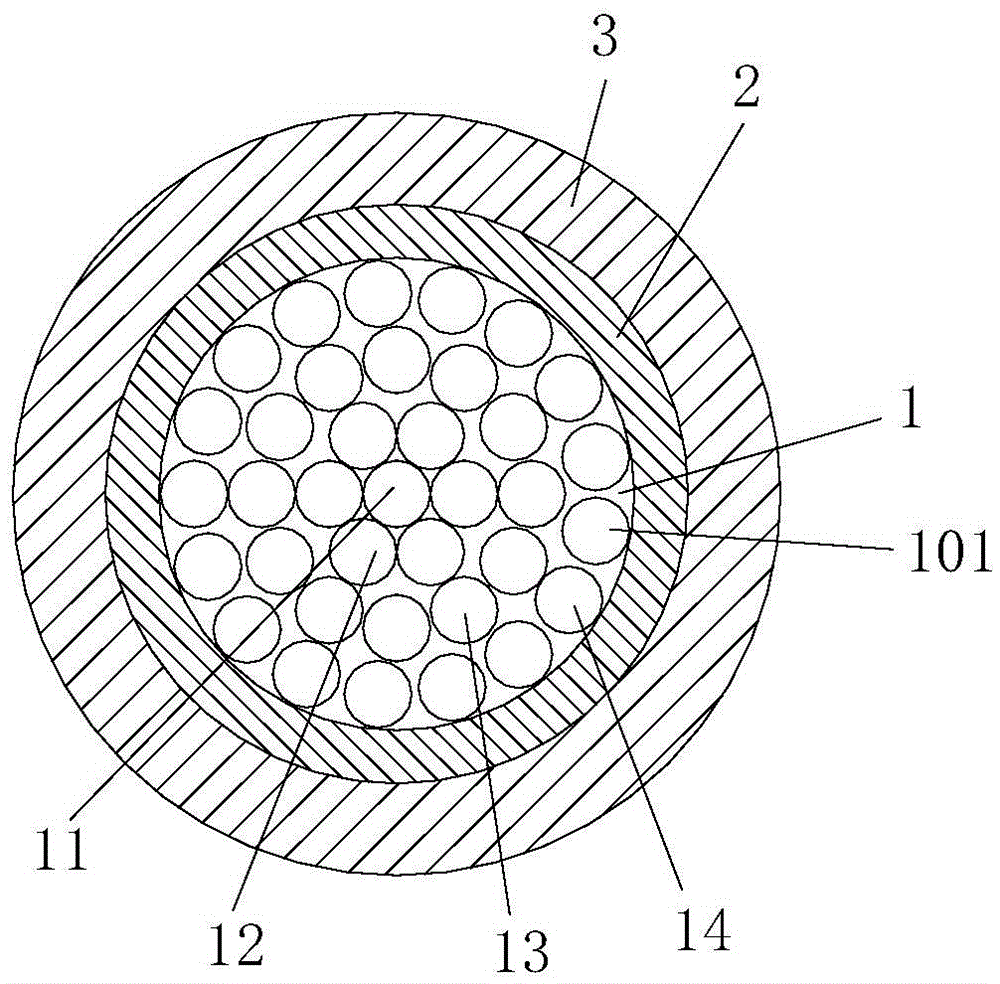

[0037] according to figure 1 As shown, the insulated overhead aluminum alloy cable according to Embodiment 1 of the present invention includes an aluminum alloy cable core 1 and a shielding layer 2 and an insulating layer 3 which are sequentially extruded outside the aluminum alloy cable core 1 from inside to outside; Layer 2 is extruded by silane cross-linked polyolefin semi-conductive material; the insulating layer 3 is extruded by silane cross-linked polyethylene material; It is a compact circular structure made of 3mm heat-resistant aluminum alloy monofilament 101 twisted.

[0038] Such as figure 1 As shown in , the structure of the preferred aluminum alloy cable core 1 is as follows: aluminum alloy monofilaments 101 are arranged in 4 layers, including 1 inner layer aluminum alloy monofilament 11, 6 middle layer aluminum alloy monofilaments 12, 12 times The outer layer aluminum alloy monofilaments 13 and 17 outer layer aluminum alloy monofilaments 14 are twisted in oppos...

Embodiment 2

[0047] Compared with the structure of the embodiment 1, the insulated overhead aluminum alloy cable of the embodiment 2 is different in that the insulating layer is obtained by extrusion molding of a silane cross-linked polyethylene material and then subjected to irradiation treatment. The other structures are the same as those of the insulated overhead aluminum alloy cable in Example 1.

[0048] Compared with the preparation method of Example 1, the preparation method of the insulated overhead aluminum alloy cable in Example 2 differs in that the shielding layer in Step 2 and the insulating layer in Step 3 are separately extruded, and different crosslinking methods are used. Specifically, the cable with shielding layer extruded in step 2 is subjected to steam cross-linking, and the steam cross-linking parameters are: at a temperature of 110°C-120°C and a pressure of 0.2-0.4MPa steam cross-linking for 3 hours; then extrude the insulating layer of the cable after steam cross-li...

Embodiment 3

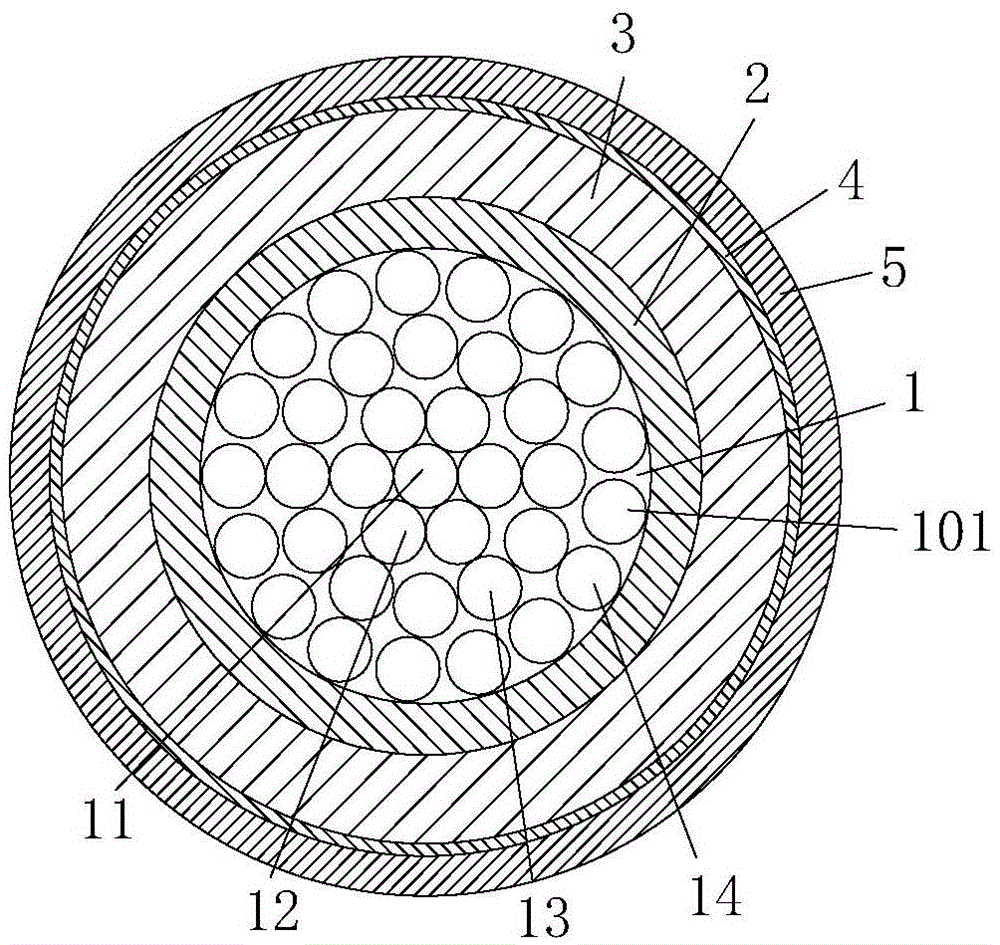

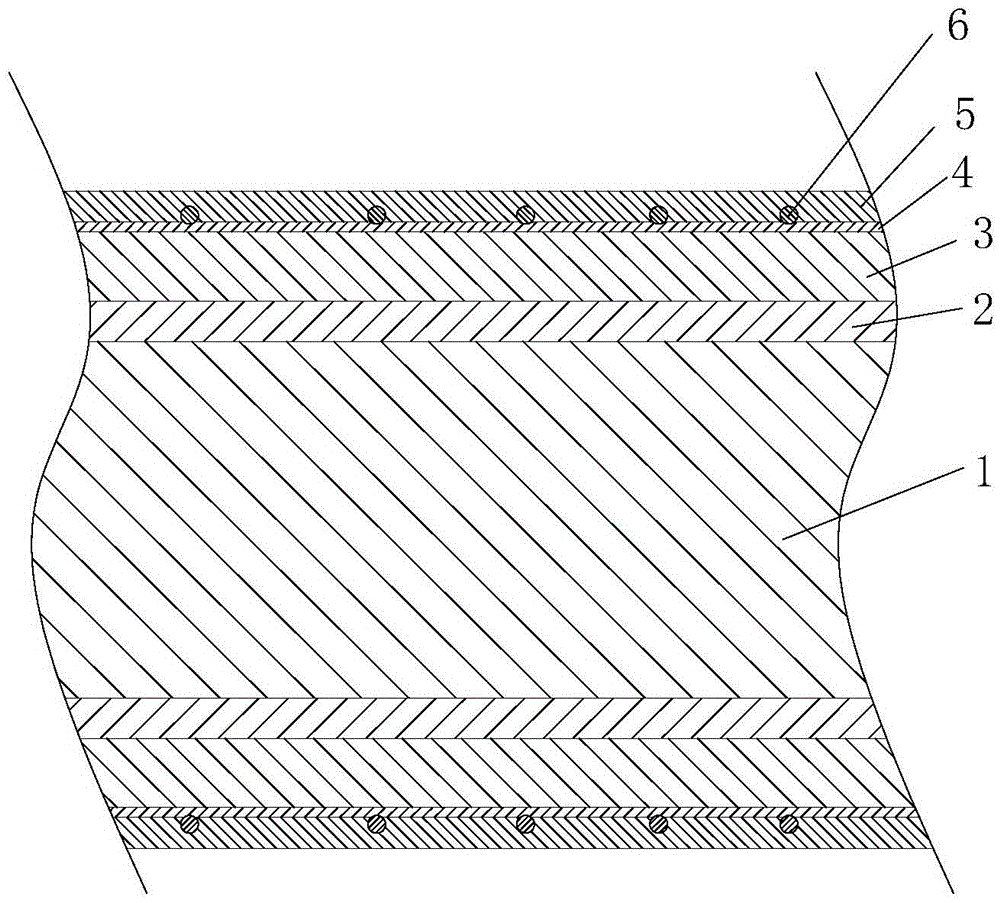

[0050] Such as figure 2 with image 3 As shown, the insulated overhead aluminum alloy cable of the present embodiment 3 is based on the insulated overhead aluminum alloy cable of the embodiment 1 or the embodiment 2, and the insulating layer 3 of the insulated overhead aluminum alloy cable also includes the outer layer connected in sequence. The shielding layer 4 and the outer insulating layer 5, and a plurality of polyurethane foam fillets 6; in the manner of being wound on the outer surface of the outer shielding layer 4, the plurality of polyurethane foam fillets 6 are embedded at intervals along the outer shielding layer 4 and the connection interface of the outer insulating layer 5. Wherein, the outer shielding layer is extruded by silane cross-linked polyolefin semi-conductive material; the outer insulation is obtained by extrusion molding of silane cross-linked polyethylene material containing carbon black and subjected to irradiation treatment, wherein the carbon bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com