Organic working medium thermal power generation circulating system boosted by aid of gravity

A thermal power generation and circulation system technology, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of easy cavitation unit power cost, low efficiency, and technical difficulty, so as to ensure the efficiency of thermal power conversion and avoid Highly efficient conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

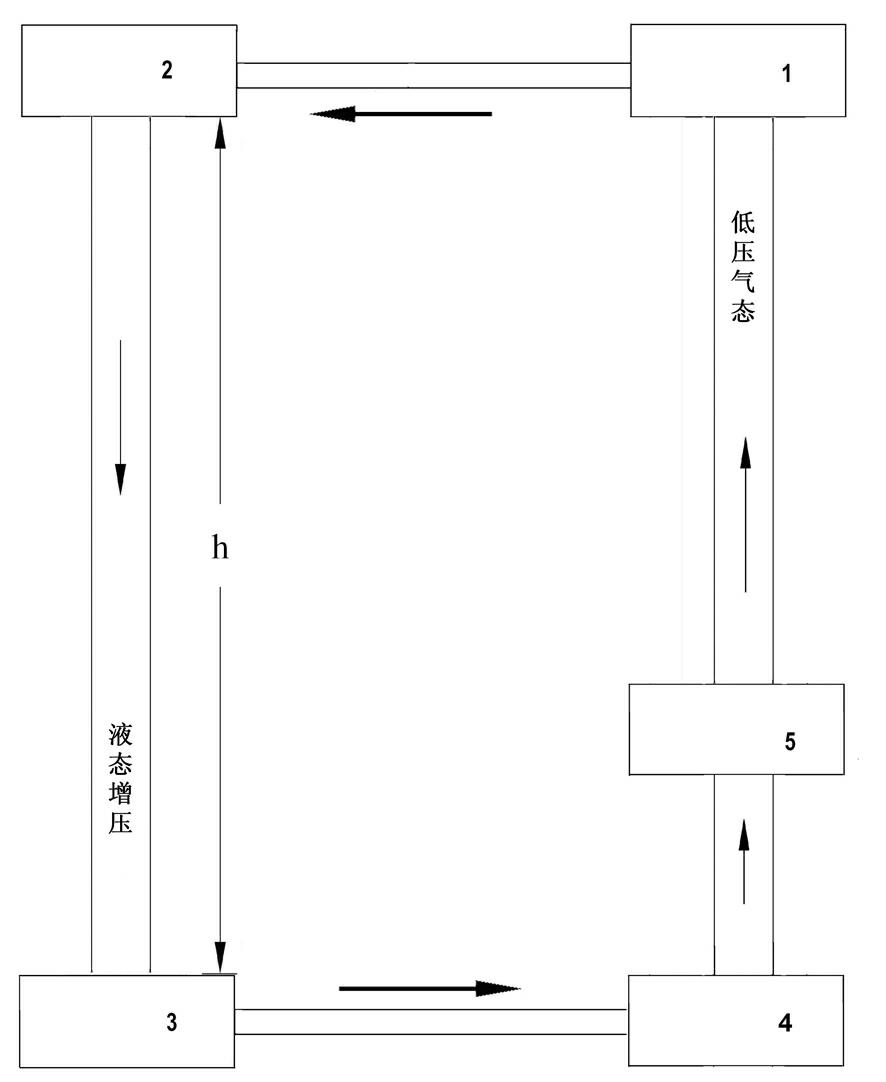

[0031] see figure 1 , the organic working fluid thermal power generation cycle system using gravity pressurization includes a condenser 1 , a liquid storage tank 2 , an evaporator 3 , a gas storage tank 4 and an expander 5 . The working medium outlet of the expander 5 is connected to the working medium inlet of the condenser 1 through a pipeline, the working medium outlet of the condenser 1 is connected to the inlet of the liquid storage tank 2 through a pipeline, and the outlet of the liquid storage tank 2 is connected to the working medium of the evaporator 3 through a pipeline. The refrigerant inlet, the working medium outlet of the evaporator 3 are connected to the inlet of the gas storage tank 4 through the pipeline, and the outlet of the gas storage tank 4 is connected to the inlet of the expander 5 through the pipeline; the circulating working fluid in the system is trichlorotrifluoroethane (R113); The position of liquid storage tank 2 in the gravity field is 23 meters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com