Improvements relating to hose

A technology for hoses and hose parts, which is applied in the field of manufacturing super-long hoses and can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

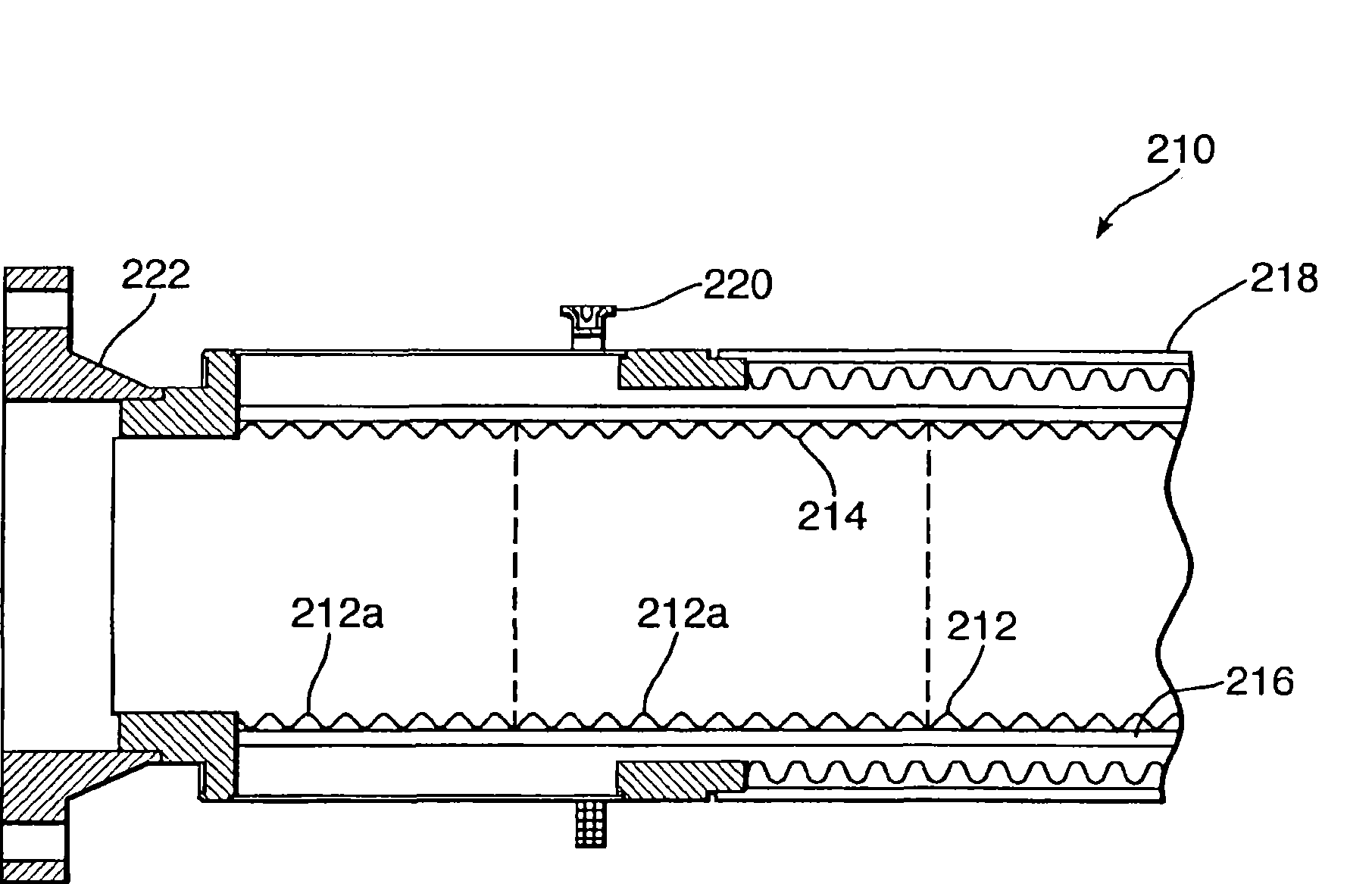

[0087] exist figure 1 In general, 210 denotes a corrugated hose according to the invention.

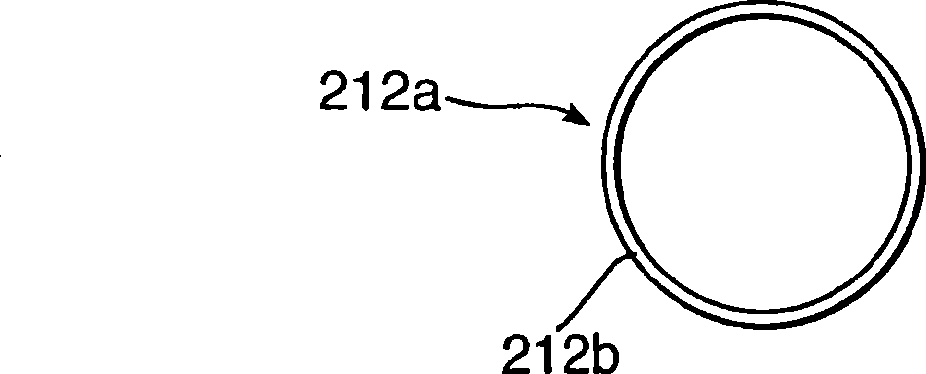

[0088] The hose 210 includes an inner tubular corrugated layer 212 and an outer tubular corrugated layer 214 each comprised of a plurality of corrugated portions 212a and 214a arranged end to end and secured to each other. Layers 212 and 214 each have sinusoidal (or U-shaped or Ω-shaped) corrugations. An insulating layer 216 is disposed between the bellows 212 and 214 . In addition, the space between the bellows 212 and 214 is placed in a vacuum to further improve the insulation. An armor layer 218 is provided around the outer bellows 214 to further improve insulation. A pumping port 220 is provided for evacuating air from between the layers 212 and 214 to create a vacuum. Hose 210 also includes end fittings 222 at each end of the corrugated hose (at figure 1 Only one end fitting 222 is shown in .

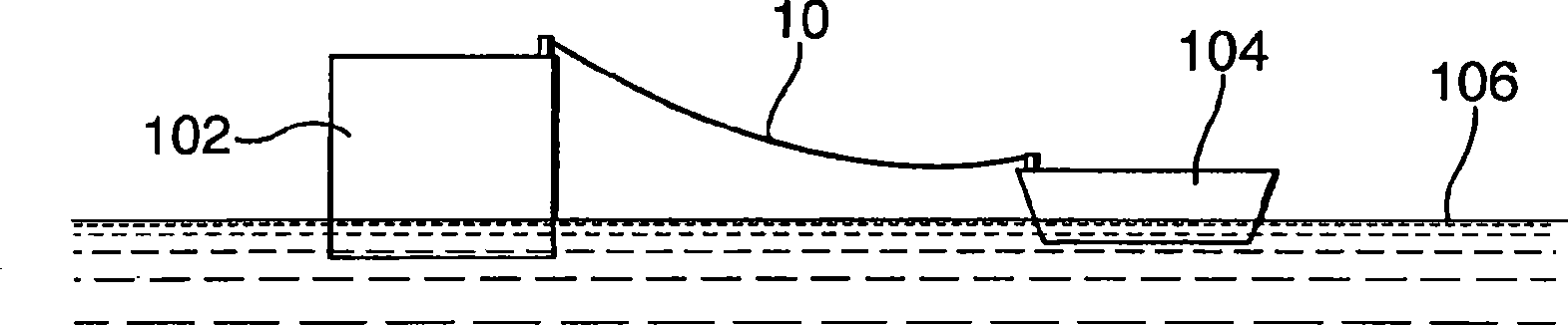

[0089] Figure 3A-3D Three applications for the hose 10 are represented. exist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com