Method for operating motor vehicle with hybrid drive

A technology for hybrid power systems and automobiles, which is applied to the layout of multiple different prime movers of hybrid vehicles and general-purpose power plants, and motor vehicles, and can solve the problems of non-production and inefficient work, and achieve low energy loss and low energy consumption. Avoid energy loss, small carbon dioxide emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

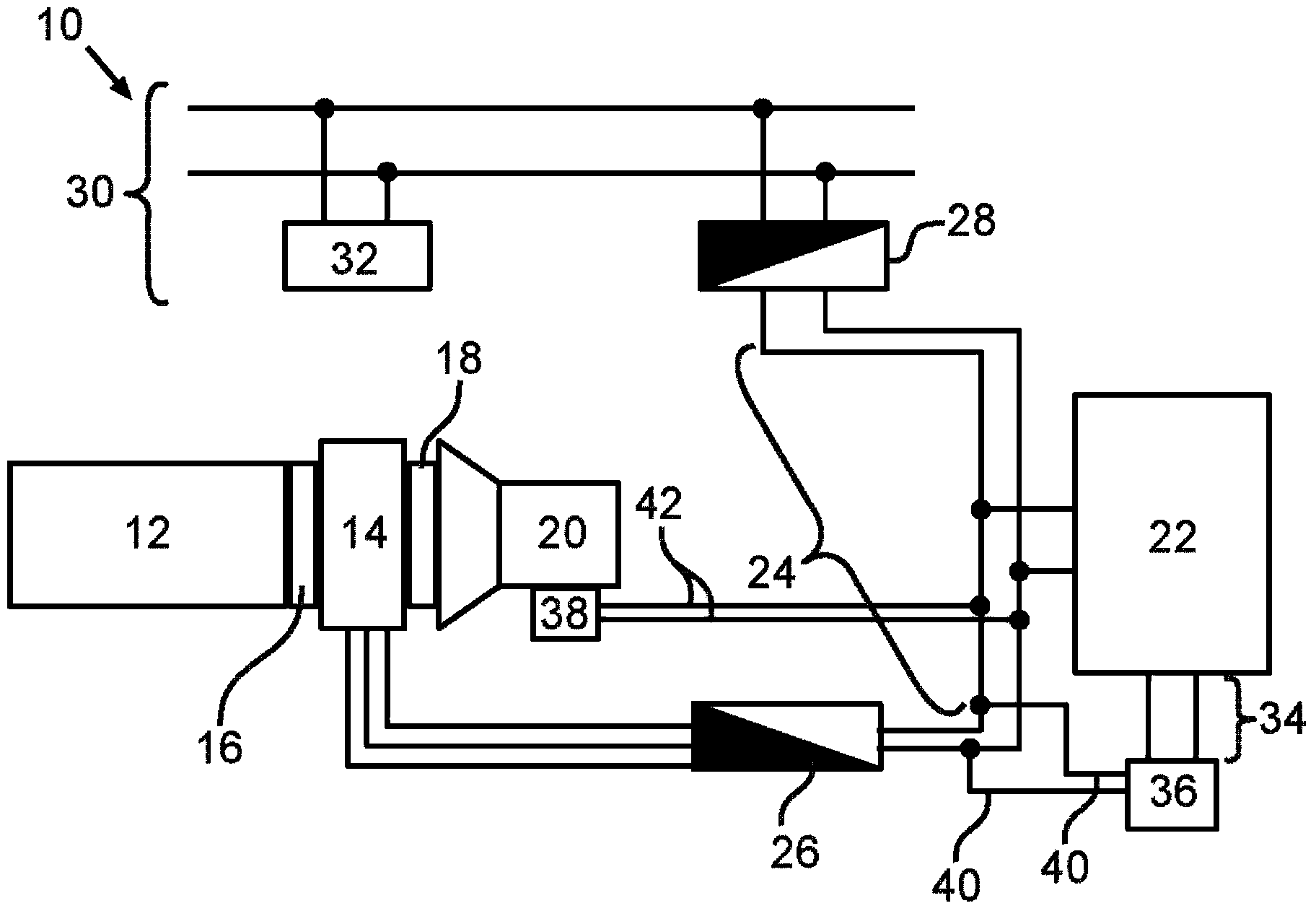

[0026] A powertrain for a hybrid vehicle, generally indicated at 10 , includes an internal combustion engine 12 and a drive electric machine 14 . The internal combustion engine 12 can be coupled via a first clutch 16 to a drive motor 14 , which can itself be coupled to an automatic transmission 20 via a second clutch 18 . Drive energy is transmitted from the automatic transmission to the likewise not shown vehicle wheels via a further drive train, not shown in the drawing.

[0027] A high-voltage battery 22 is used to supply current to the drive motor 14 , which supplies the high-voltage on-board electrical system 24 of the motor vehicle. The voltage of the high-voltage vehicle electrical system 24 is converted by the inverter 26 into the three-phase voltage necessary for the operation of the drive motor 24 . DC transformer 28 also connects high-voltage vehicle electrical system 24 to low-voltage vehicle electrical system 30 , which also has its own 12V battery 32 .

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com