Patents

Literature

190 results about "Dielectric heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

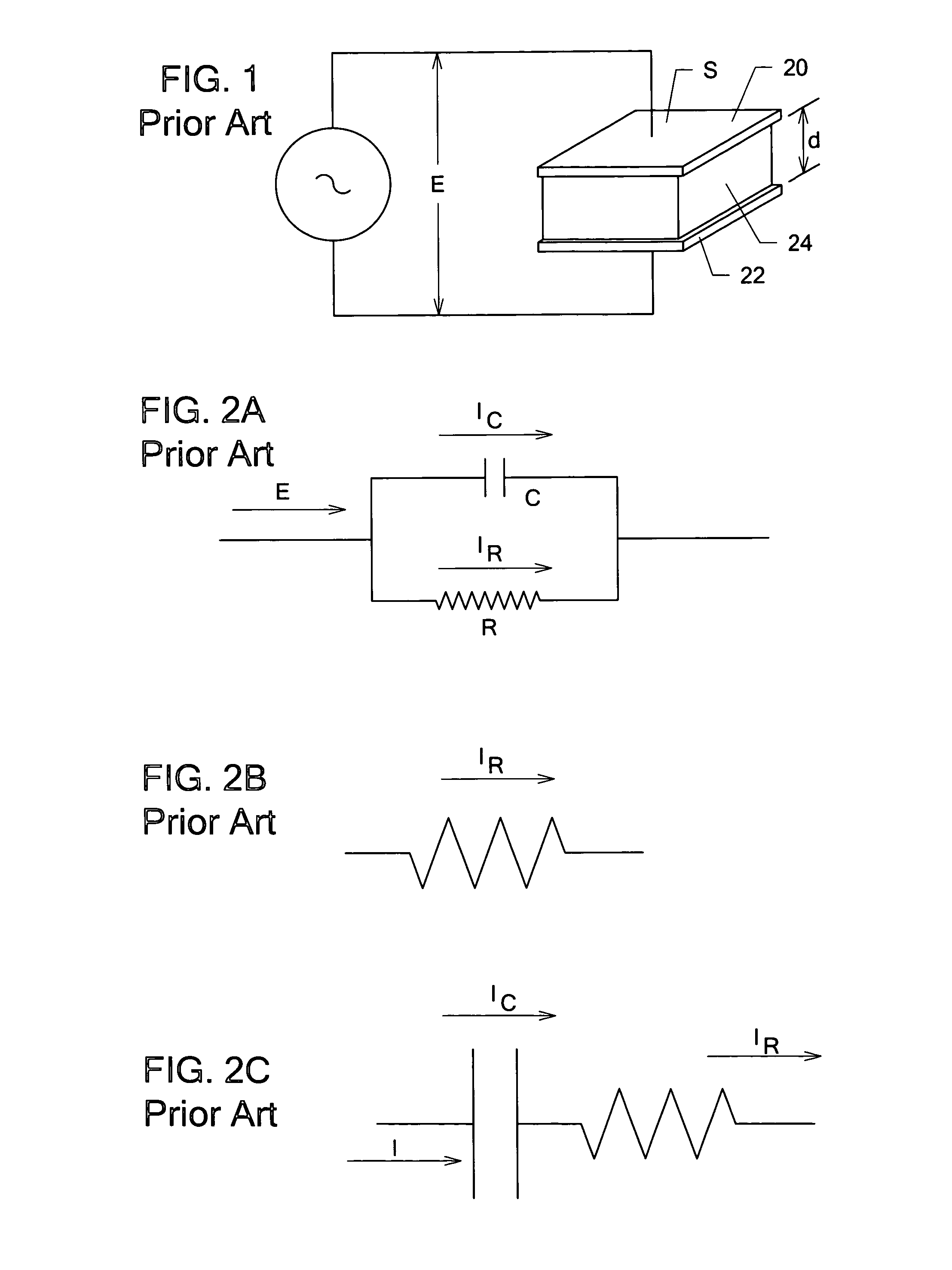

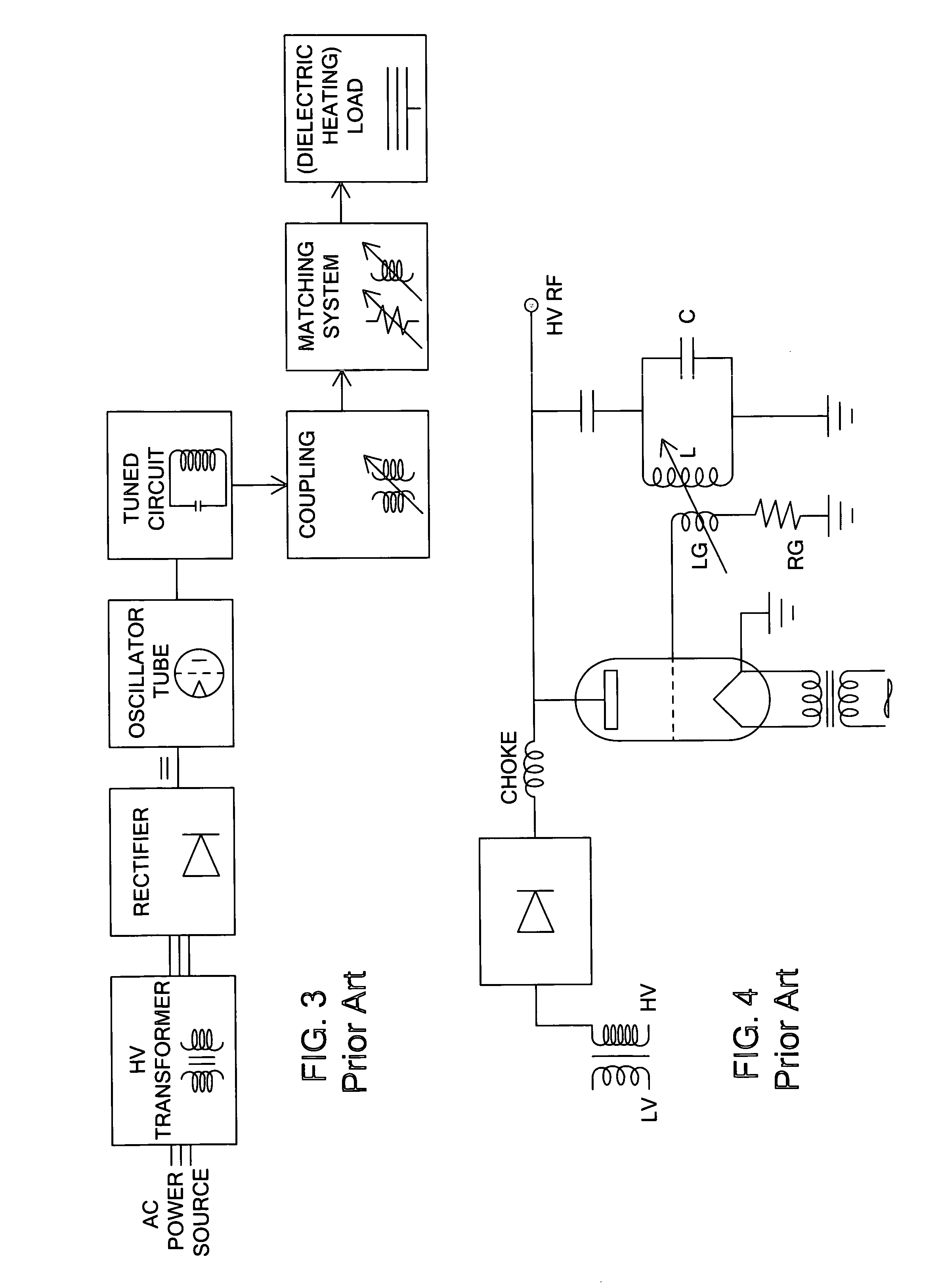

Dielectric heating, also known as electronic heating, radio frequency heating, and high-frequency heating, is the process in which a radio frequency (RF) alternating electric field, or radio wave or microwave electromagnetic radiation heats a dielectric material. At higher frequencies, this heating is caused by molecular dipole rotation within the dielectric.

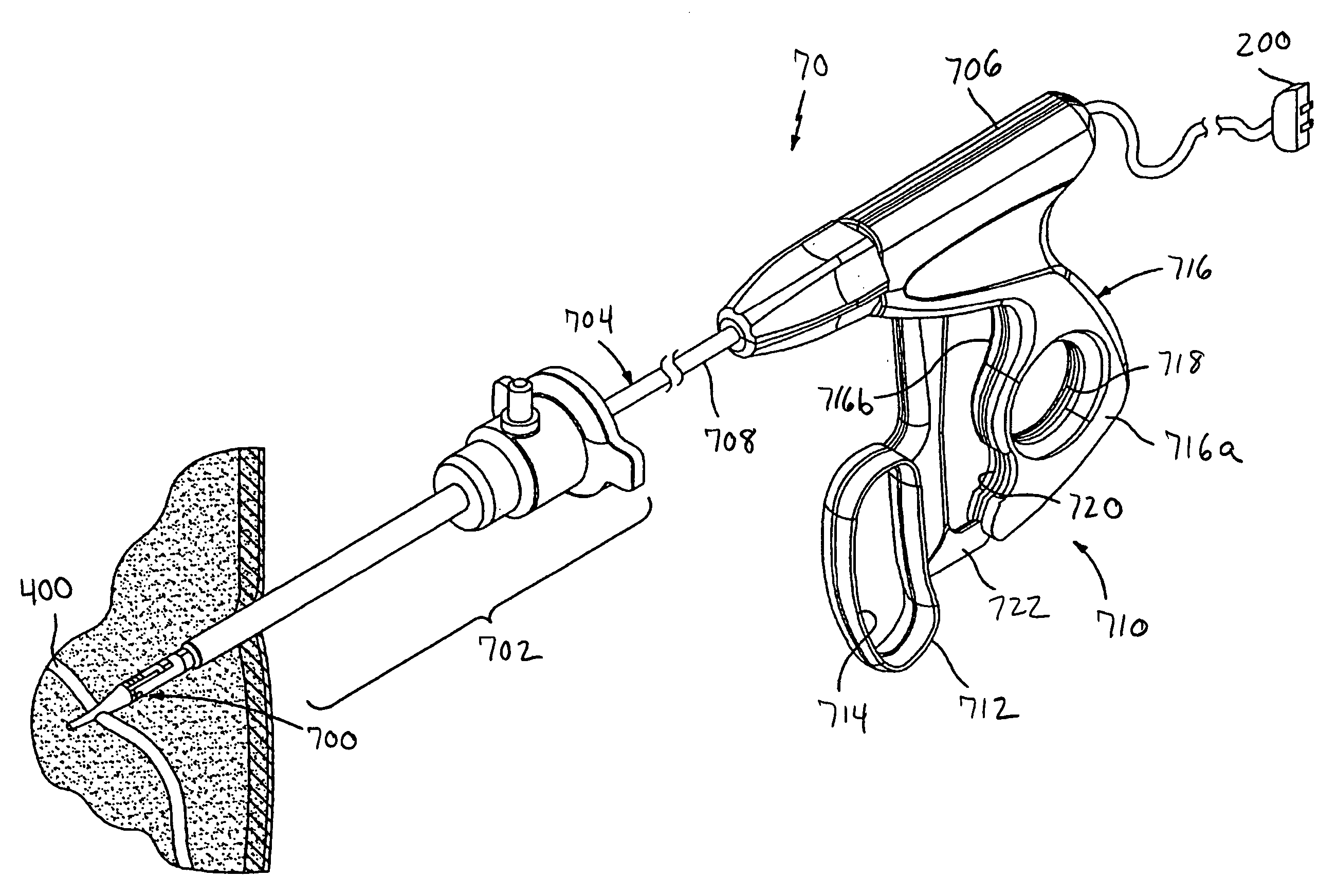

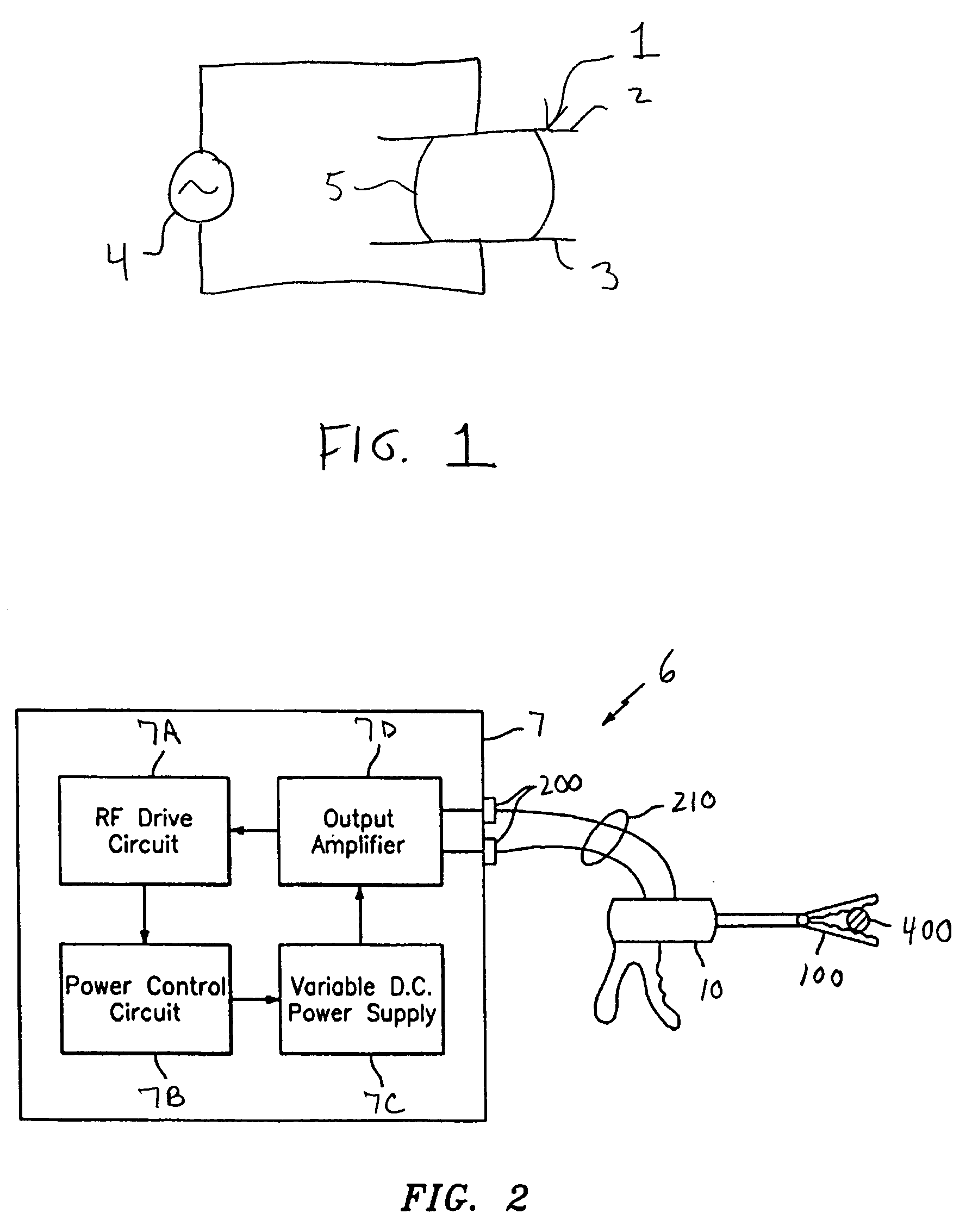

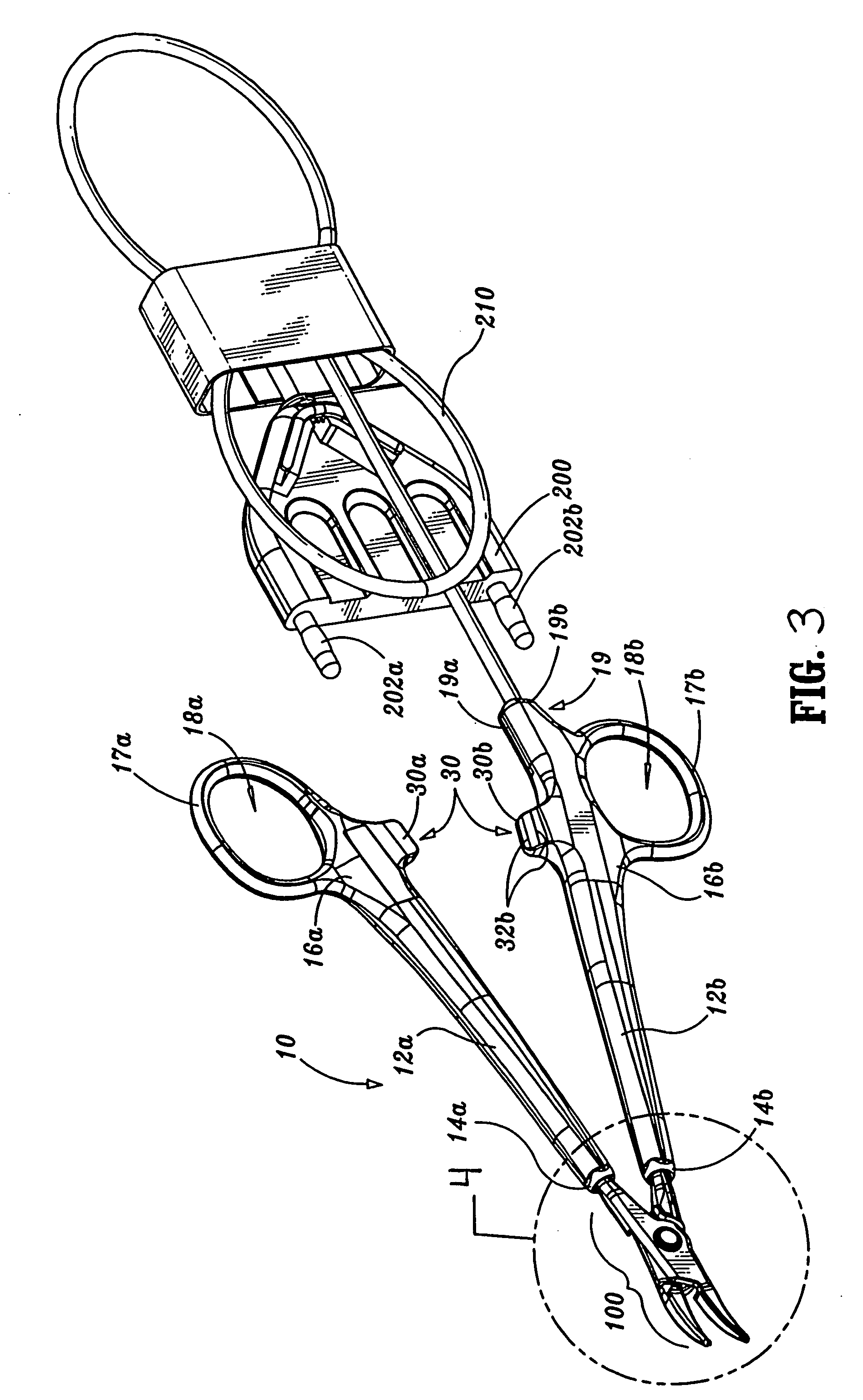

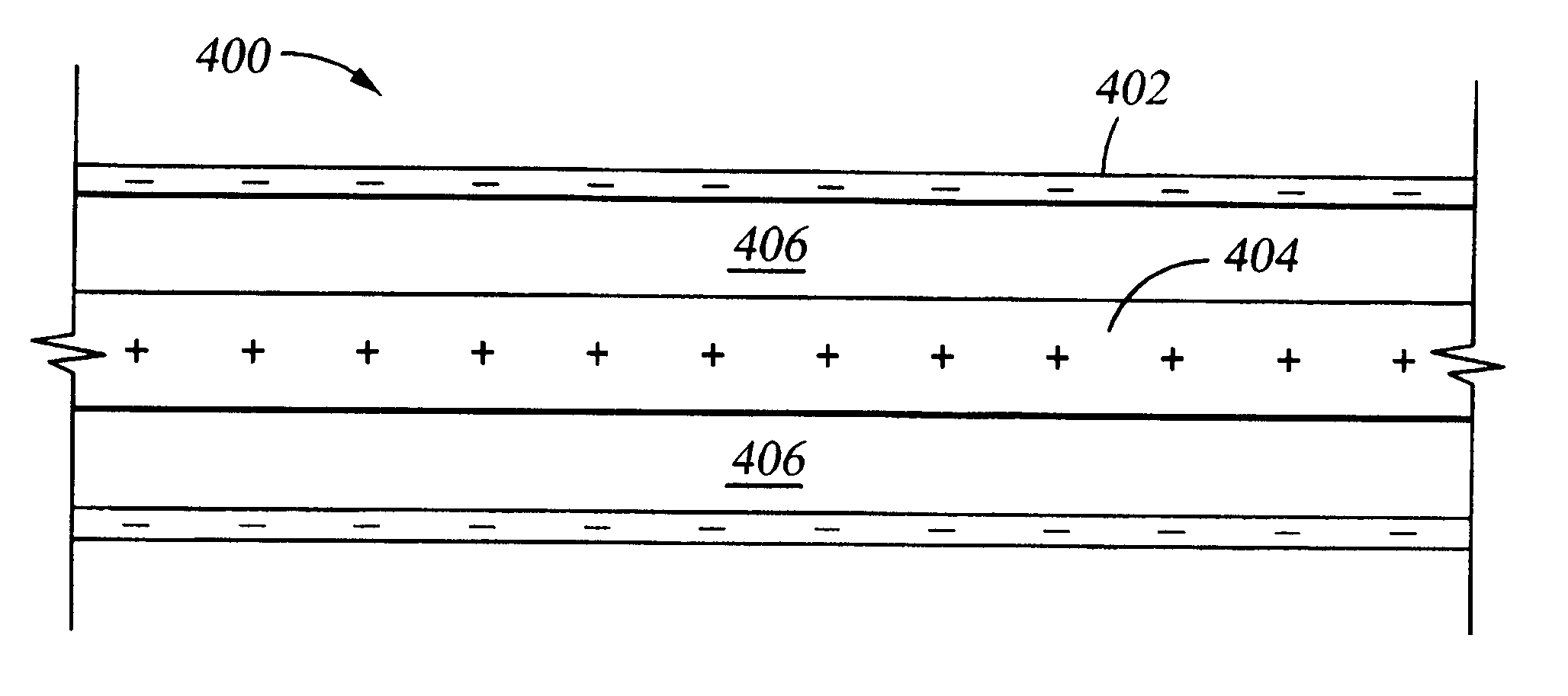

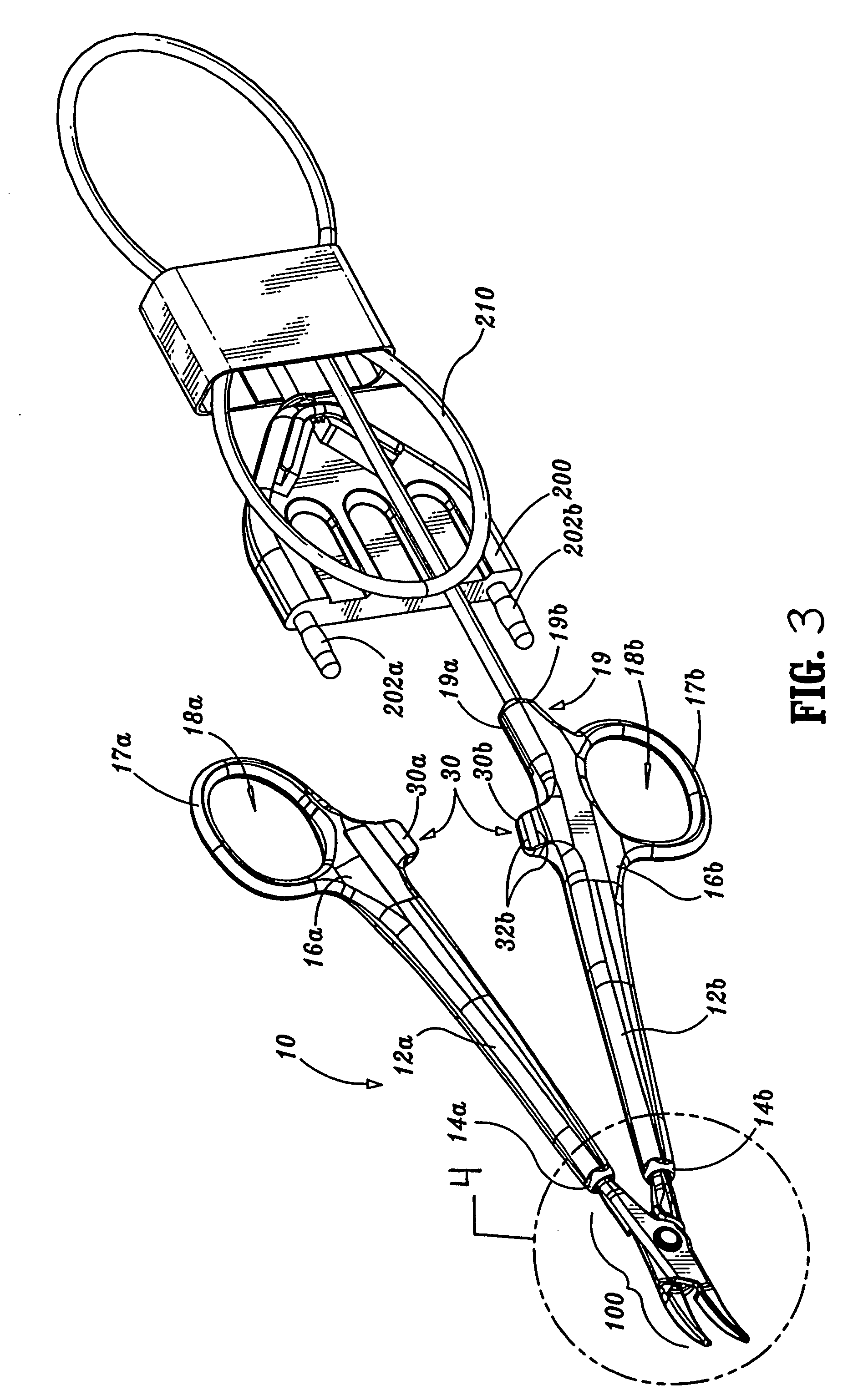

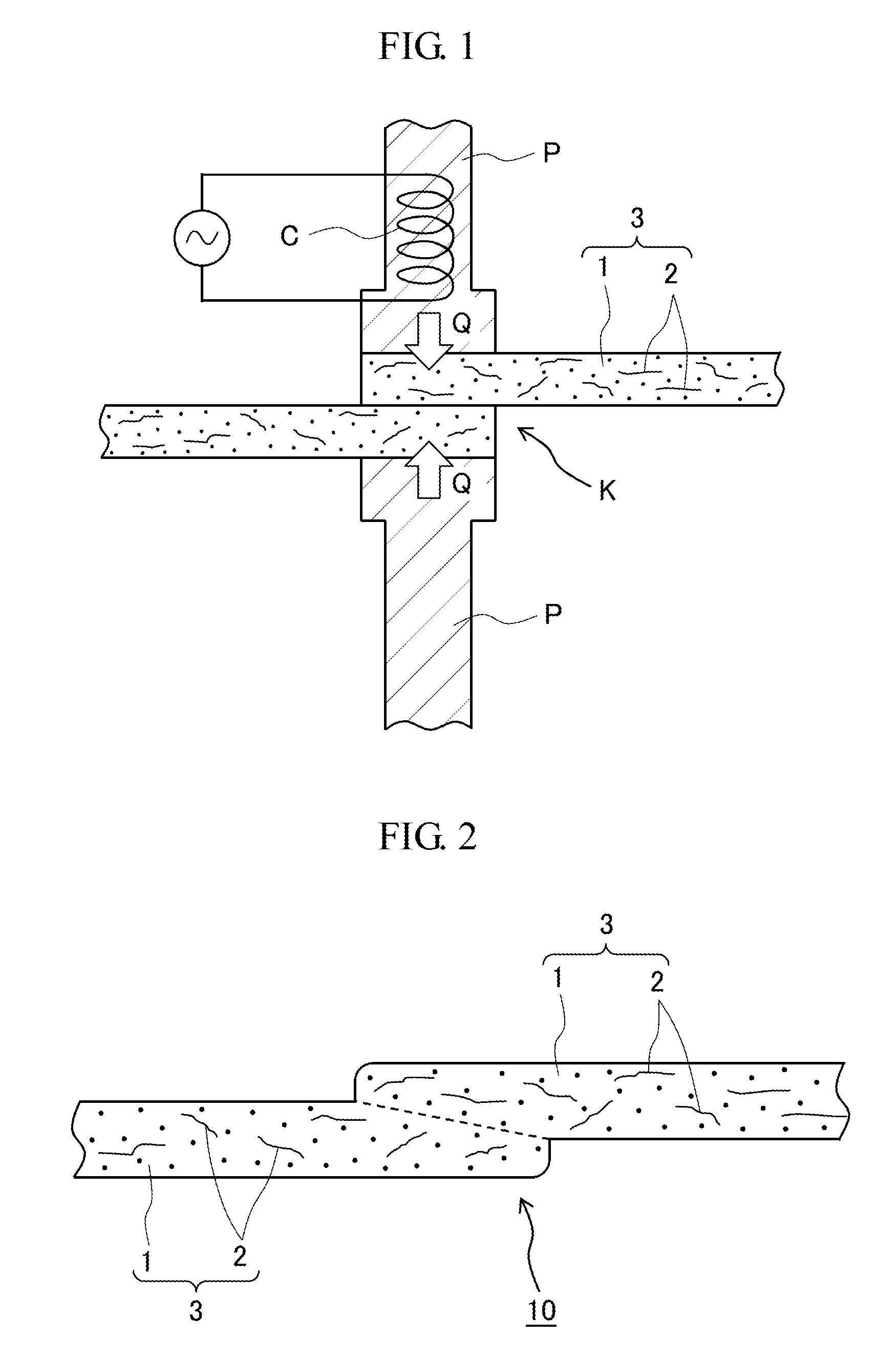

Vessel sealing system using capacitive RF dielectric heating

ActiveUS20050197659A1Heating evenlyReduce heat spreadSurgical instruments for heatingCoatingsCapacitanceVessel sealing

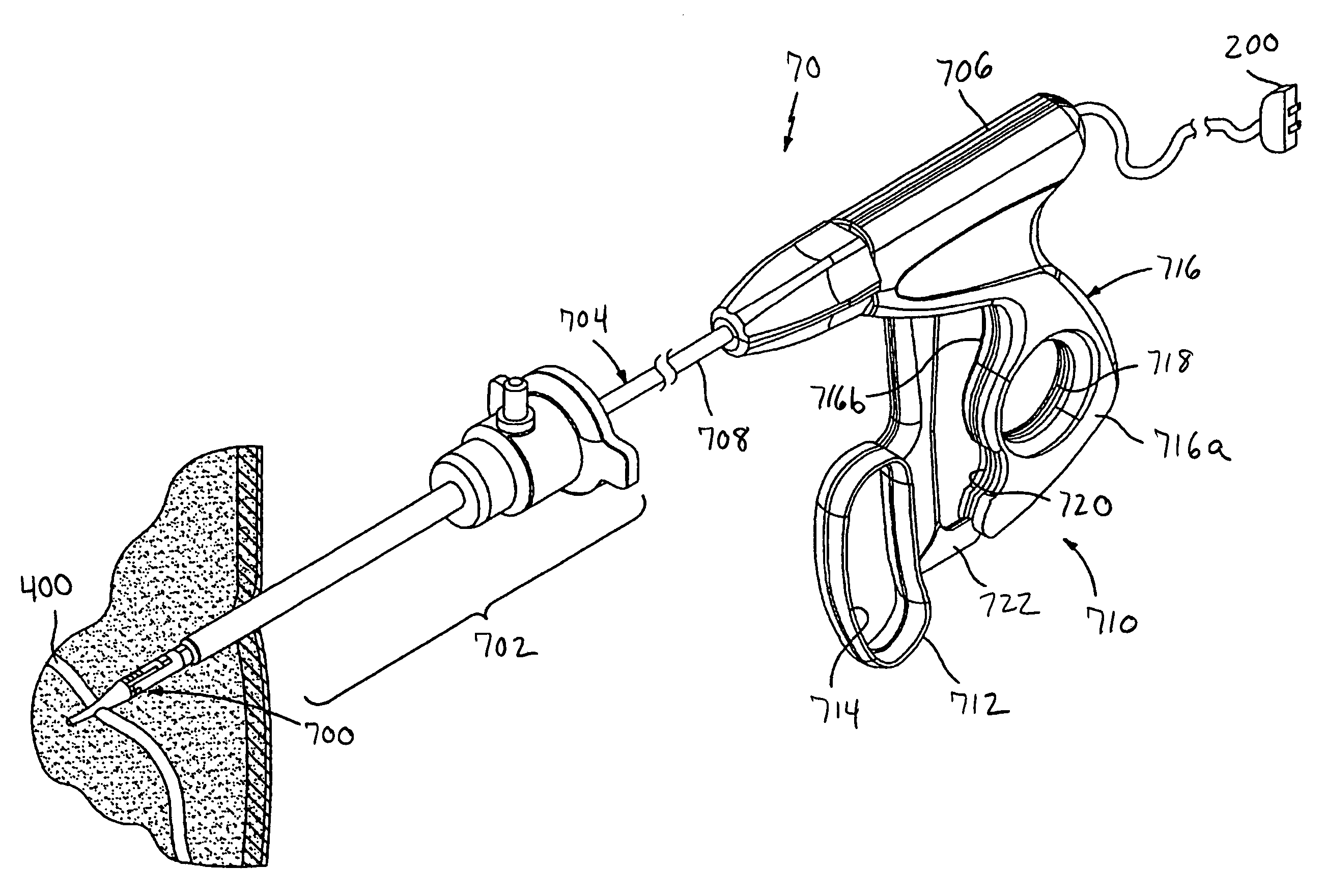

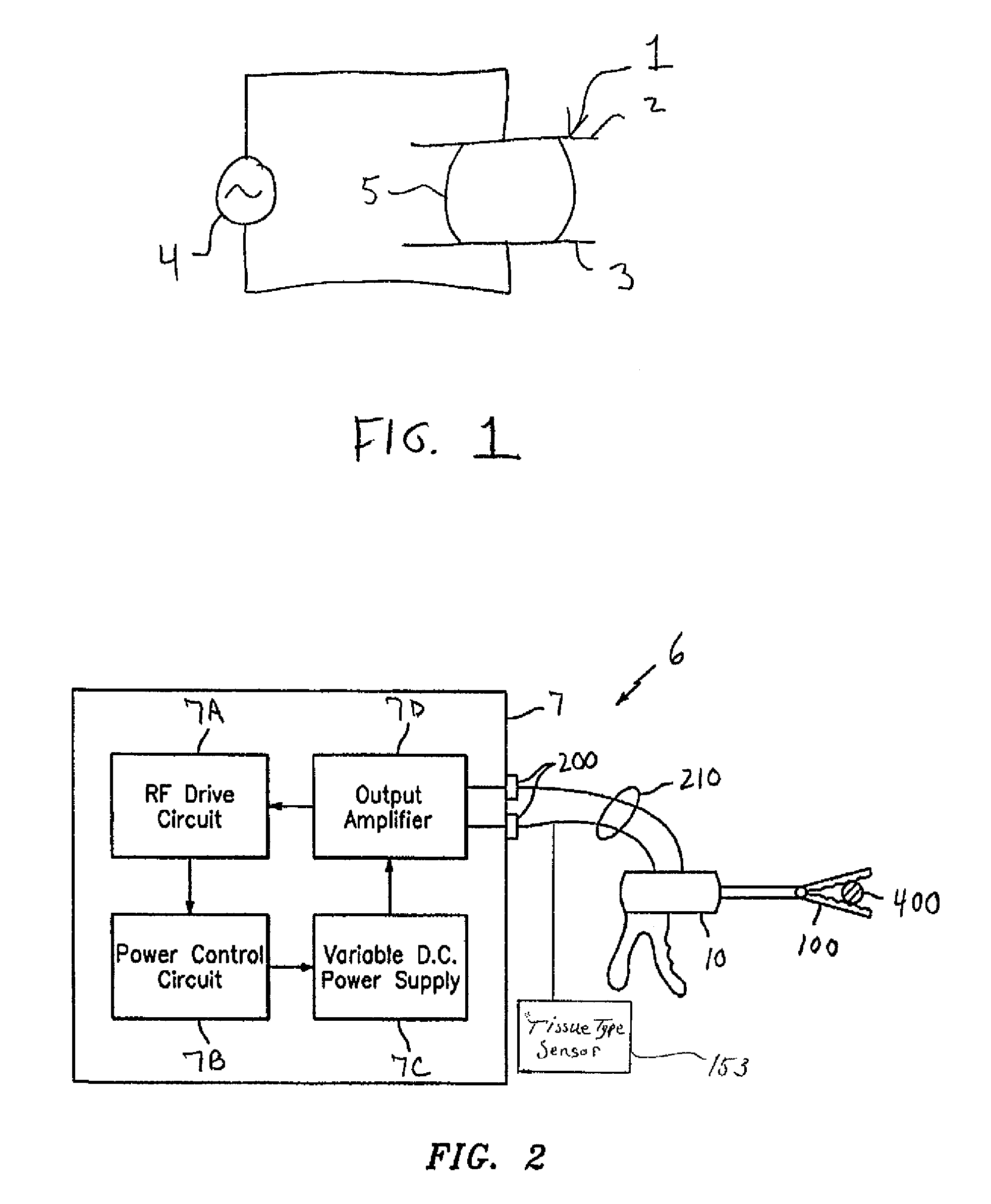

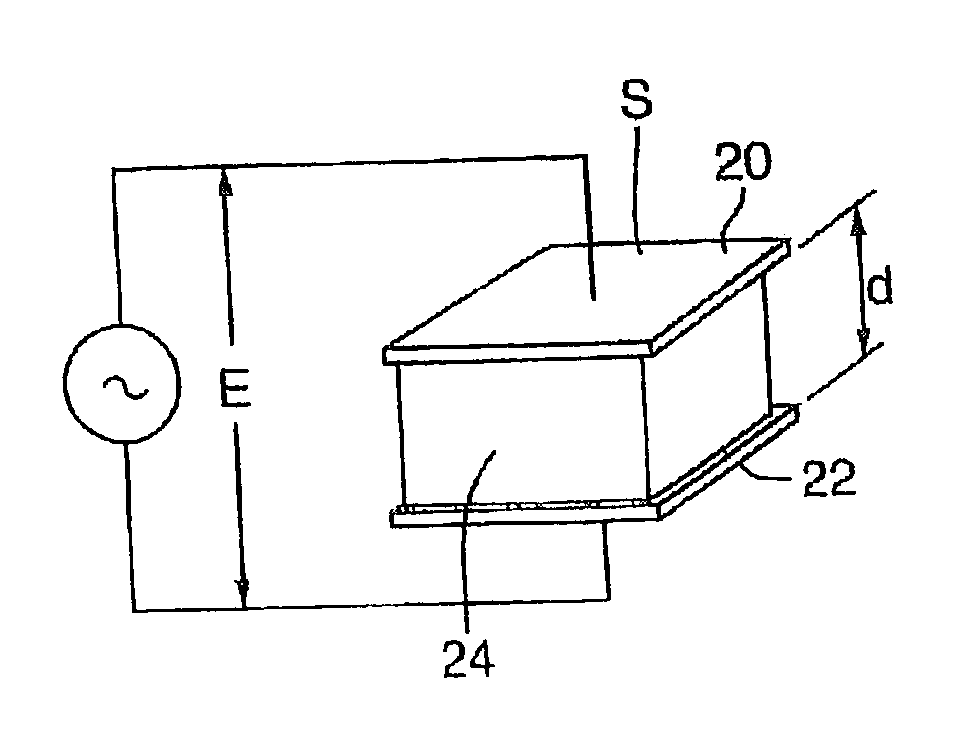

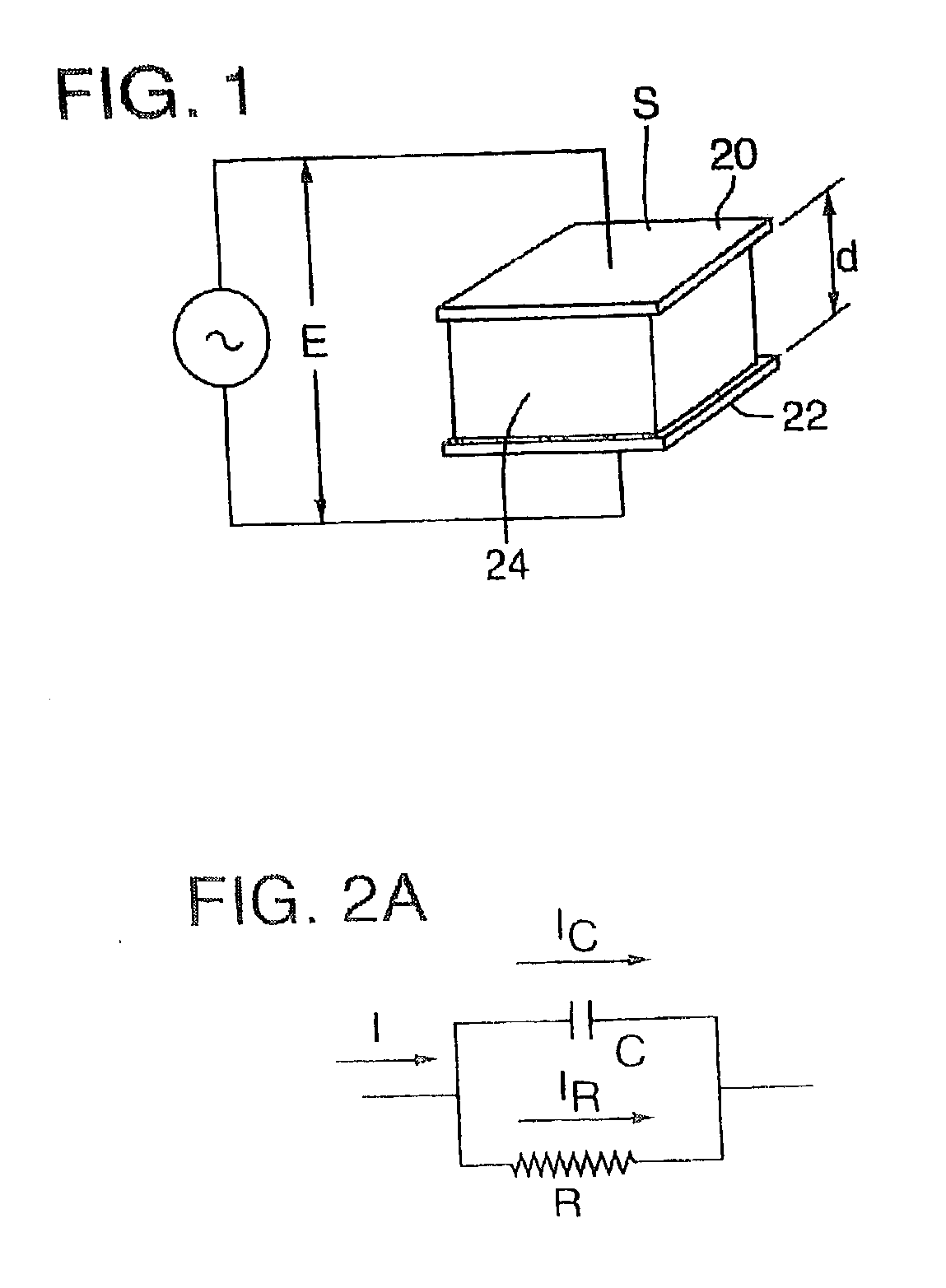

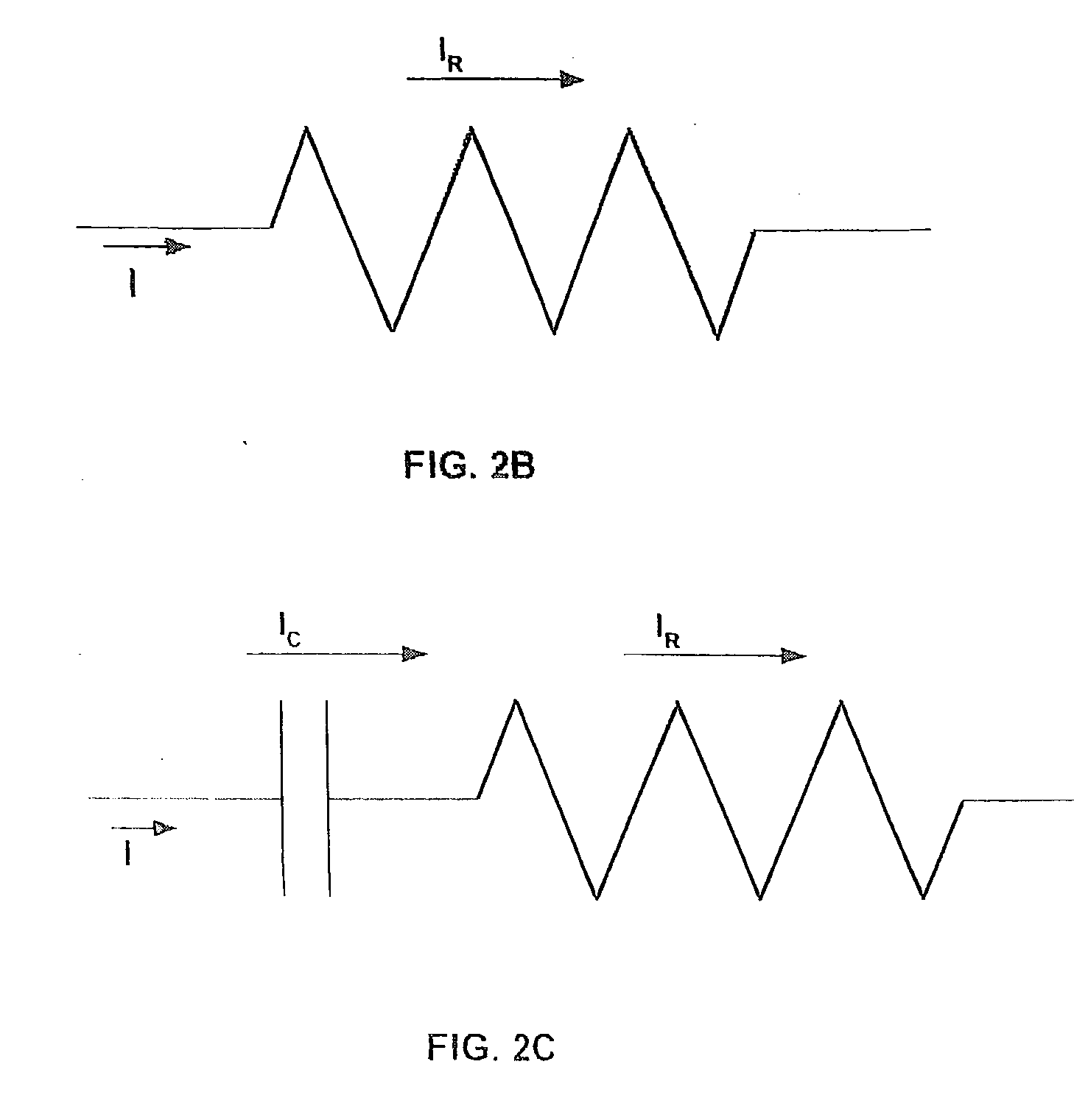

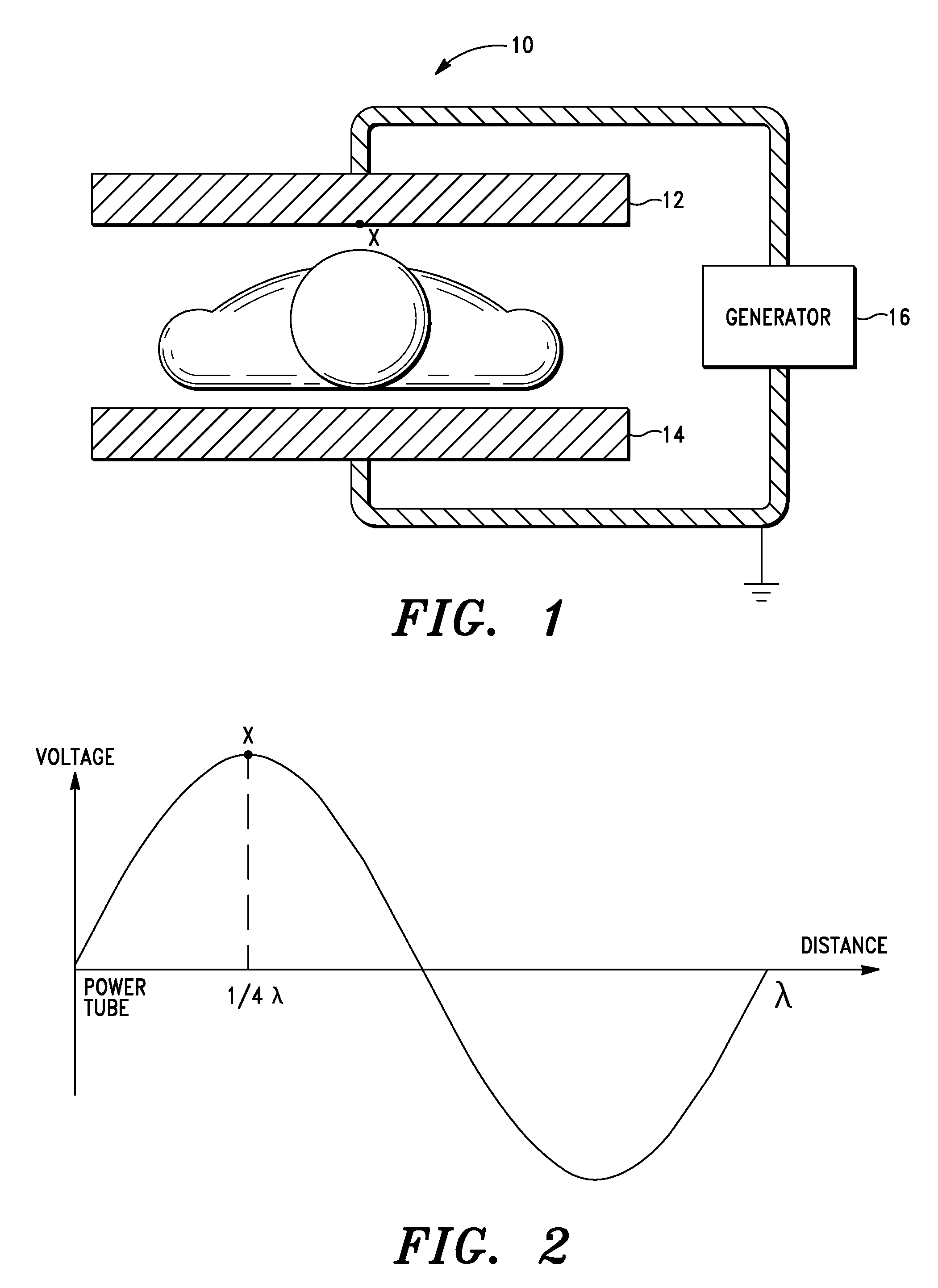

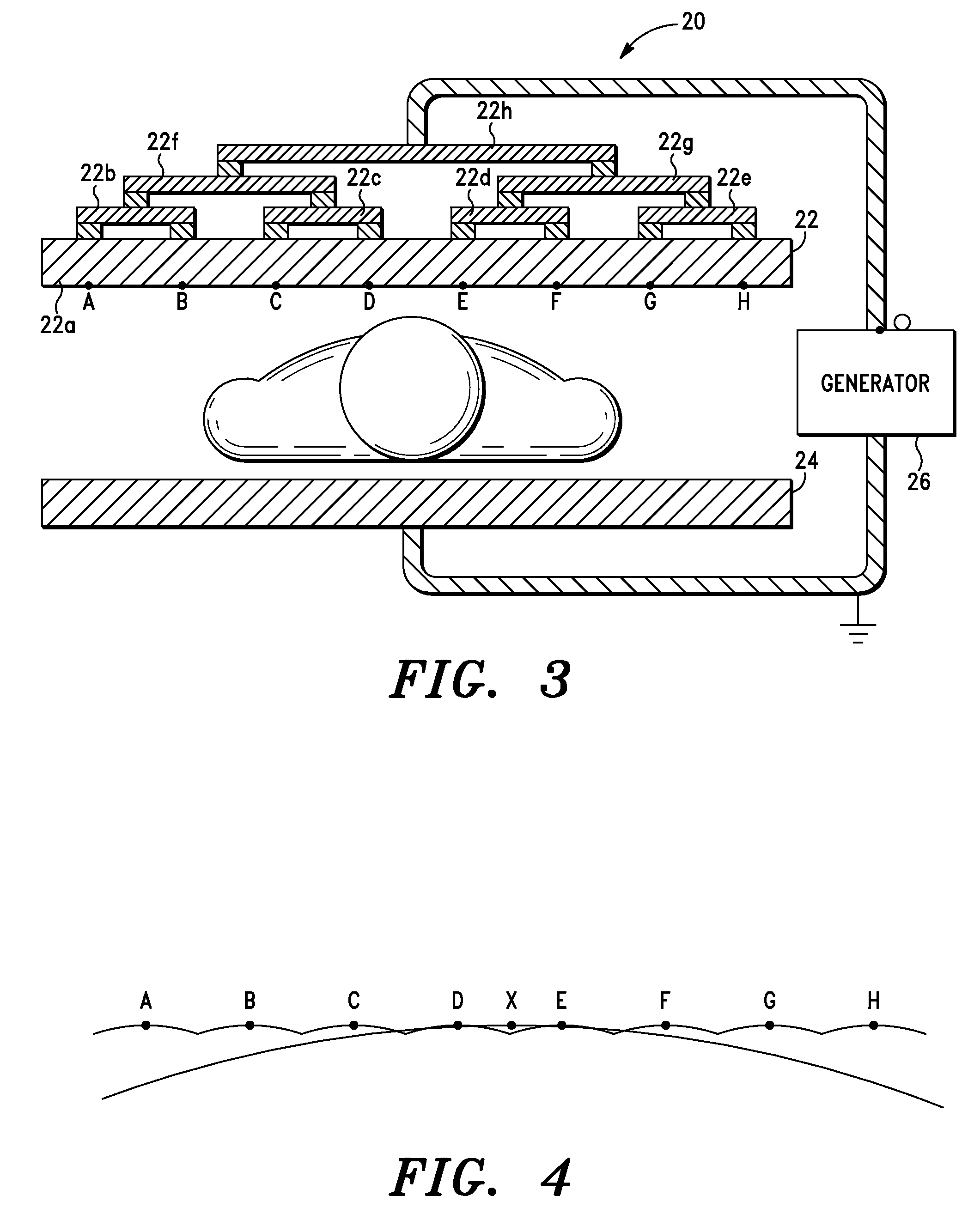

An electrosurgical system for sealing vessels using capacitive (RF) dielectric heating and a method thereof are provided. The system includes an electrosurgical instrument having an end effector with parallel plate electrodes that will clamp onto a vessel and maintain a specified gap distance; however, the electrodes will be coated with a non-conductive dielectric material. Such an end effector will ensure that direct conduction between the electrodes does not occur through tissue or fluids and effectively creates a parallel plate capacitor with a dielectric, e.g., tissue and coating, in between the plates. The electrosurgical instrument will be activated with an AC signal at a specified RF frequency, e.g., a Debye resonance frequency, via an electrosurgical generator. An effective AC current will flow through the tissue and cause heating due to fictional losses from rotating polar molecules in the tissue.

Owner:COVIDIEN AG

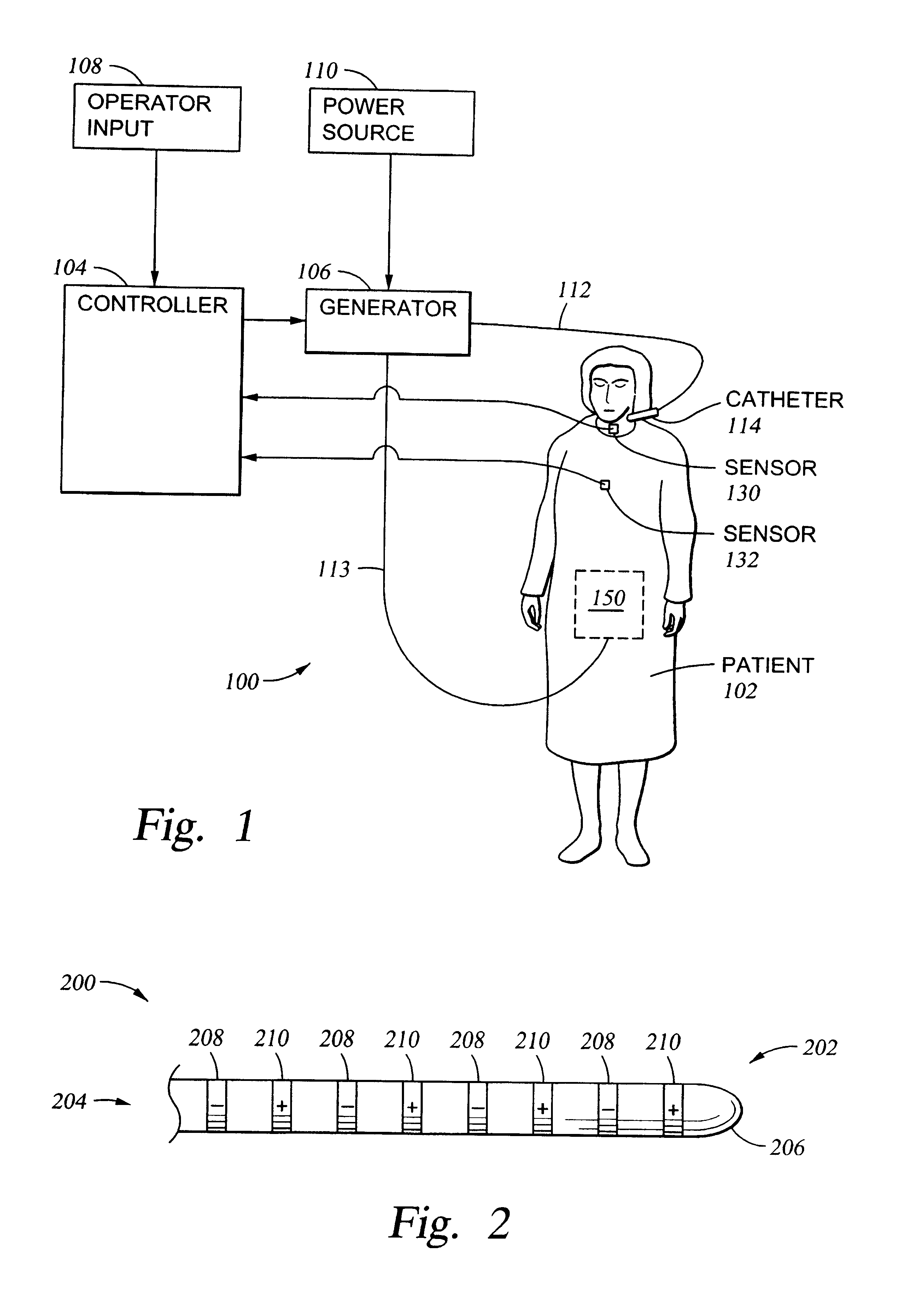

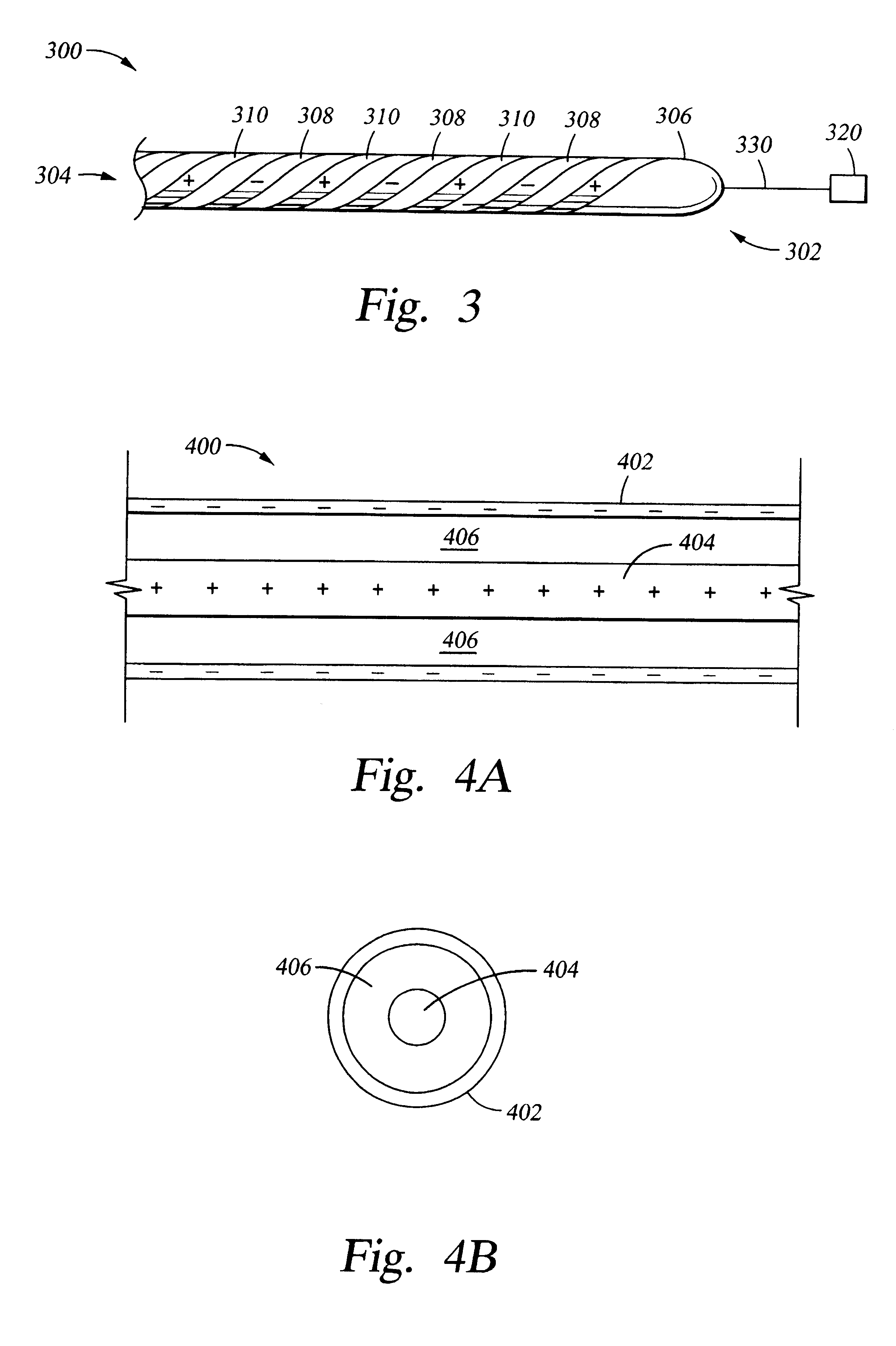

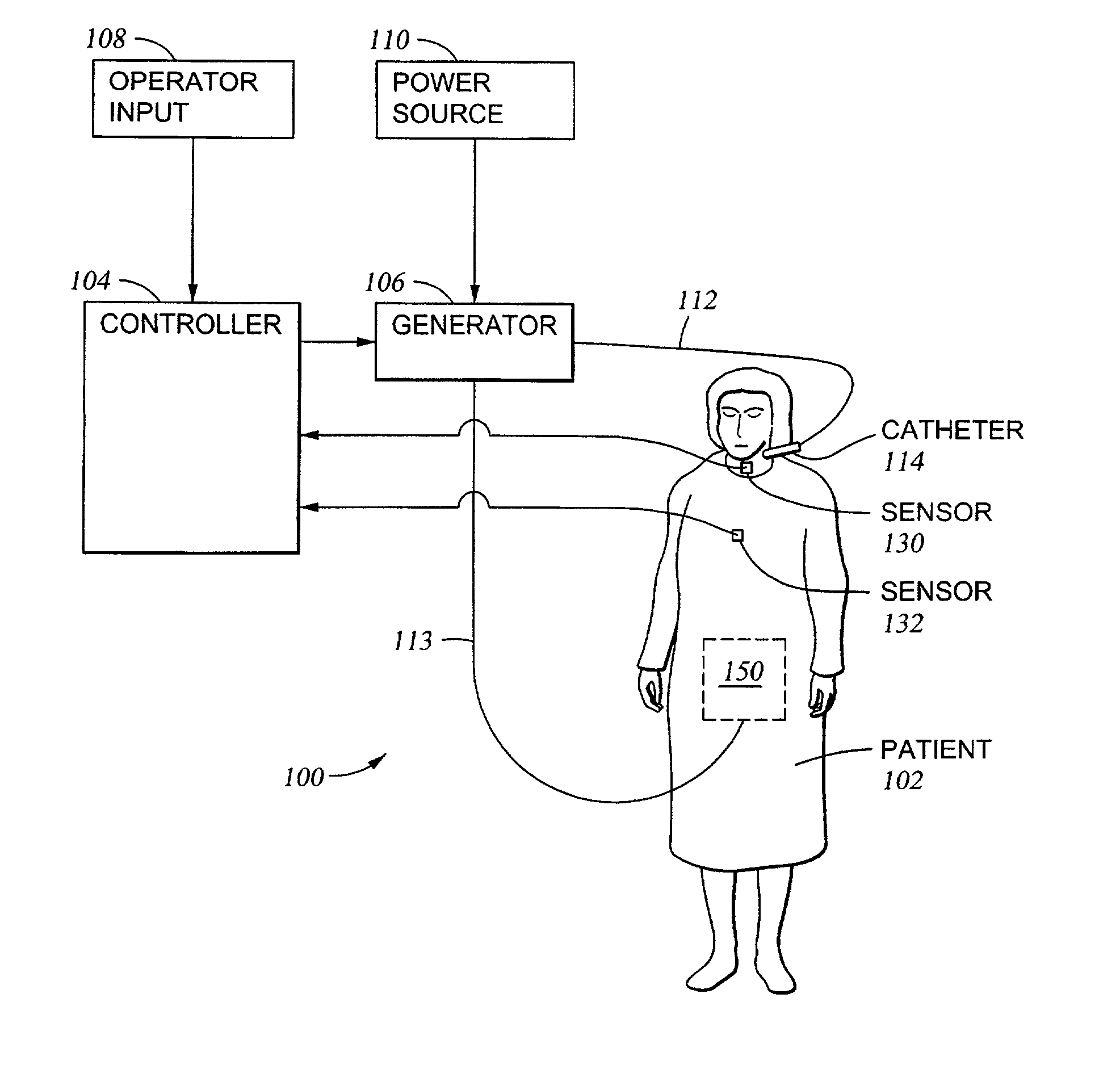

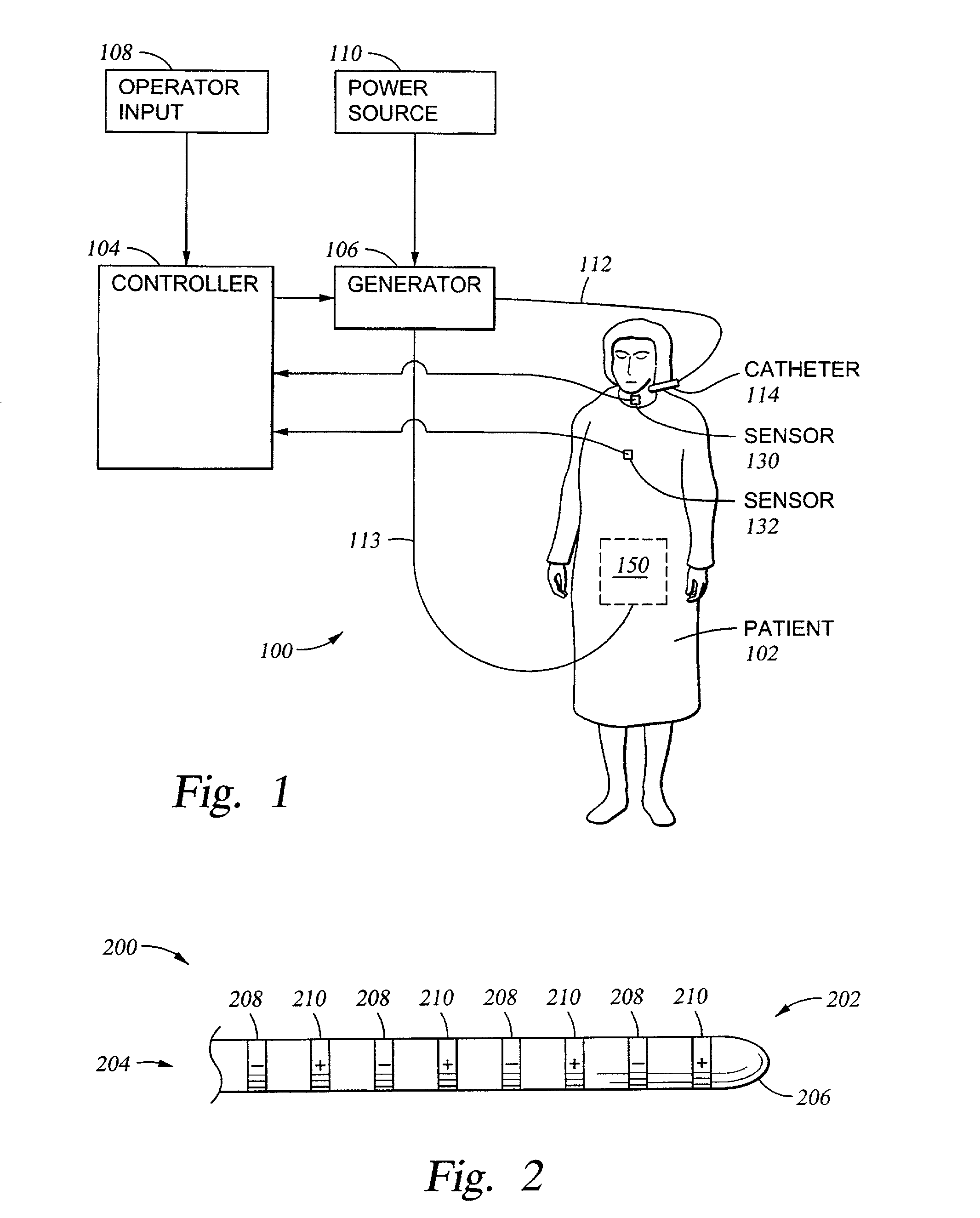

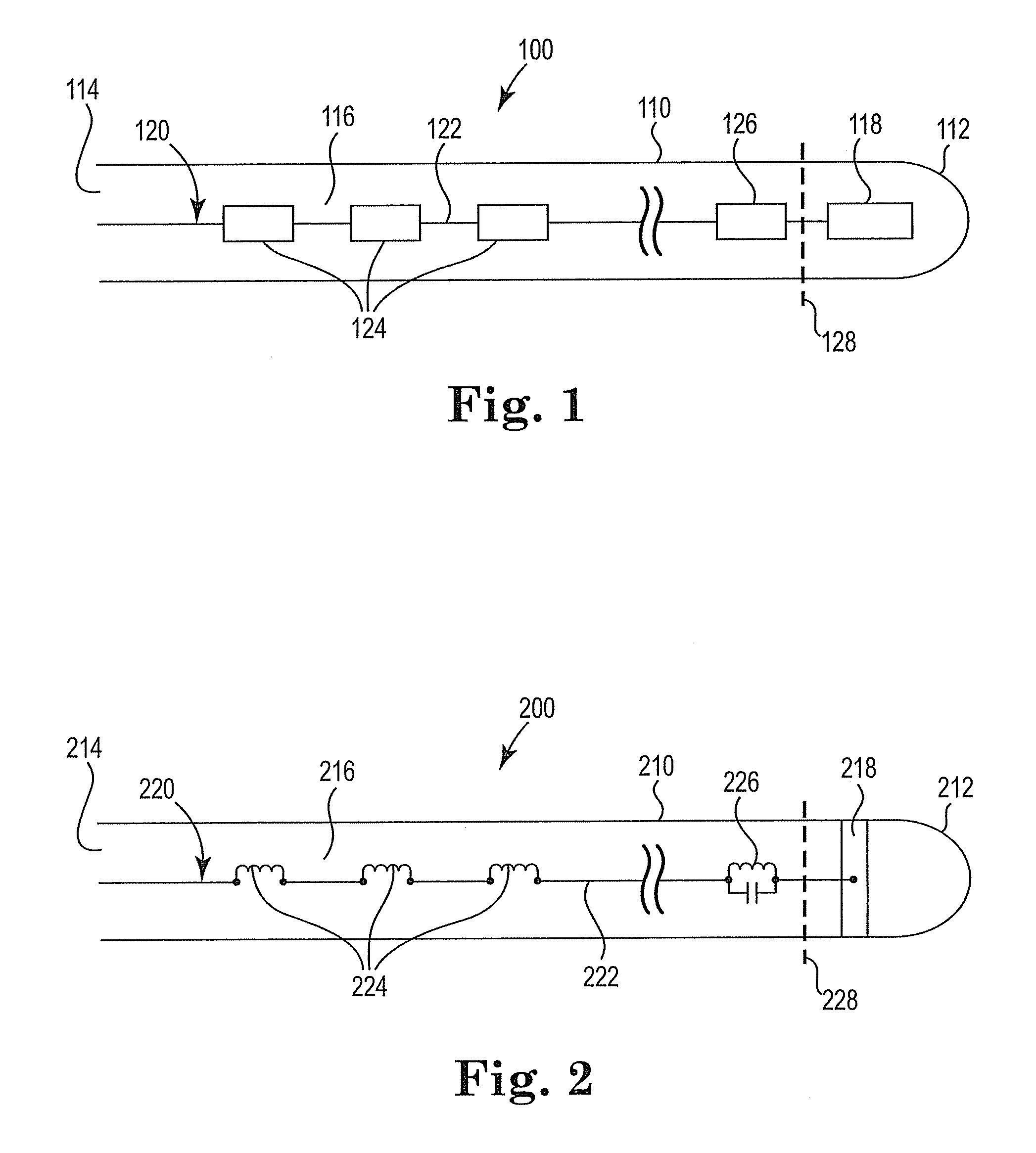

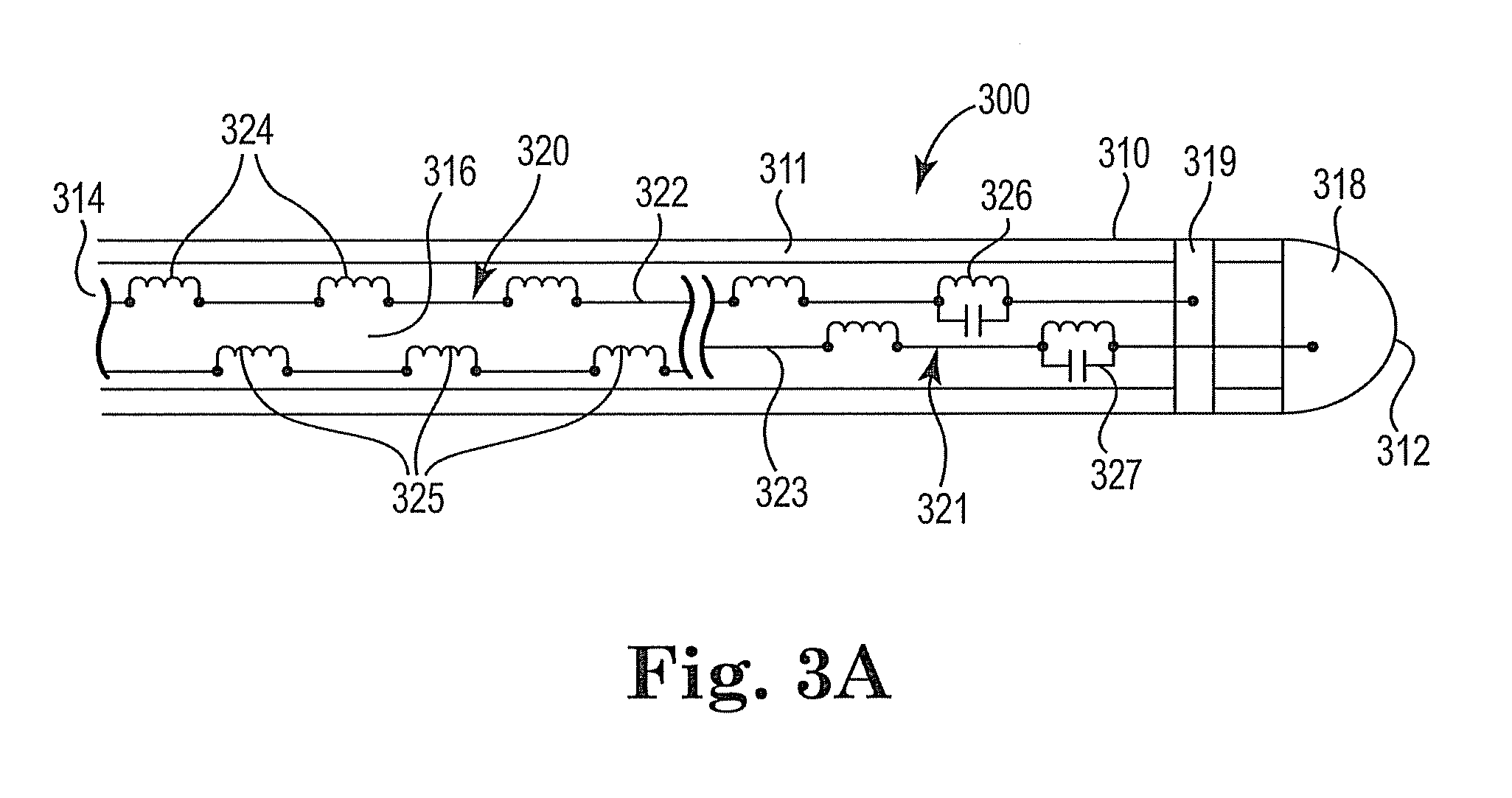

System and method employing indwelling RF catheter for systemic patient warming by application of dielectric heating

An indwelling RF catheter achieves warming of patients by dielectric heating of blood or other bodily fluids. In one example, the catheter is deployed in a suitable blood vessel, such as the inferior vena cava. The catheter design includes an emitter structure electrically coupled to an RF generator, which provides a source of RF power. The emitter structure, distally located upon the catheter, administers electromagnetic radiation to the blood within the patient, thereby creating heat due to the dielectric qualities of blood. As blood heated by the indwelling RF catheter courses through the patient's body, the patient's body is systemically warmed, raising the body core temperature.

Owner:QUASIMOTO +1

Vessel sealing system using capacitive RF dielectric heating

ActiveUS7780662B2Heating evenlyReduce heat spreadSurgical instruments for heatingCoatingsElectricityVessel sealing

An electrosurgical system for sealing vessels using capacitive (RF) dielectric heating and a method thereof are provided. The system includes an electrosurgical instrument having an end effector with parallel plate electrodes that will clamp onto a vessel and maintain a specified gap distance; however, the electrodes will be coated with a non-conductive dielectric material. Such an end effector will ensure that direct conduction between the electrodes does not occur through tissue or fluids and effectively creates a parallel plate capacitor with a dielectric, e.g., tissue and coating, in between the plates. The electrosurgical instrument will be activated with an AC signal at a specified RF frequency, e.g., a Debye resonance frequency, via an electrosurgical generator. An effective AC current will flow through the tissue and cause heating due to fictional losses from rotating polar molecules in the tissue.

Owner:COVIDIEN AG

Variable frequency automated capacitive radio frequency (RF) dielectric heating system

InactiveUS20030205571A1Near independence of thermal conductivityEasy to adaptMeat/fish preservation by heatingDielectric heating circuitsEngineeringImpedance matching

A food product is heated by maintaining the food product in an AC electrical field generated by an RF signal. As the heating takes place, maximum energy is delivered to the food product using automatic impedance matching to adjust the rate of the process.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV +1

System and method employing indwelling RF catheter for systemic patient warming by application of dielectric heating

An indwelling RF catheter achieves warming of patients by dielectric heating of blood or other bodily fluids. In one example, the catheter is deployed in a suitable blood vessel, such as the inferior vena cava. The catheter design includes an emitter structure electrically coupled to an RF generator, which provides a source of RF power. The emitter structure, distally located upon the catheter, administers electromagnetic radiation to the blood within the patient, thereby creating heat due to the dielectric qualities of blood. As blood heated by the indwelling RF catheter courses through the patient's body, the patient's body is systemically warmed, raising the body core temperature.

Owner:QUASIMOTO +1

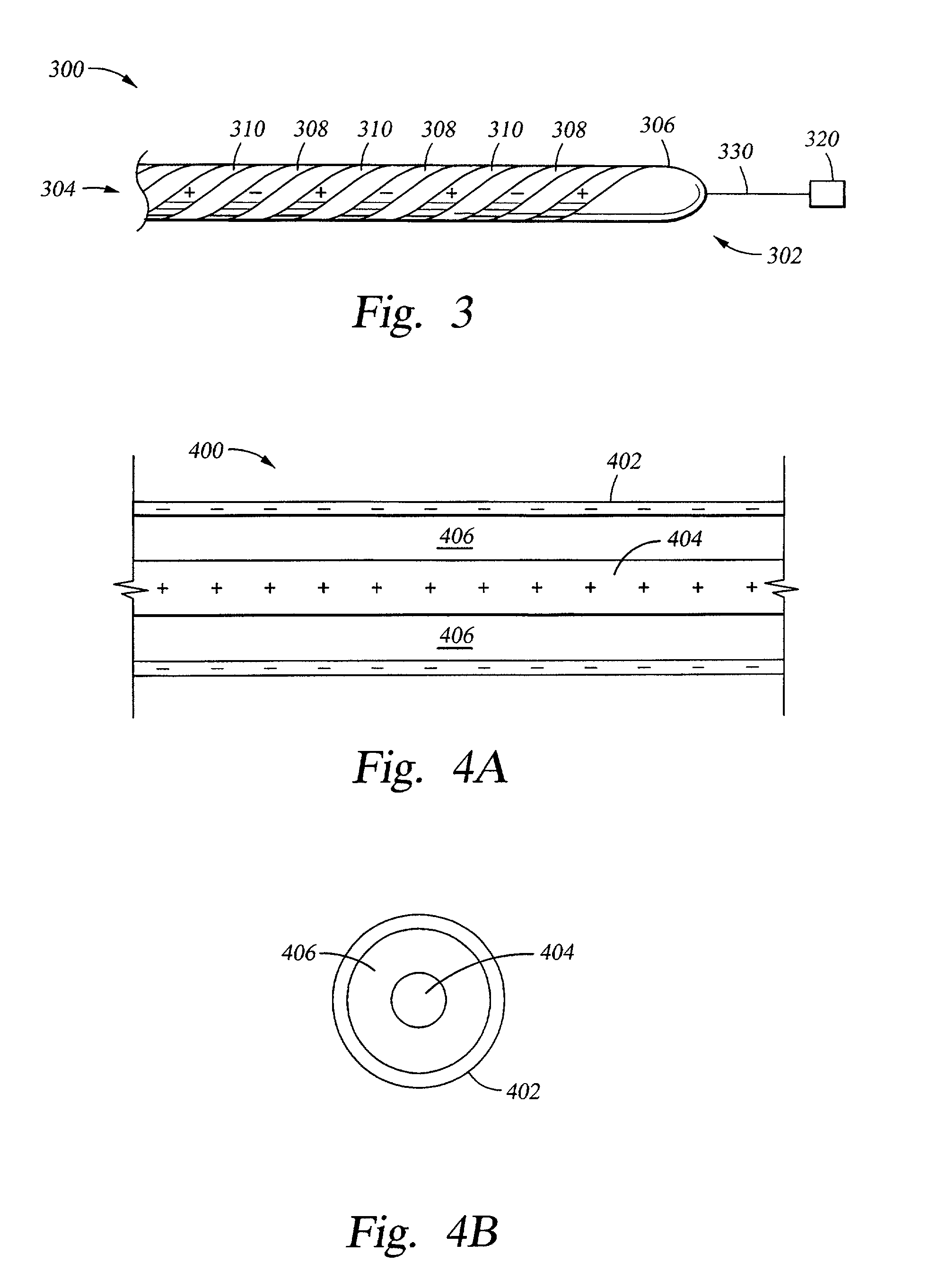

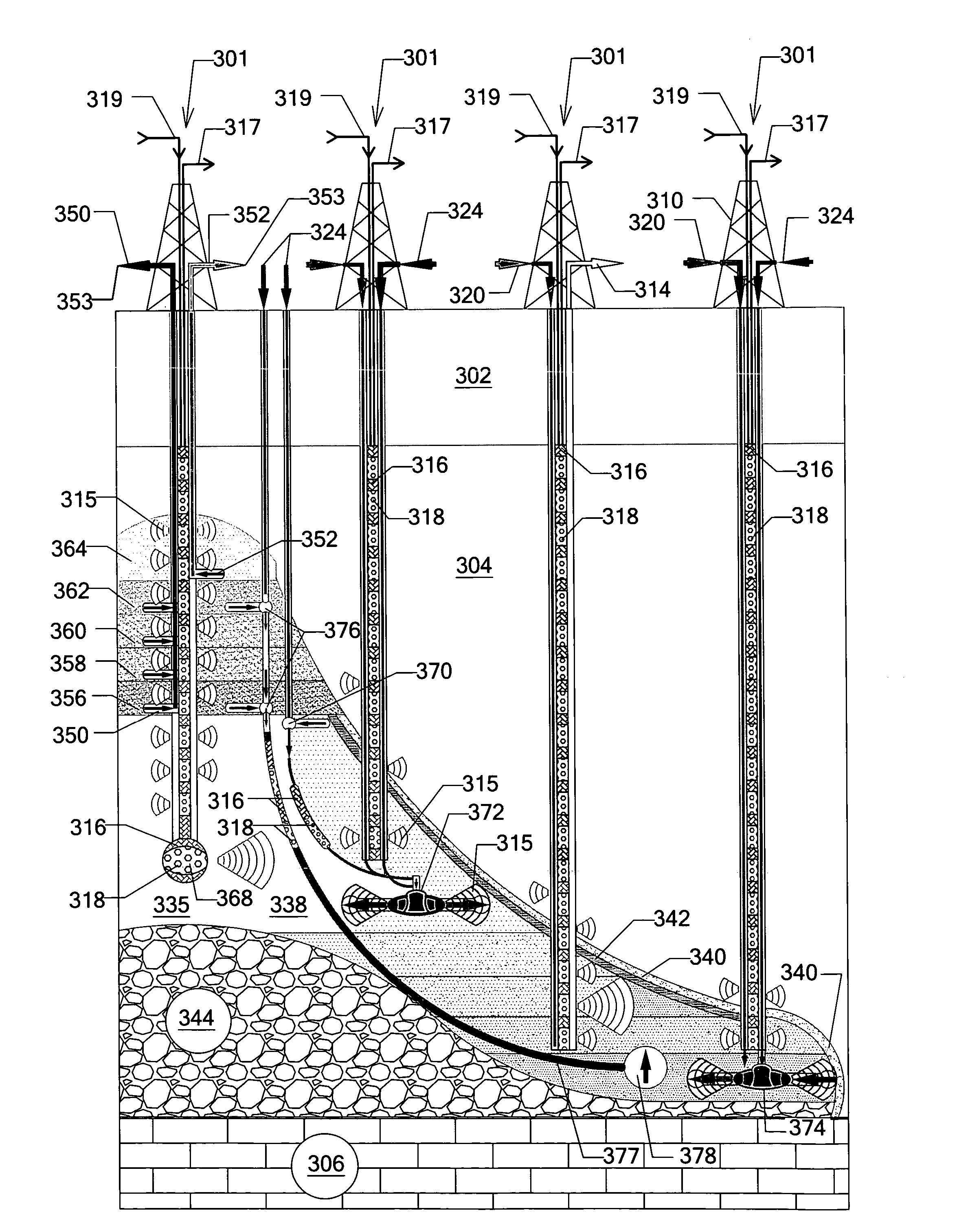

In situ processing of hydrocarbon-bearing formations with variable frequency dielectric heating

A hydrocarbon bearing formation (304) which is heated using a variable frequency capacitive radio frequency dielectric heating (334) in situ process. Hydrocarbons or other substances natural to a hydrocarbonaceous formation may be produced by heating specific chemical compositions with or without the use of a carrier medium (320) in a subterranean reservoir. Hydrocarbons or other substances natural to a hydrocarbonaceous formation are heated by maintaining specific chemical compositions in an alternating current electrical field generated by a radio frequency signal. As the targeted chemical compositions increase in temperature, maximum energy is delivered using variable frequency radio frequency dielectric heating to adjust the rate of the heating process.

Owner:HEAT ENERGY & ASSOCD TECH

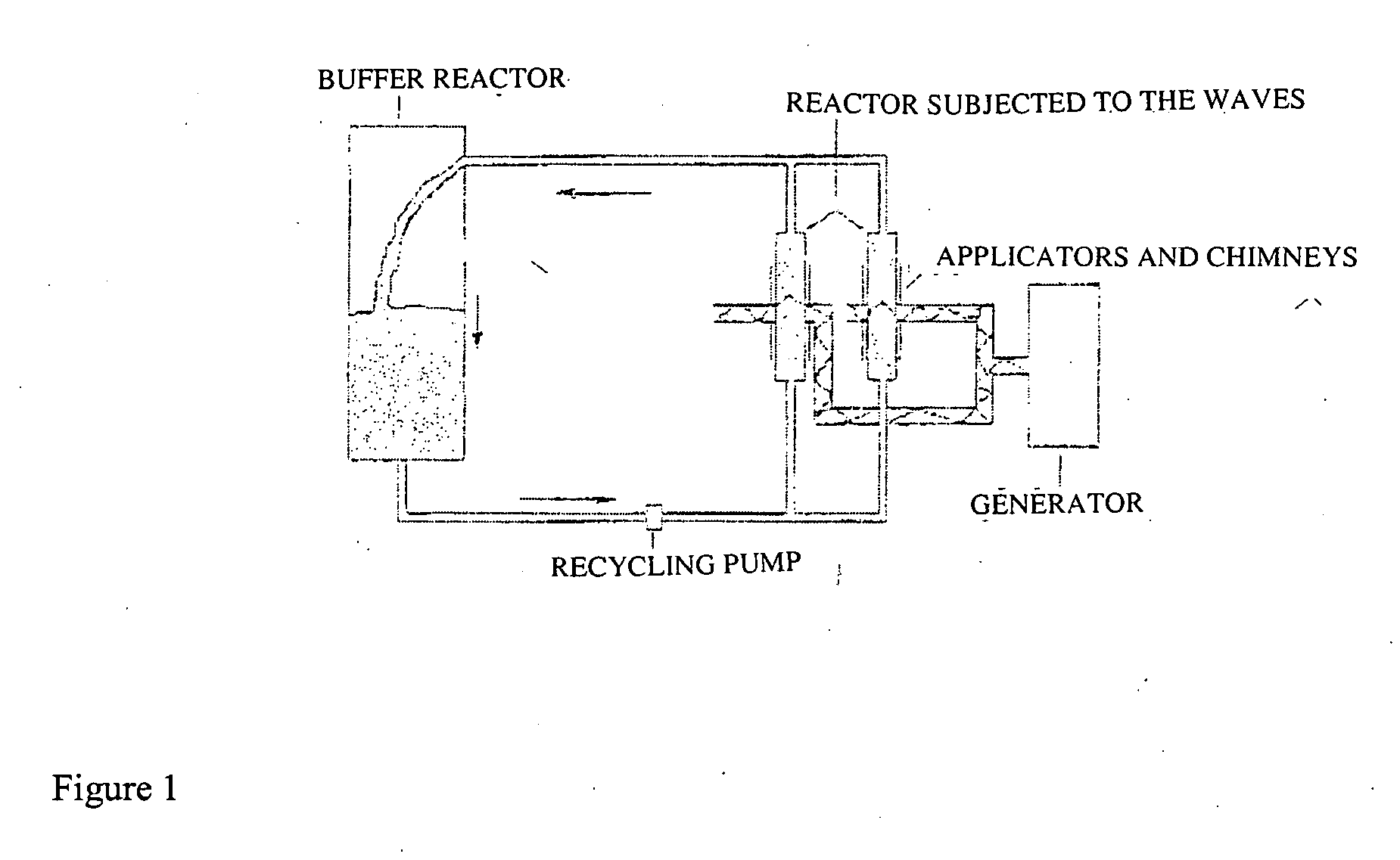

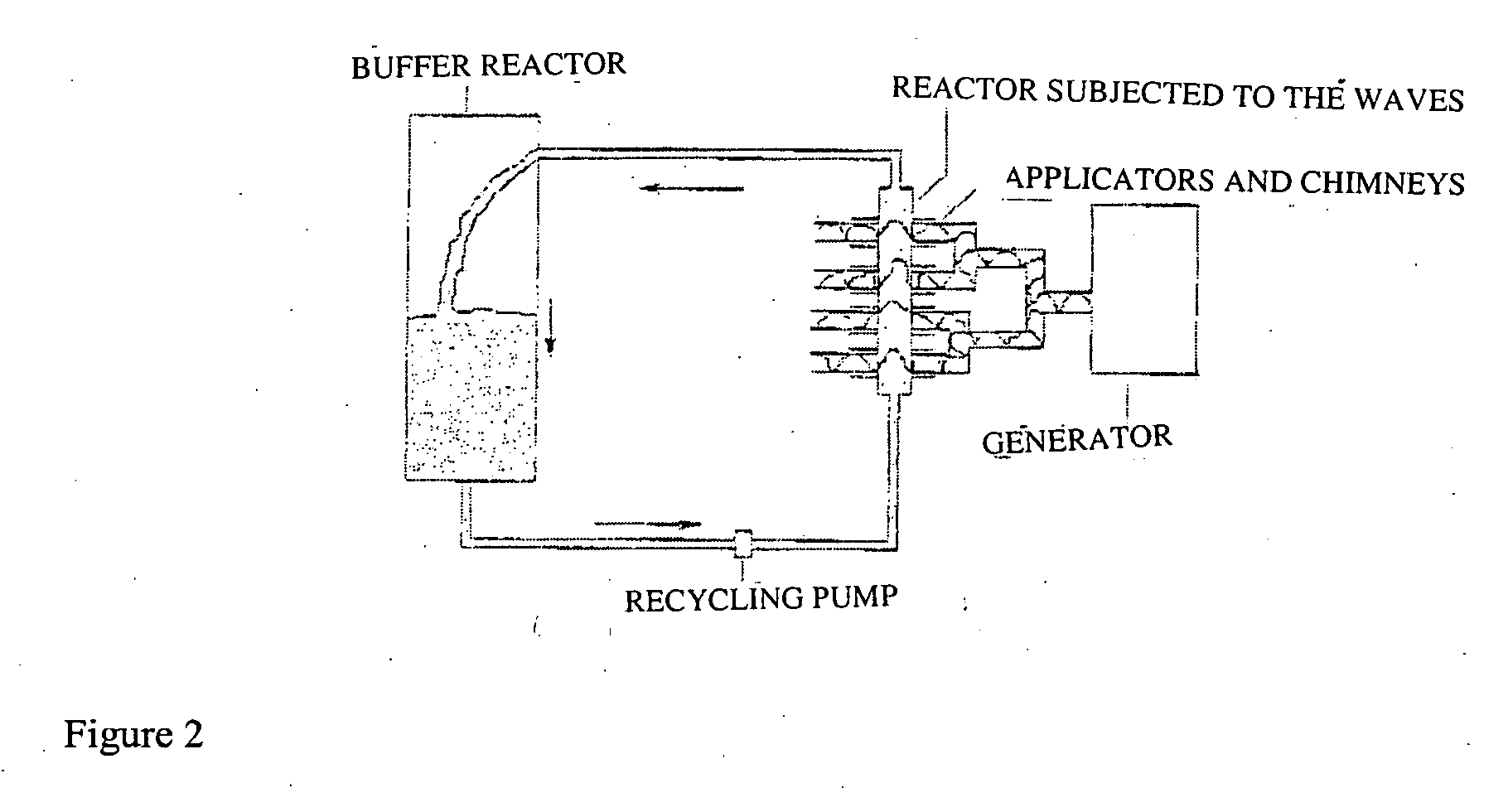

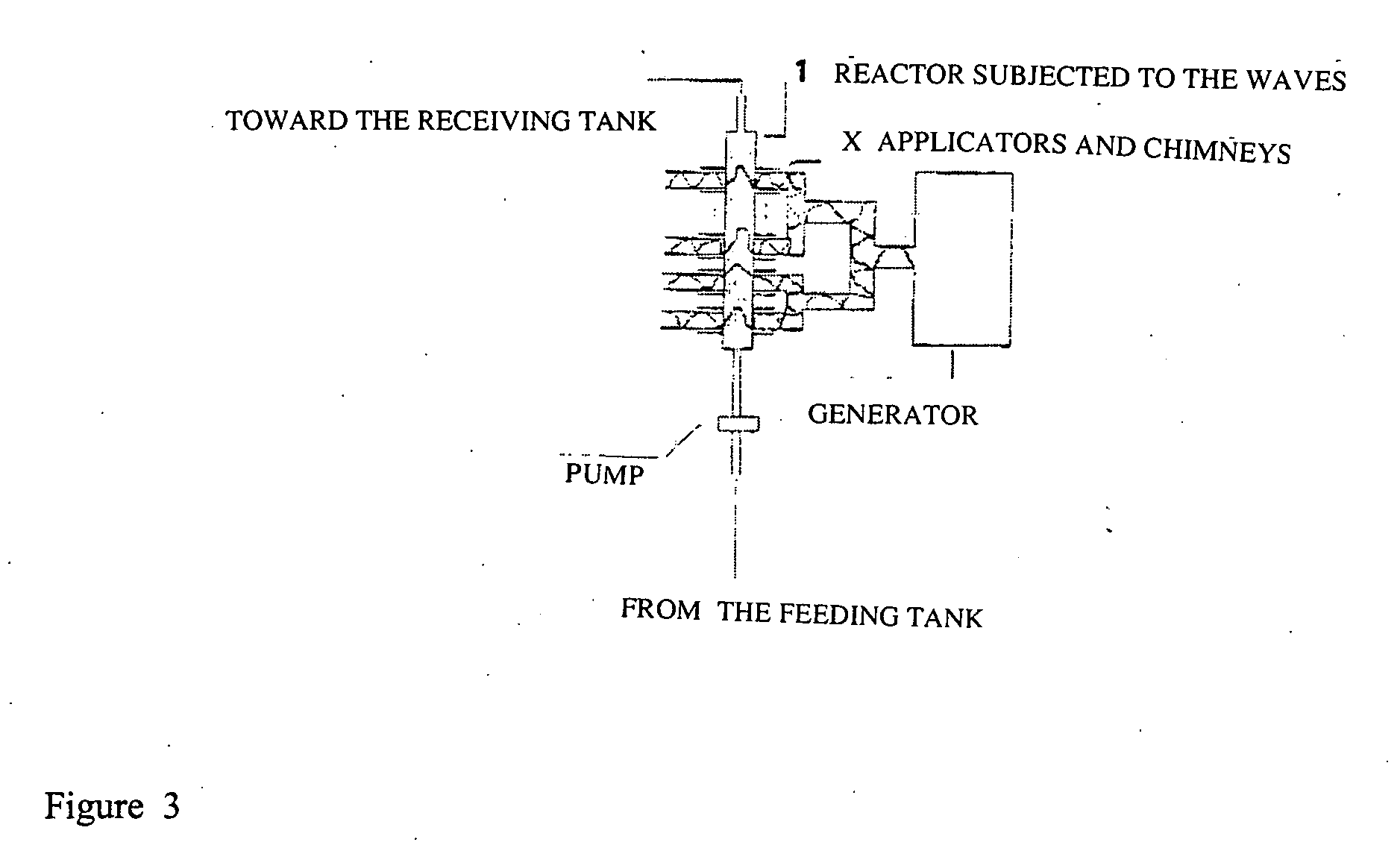

Chemical synthesis comprising heat treatment by intrmittent dielectric heating combined with a recycling system

InactiveUS20060228088A1Low costEfficient and rapid heat treatmentDielectric heatingBiofuelsChemical synthesisElectricity

This invention relates to the design of a process by intermittent dielectric heating combined with a recycling system. This process consists in subjecting reagents to electromagnetic waves selected in the frequencies ranging between 300 GHz and 3 MHz intermittently using a recycling system. This process enables the treatment of oils that are hardly absorbent as well as great investment savings. This process enables operation on different scales, whether in laboratories, on a semi-industrial or industrial scale, without forfeiting the advantages of continuous dielectric heating.

Owner:ALDIVIA

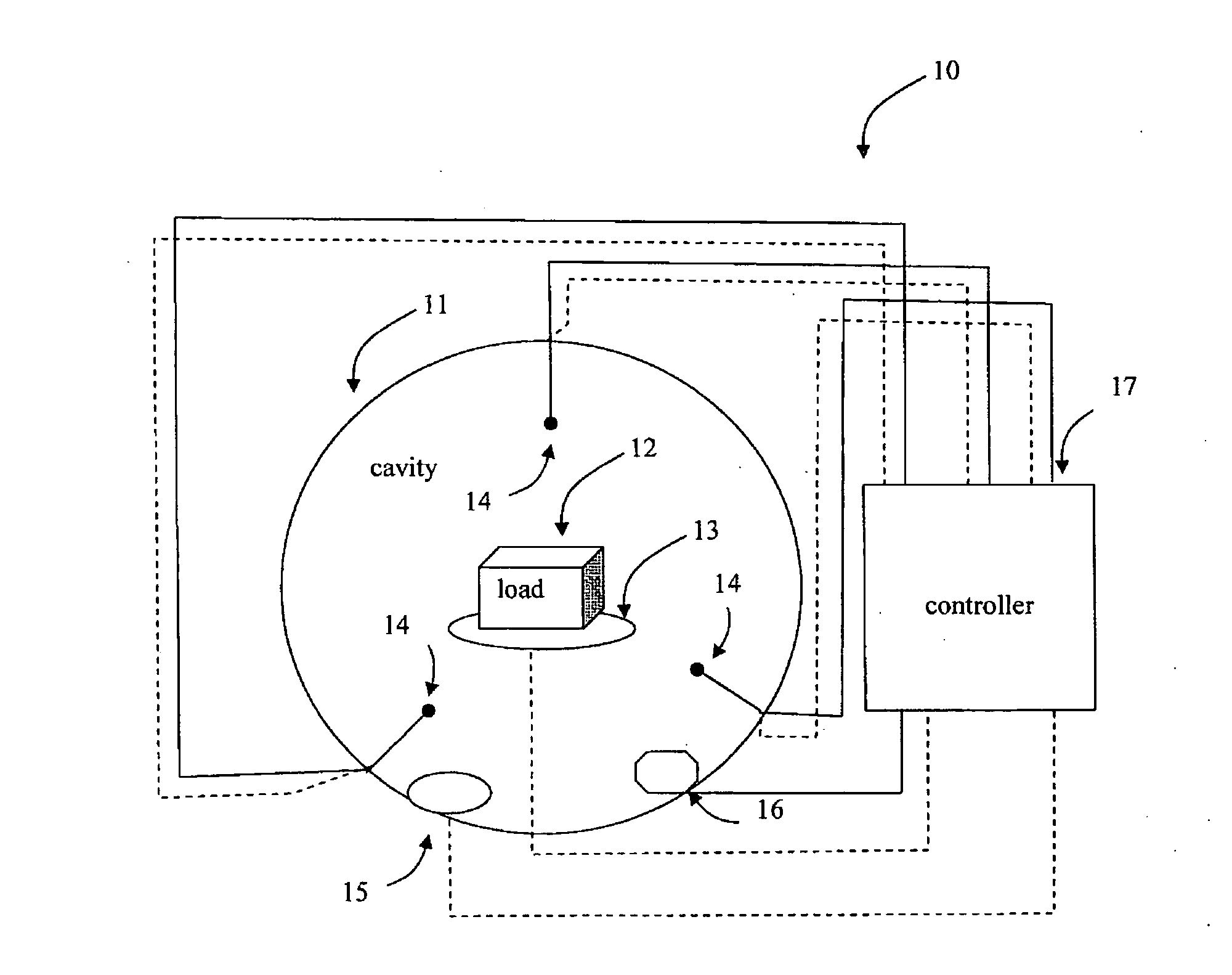

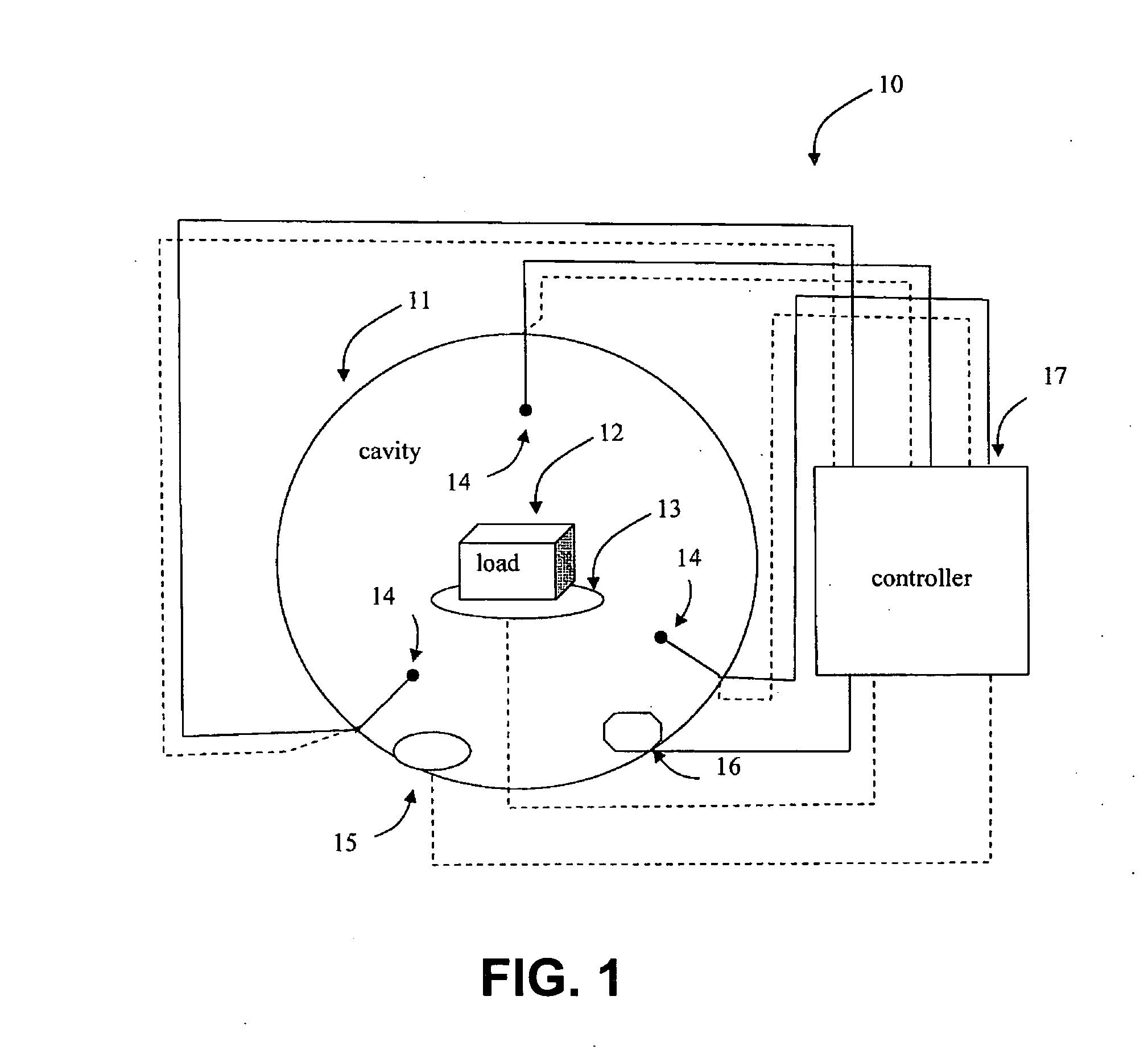

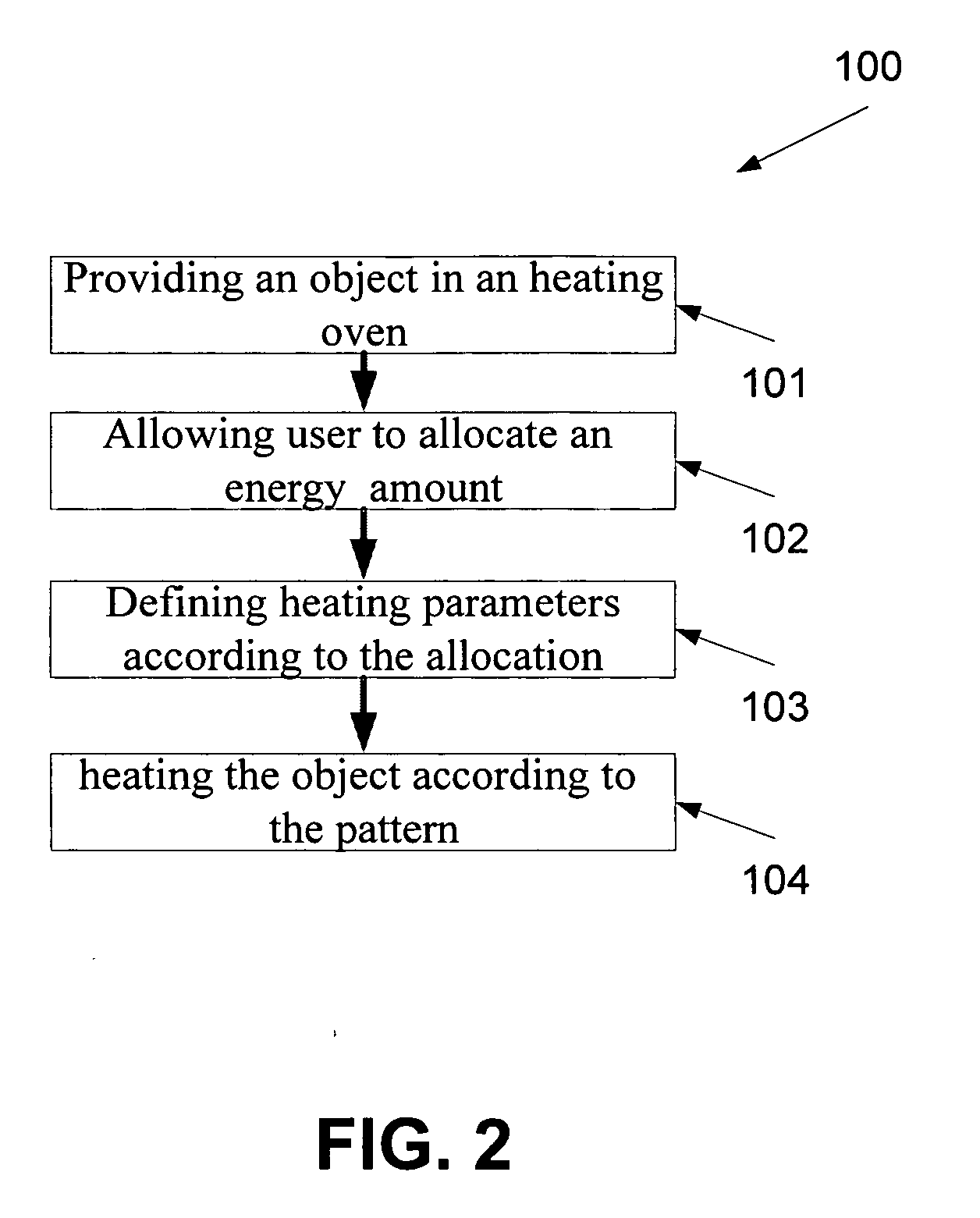

Method and system for dielectric heating and cooking

A method of heating an object using a dielectric heating. The method comprises positioning an object in a cavity of a dielectric heating oven, allowing a user to allocate an amount of energy to dissipate in the object during a temperature elevation of the object, and elevating the temperature of the object by using the dielectric heating oven according to the amount of energy.

Owner:GOJI LTD

MRI compatible electrode circuit

ActiveUS20110046707A1Reducing RF-induced heatingStay flexibleElectrotherapyElectrocardiographyUltrasound attenuationElectricity

An MRI compatible electrode circuit construct is provided. The construct includes at least two filter components constructed from an electrode wire. One filter component may be a resonant LC filter at or near an electrode / wire interface that resolves the issue of insufficient attenuation by effectively blocking the RF induced current on the wire from exiting the wire through the electrode. The second filter component may include one or more non-resonant filter(s) positioned along the length of the electrode wire that resolve(s) the issue of excessive heating of the resonant LC filter by significantly attenuating the current induced on the wire before it reaches the resonant LC filter. The non-resonant filter(s) may also attenuate the RF current reflected from the resonant LC filter thereby resolving the issue of the strong reflected power from the resonant filter and the associated dielectric heating.

Owner:IMRICOR MEDICAL SYST

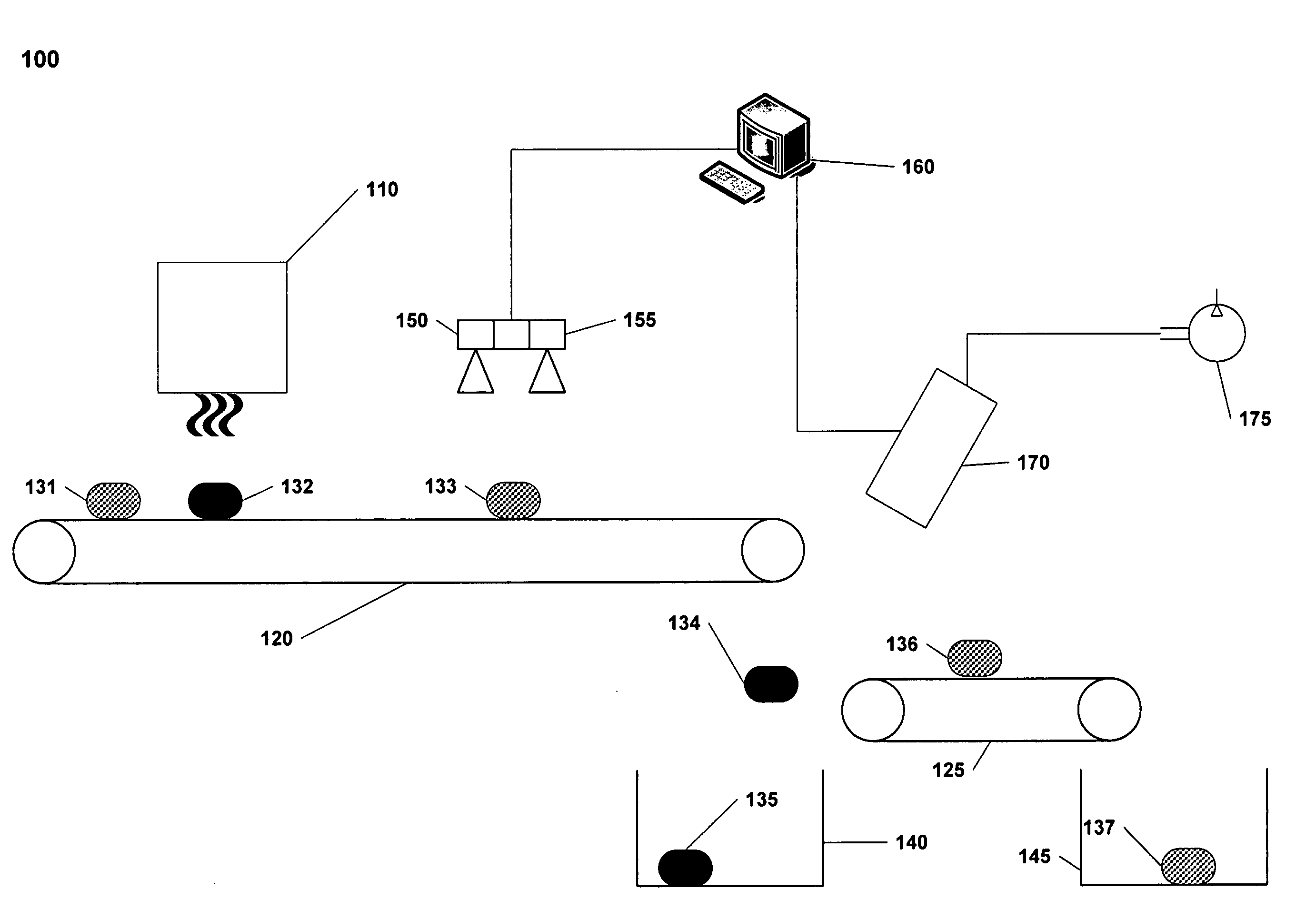

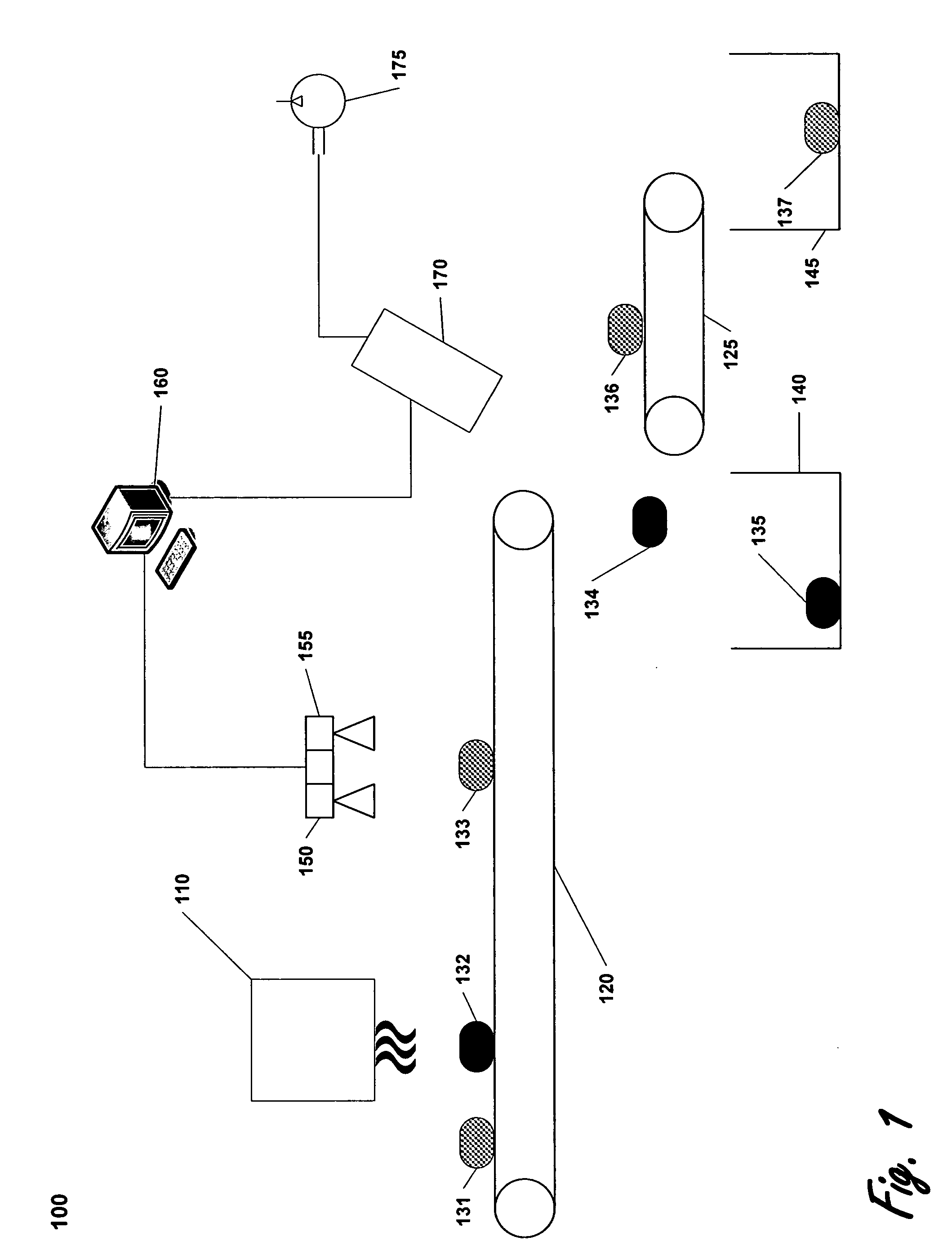

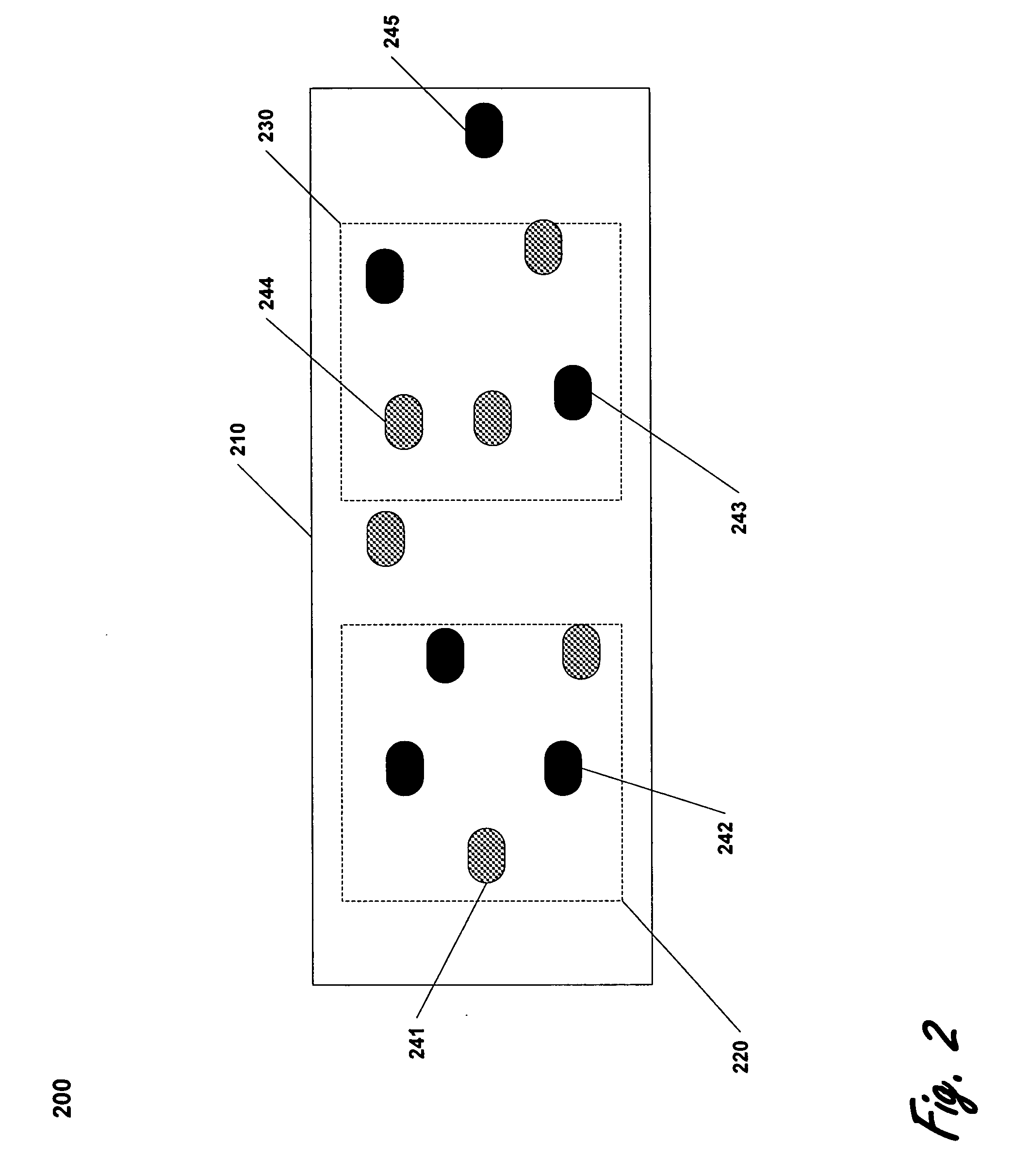

System and method for sorting dissimilar materials

Sorting dissimilar materials, such as sorting plastics from wood, foam, or rubber. These systems and methods employ either dielectric heating or fluorescent dye absorption characteristics of materials to distinguish the materials. The systems and methods may employ differential dielectric heating and thermal imaging to sort wood, rubber, and foam, from plastic, metals, and other materials that do not undergo dielectric heating. Similarly, systems and methods may employ the greater liquid absorption properties of wood, rubber, and foam as compared to plastic. The dissimilar materials are subjected to fluorescent dye and carrier liquid, that is differentially absorbed by objects. Fluorescent imaging can be used to distinguish the materials. In either case, a computer-controlled system can be used to sort material types based on an evaluation of the thermal or fluorescent image.

Owner:VALERIO THOMAS A

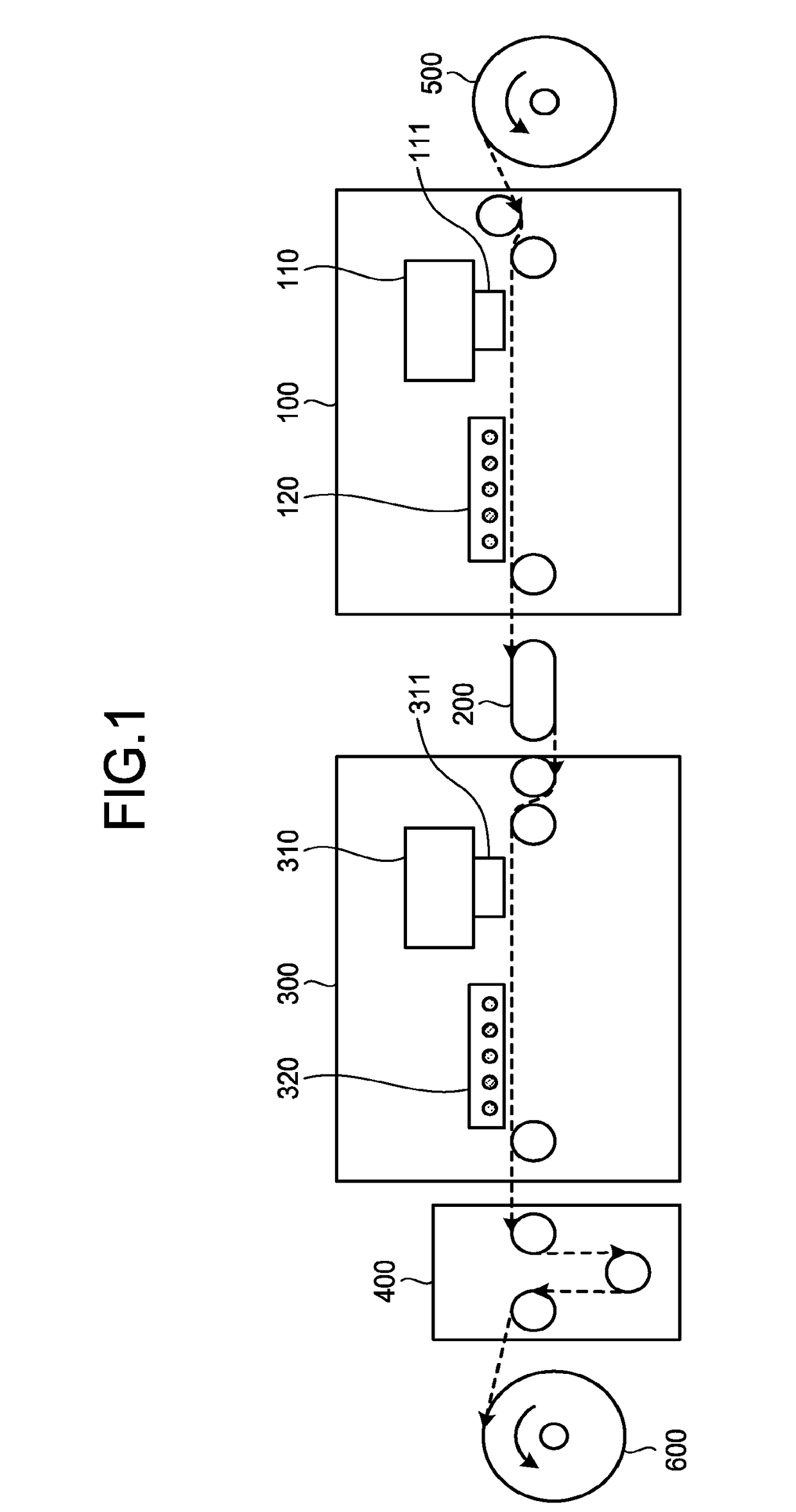

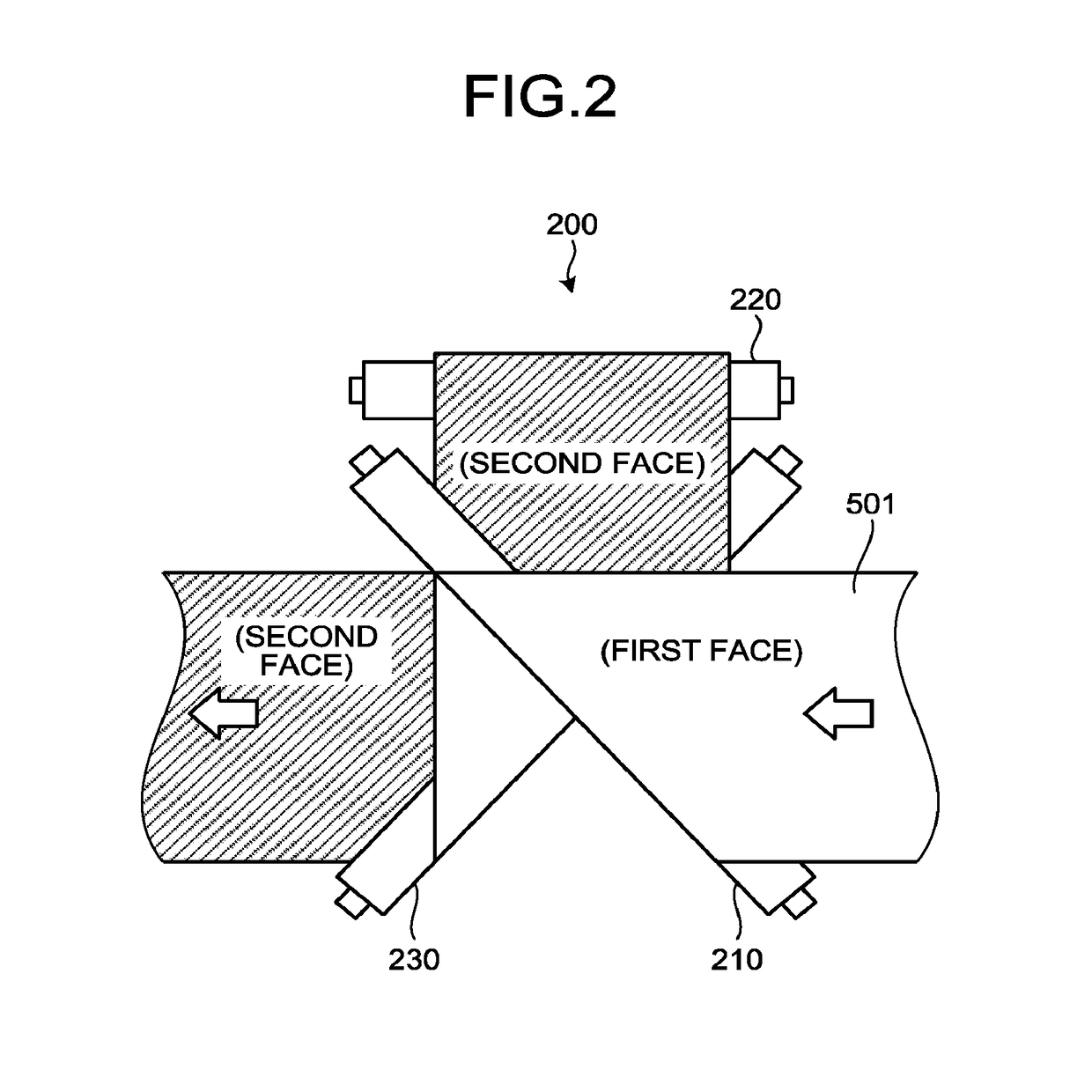

Drying device and liquid discharging device

ActiveUS20170266986A1Dielectric heatingDrying solid materials with heatElectricityConductive materials

A drying device includes: a dielectric heating unit configured to apply an alternating electrical field to a medium onto which a liquid containing a conductive material, water, and a solvent has been discharged, and perform dielectric heating of the liquid; and a conductive member disposed either to make contact with or to be close to the medium to which the alternating electrical field is being applied.

Owner:RICOH KK

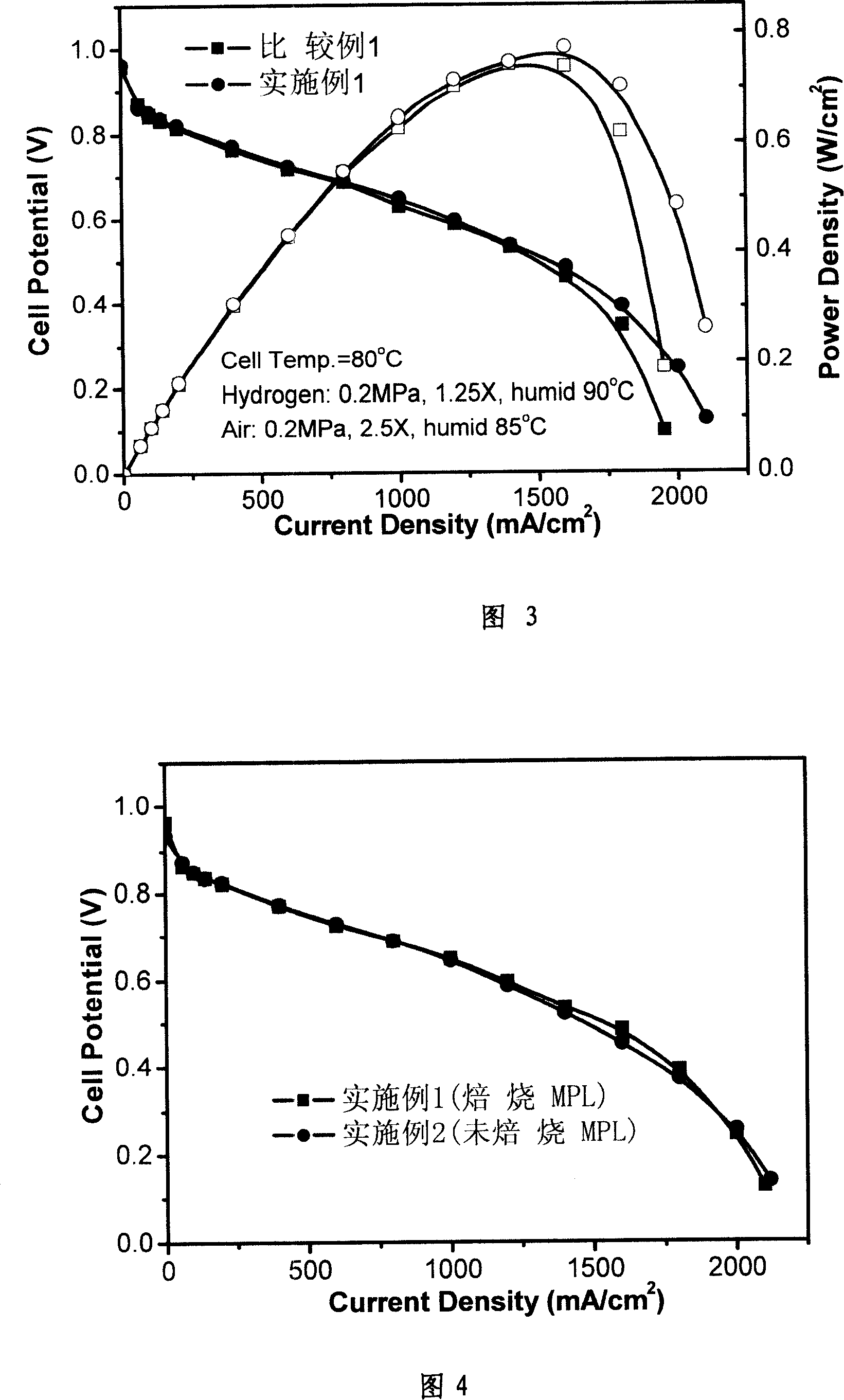

Gas diffusion layer for fuel cell and its production

InactiveCN101154733AGuaranteed hydrophobicityAchieve hydrophobicityCell electrodesFinal product manufactureFuel cellsElectrical battery

The invention relates to a fuel battery, in particular to a gas diffusing layer and the preparation for the fuel battery; the gas diffusing layer consists of basic bottom layer and a micro-hole layer, which is made by fabricating the micro-hole constructed by a water repellent agent / a composite powder body of electric conduction copper material at one side or two sides of a porous electric conduction basic bottom processed by a hydrophobic water; the water repellent agent / the composite powder body of electric conduction copper material is made by a microwave dielectric heating technology; because of the favorable water repellent performance and the grain diameter structure therefore, the gas diffusing layer to be fabricated has a strong and even water repellent performance and a suitable hole structure, so that the favorable mass transfer capability of the gas diffusing layer can be assured. The fuel battery assembled by the invention can show a better battery output performance, and is particularly suitable to be used in the fuel battery where the air is used as oxidizer with a strong practicality value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

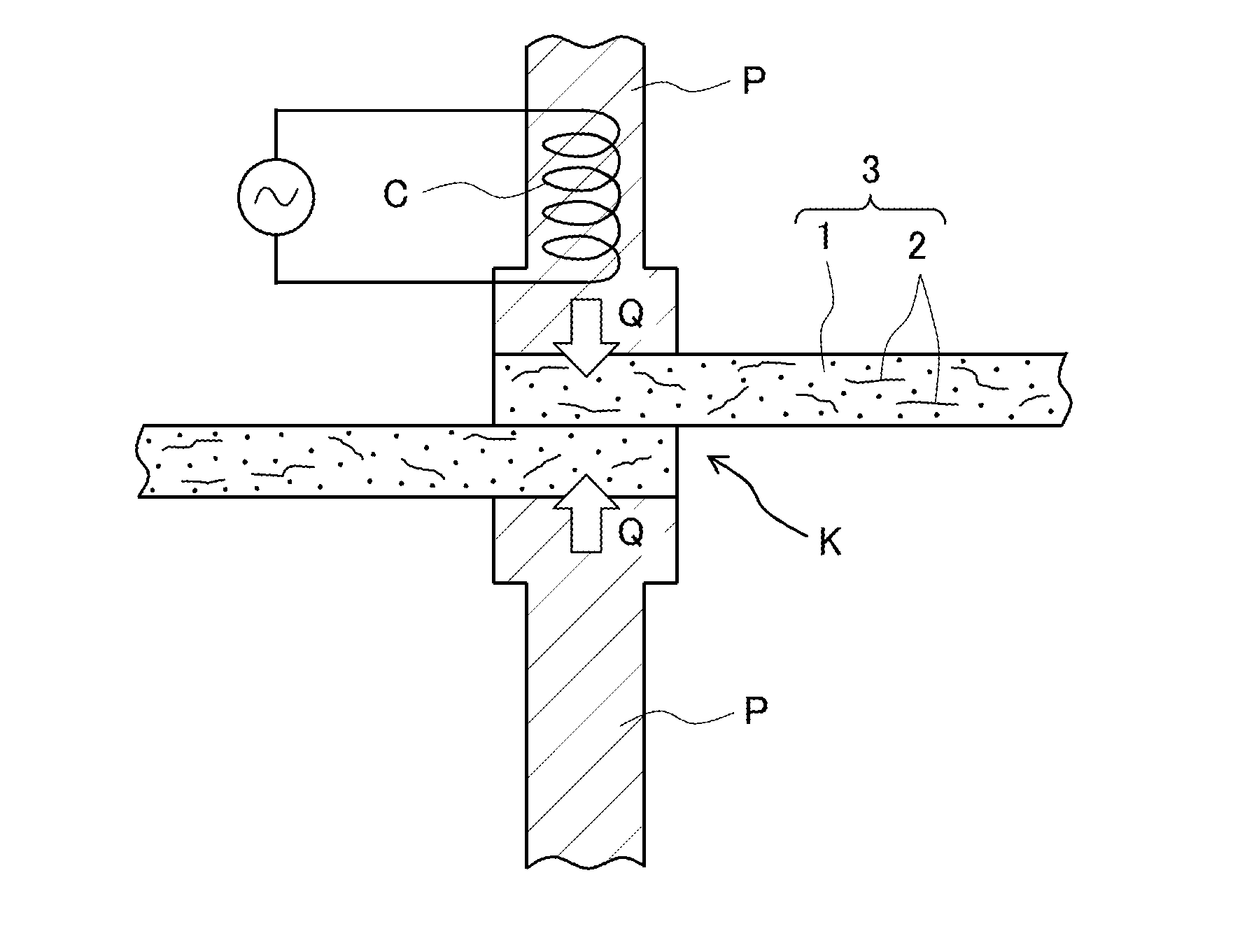

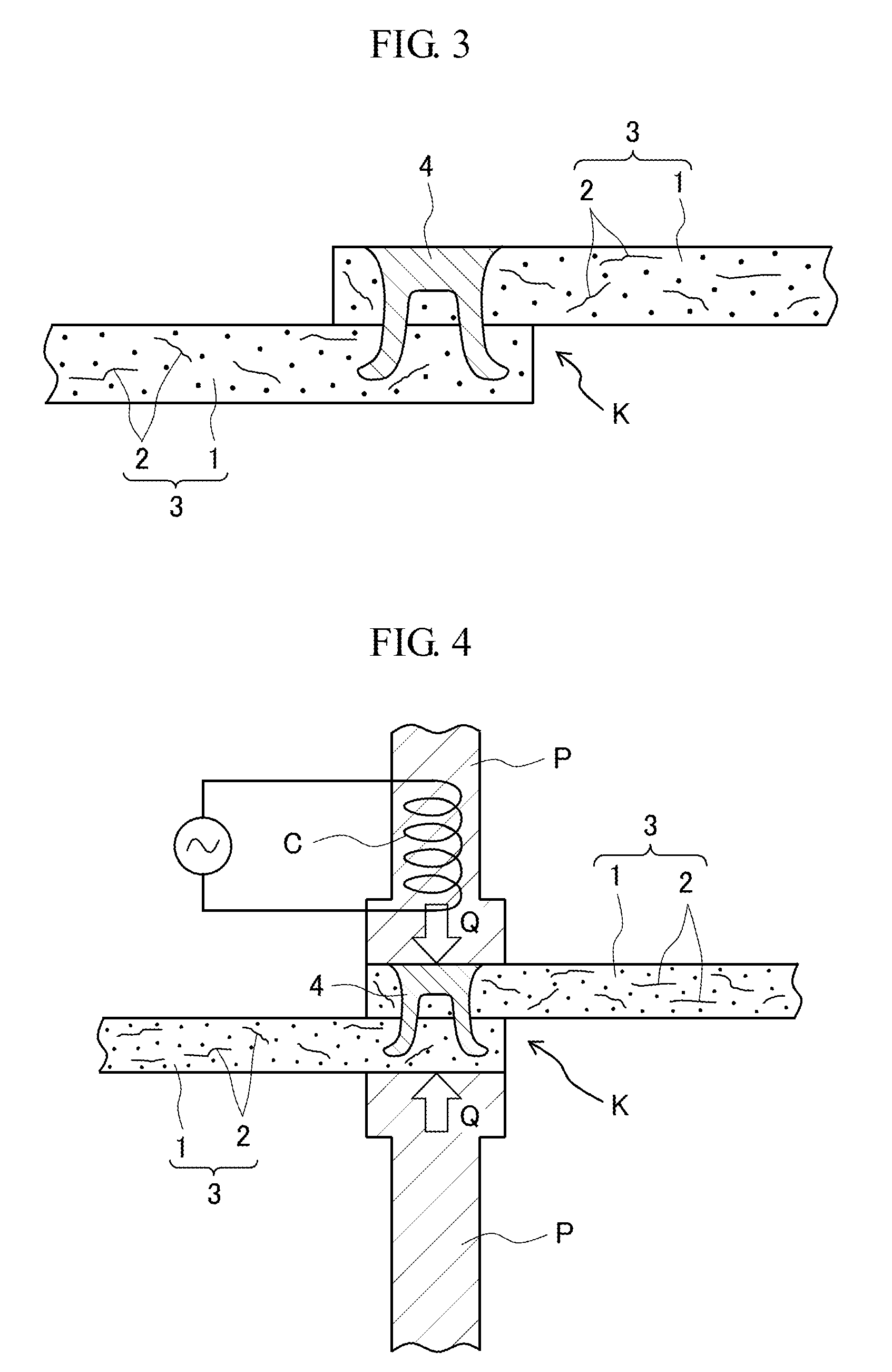

Method for connecting members together and connection structure

InactiveUS20140356053A1Improve the level ofWell formedLaminationLamination apparatusFiberEngineering

Provided are a method for connecting members together that can easily form a connection structure, which has about the same high level of connection strength over the entire range of a position of superposition, in a short time, and a connection structure. The method is a method for connecting two or more members together, at least one of which is a fiber reinforced resin member containing a thermoplastic resin and also containing a reinforcing fiber material that serves as a heating element in the thermoplastic resin, at a position of superposition. The method includes pressing the members against each other while heating the members at a position of superposition using one of induction heating or dielectric heating and thus melting the thermoplastic resin with heat generated from the fiber material that serves as the heating element, thereby connecting the members together.

Owner:TOYOTA JIDOSHA KK

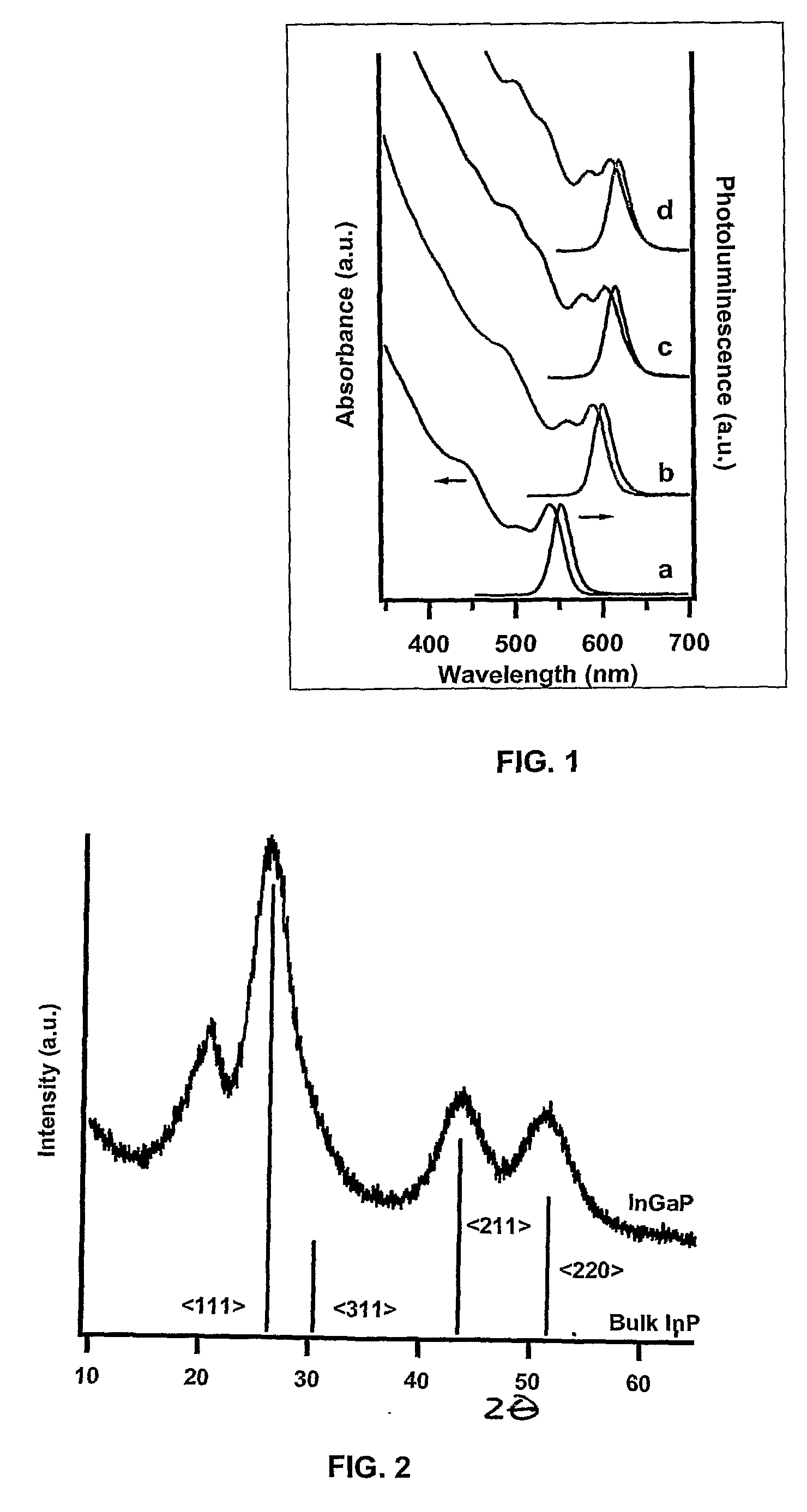

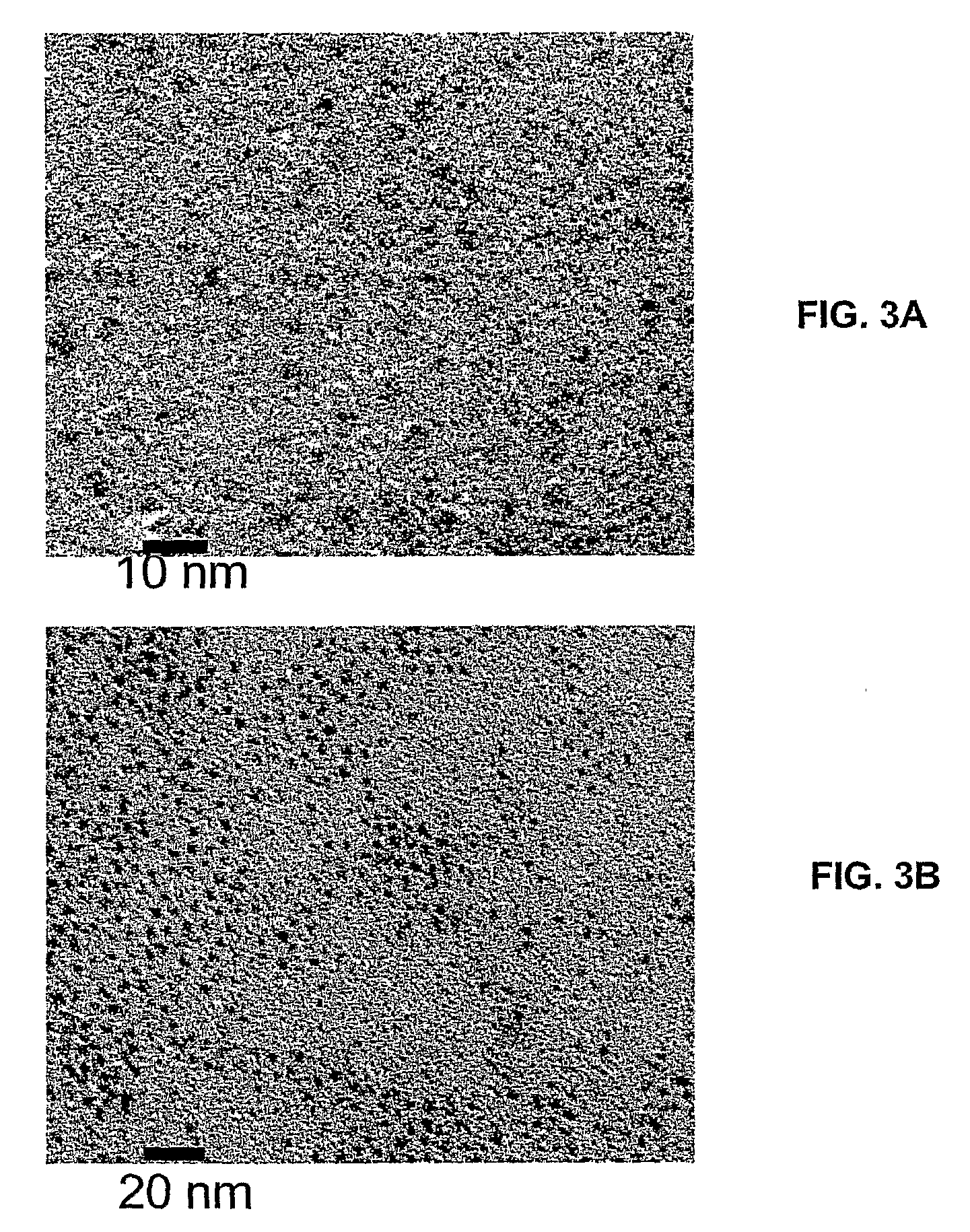

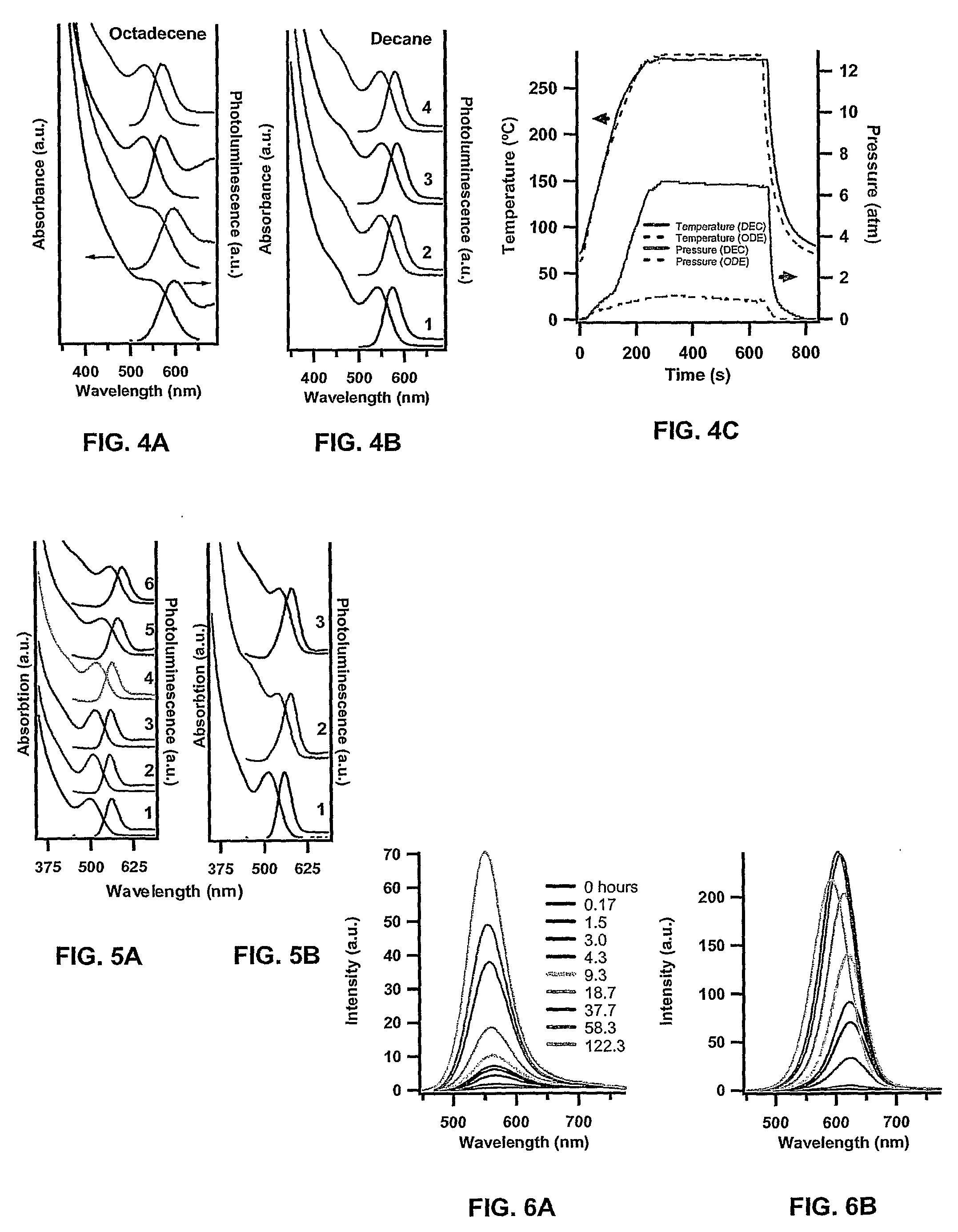

Nanoparticle Synthesis and Associated Methods

ActiveUS20080296144A1Avoid small quantitiesHigh out-of-batch quantum efficiencyMaterial nanotechnologyPolycrystalline material growthGrowth phaseSemiconductor materials

A method is provided for producing crystalline nanoparticle semiconductor material. The method includes the steps of mixing a precursor in a solvent to form a reaction mixture and subjecting the reaction mixture to microwave dielectric heating at sufficient power to achieve a superheating temperature of the reaction mixture. A growth-phase reaction is permitted to proceed, wherein nanoparticles are formed in the heated reaction mixture. The reaction is then quenched to substantially terminate nanoparticle formation.

Owner:FLORIDA STATE UNIV RES FOUND INC

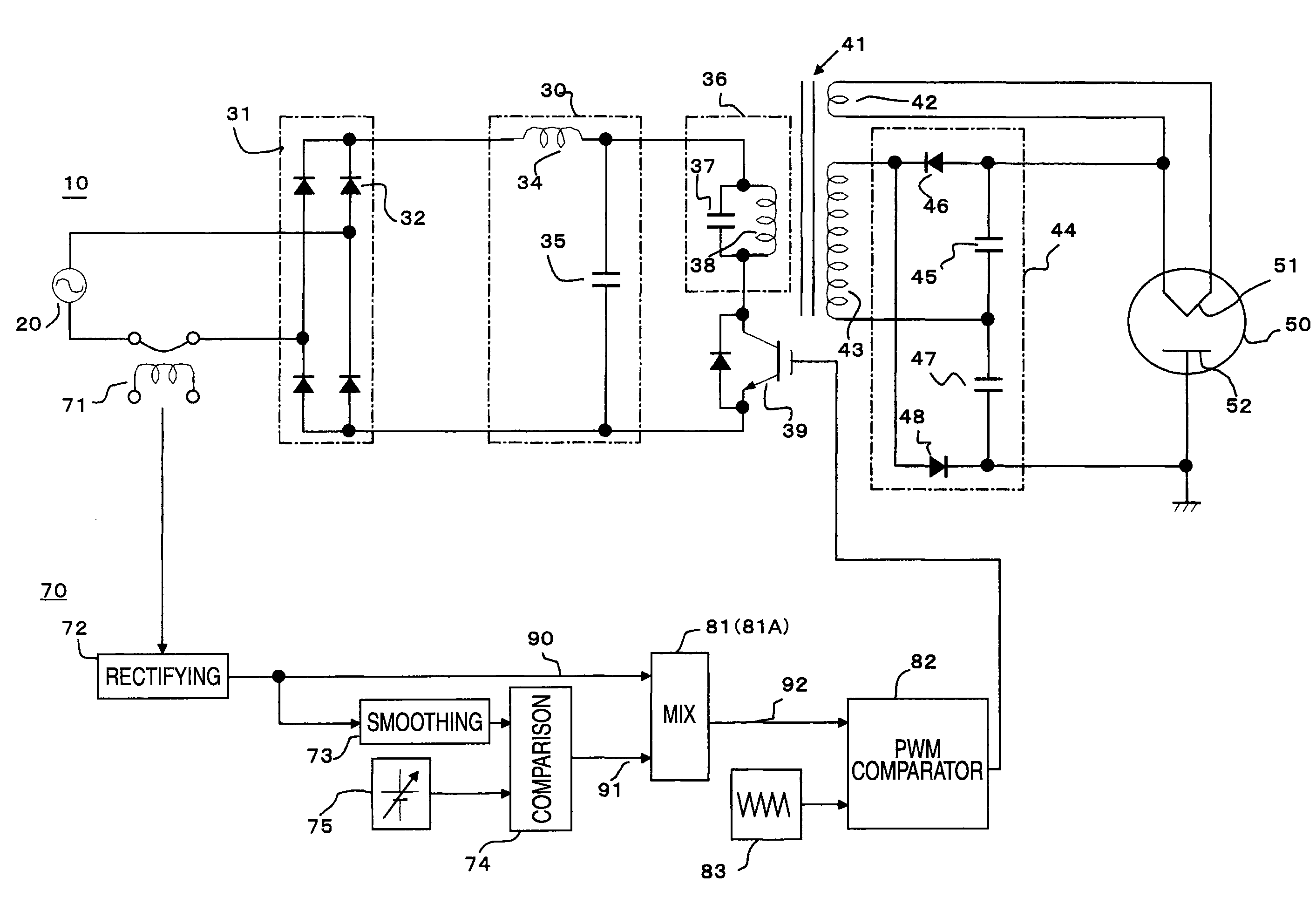

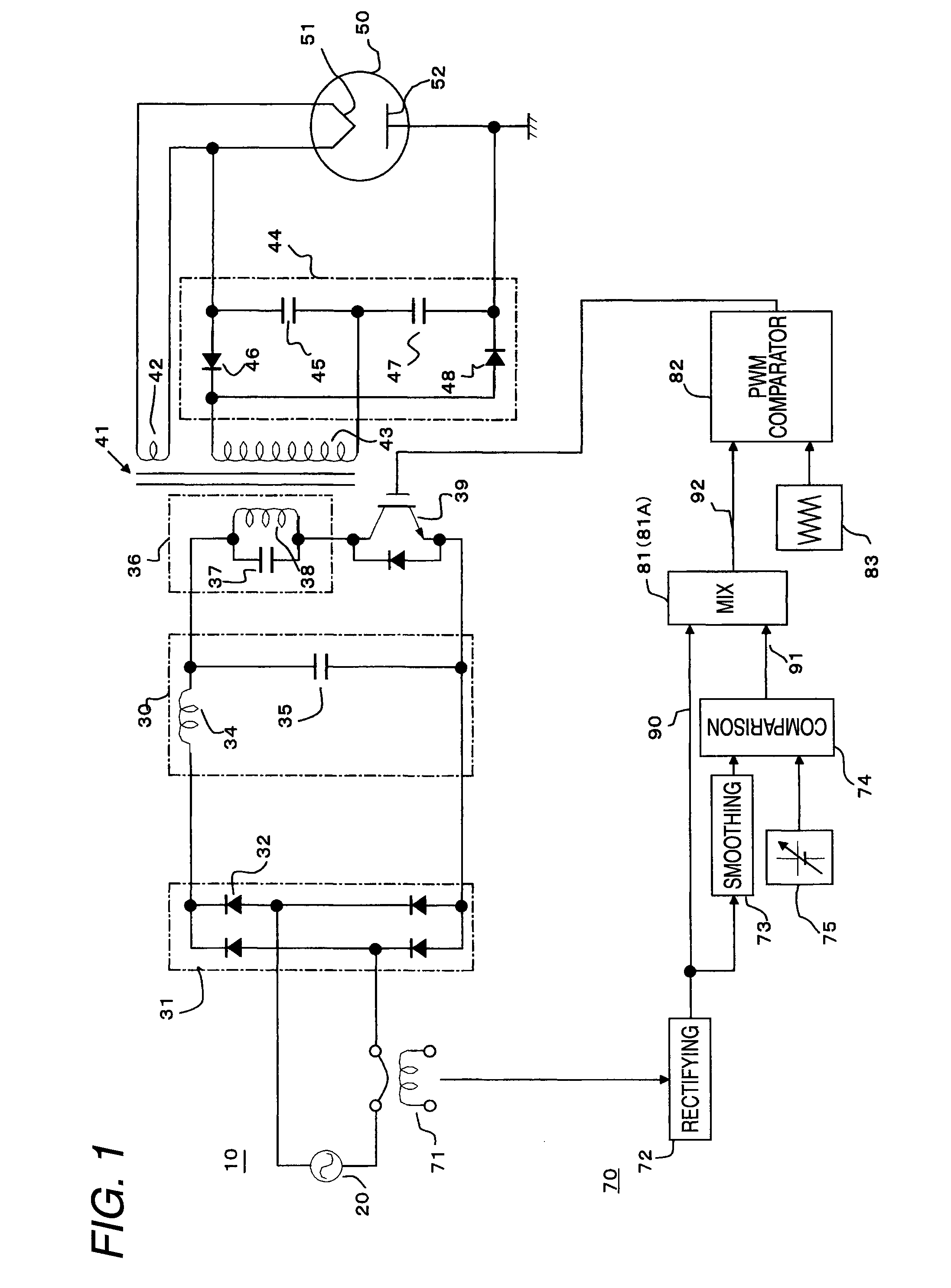

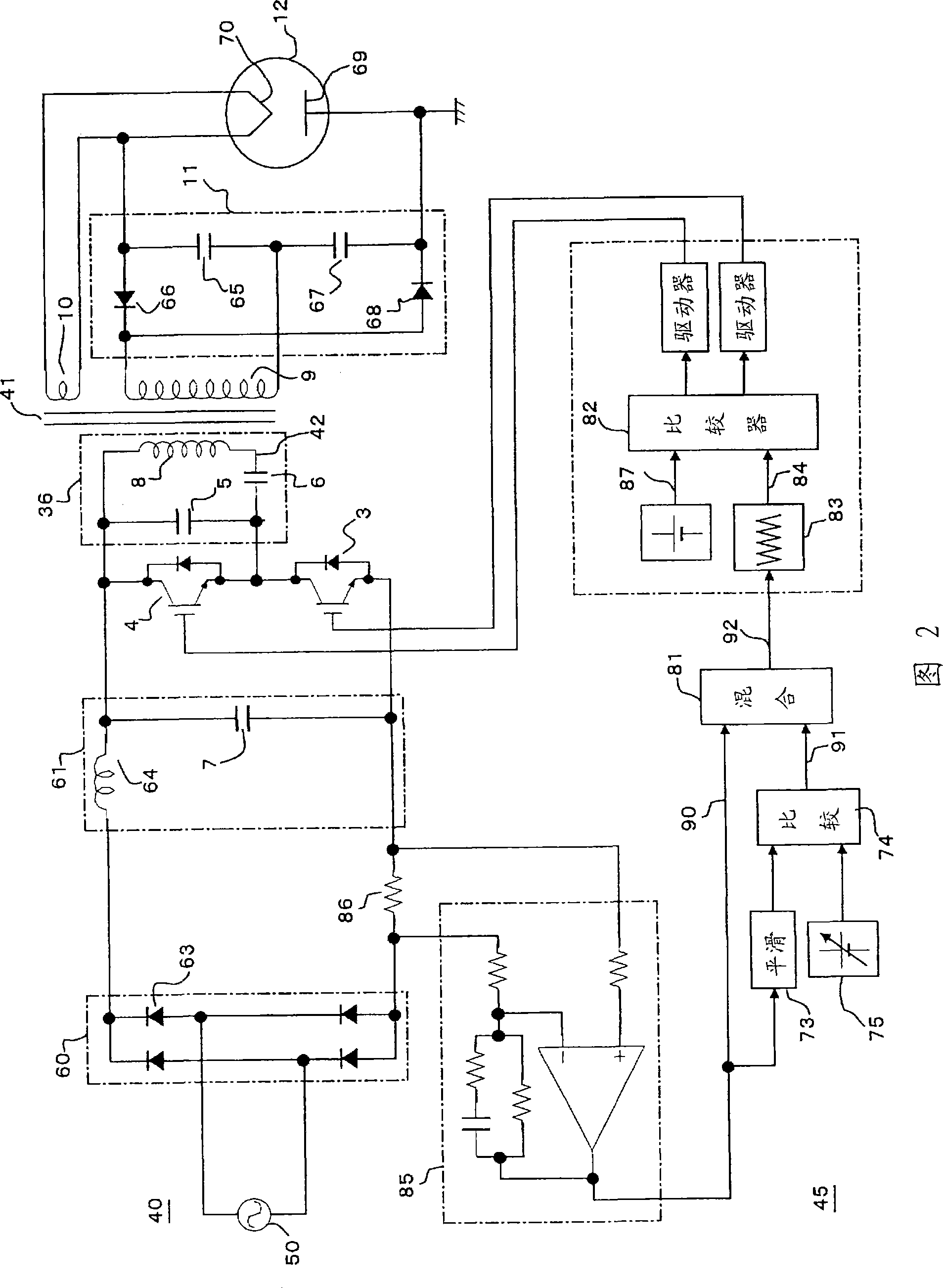

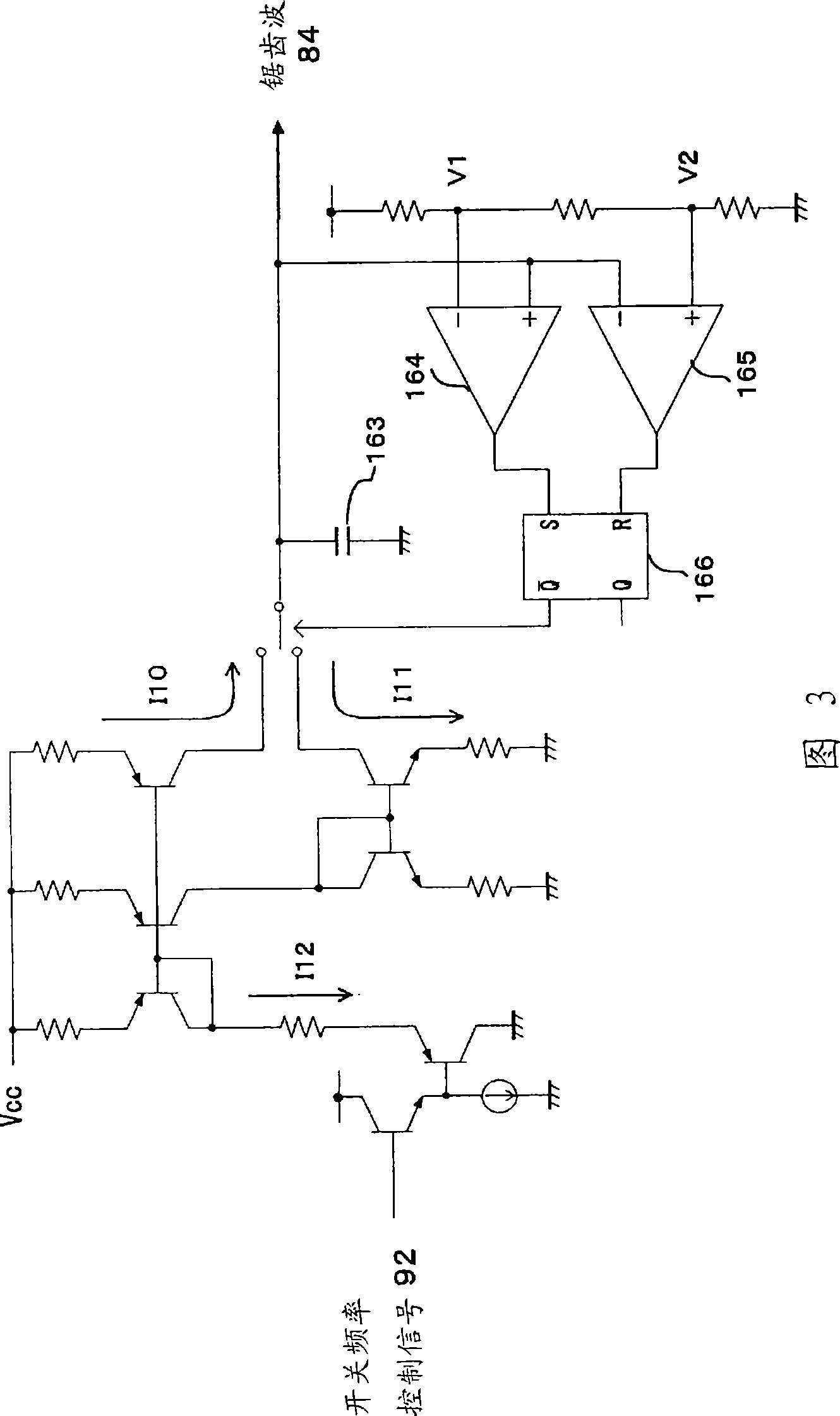

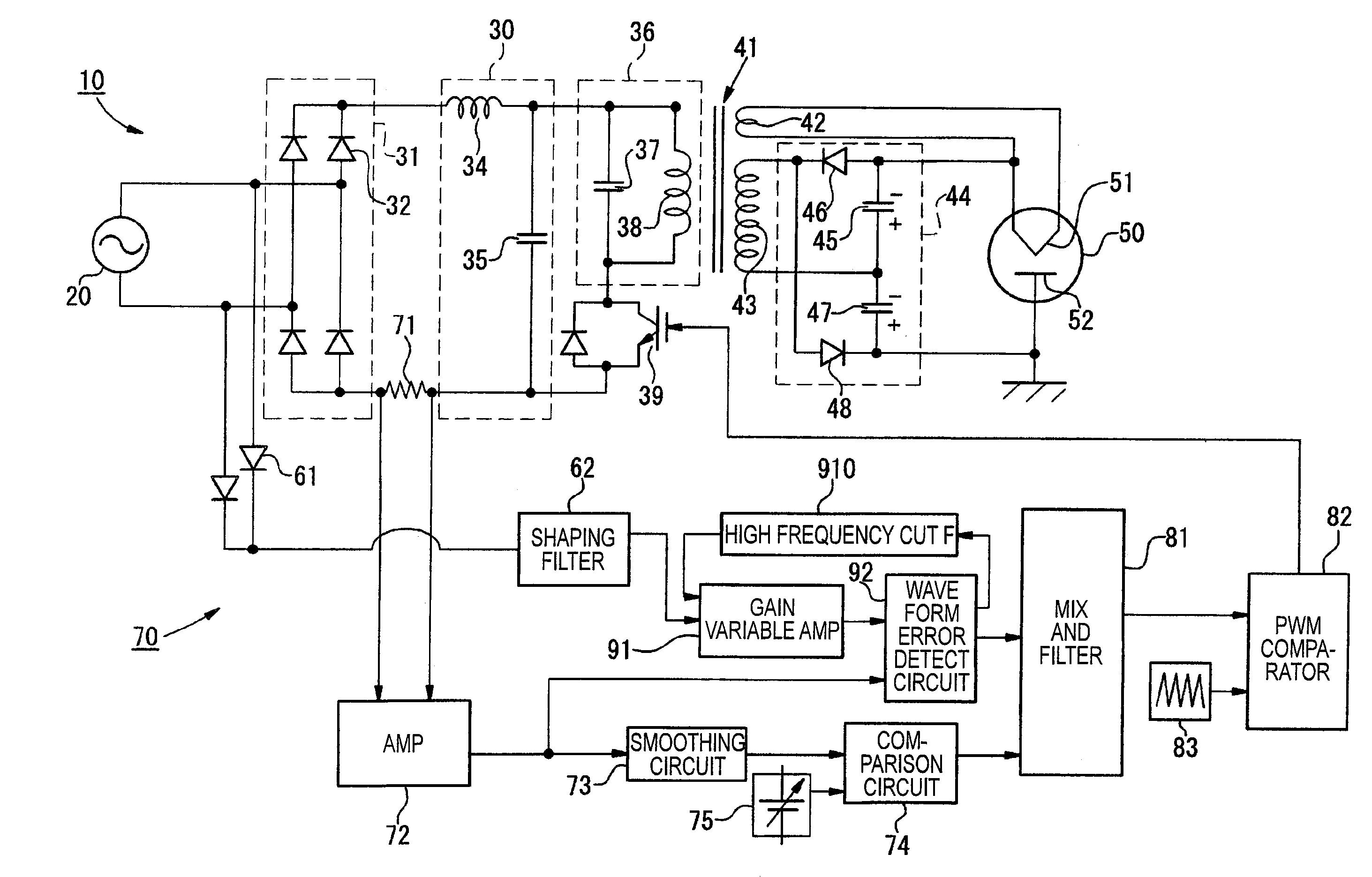

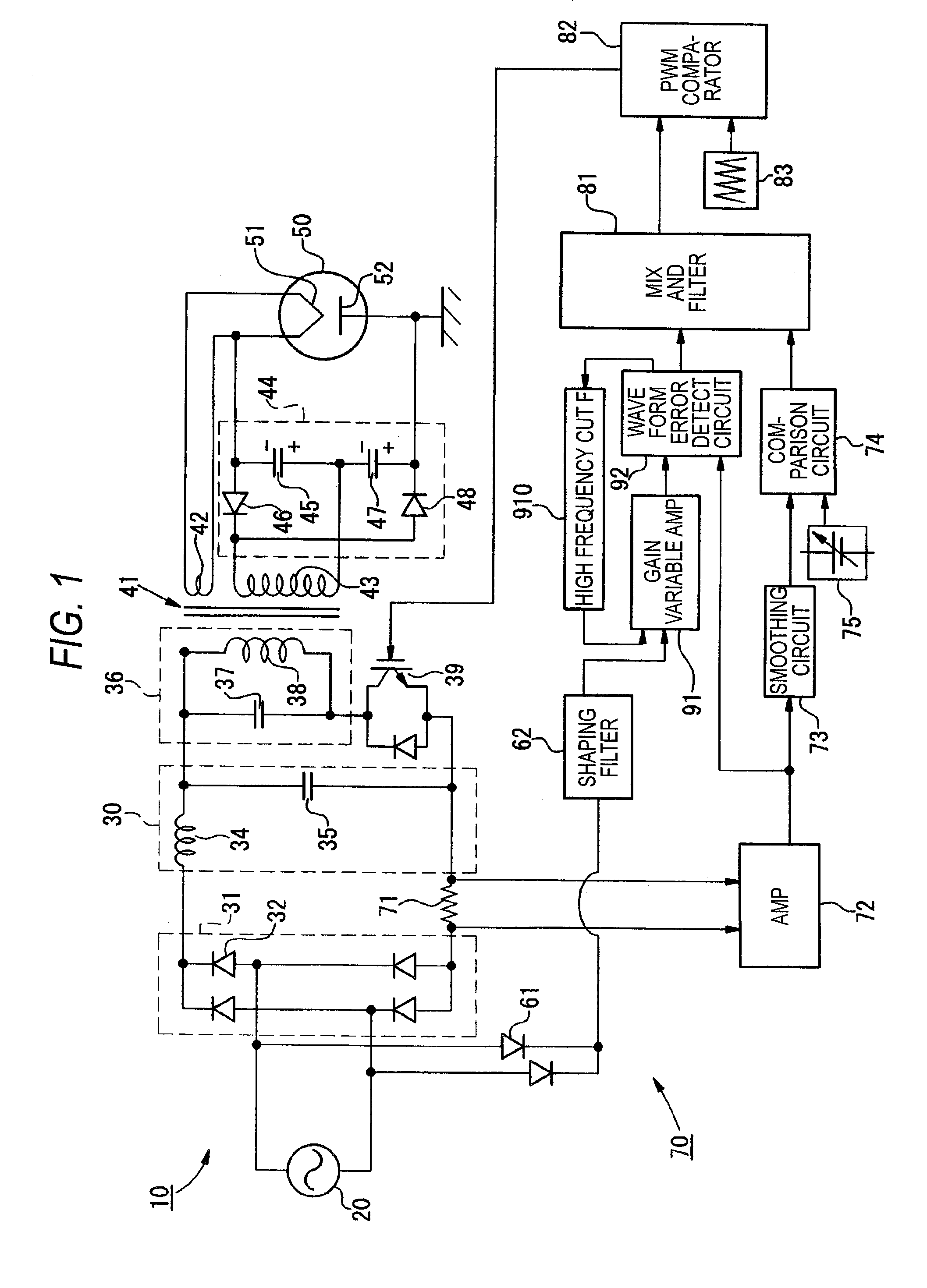

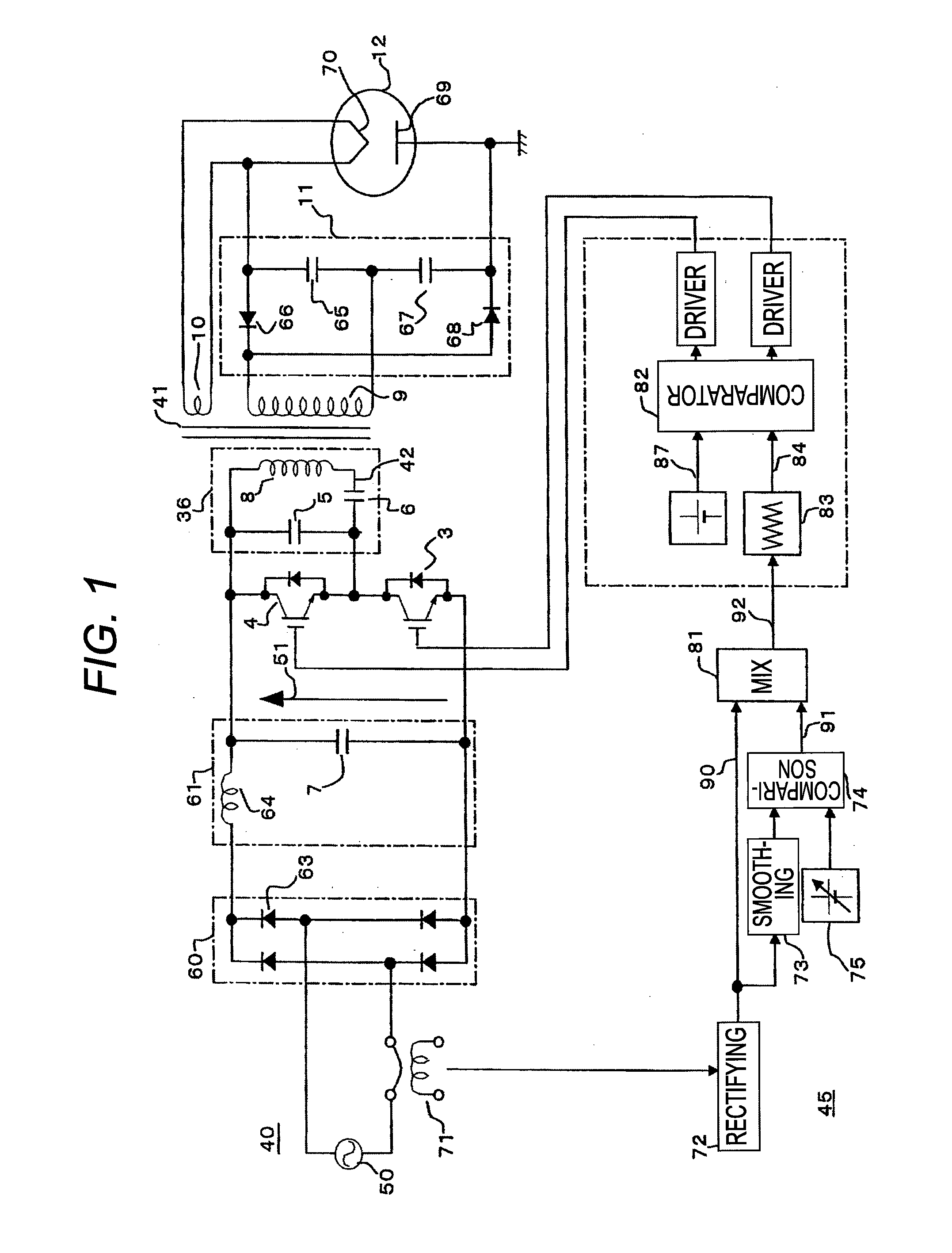

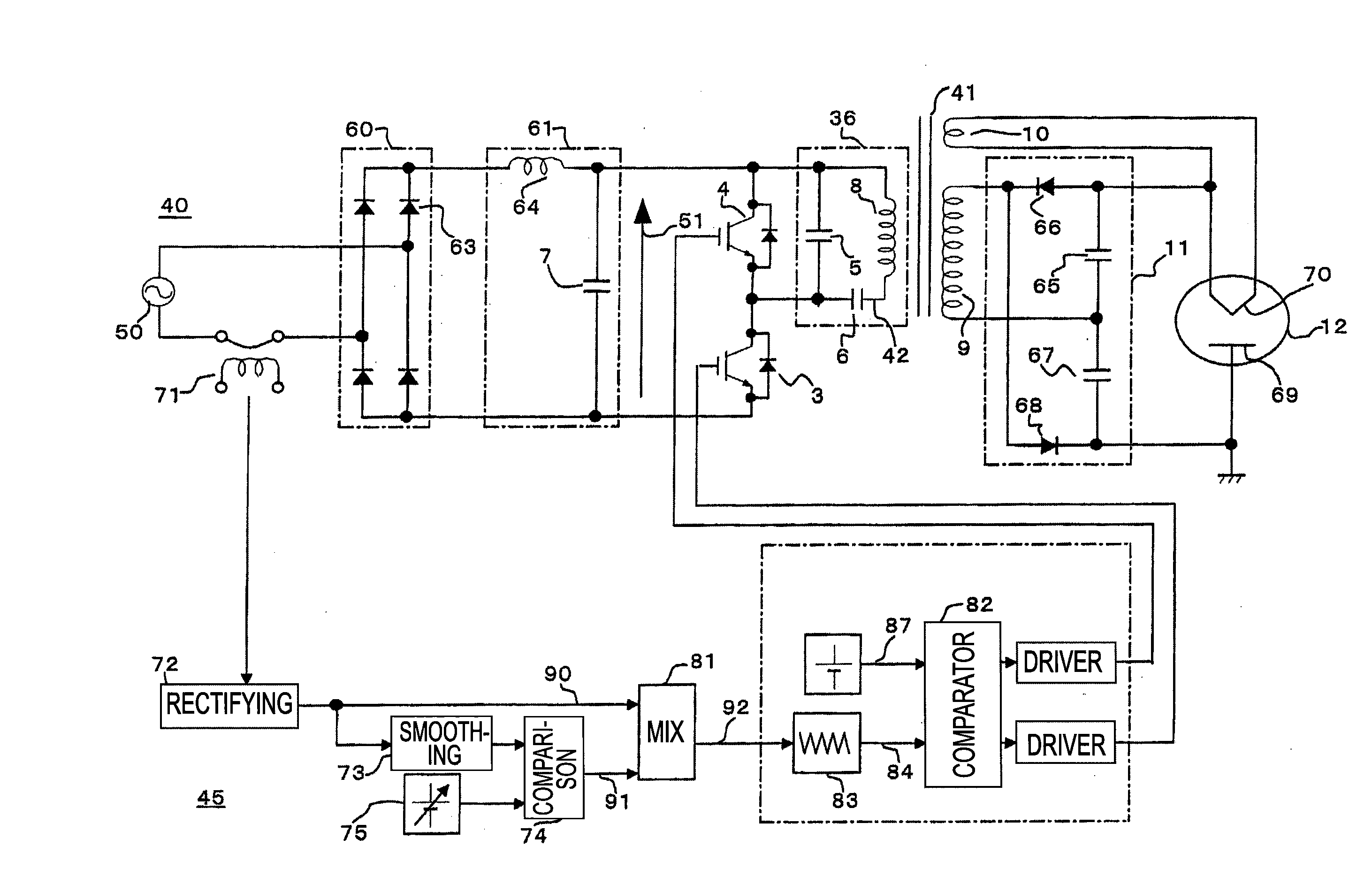

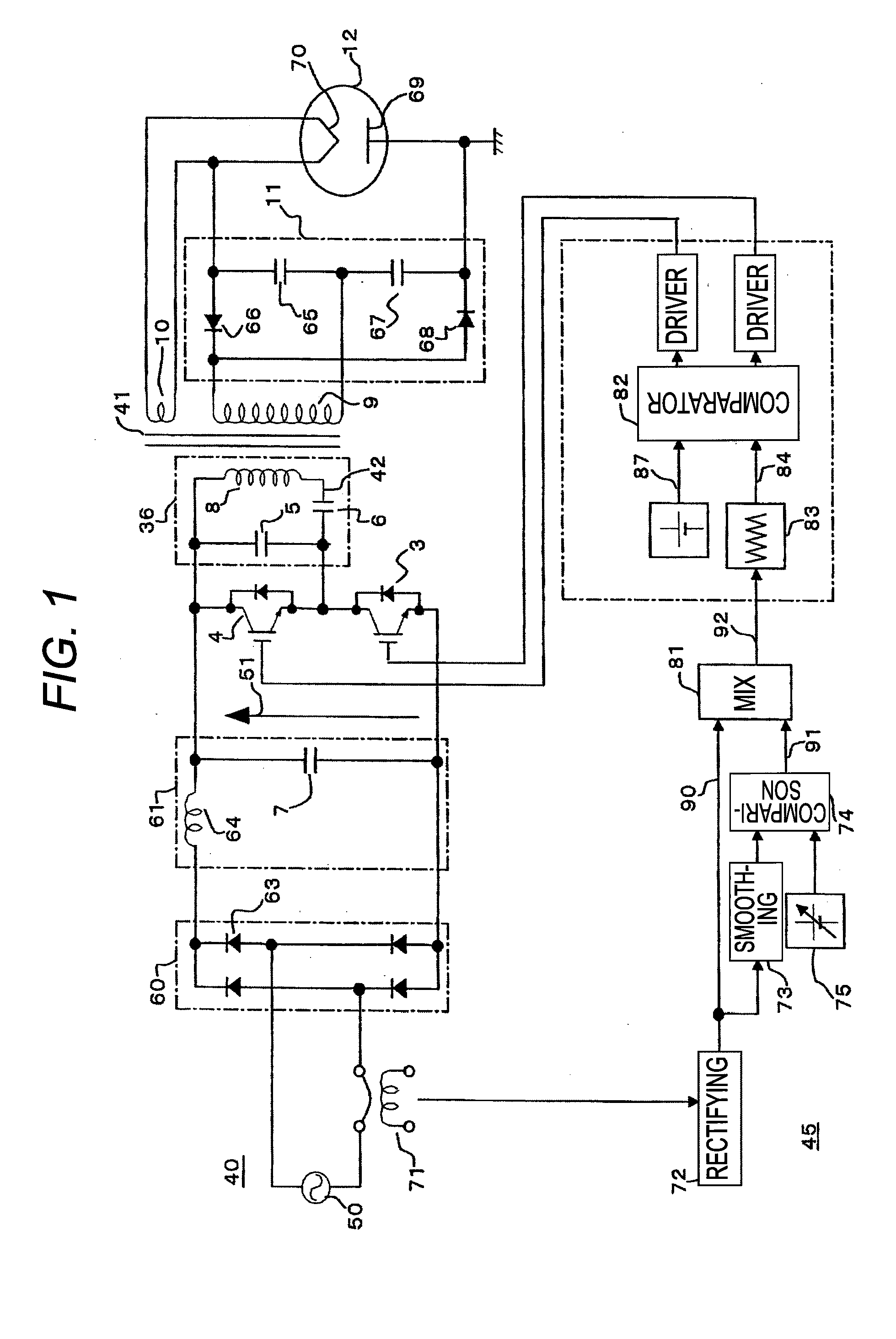

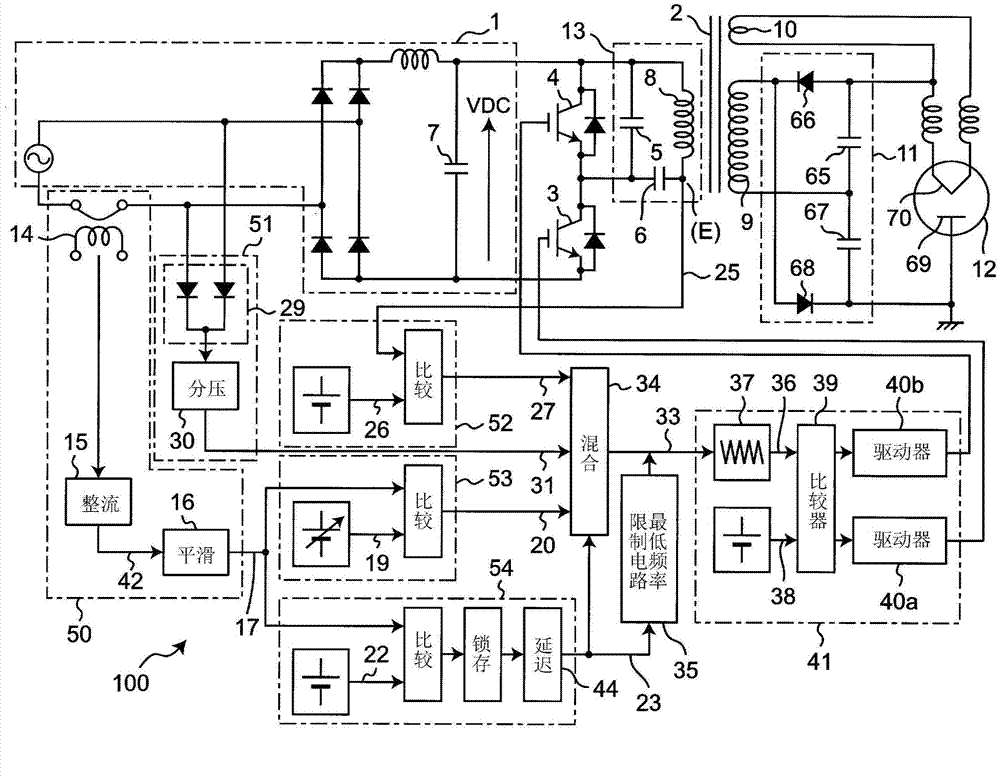

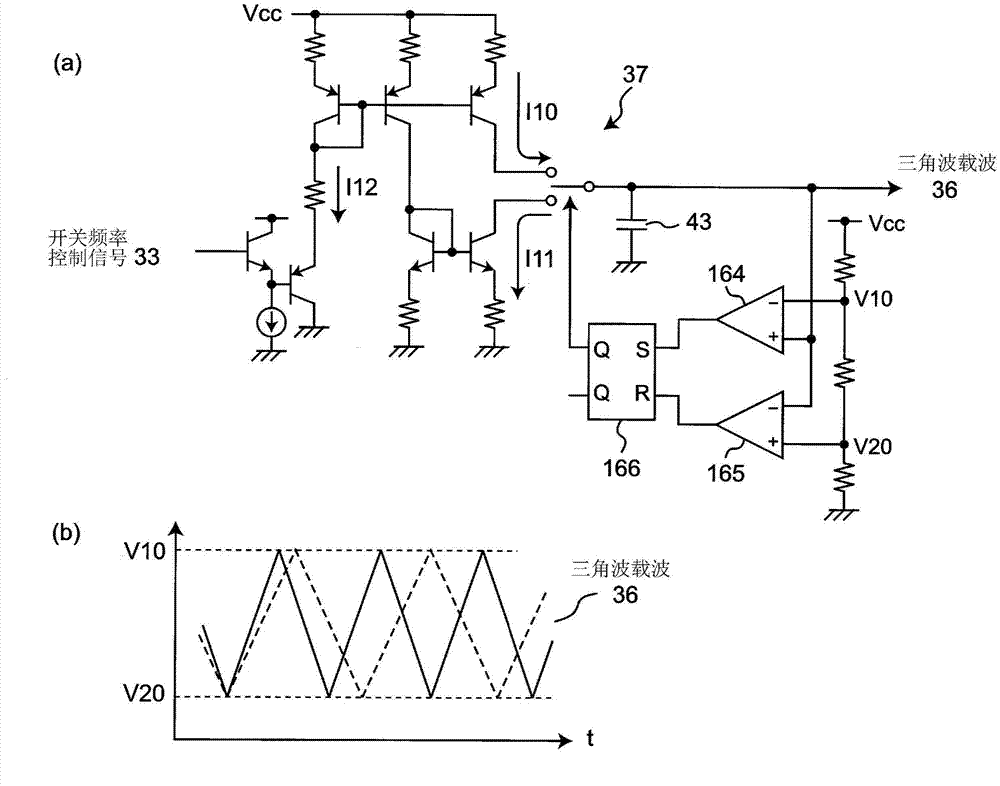

Power control apparatus for high-frequency dielectric heating and power control method for the same

ActiveUS20090289056A1Suppress transient fluctuationsStable outputDielectric heating circuitsMicrowave heatingHigh frequency powerTransistor

A power control unit for high-frequency dielectric heating not affected by variations in the types or the characteristics of magnetrons, power supply voltage fluctuation, etc., is provided.The unit has an input current detection section 71, 72 for detecting input current of an inverter circuit 10 for rectifying 31 AC power supply voltage 20, performing high frequency switching, and converting into high frequency power, mixes input current waveform information 90 of the input current detection section and power control information 91 for controlling so that output of the input current detection section becomes a predetermined value in a mix circuit 81, outputs ON voltage information 92, makes a comparison between the ON voltage information and a sawtooth wave from a sawtooth wave generation circuit 83 in a PWM comparator 82, performs pulse width modulation, and outputs a drive signal for controlling turning on / off of a switching transistor 39 of an inverter circuit.

Owner:PANASONIC CORP

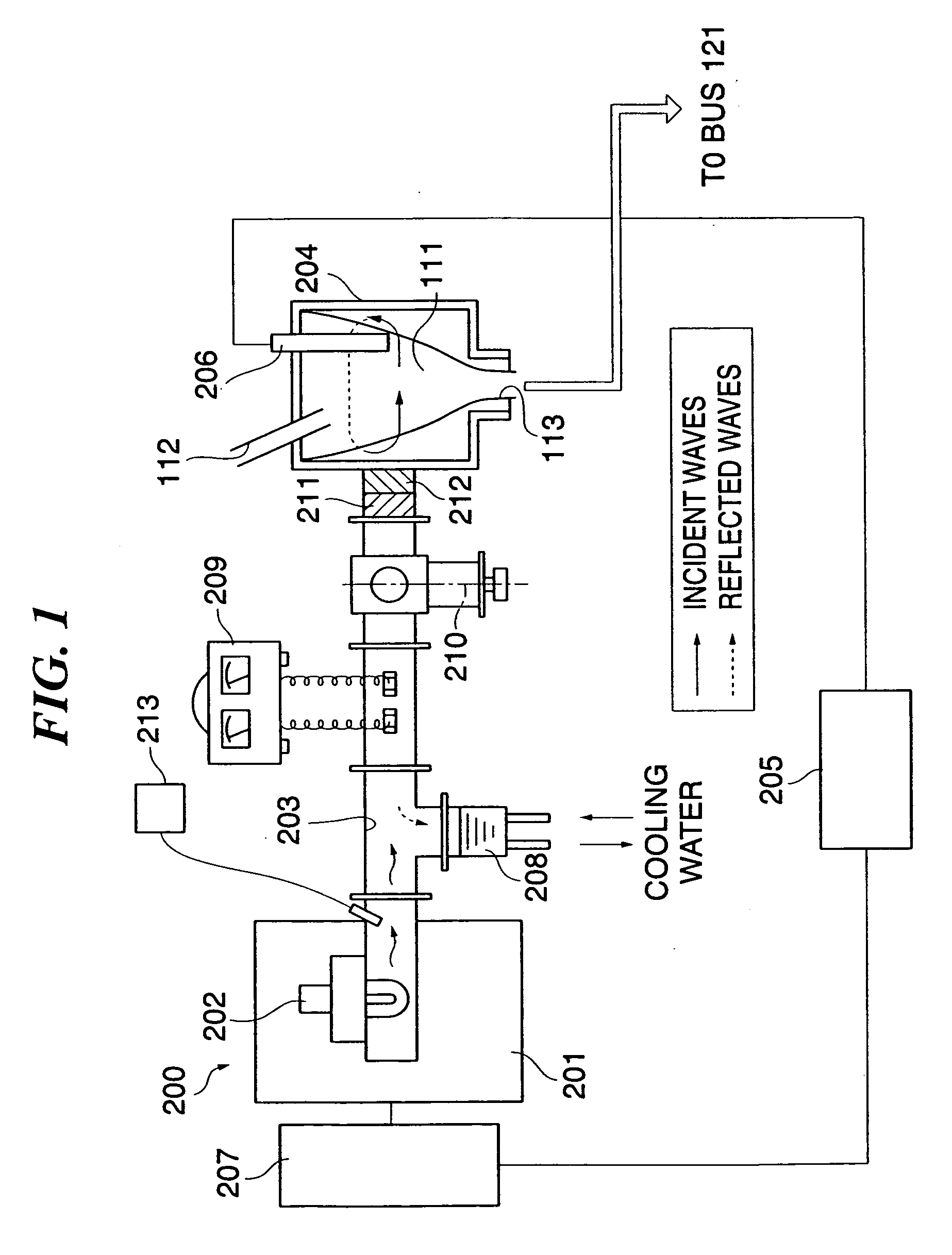

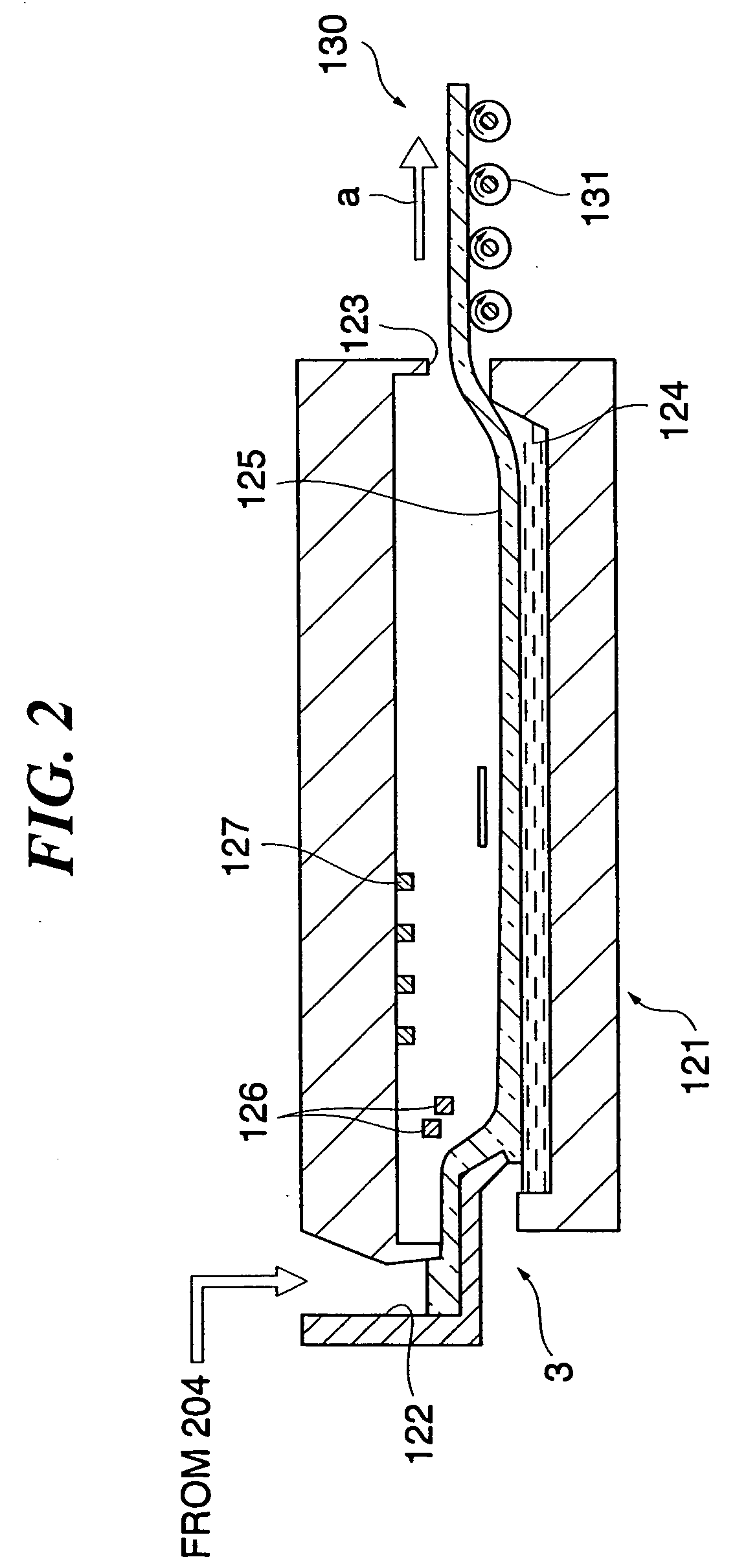

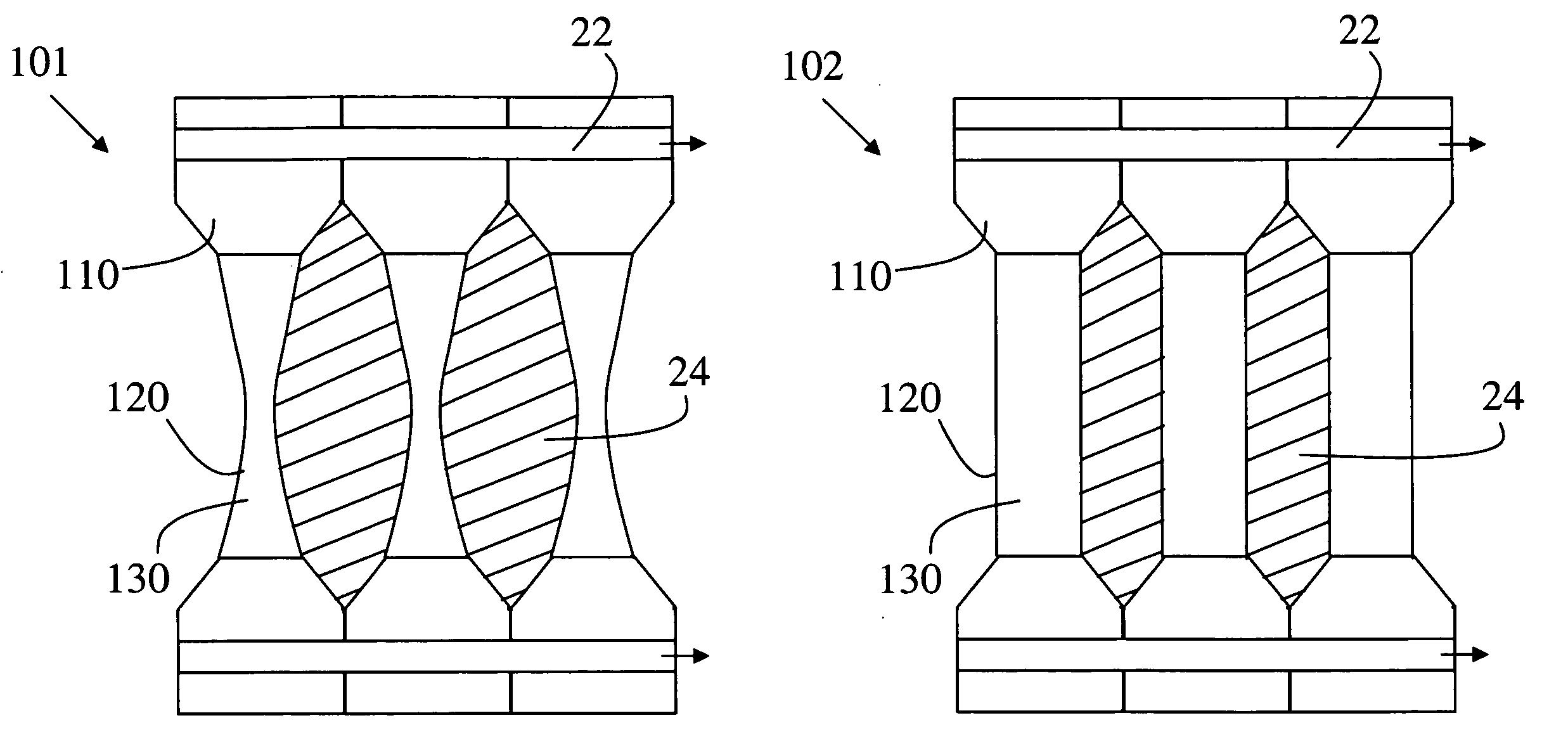

Glass melting apparatus and glass melting method

There are provided a glass melting apparatus and a glass melting method which are capable of uniformly melting glass materials and shortening or dispensing with a fining process. The glass melting apparatus 200 is comprised of an oscillator 201 having a gyrotron 202 disposed therein for emitting high-frequency waves of 28 GHz, a circular waveguide 203 for transmitting the millimeter waves from the oscillator 201, an applicator 204 having a ceramic furnace 111 disposed therein, and a CPU 205 controlling a thermocouple 206 for measuring the temperature of molten glass within the furnace 111 and a power supply panel 207 for supplying electric power to the oscillator 201. The furnace 111 has an upper part thereof formed with a batch inlet port 112 through which a mixture of glass materials (hereinafter referred to as “the batch”) is charged, and a lower part thereof formed with an outlet end 113 through which the batch melted uniformly by dielectric heating within the furnace 111 is dropped into a bus 121.

Owner:NIPPON SHEET GLASS CO LTD

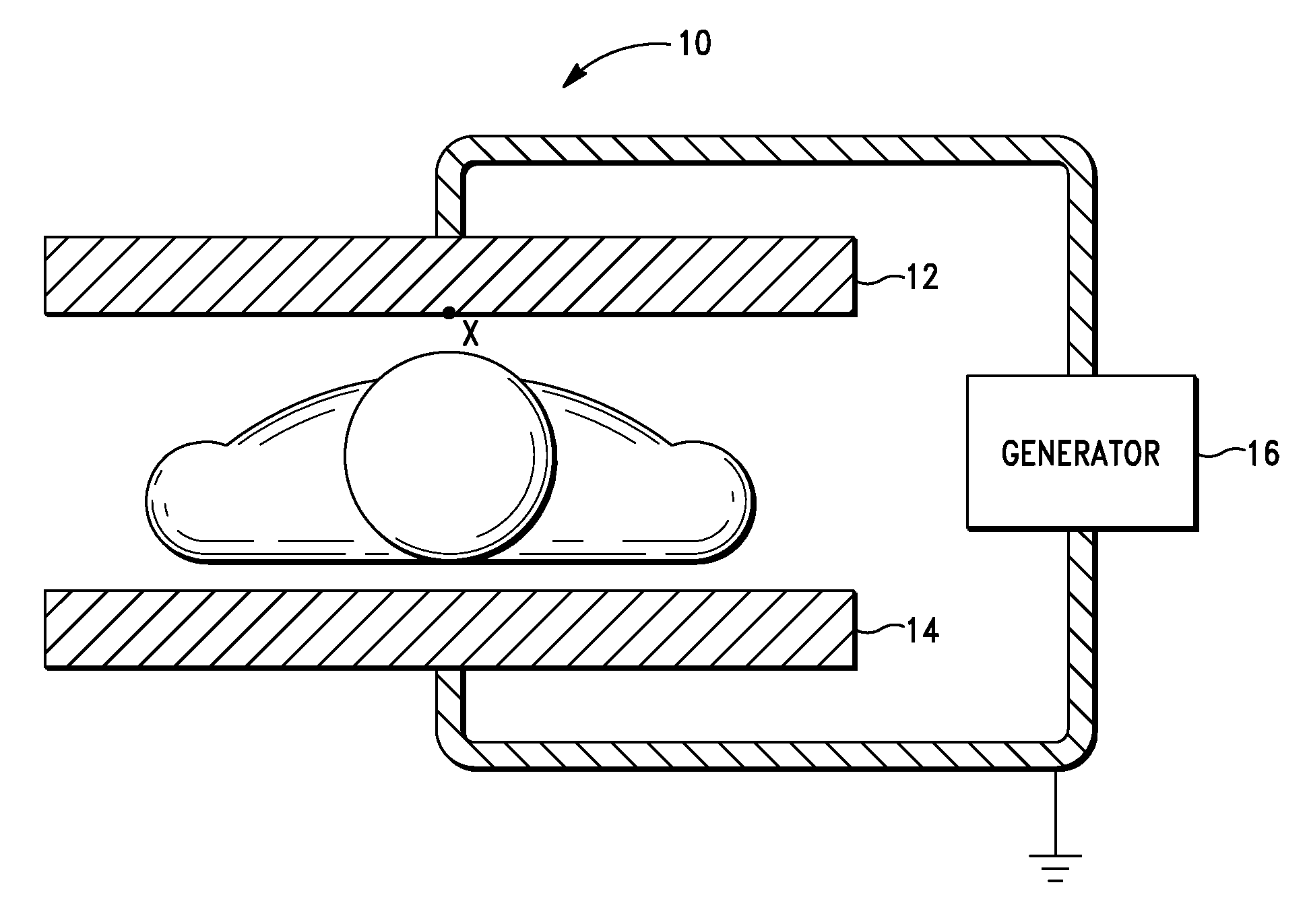

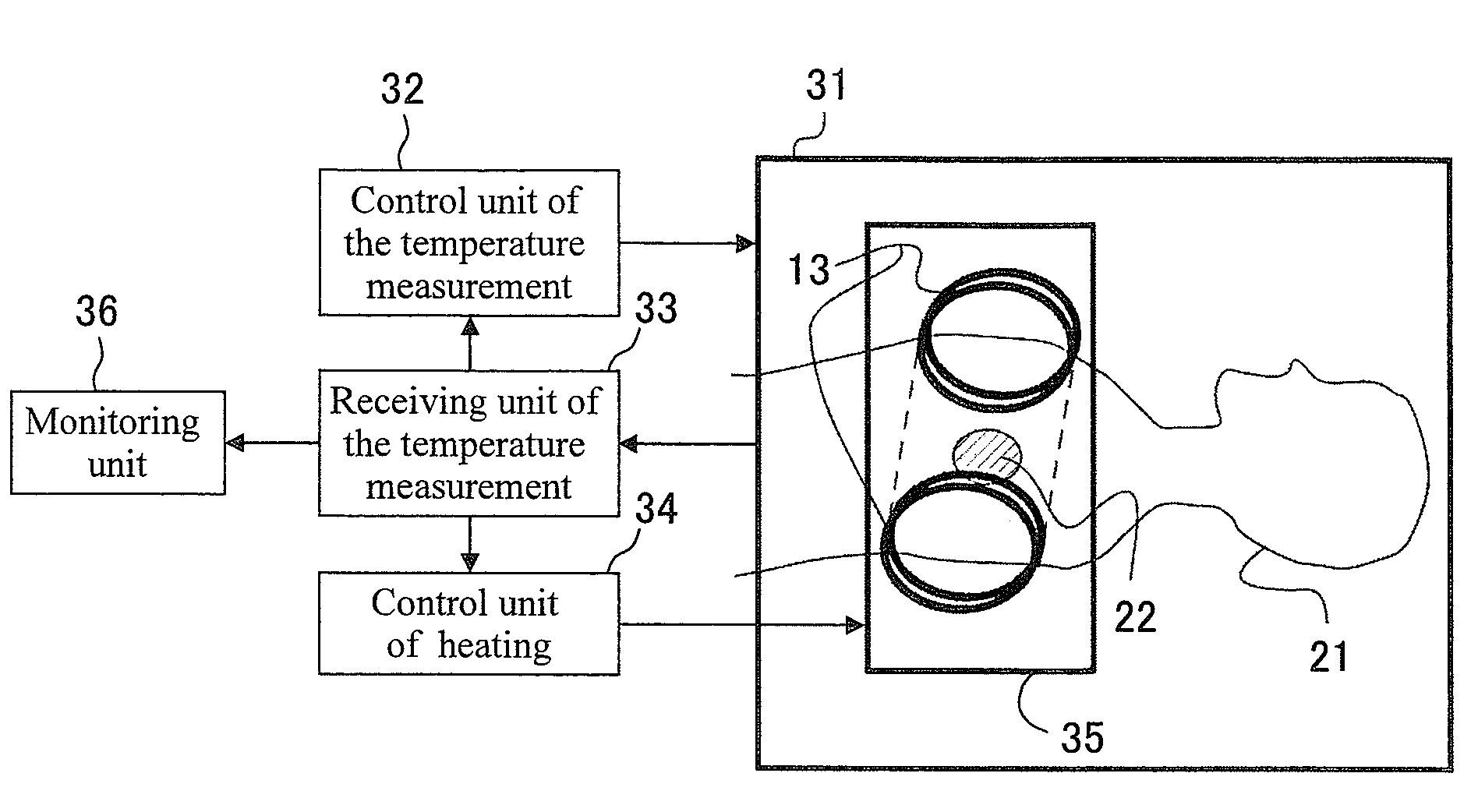

Apparatus and Method for Heating Biological Targets

An apparatus and method for selectively heating a biological target within a treatment region of a subject is disclosed. The method includes administering to the subject a dielectric heating modulator that becomes associated with the biological target. The method also includes positioning the treatment region between first and second electrodes connected to a generator, and activating the generator to apply an alternating electric field between the first and second electrodes and across the treatment region to thereby heat the treatment region. The dielectric heating modulator causes the biological target to heat at a faster rate than non-targets within the treatment region, which preferably results in the killing of the biological target.

Owner:INNOVOLINK

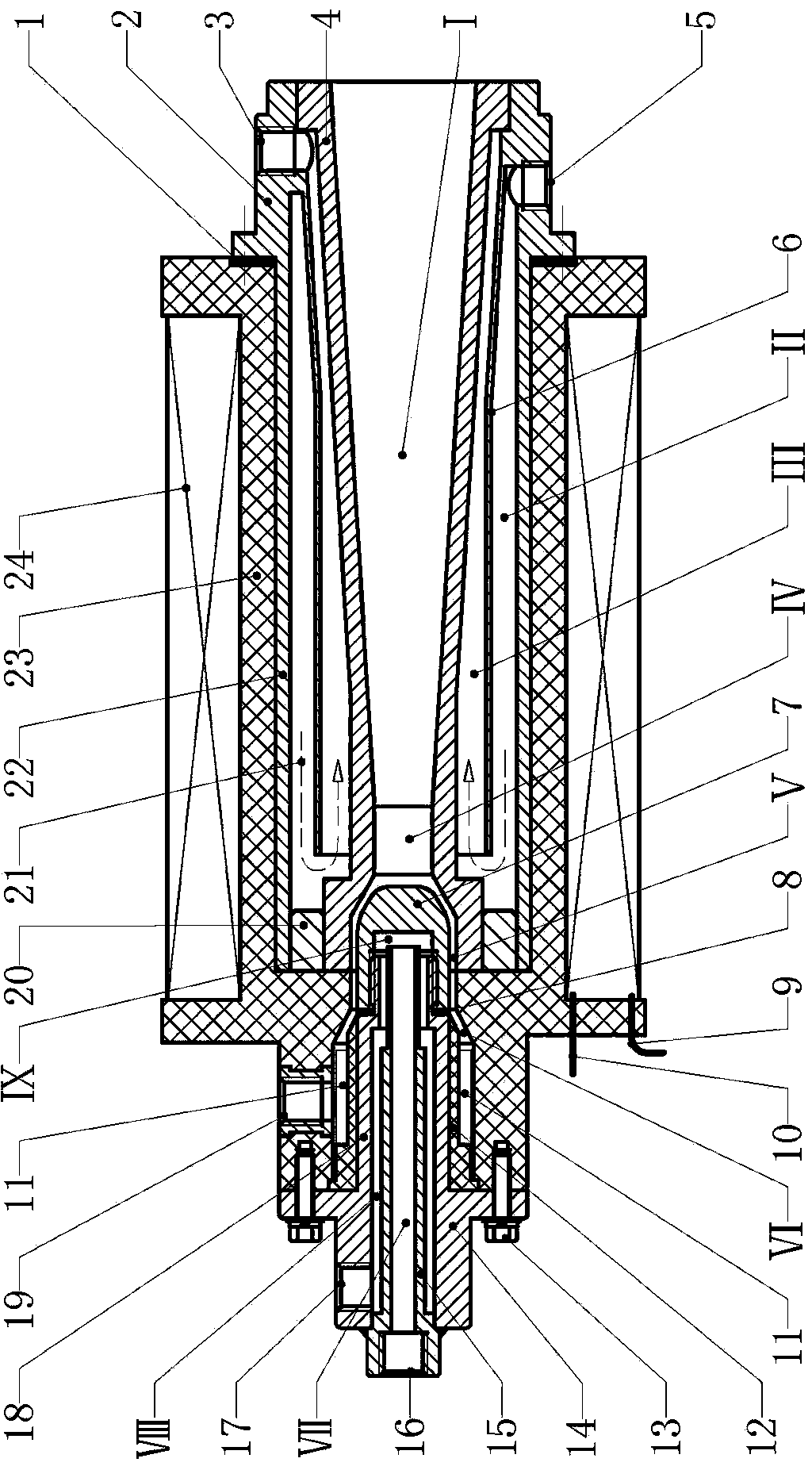

Plasma torch for dielectric heating

ActiveCN103906337AEasy to installAvoid parasitic arcingPlasma techniqueEcological environmentHydrogen

The invention provides a plasma torch for dielectric heating, and relates to plasma equipment. The plasma torch is mainly composed of a front torch body, an anode, a rear torch body, a cathode and an insulation frame. The front torch body is provided with a guide sleeve and a cylinder extending backwards, and the guide sleeve is arranged in the inner space of the cylinder; the anode is embedded into the front torch body, the space between the cylinder of the front torch body and the wall of the anode forms a cooling water jacket, a cathode base is arranged on a rotary body structure of the rear torch body, the cathode is installed at the front end of the cathode base, and a cooling cavity is formed in the cathode. The front torch body is installed at the front end of the insulation frame, the extending cylinder of the front torch body is inserted into a front inserting port of the insulation frame, the rear torch body is installed at the rear end of the insulation frame, the cathode base on the rear torch body enters a rear inserting port of the insulation frame, the head of the cathode stretches into a cylindrical space in the rear portion of the anode, and the space between the head of the cathode and the wall of the rear portion of the anode forms an ionization channel. The plasma torch is used for pyrolyzing water to manufacture hydrogen or used for processing harmful substances, thereby reducing the dependence on coal and oil of people and preserving the ecological environment.

Owner:JIANGSU YAFENG ALLOY MATERIAL

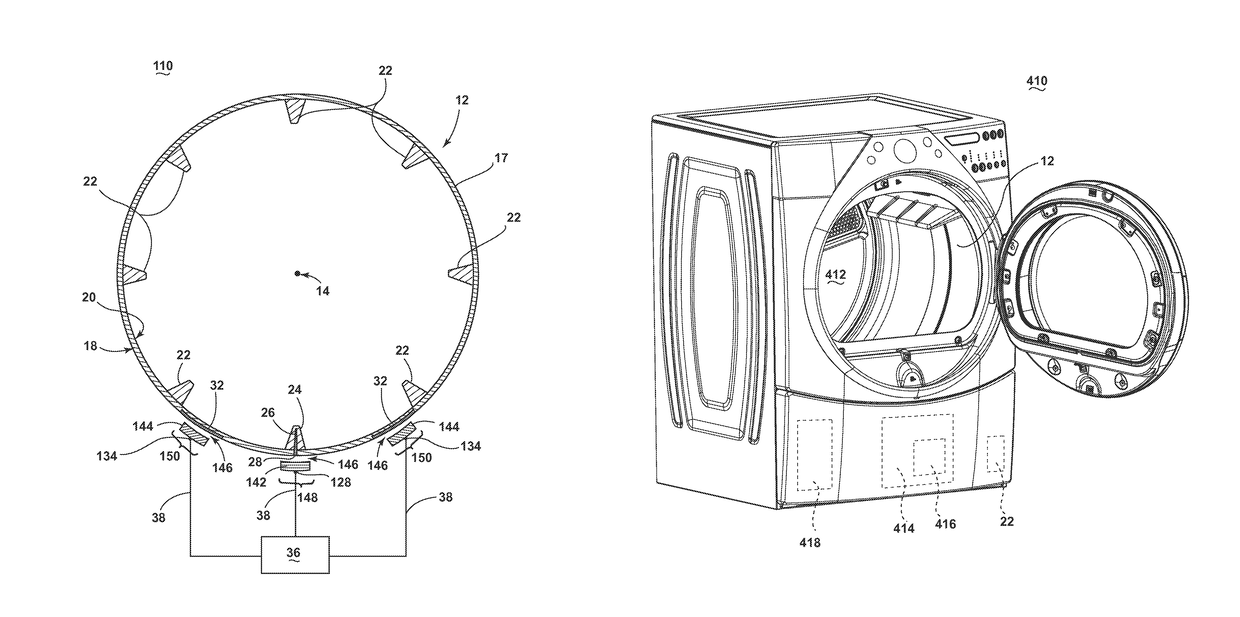

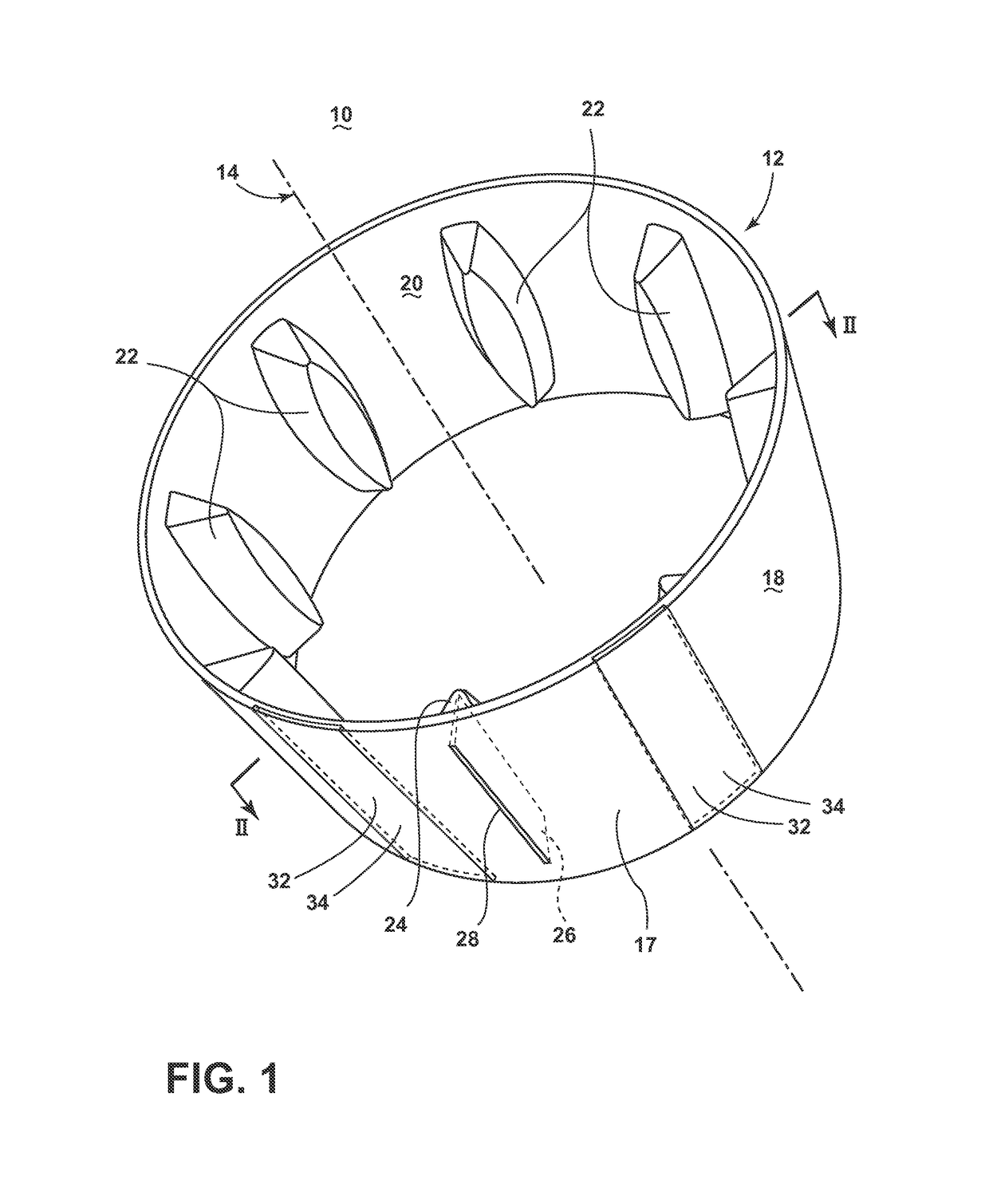

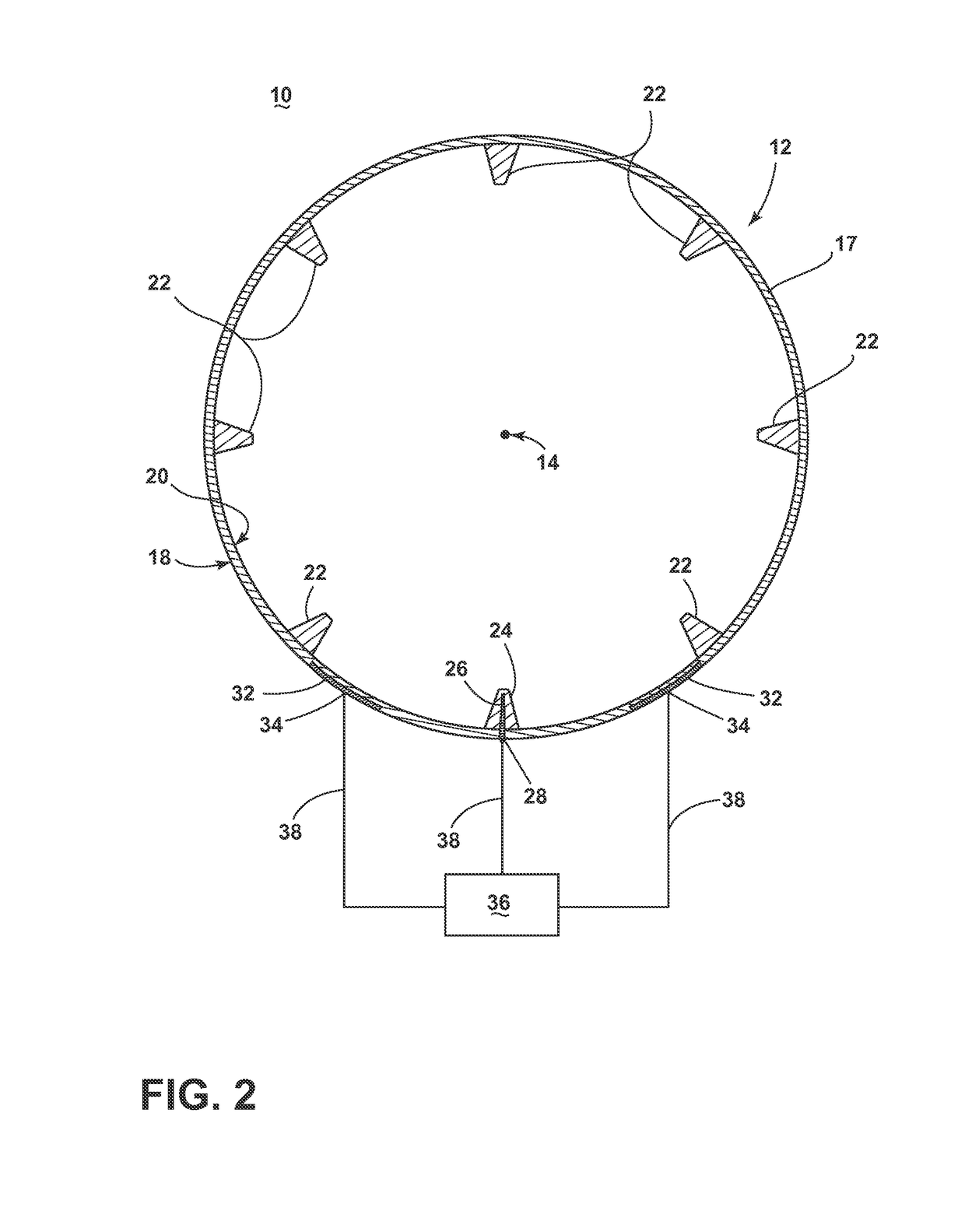

Apparatus for drying articles

A laundry treating applicator for drying laundry with a radio frequency (RF) applicator having a baffle on a drum rotatable on a non-vertical axis, an anode element in the baffle and a cathode element spaced from the anode element, wherein energization of the RF generator sends electromagnetic radiation through the applicator via the anode element and cathode element to form a field of electromagnetic radiation (e-field) in the radio frequency spectrum to dielectrically heat liquid within laundry disposed within the e-field.

Owner:WHIRLPOOL CORP

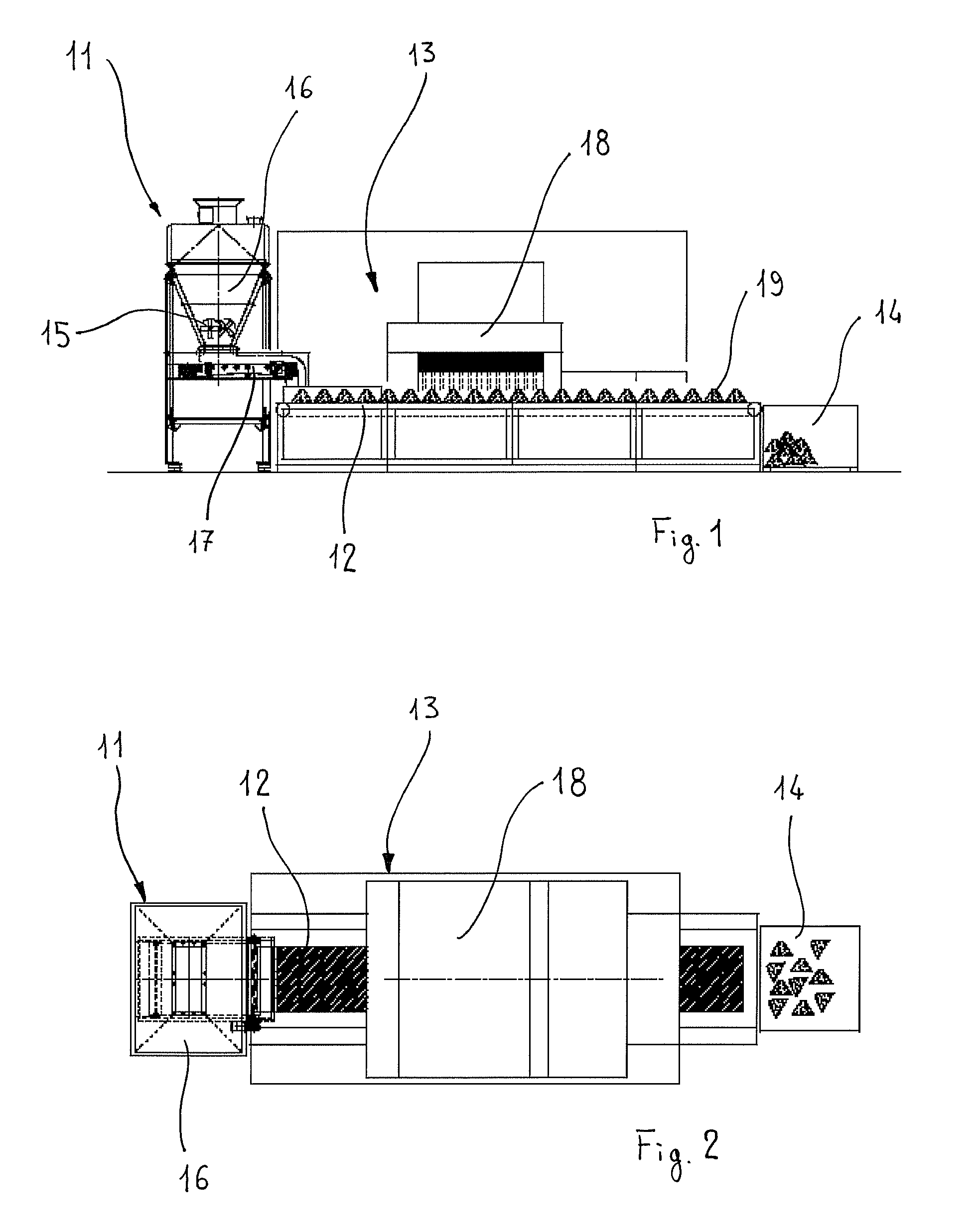

Method and plant for rendering inert toxic substances in uncompacted residual material containing hardenable resin and aggregrates

ActiveUS8030441B2Eliminate the risk of contaminationDielectric heating circuitsSolid waste disposalOrganic solventToxic material

A loose mixture formed of one or more solid inert materials and a hardenable resin dissolved in an organic solvent, in particular the remainder of the initial mix used for the manufacture of conglomerate stone sheets, is rendered inert by means of dielectric heating at a frequency of less than 300 MHz. A plant for implements a method where a loose mixture is formed of one or more solid inert materials and a hardenable resin dissolved in an organic solvent, in particular the remainder of the initial mix used for the manufacture of conglomerate stone sheets, is rendered inert by means of dielectric heating at a frequency of less than 300 MHz.

Owner:TONCELLI DARIO

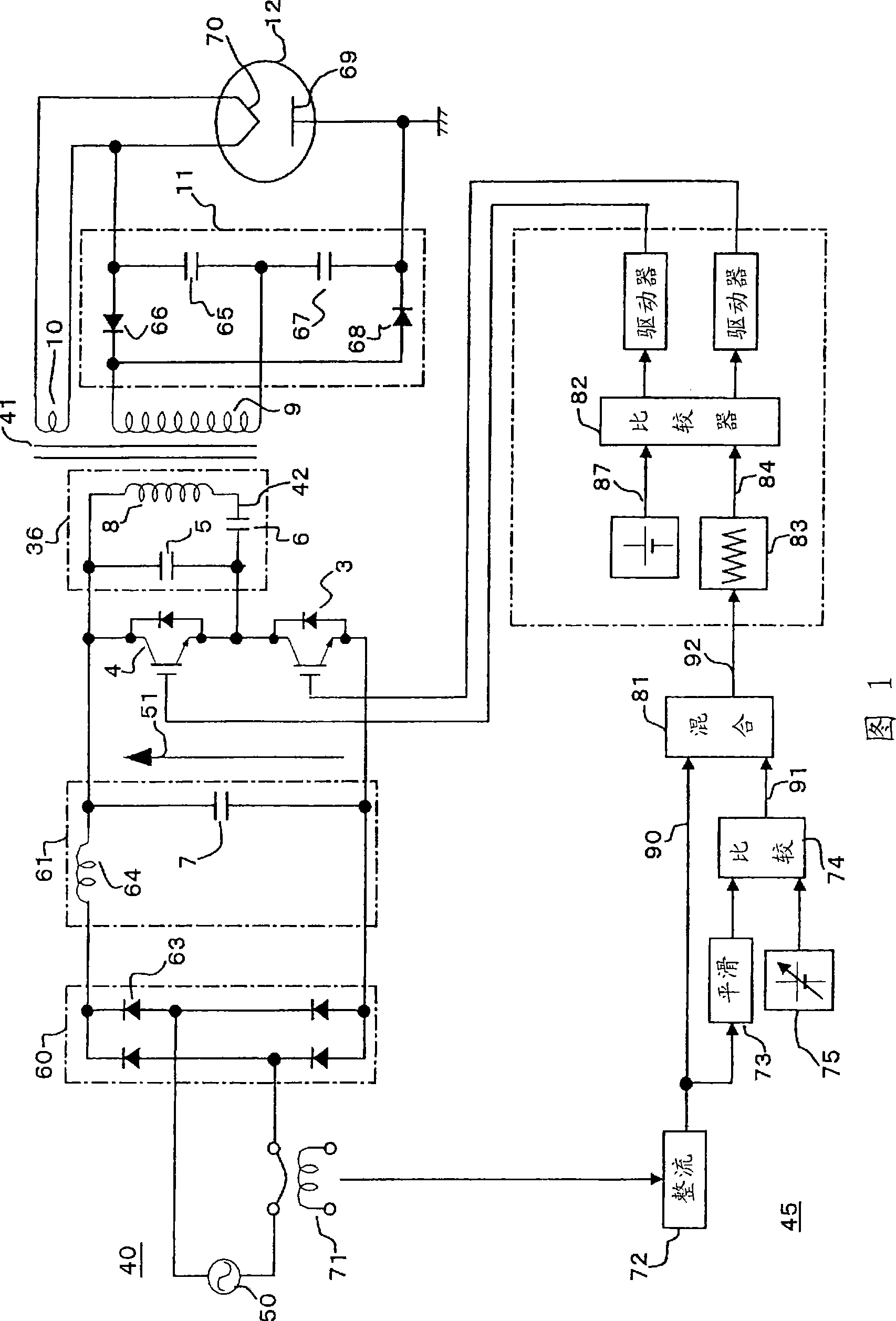

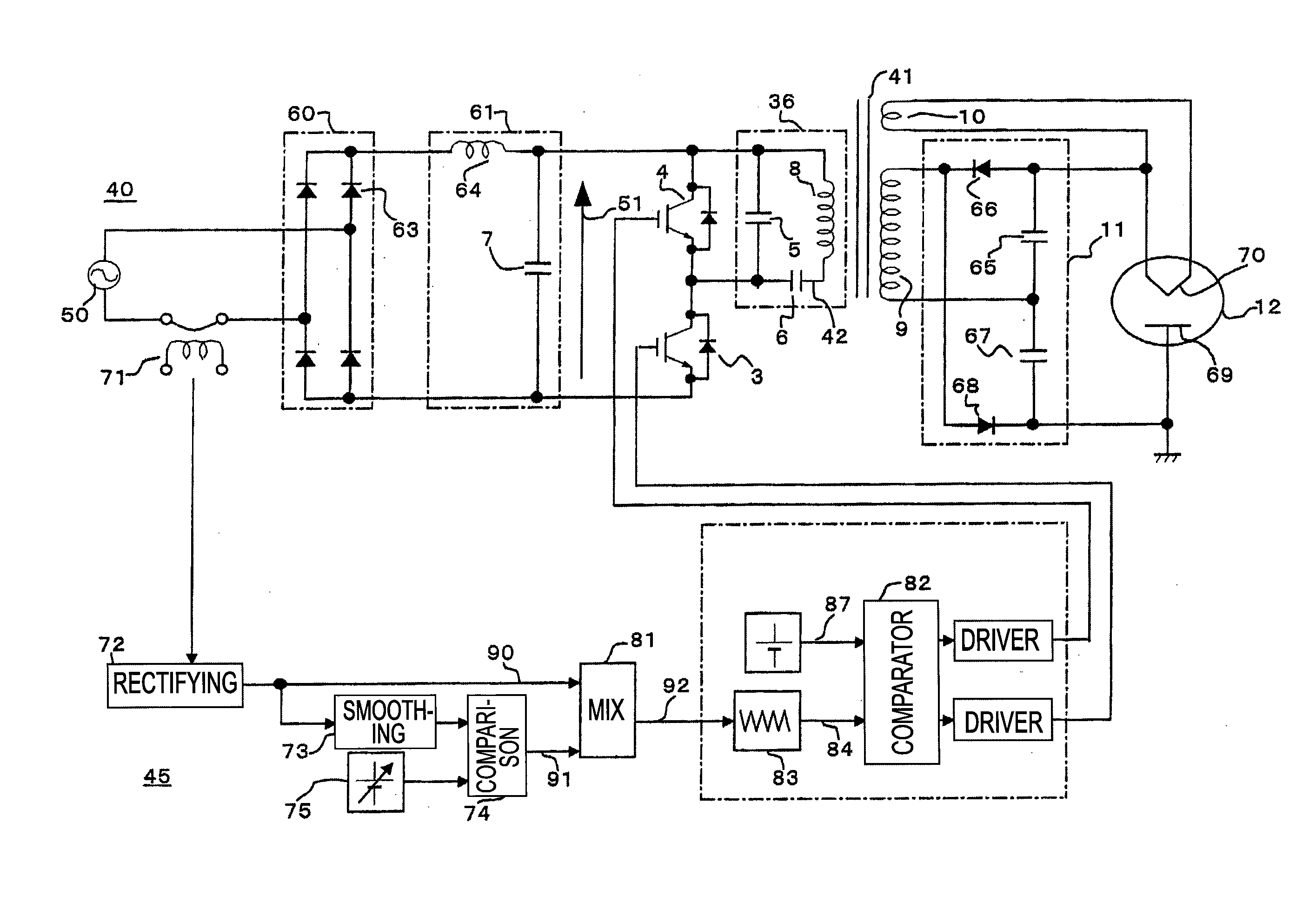

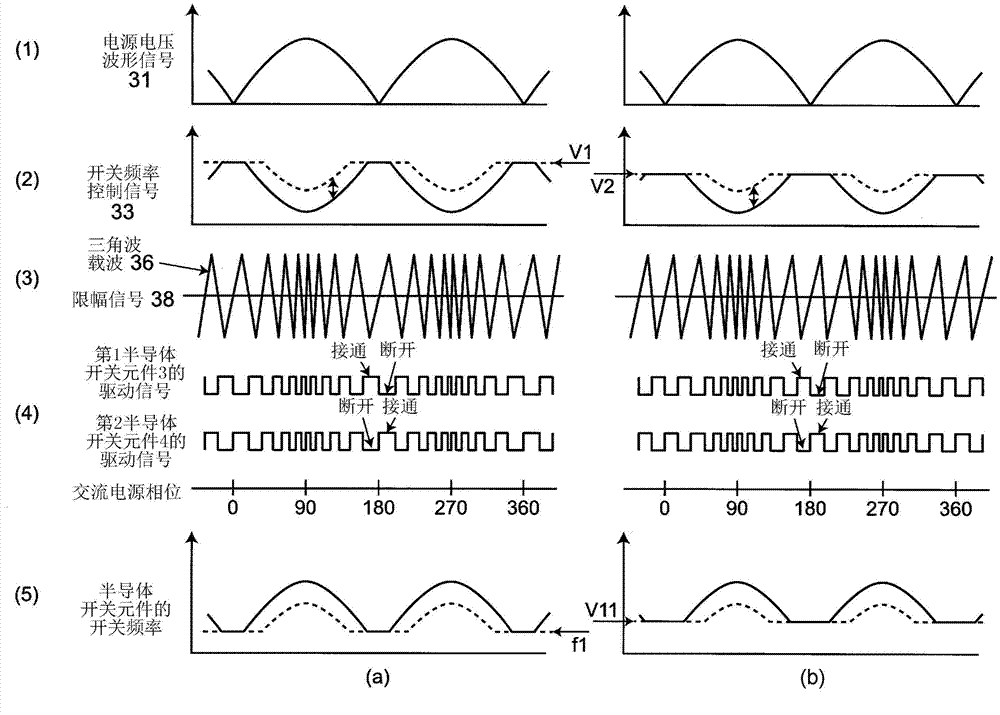

Power control apparatus for high frequency dielectric heating and control method employed by the power control apparatus

ActiveCN101461283ASuppress transient fluctuationsReduce startup timeMicrowave heatingDomestic cooking appliancesHigh frequency powerEngineering

Provided is a power control apparatus for high frequency dielectric heating, which is not affected by magnetron types, fluctuations of characteristics, power supply voltages and the like. The power control apparatus is provided with input current detecting sections (71, 72) for detecting an input current to an inverter circuit (10), which rectifies (31) an alternating current power supply voltage (20) and converts it into high-frequency power by performing high-frequency switching. A switching frequency control signal (92) wherein input current waveform information (90) from the input current detecting section and power control information (91) are mixed, is converted into a drive signal of semiconductor switching elements (3, 4) of the inverter circuit.

Owner:PANASONIC CORP

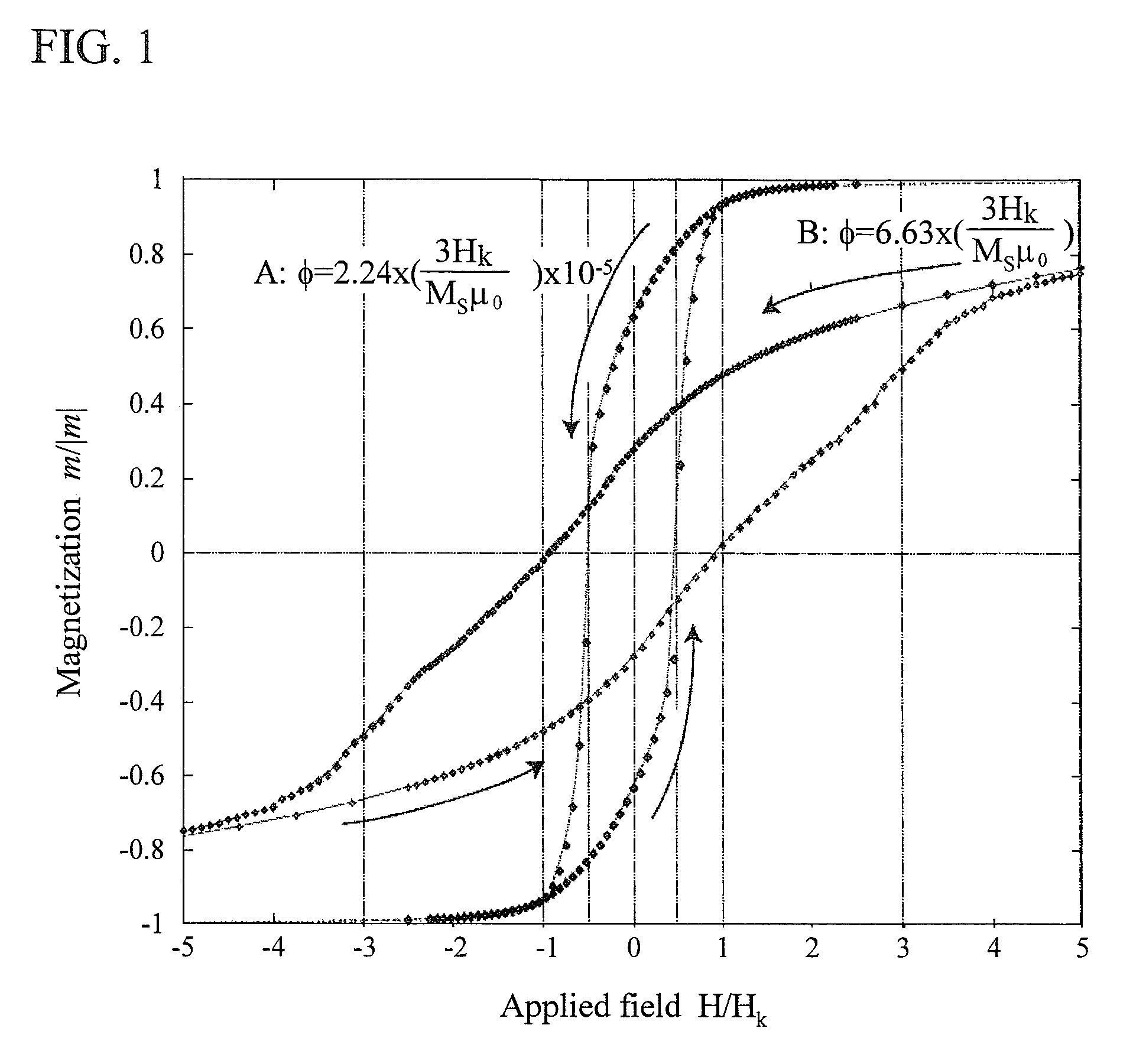

Drug Carrier Containing Magnetic Fine Particles and System Using the Same

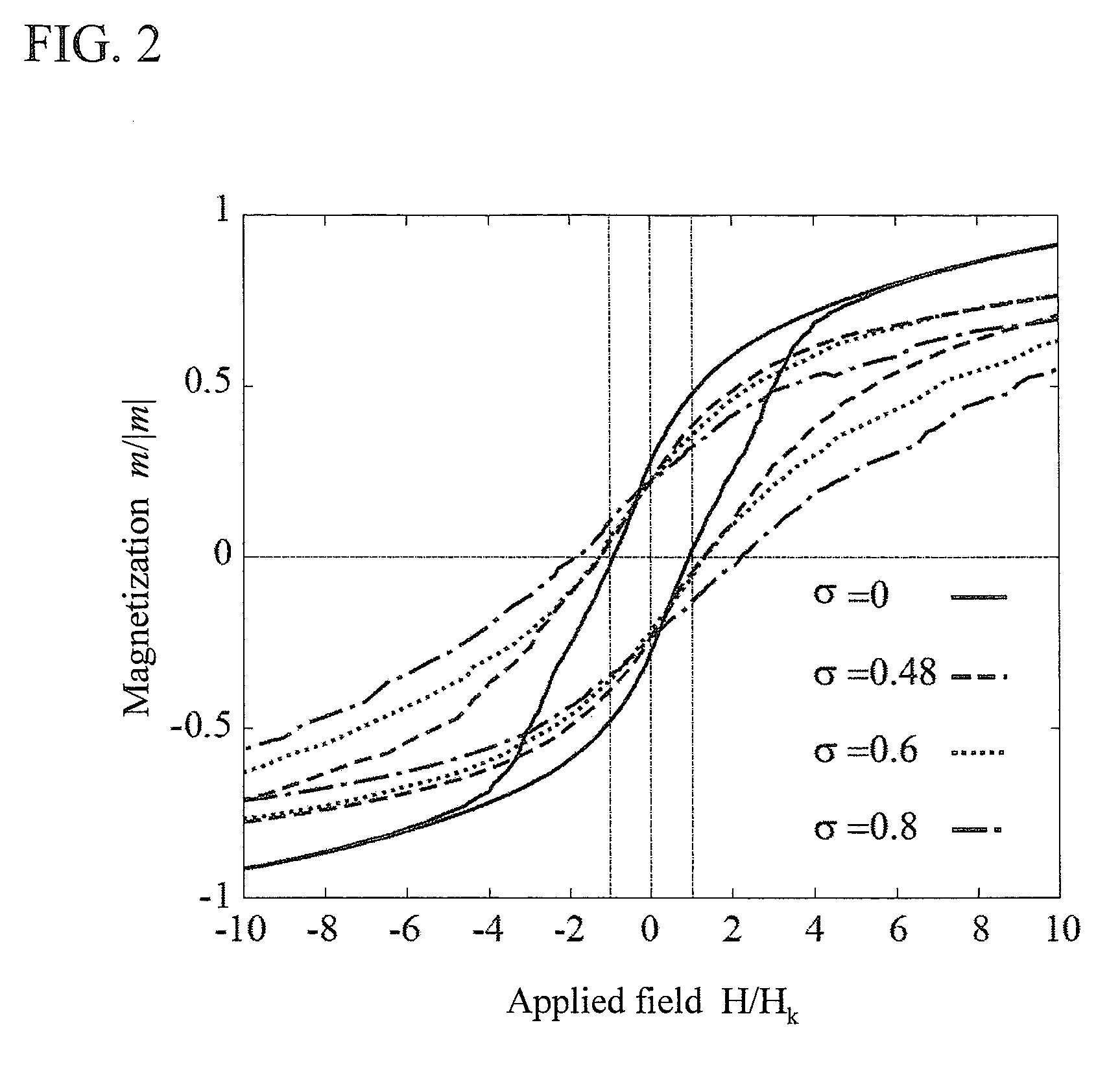

InactiveUS20090054722A1Quick effectRapidly of efficacyPowder deliveryElectrotherapyHysteresisElectricity

The present invention provides drug carriers having high heating efficiency by high-frequency dielectric heating in a state of being selectively accumulated in a target site. The drug carriers each consist of a drug, magnetic fine particles, and a shell containing the drug and the magnetic fine particles. The shell has an outer diameter in a range from 10 nm to 200 nm. The magnetic fine particles having an average particle diameter of d has a standard deviation σ of particle diameter distribution satisfying 0.8d>σ>0.4d. The magnetic fine particles contained in the individual drug carriers generate hysteresis heat due to high-frequency dielectric heating by irradiation of a high-frequency magnetic field.

Owner:HITACHI LTD

Three-Dimensional Decoration Piece Made Of Synthetic Resin And Method Of Manufacturing The Same

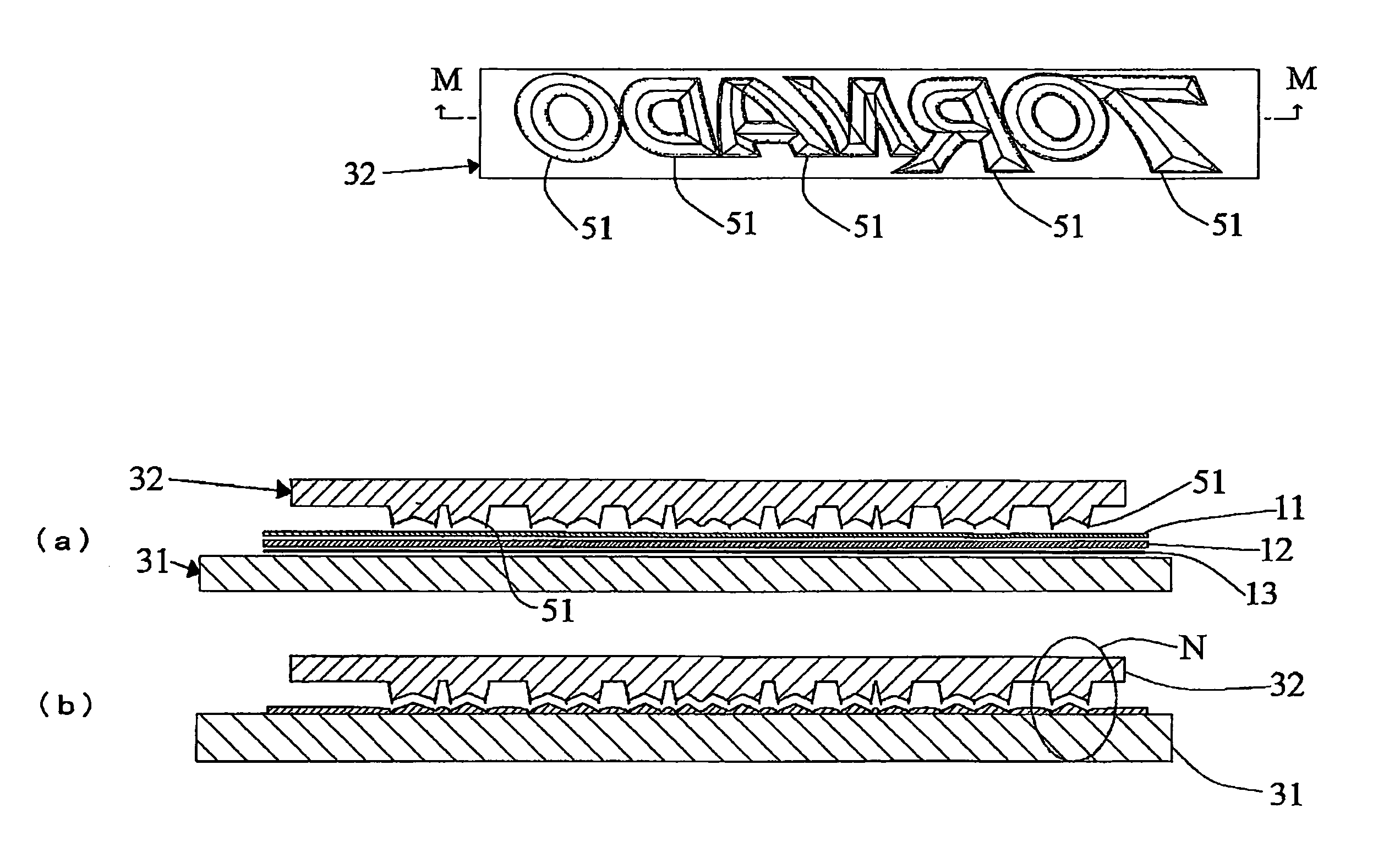

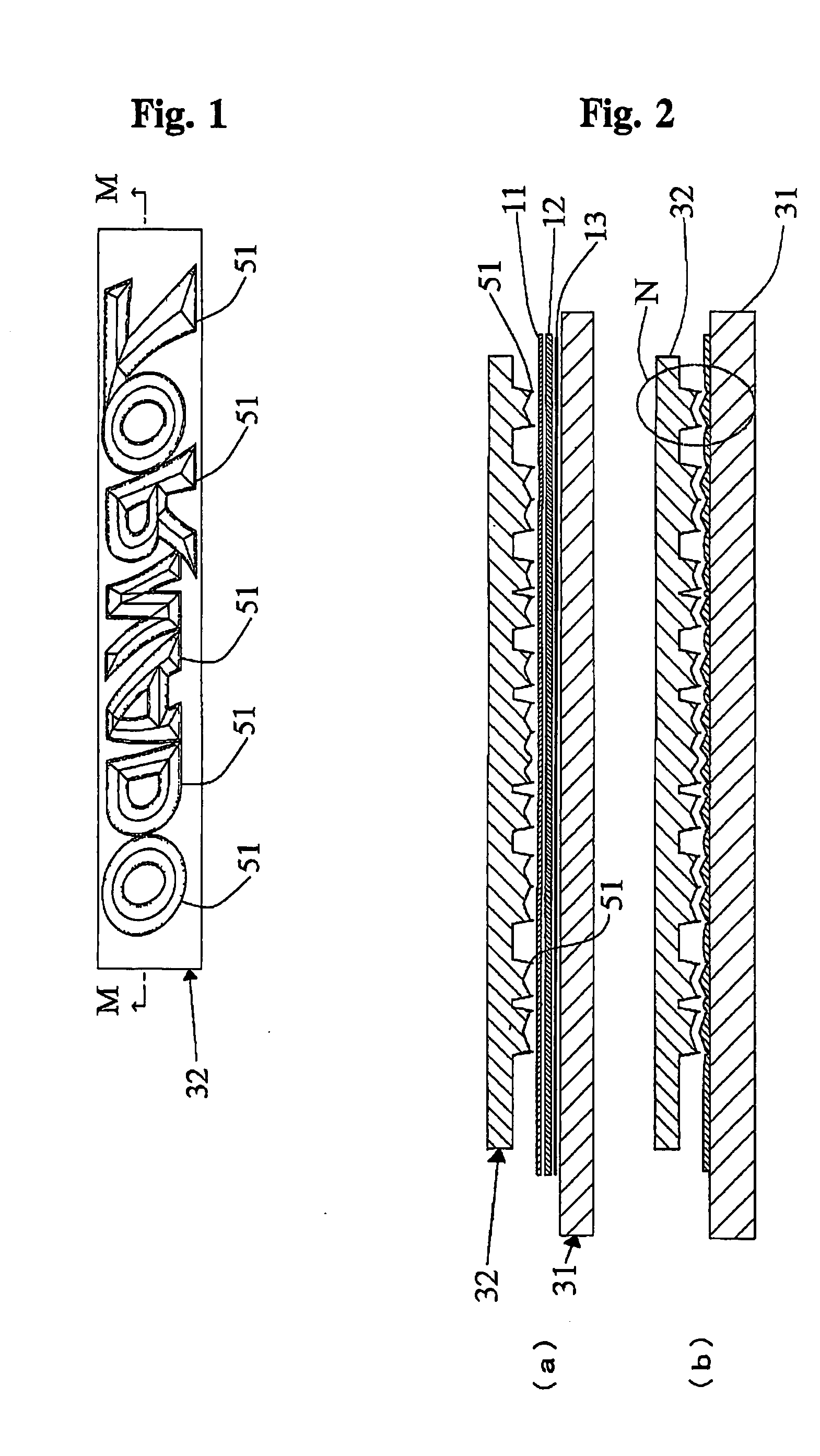

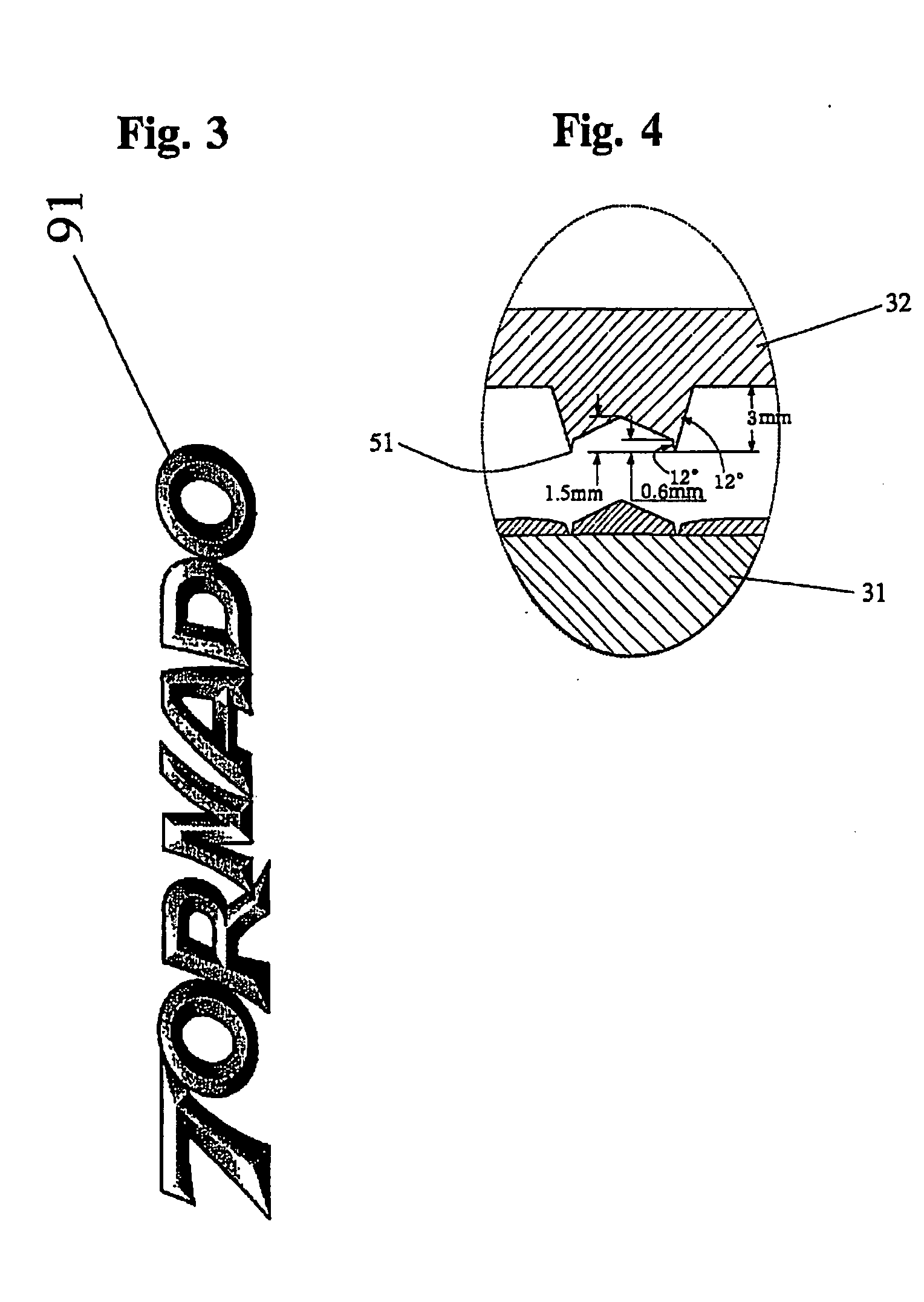

ActiveUS20070296118A1High bonding strengthEasy to disassembleLamination ancillary operationsDecorative surface effectsSynthetic resinBiomedical engineering

There are provided (1) a method of manufacturing a three-dimensional decoration piece having a flat rear surface, (2) a method of manufacturing the decoration piece by easily cutting the same by means of a fusion cutter, (3) a method of manufacturing the decoration piece having a bonding or sticking feature on the rear surface and (4) a method of manufacturing a three-dimensional decoration piece without limiting the characteristics of the base member thereof. The three-dimensional decoration piece is manufactured by using an indented mold and high frequency dielectric heating. An indented mold having a second fusion cutter and arranged along an outer periphery of the fusion cutter is used. Firstly, a three-dimensional molded body of upper and intermediate layers having a recessed section on a lower surface thereof is molded by means of an indented mold and a protruding mold, and subsequently a lower layer material is molten by high frequency dielectric heating and made to flow into the recessed section. Firstly, a three-dimensional molded body of upper and intermediate layers is molded, and subsequently the three-dimensional molded body is welded to a base member by means of high frequency dielectric heating.

Owner:NOBUO KURODA +2

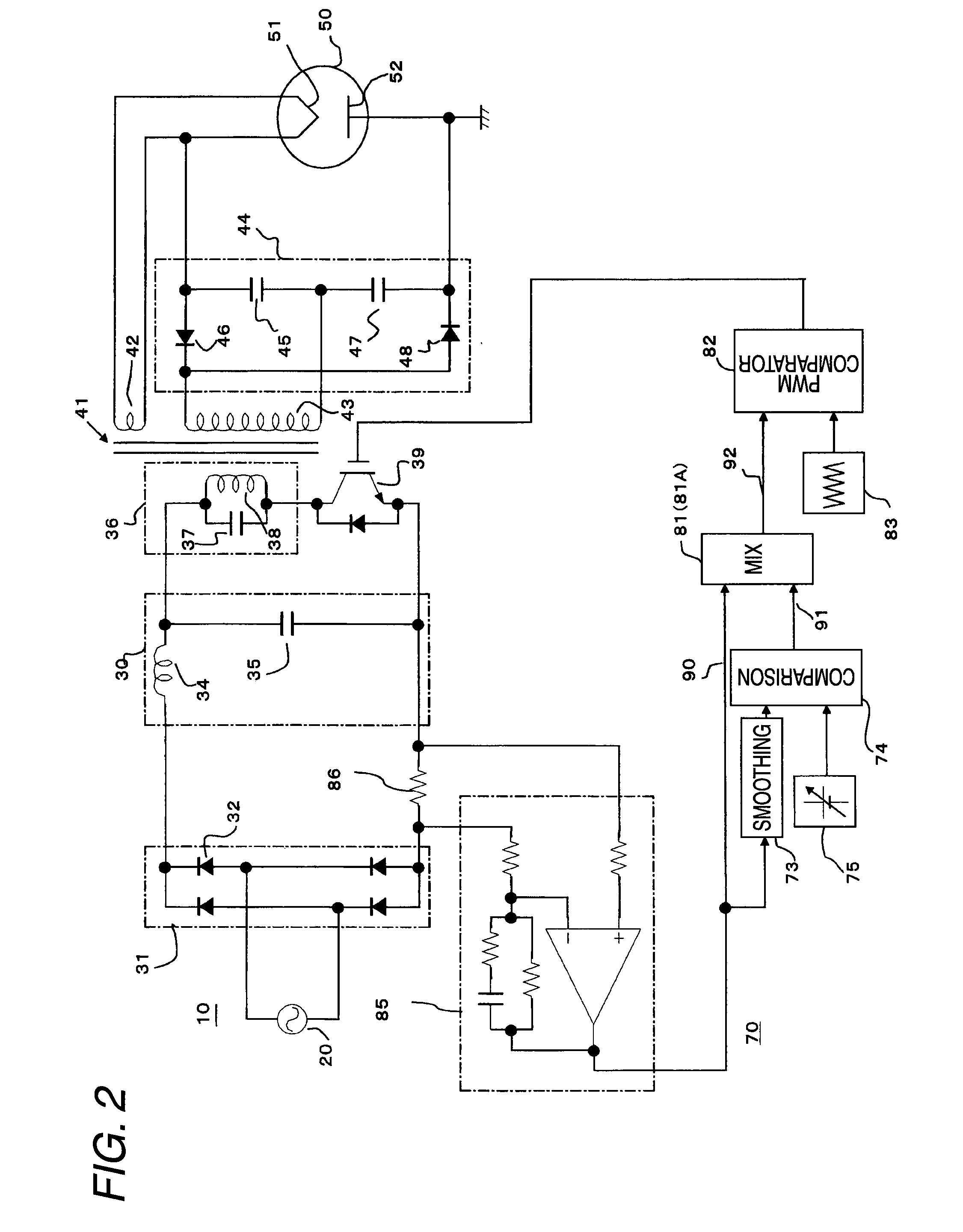

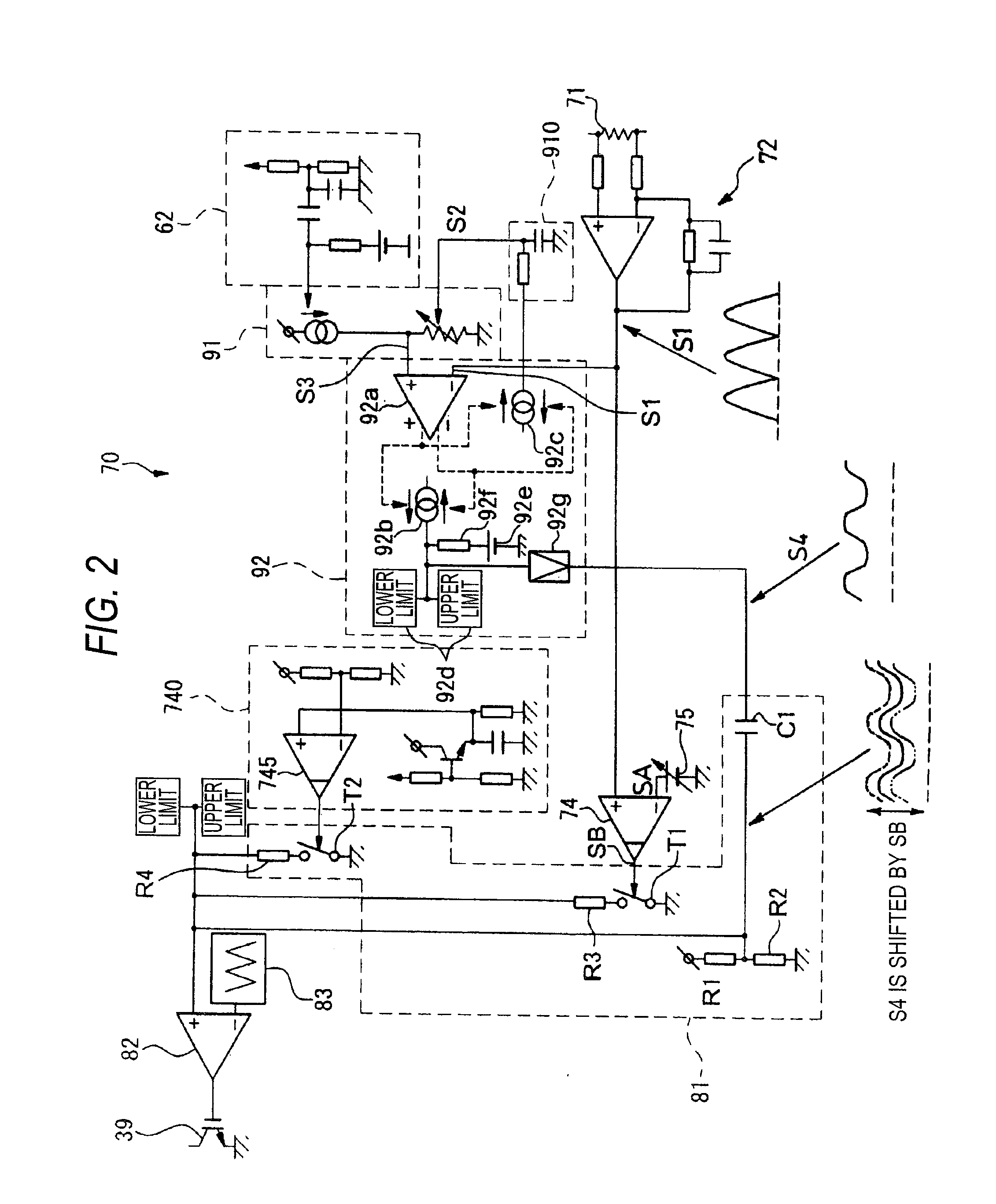

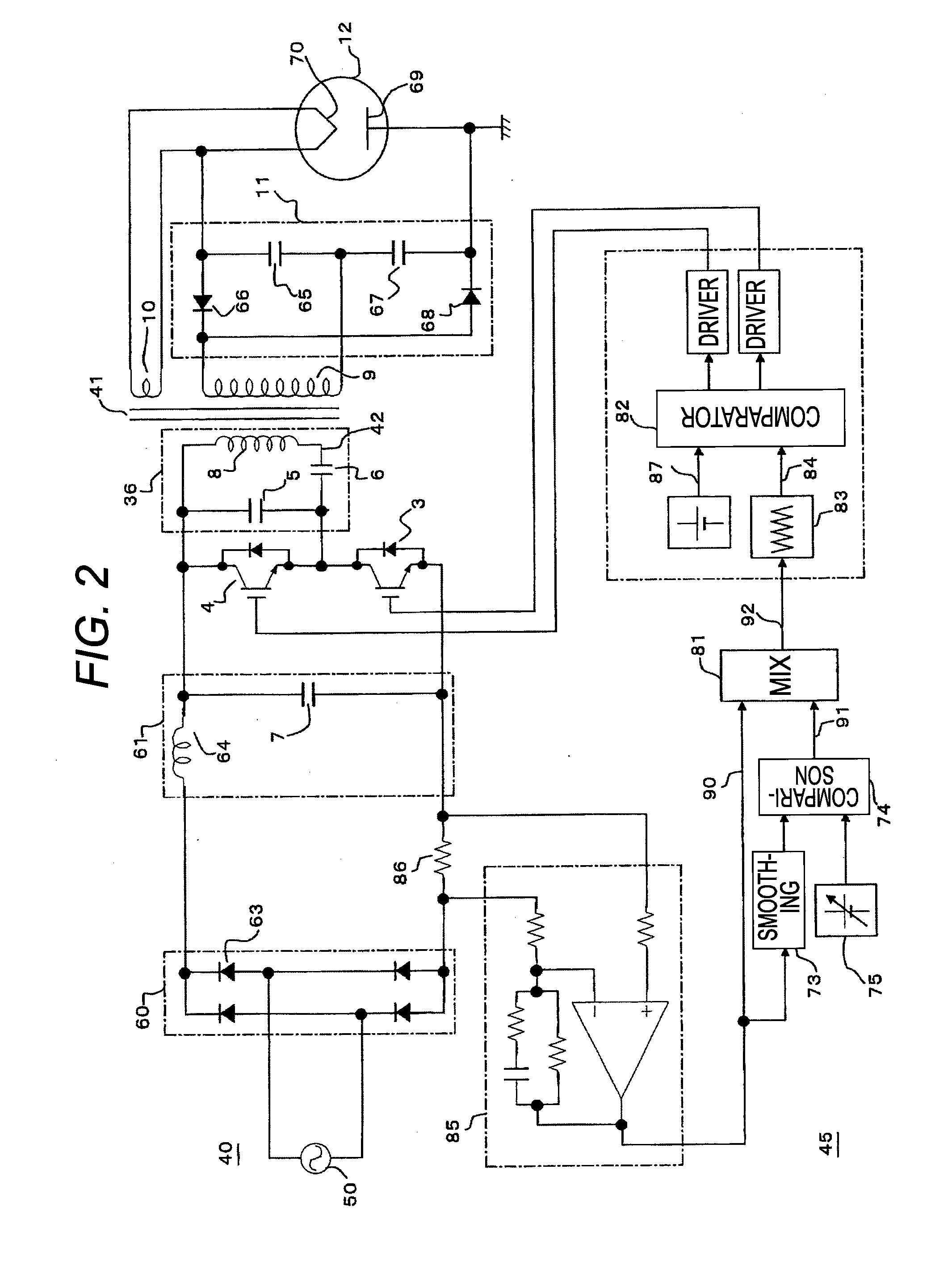

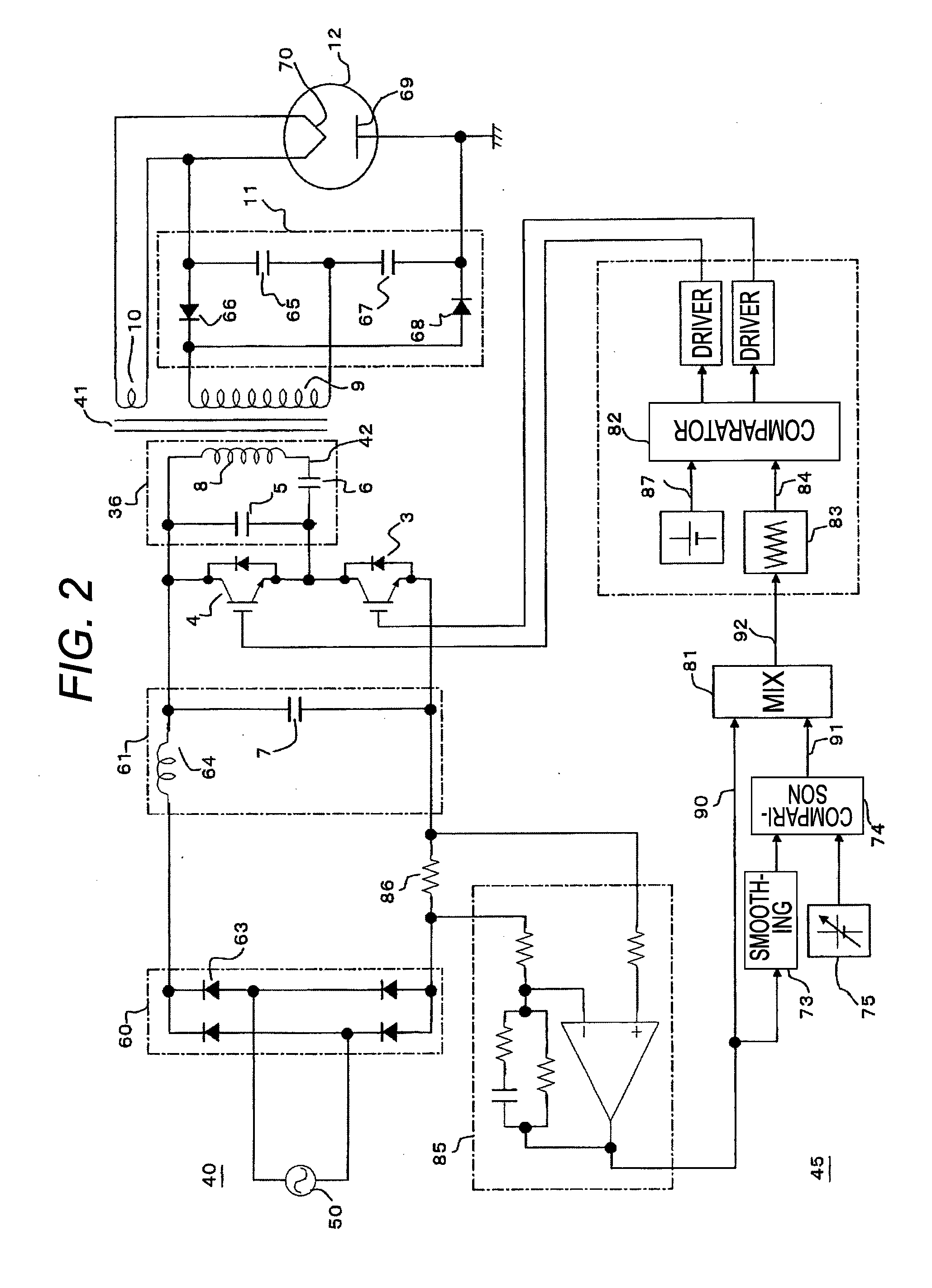

Power control method of high frequency dielectric heating and apparatus thereof

InactiveUS20090065502A1Small sizeSimple structureMicrowave heatingInduction current sourcesAlternating currentReference wave

The object of the invention is not only to simplify the structure of a high frequency dielectric heating power control apparatus and reduce the size of the apparatus but also to eliminate the need for control and design corresponding to the kind of a magnetron and thus enhance the running efficiency of the apparatus.An input current to an inverter circuit is detected by a shunt resistor 71 and is converted to an input current wave form through an input current signal amplifier 72. On the other hand, based on an alternating current power supply voltage wave form from an alternating power supply voltage, there is obtained through a gain variable amplifier 91 a reference wave form following the size of the input current wave form. A wave form error detect circuit 92 compares the input current wave form with the reference wave form to obtain a wave form error signal. A comparison circuit 74 compares the input current wave form with an input current reference signal obtained from an output setting part 75 for obtaining a desired high frequency output to thereby obtain a current error signal. And, a mix and filter circuit 81 adds the wave form error signal and the current error signal to obtain a power control signal for driving a switching transistor 39 of the inverter circuit. Here, the reference wave form is generated based only on the alternating current power supply voltage wave form and on the feedback signal of the wave form error signal.

Owner:PANASONIC CORP

Power control unit for high-frequency dielectric heating and control method thereof

InactiveUS20090272735A1Suppress transient fluctuationsSimple configurationMicrowave heatingDomestic cooking appliancesHigh frequency powerElectric power

A power control unit for a high-frequency dielectric heating not affected by variations in the magnetron type or characteristic, and power supply voltage fluctuation, etc., is provided. The power control unit for a high-frequency dielectric heating has an input current detection section 71, 72 for detecting input current of an inverter 10 for rectifying 31 an AC power supply voltage 20, performing high-frequency switching of the voltage, and converting the voltage to high-frequency power. The power control unit for a high-frequency dielectric heating converts a switching frequency control signal 92 provided by mixing input current waveform information 90 and power control information 91 into a drive signal of a semiconductor switching element 3, 4 of the inverter.

Owner:PANASONIC CORP

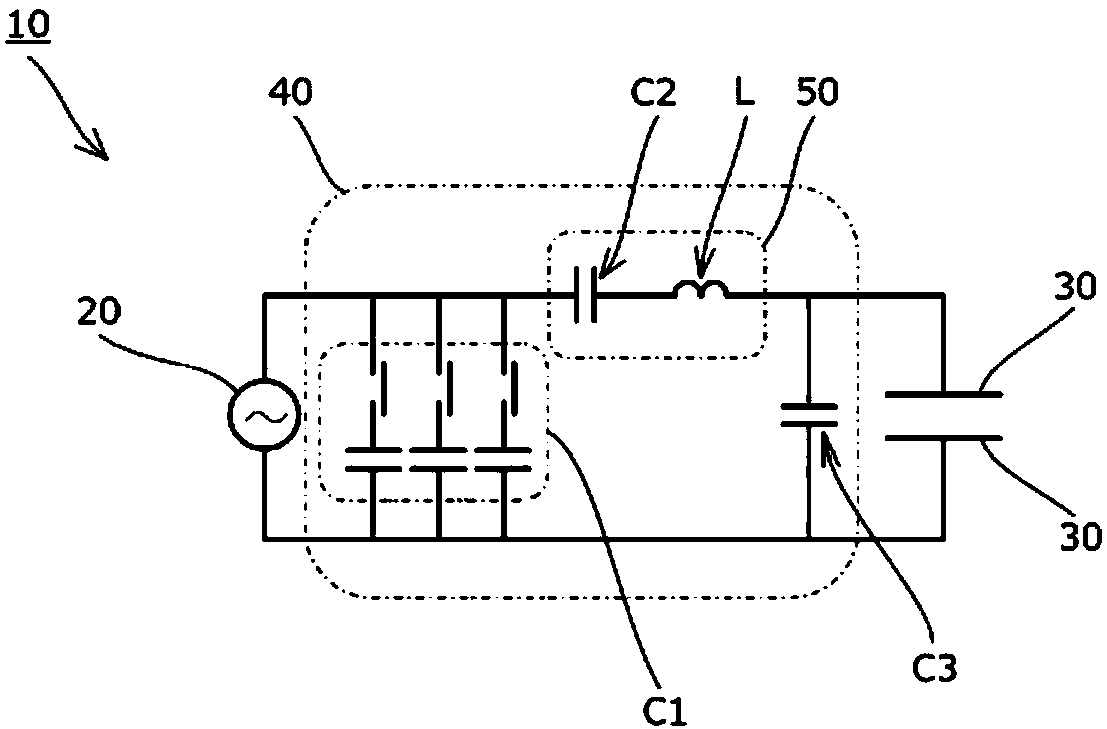

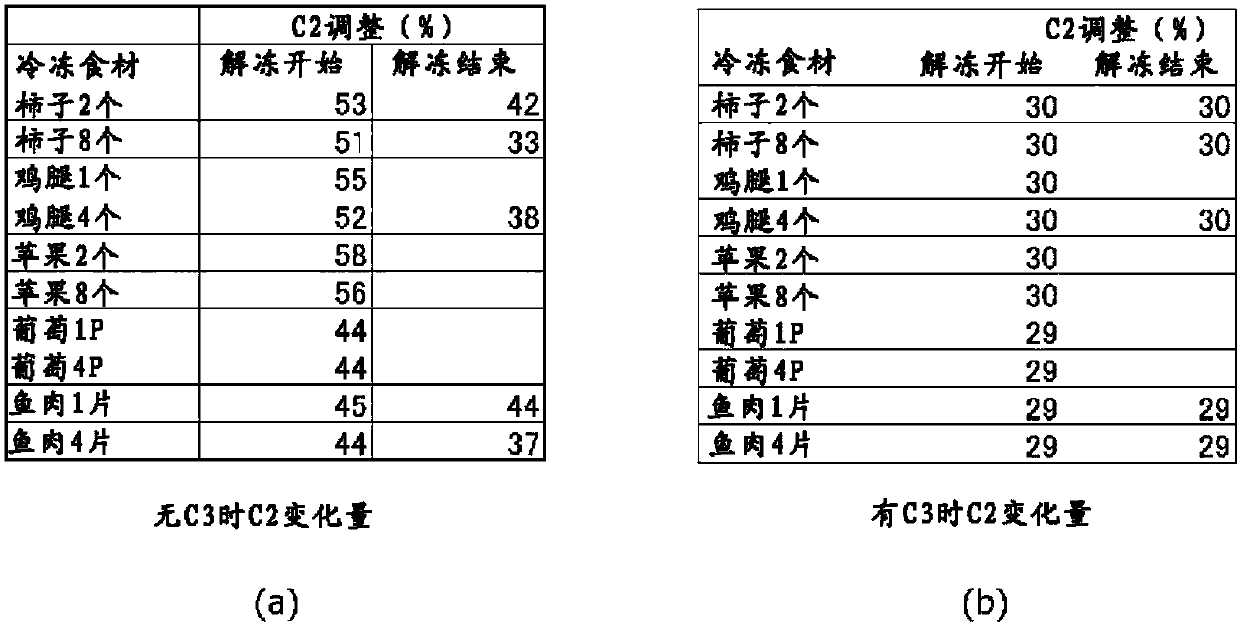

High-frequency dielectric heating device

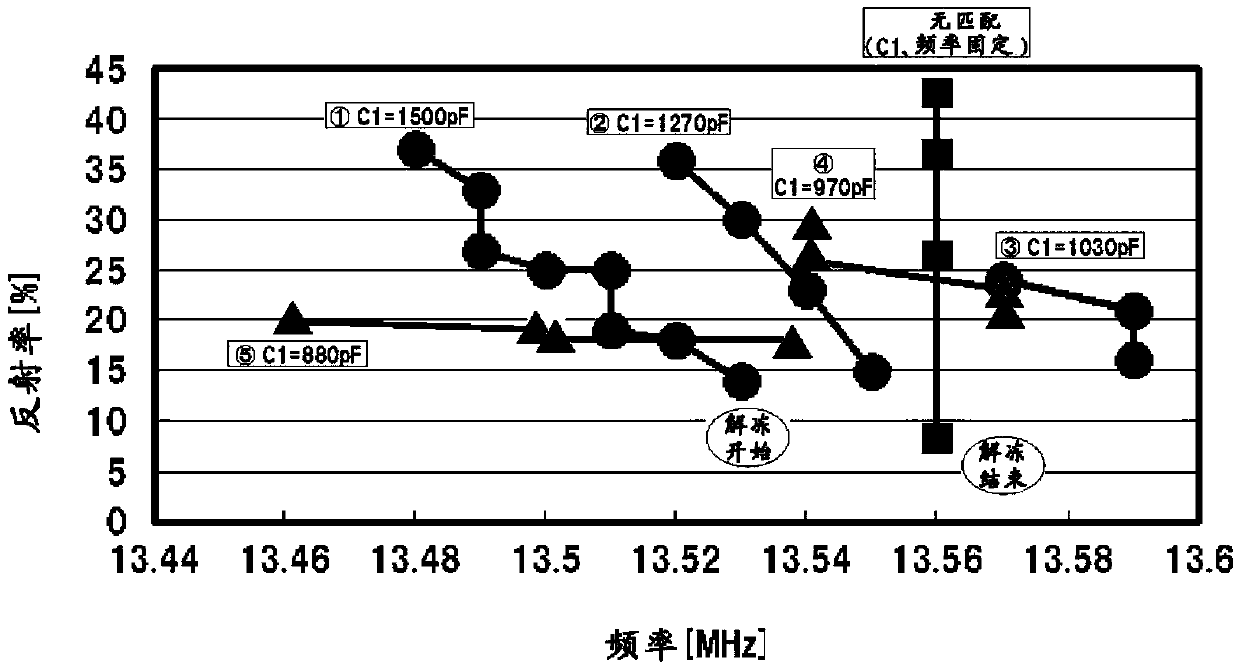

ActiveCN107710869AImprove oscillation efficiencyMiniaturizationDielectric heating circuitsDielectric heating electrodesHigh frequency powerImpedance matching

Provided is a high-frequency dielectric heating device for which fine adjustment of inductance is achieved easily and with high precision, while reducing device cost and simplifying device structure.A high-frequency dielectric heating device (10) comprising a high-frequency power source (20), a pair of electrodes (30) disposed facing each other, a reflected power detection means for detecting reflected power occurring due to heating of a substance to be heated, the reflected power detection means being connected between the electrodes (30) and the high-frequency power source (20), and an inductance matching device (40) for adjusting the reflected power, wherein the matching device (40) is provided with a capacitor (C1) connected in parallel to the high-frequency power source (20), and a capacitor (C2) and / or coil (L) with which it is possible to adjust at least reactance, the capacitor (C2) and / or coil (L) being connected in series to the electrodes (30), the high-frequency power source (20) being configured such that frequency can be varied.

Owner:TOYO SEIKAN GRP HLDG LTD

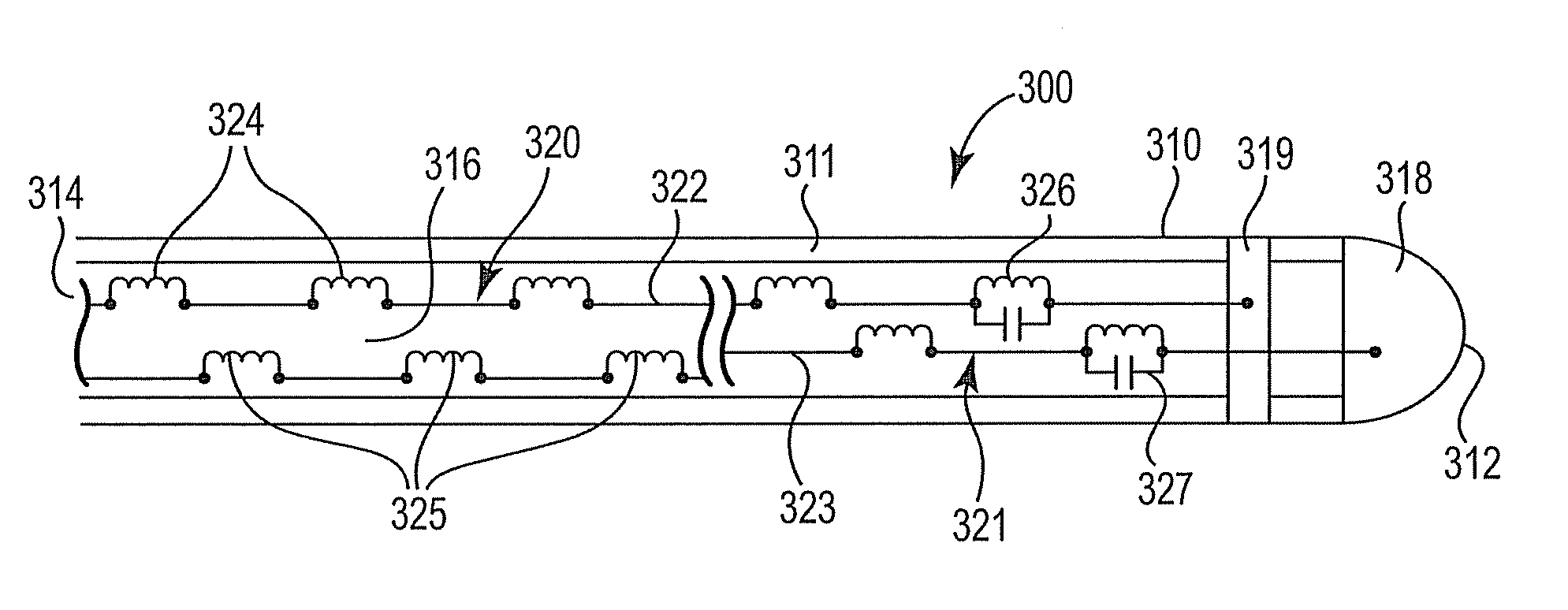

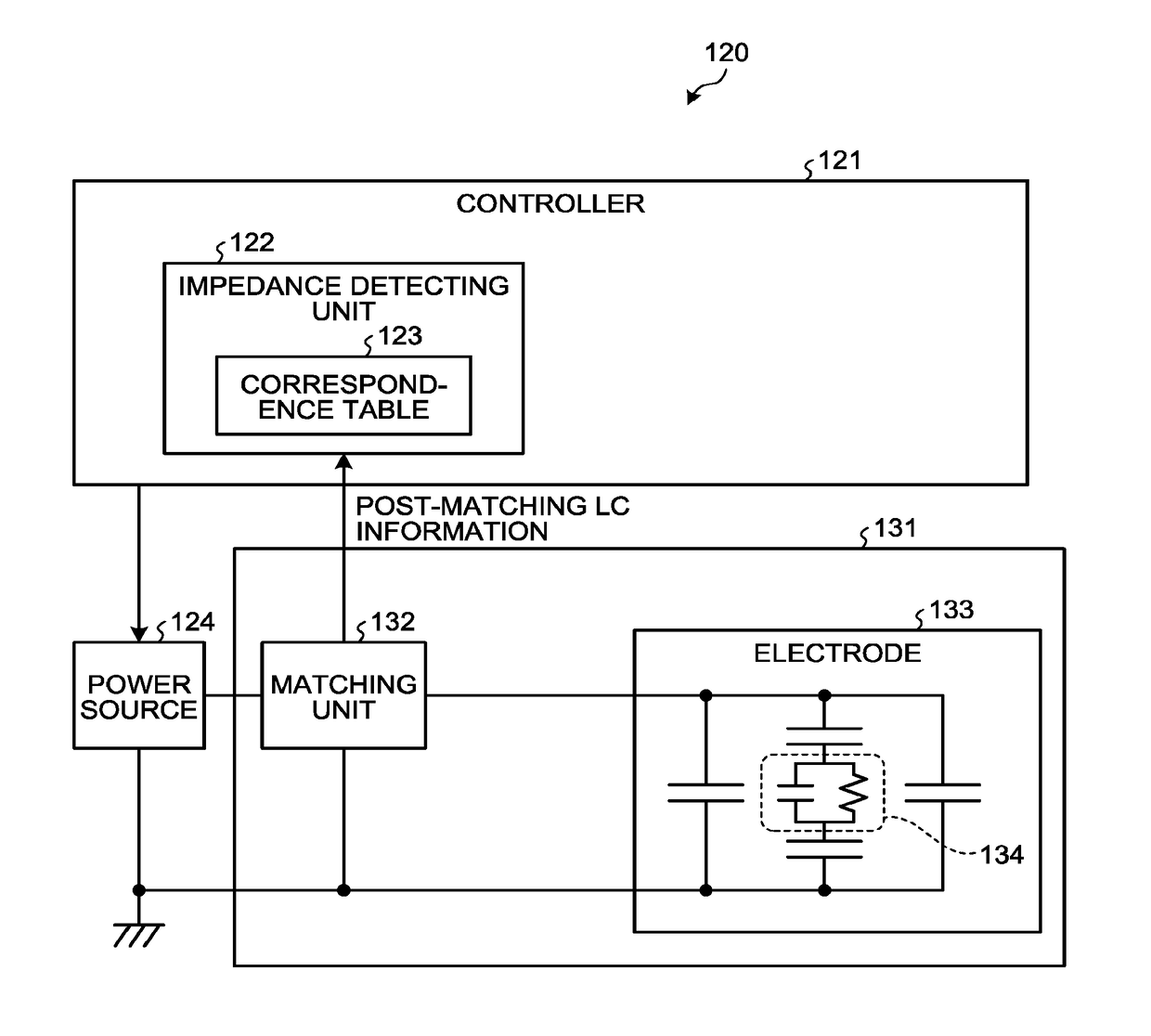

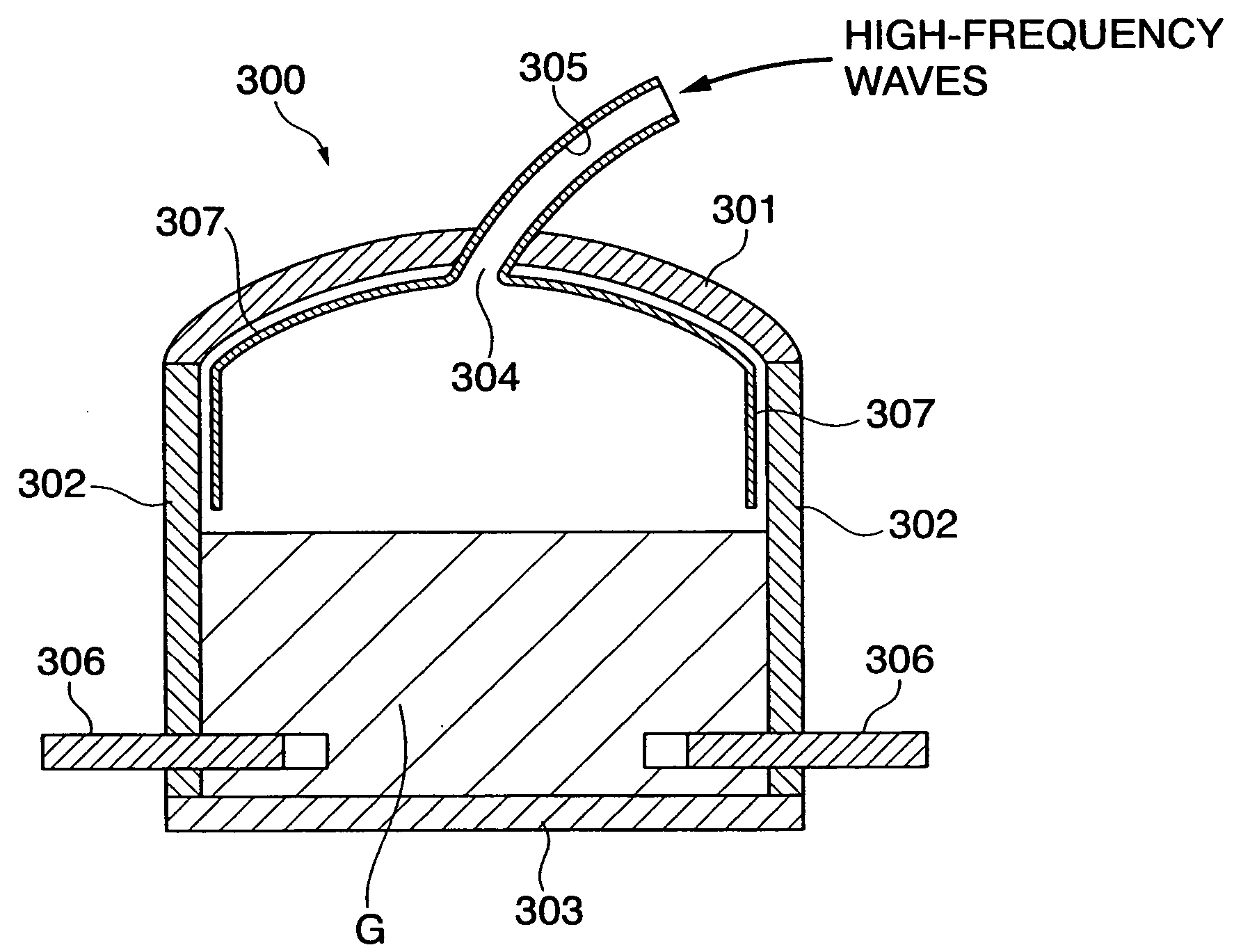

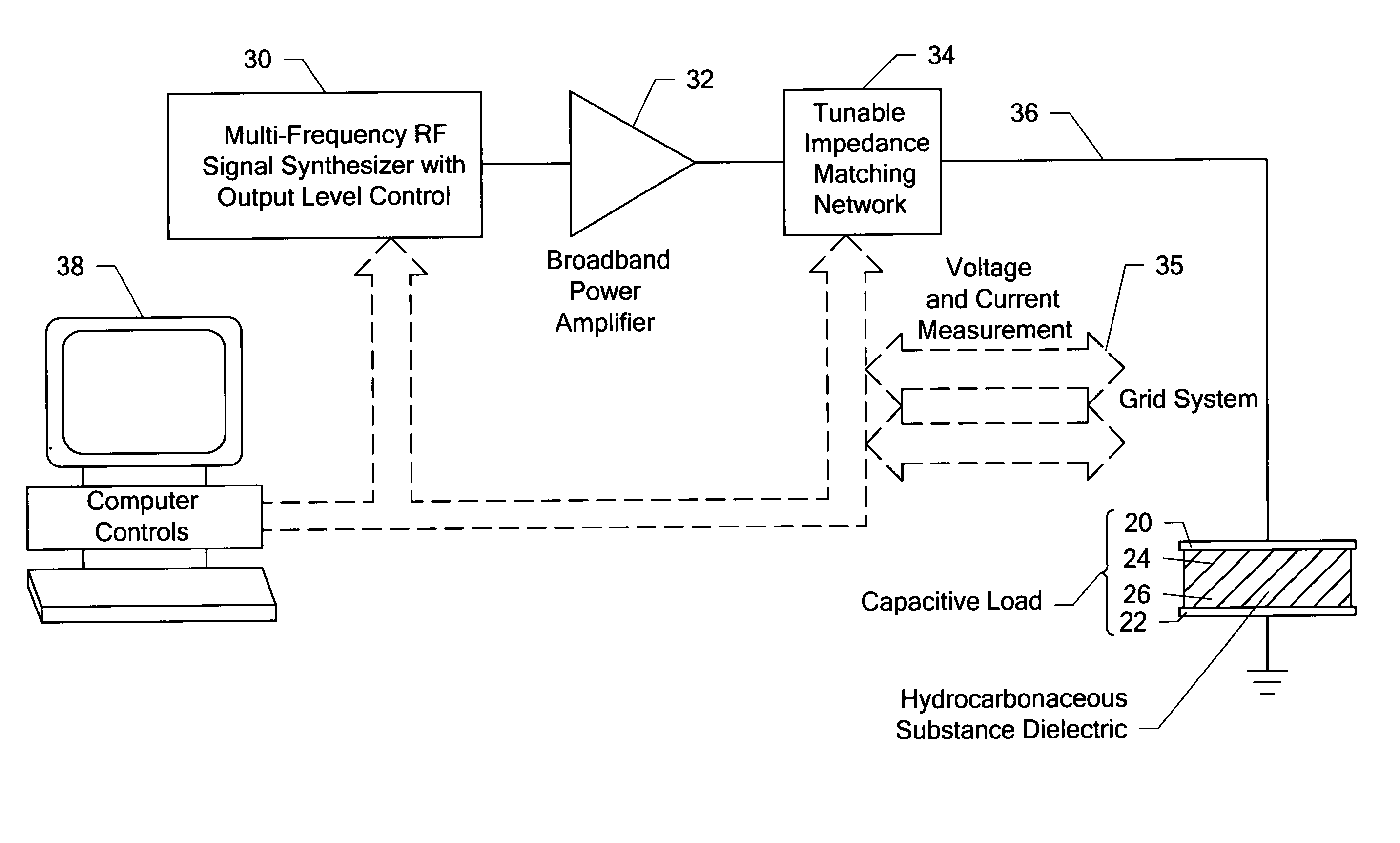

In situ processing of hydrocarbon-bearing formations with automatic impedance matching radio frequency dielectric heating

A hydrocarbon bearing formation (304) which is heated using a automatic impedance matching (181) capacitive radio frequency dielectric heating (334) in situ process. Hydrocarbons or other substances natural to a hydrocarbonaceous formation may be produced by heating specific chemical compositions with or without the use of a carrier medium (320) in a subterranean reservoir. Hydrocarbons or other substances natural to a hydrocarbonaceous formation are heated by maintaining specific chemical compositions in an alternating current electrical field generated by a radio frequency signal. As the targeted chemical compositions increase in temperature, maximum energy is delivered using automatic impedance matching to adjust the rate of the heating process.

Owner:HEAT ENERGY & ASSOCD TECH

Power control unit for high-frequency dielectric heating and control method thereof

InactiveUS20100155395A1Stable outputSuppress transient fluctuationsMicrowave heatingDomestic cooking appliancesHigh frequency powerEngineering

A power control unit for a high-frequency dielectric heating not affected by variations in the magnetron type or characteristic, and power supply voltage fluctuation, etc., is provided. The power control unit for a high-frequency dielectric heating has an input current detection section 71, 72 for detecting input current of an inverter 10 for rectifying 31 an AC power supply voltage 20, performing high-frequency switching of the voltage, and converting the voltage to high-frequency power. The power control unit for a high-frequency dielectric heating converts a switching frequency control signal 92 provided by mixing input current waveform information 90 and power control information 91 into a drive signal of a semiconductor switching element 3, 4 of the inverter.

Owner:PANASONIC CORP

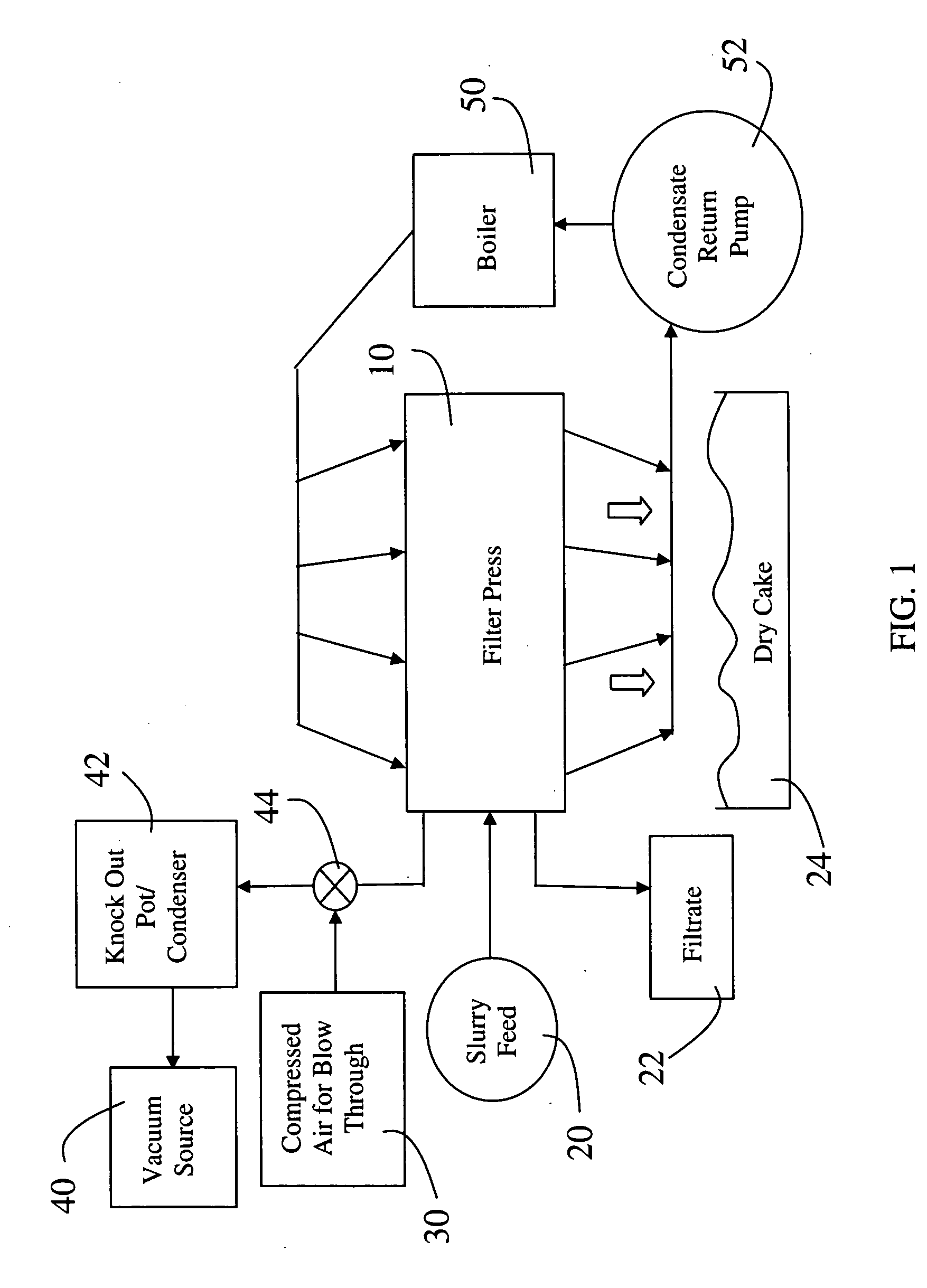

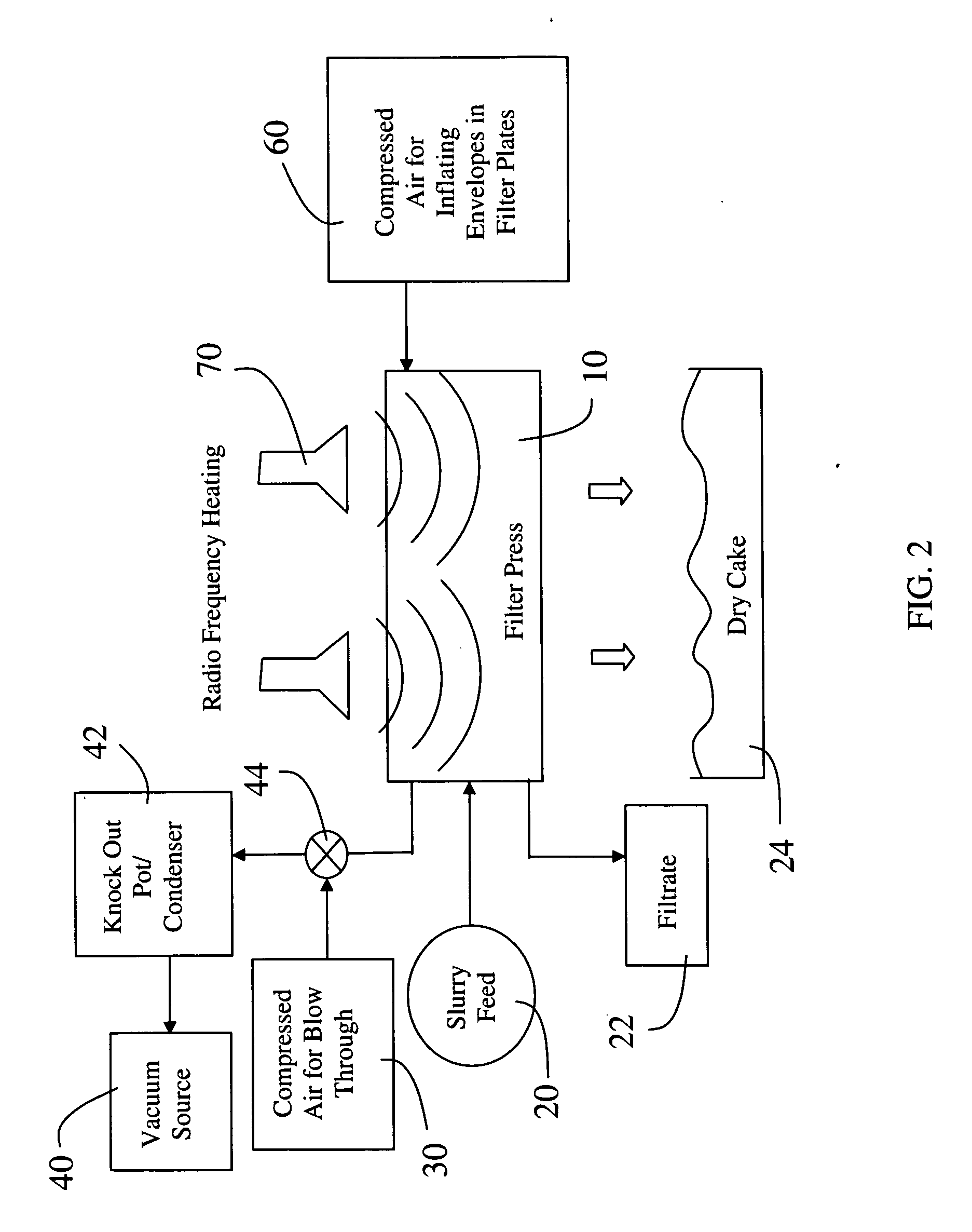

Filter press with integrated radio frequency heating

ActiveUS20100116755A1Effective destructionReduce radio frequency radiationVacuum distillation separationLoose filtering material filtersParallel plateFilter press

A method of separating a mixture of liquid and insoluble solids in a filter press may comprise: pumping the mixture into a chamber between two filter plates in the filter press to form a filter cake, wherein the chamber is lined by filter cloths, and wherein, during the pumping, filtrate is forced through the filter cloths and out of the chamber; heating the filter cake in the chamber, wherein, during the heating, filtrate is forced through the filter cloths and out of the chamber, and wherein the heating is by radio frequency irradiation of the filter cake in the chamber; and releasing dried filter cake from the chamber. A filter press system for separating a mixture of liquid and insoluble solids may comprise: a frame; a plurality of filter plates configured to form a stack of parallel plates, each of the plurality of filter plates being movably attached to the frame, the plurality of filter plates further being configured to form a multiplicity of chambers, each of the multiplicity of chambers being lined by filter cloths, wherein the plurality of filter plates, the multiplicity of chambers and the filter cloths are configured to allow filtrate to escape from the chambers while retaining solids from the mixture to form a filter cake; and a radio frequency heater, for directly heating the filter cake in the multiplicity of chambers. The radio frequency heating may include microwave heating, or dielectric heating by lower frequency radio waves in the range of 1 to 100 MHz.

Owner:SIMPSON DANIEL J

Power control apparatus for high-frequency dielectric heating

ActiveCN103716931AImprove reliabilityShorten the timeMicrowave heatingDomestic cooking appliancesPower flowEngineering

In order to prevent an excessive voltage from being applied to a magnetron and a rectifier circuit on a secondary side of a leakage transformer and reduce a required time until the start of oscillation of the magnetron, a power control apparatus for high-frequency dielectric heating of the present invention is equipped with a magnetron oscillation detection section for setting magnetron oscillation detection information to be true after a predetermined time has elapsed since the start of the oscillation of the magnetron was detected; and has a configuration in which control is switched, depending on the magnetron oscillation detection information, between a voltage control in which an applied voltage to the magnetron is controlled and a power control in which the input current of an inverter power supply circuit is controlled, and in which the minimum frequency of a switching frequency is switched between a first frequency and a second frequency higher than the first frequency.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com