Method for connecting members together and connection structure

a technology of connecting members and connecting structures, applied in the direction of manufacturing tools, mechanical devices, fastening means, etc., can solve the problems of long adhesion time, increased production time, and variable problems, and achieve the effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

of Method for Connecting Members Together and Connection Structure

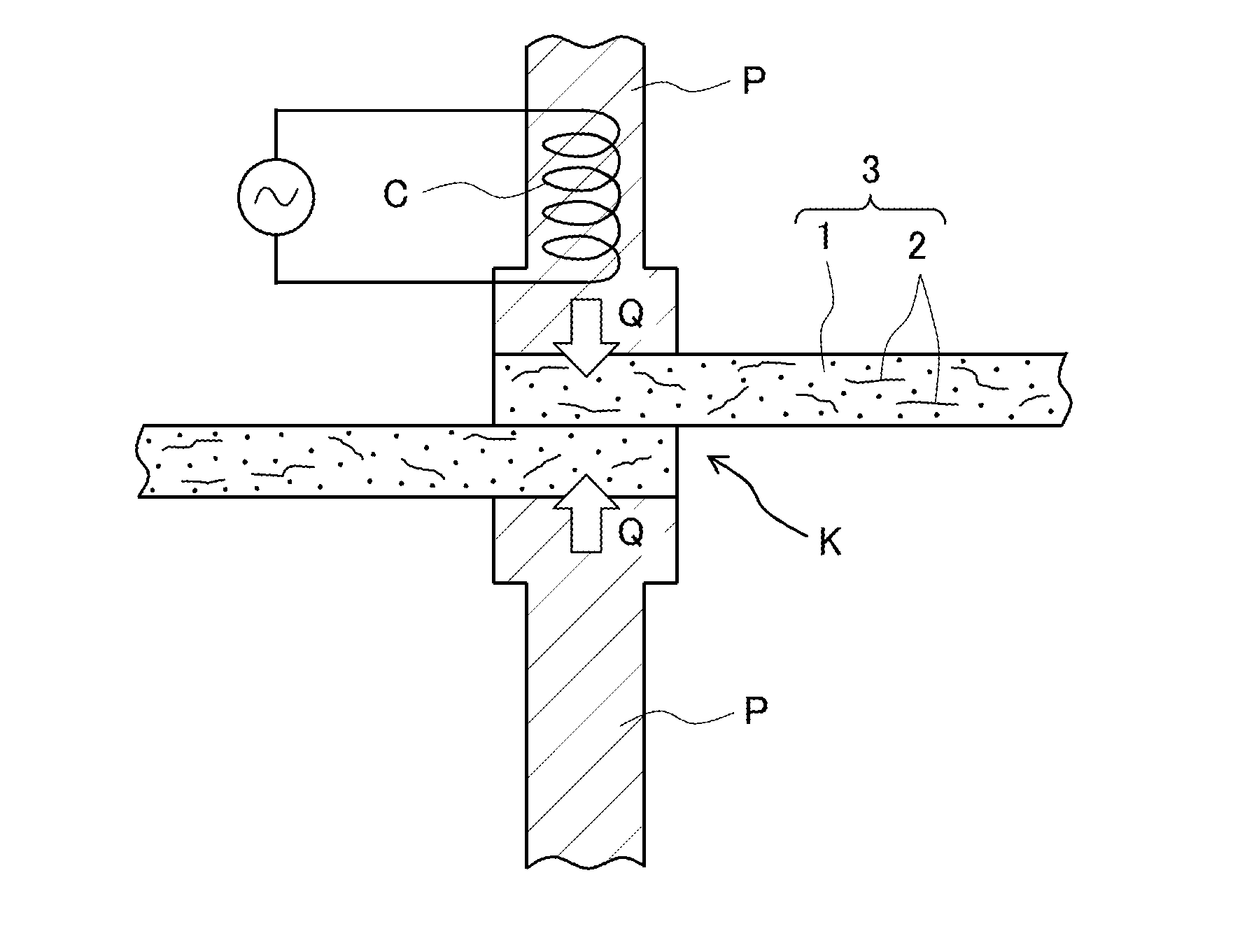

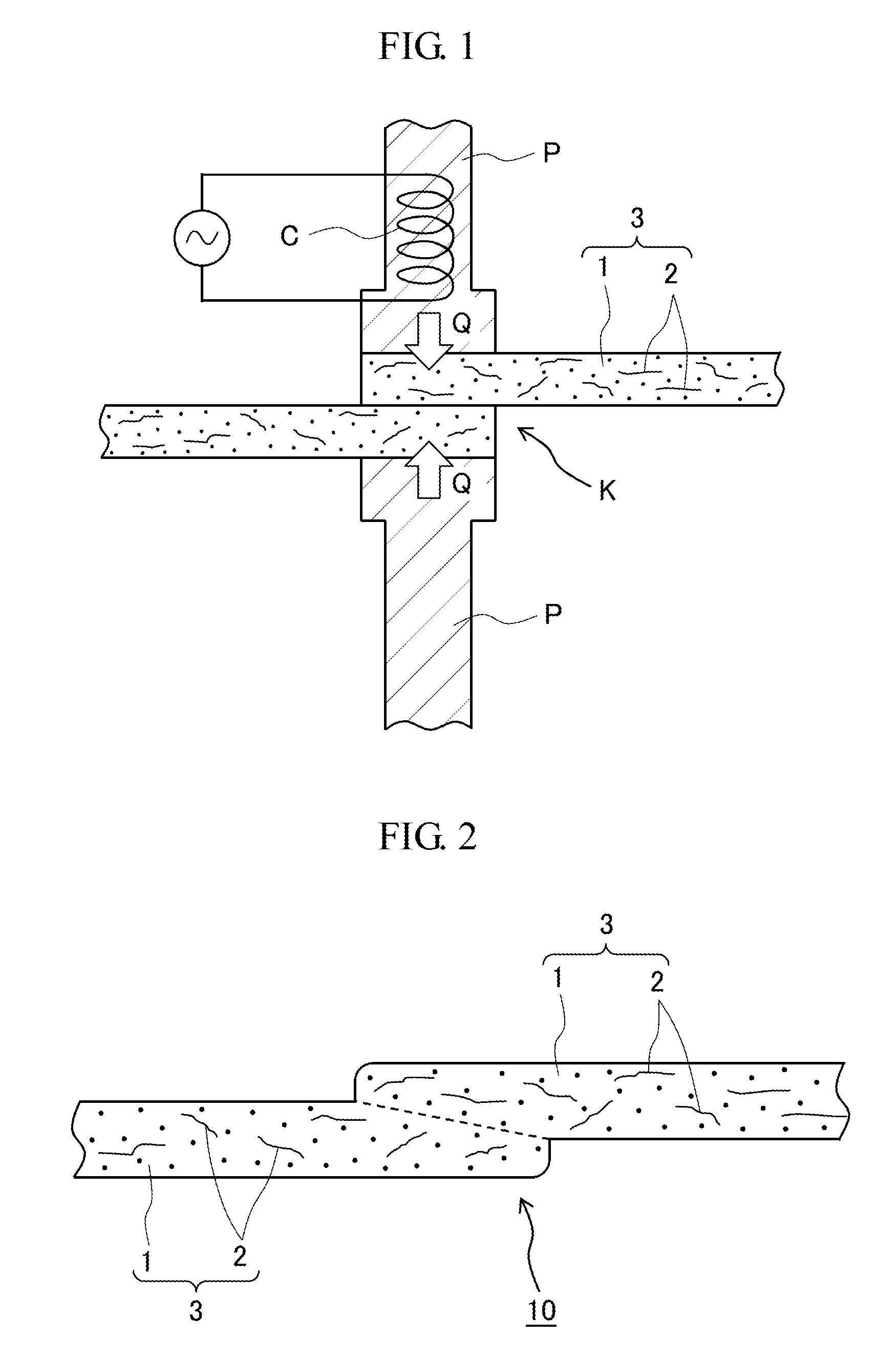

[0041]FIGS. 1 and 2 are sequential flow diagrams illustrating Embodiment 1 of a method for connecting members together of the present invention.

[0042]First, two fiber reinforced resin members 3, which are members to be connected together, are prepared. Each fiber reinforced resin member 3 contains a matrix resin, which is a thermoplastic resin 1, and also contains a fiber material 2, which is adapted to reinforce the member and serves as a heating element that can generate heat from heat provided thereto, in the thermoplastic resin 1.

[0043]It should be noted that the shape of the fiber reinforced resin member 3 may be, in addition to a planar shape shown in the drawing, a variety of shapes and configurations including a three-dimensional shape (i.e., a curved shape, a wavy shape, or a unitary shape of curves and planes).

[0044]Herein, for the thermoplastic resin 1, it is possible to use one of crystalline plastic such ...

embodiment 2

of Method for Connecting Members Together and Connection Structure

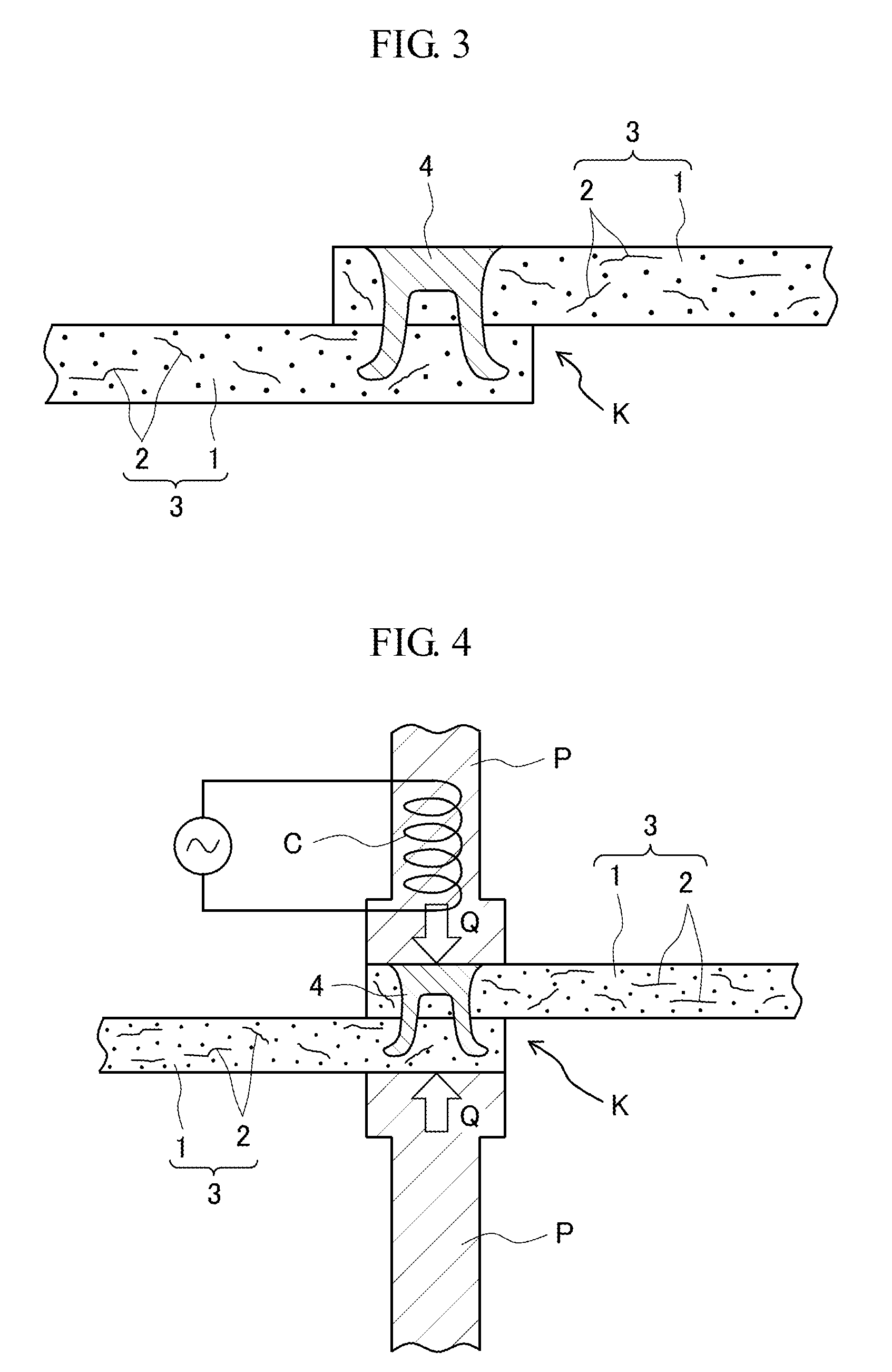

[0056]FIGS. 3 to 5 are sequential flow diagrams illustrating Embodiment 2 of a method for connecting members together of the present invention.

[0057]The connection method shown herein is a method that is suitable for a case where the fiber reinforced resin members 3, which are members to be connected together, have relatively large dimensions.

[0058]When the fiber reinforced resin members 3, which are members to be connected together, have relatively large dimensions, the fiber reinforced resin members 3,3 often have no mutually-complementary warps or deformations. When the two materials are attempted to be connected together with such warps or deformations left, it would be impossible to form a position of superposition with high accuracy, and consequently, it becomes impossible to form a connection structure having about the same level of connection strength over the entire range of the position of superposition.

[005...

examples 1 and 2

[0066]Each of test pieces in accordance with Examples 1 and 2 is obtained by welding two sheet materials together through induction heating. An electromagnetic induction oscillator (UH 2.5K) of SEIDENSHA ELECTRONICS CO., LTD. was used, and an oscillation coil in spiral form was used.

[0067]A test piece was produced by placing a PBT plate with a predetermined thickness to provide a gap on the oscillation coil, and disposing the sheet materials at a position of superposition on the plate, and further applying pressure thereto from above using a metal bar for 60 seconds, and then releasing the pressure. Examples 1 and 2 differ in the gap (i.e., gap from the coil) and the current value as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com