Chemical synthesis comprising heat treatment by intrmittent dielectric heating combined with a recycling system

a technology of intrmittent dielectric heating and heat treatment, which is applied in the direction of electric/magnetic/electromagnetic heating, instruments, optical elements, etc., can solve the problems of complex choice of applicators, electrical breakdown or electric arc risk, and cannot permit working with a high density of power without running the risk of electrical breakdown, etc., to achieve efficient and rapid heat treatment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0137] The examples given below highlight the value of the invention and will allow any person skilled in the art to easily extrapolate to other dimensions and / or geometries without departing from the true scope and spirits of the invention in its broader aspects.

[0138] Additionally, the following examples, which are given solely for purposes of description and in no way of limitation, illustrate the value of the invention. These examples aim to demonstrate that the intermittent dielectric heating process is low-in-cost and permits heating reaction volumes on an industrial scale while still benefiting from the advantages of this technology.

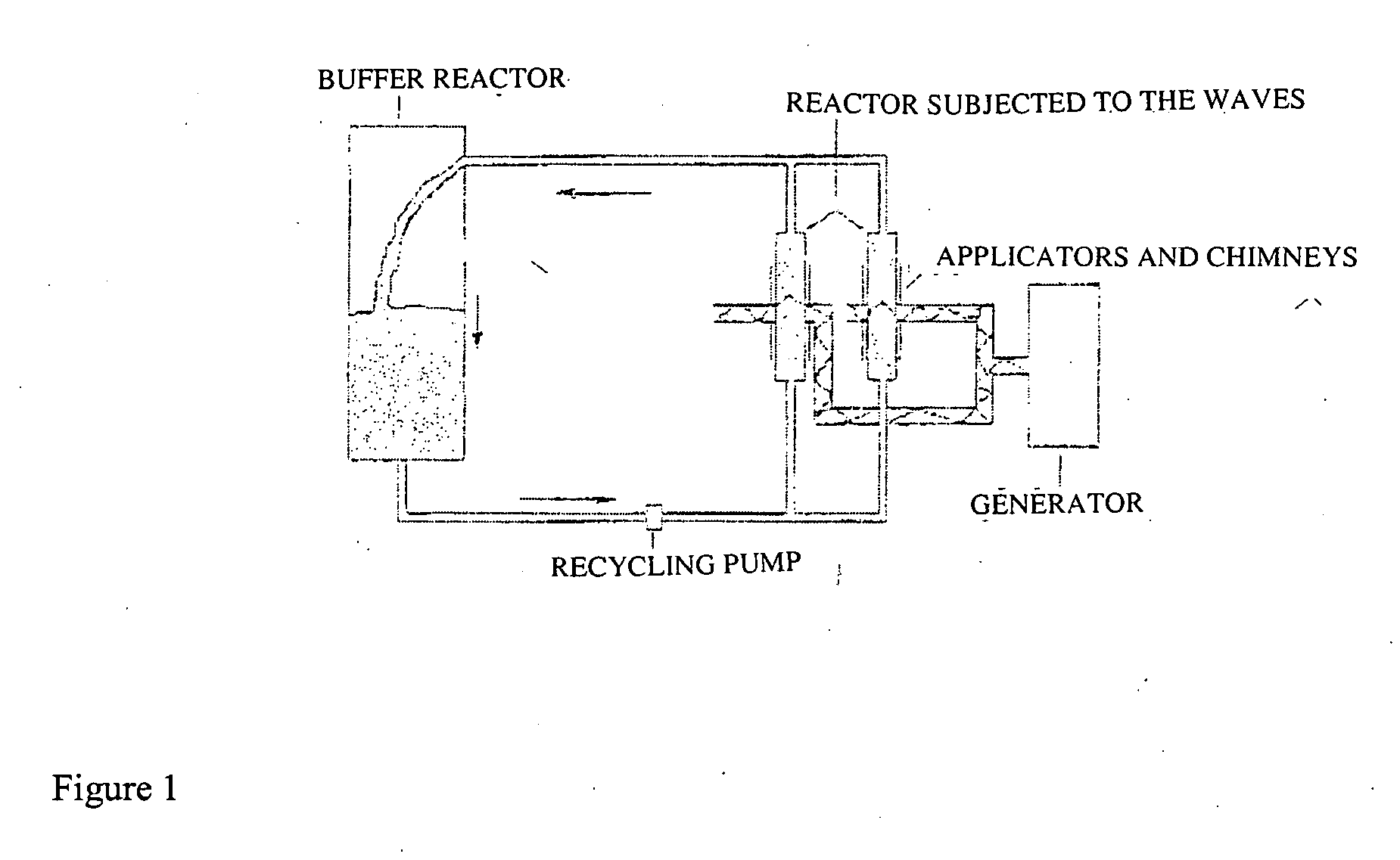

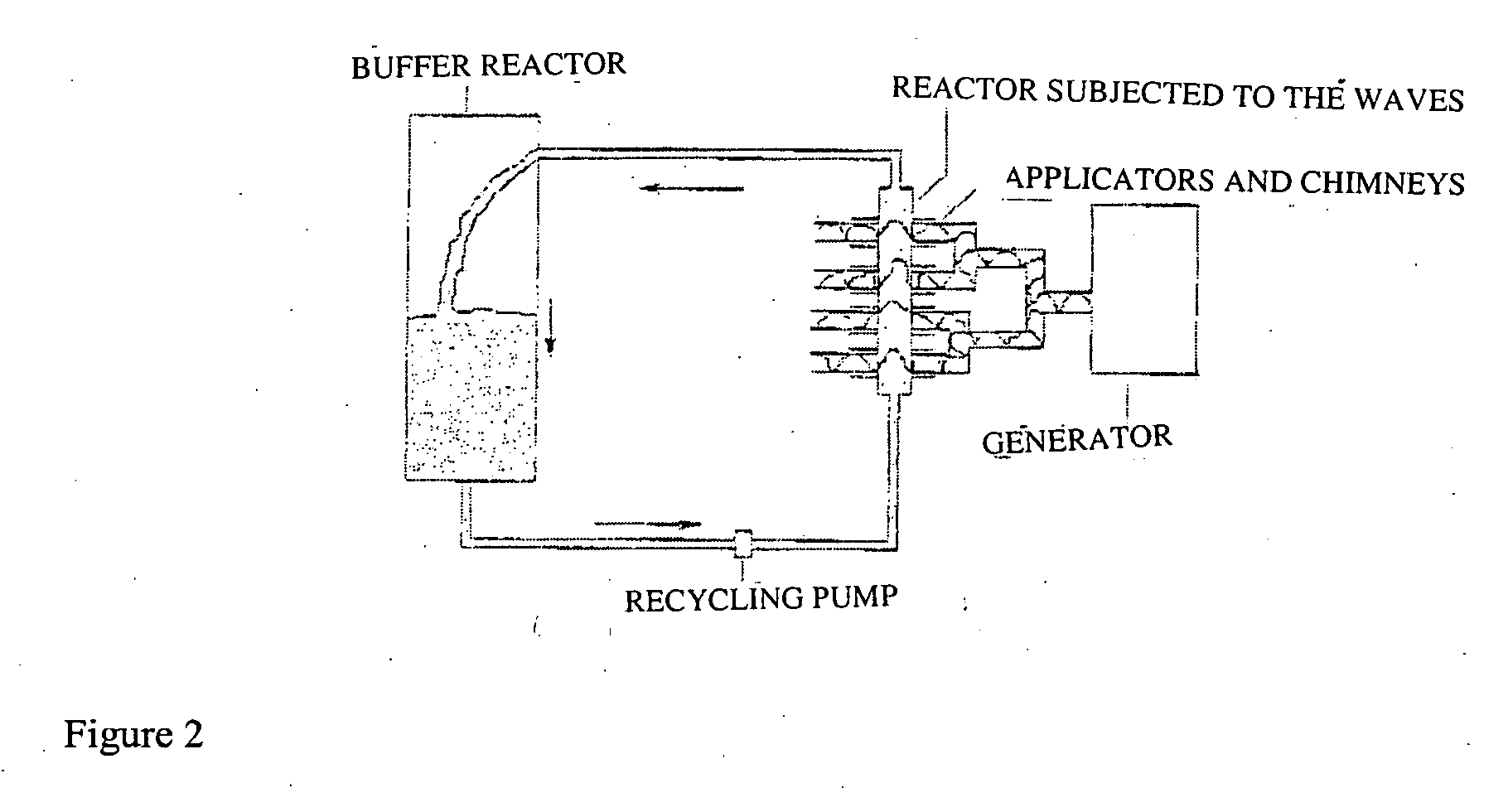

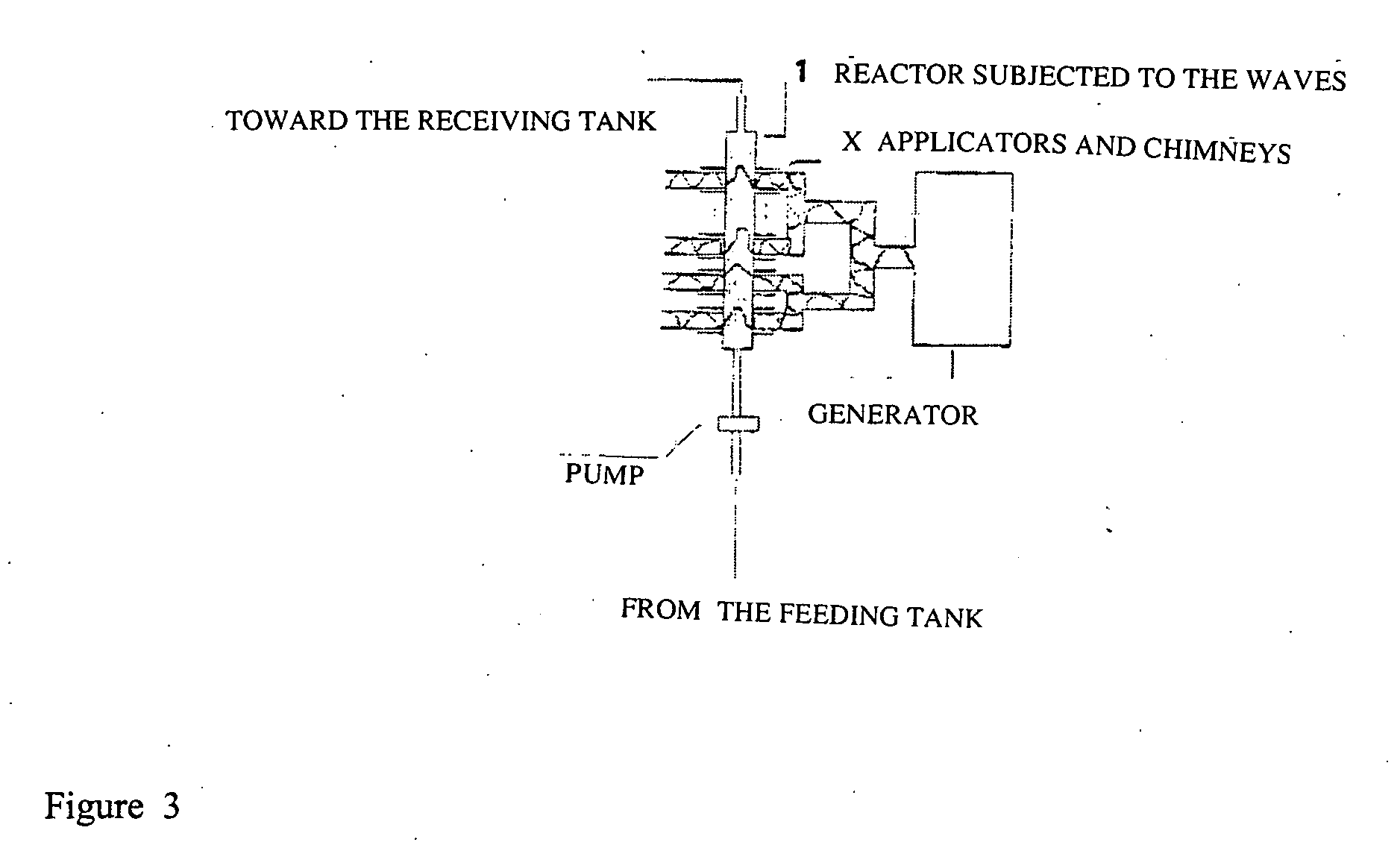

I. Volumes Exposed to Electromagnetic Waves

[0139] The tests were conducted on the laboratory and on industrial scale using two (2) generators: [0140] one (1) 6 kW magnetron generator operating at the 2450 MHz frequency for the laboratory treatments

[0141] one (1) 60 kW magnetron generator operating at the 915 MHz frequency for the industrial t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com