Power control apparatus for high-frequency dielectric heating

A technology of power control and high-frequency medium, which is applied in the field of power control devices for high-frequency medium heating, can solve problems such as excessive voltage and component damage, and achieve the effect of shortening time and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

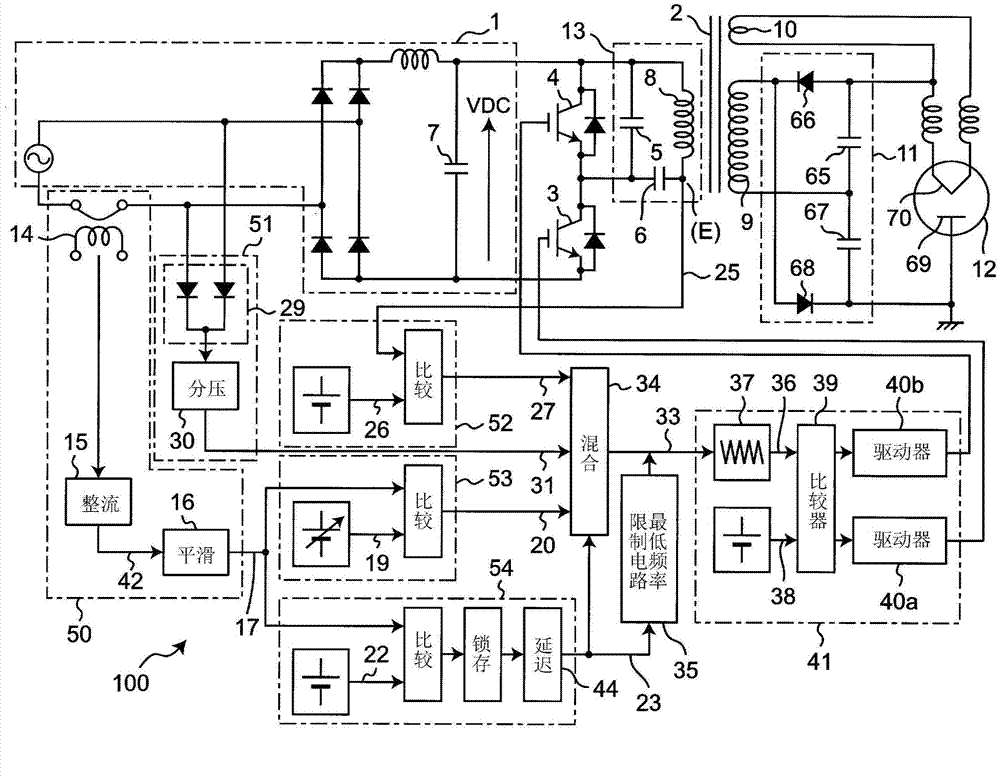

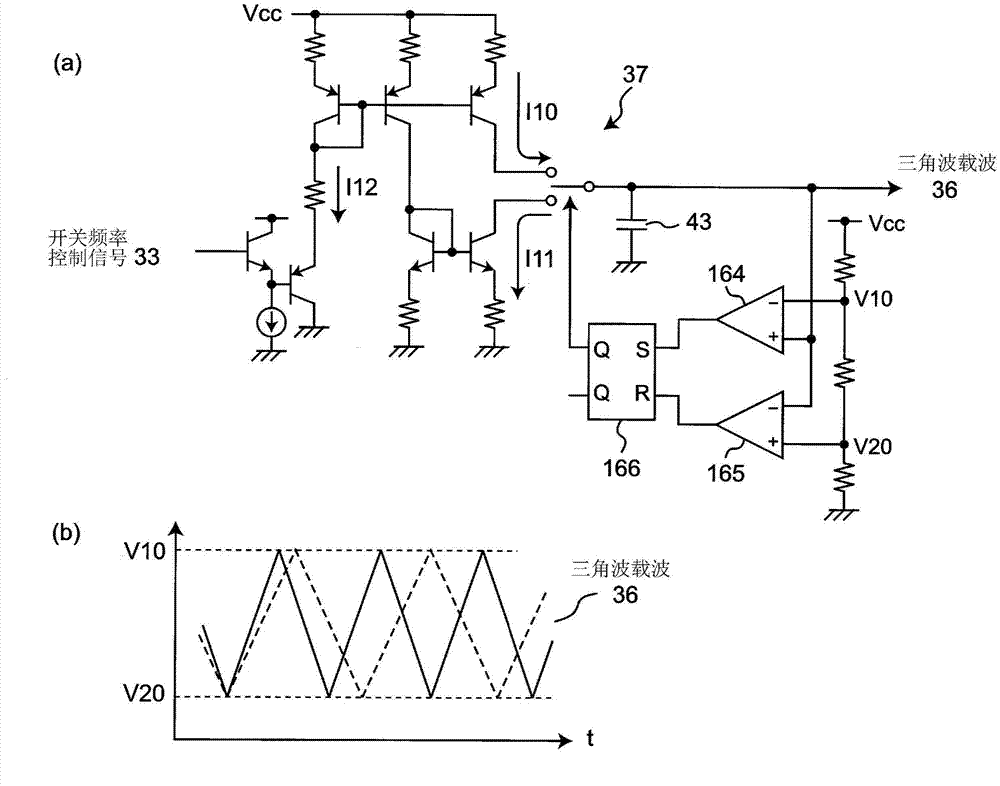

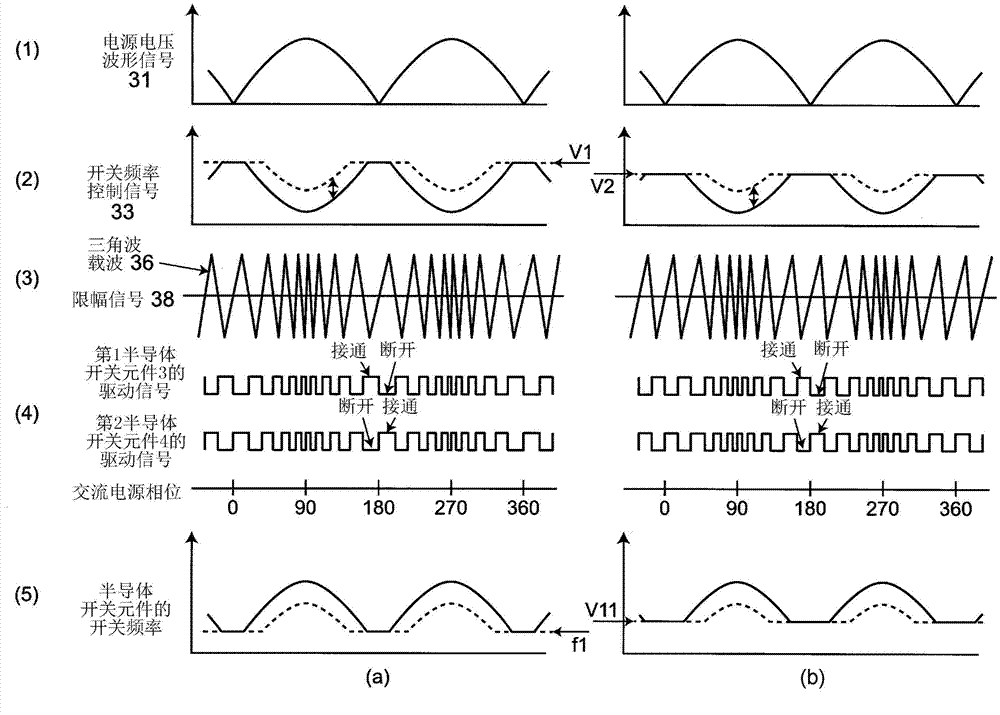

[0084] figure 1 A high-frequency dielectric heating device according to Embodiment 1 of the present invention showing an inverter power circuit with a two-transistor bridge arm structure for driving a magnetron as a microwave generating device and controlling the operation of the inverter power circuit. Power control device. In Embodiment 1, an inverter power supply circuit having a two-transistor arm structure was described, but the present invention can also be applied to an inverter power supply circuit including a plurality of transistors.

[0085] Such as figure 1 As shown, in the inverter power supply circuit of the double-transistor bridge structure, the main circuit on the primary side of the flux leakage transformer 2 consists of a DC power supply circuit 1, a flux leakage transformer 2, a first semiconductor switching element 3, and a second semiconductor switch The element 4 , the first capacitor 5 , the second capacitor 6 , and the third capacitor 7 (smoothing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com