Heat humidity independently controlled air conditioning system applied to IDC machine room and refrigeration method

A technology for heat and humidity independent control and air-conditioning systems, applied in air-conditioning systems, heating and ventilation control systems, space heating and ventilation control input, etc., can solve large water consumption, low energy efficiency ratio of refrigeration systems, high energy consumption in operation, etc. problem, to achieve the effect of high coil operating temperature, increased heat transfer area, and flexible placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

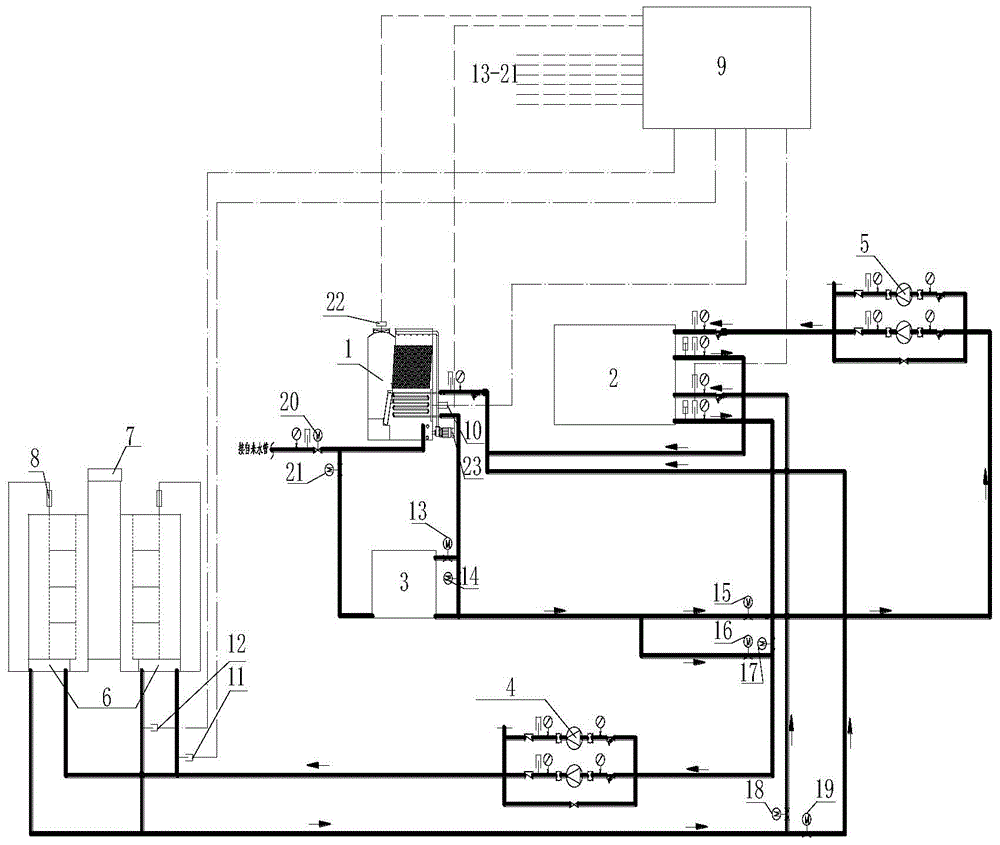

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, the refrigeration system of the present invention includes a closed cooling tower 1, a water-cooled refrigeration unit 2, a cold water tank 3, a chilled water pump 4, a cooling water pump 5, a dry coil module 6, a fresh air dehumidification module 7, an exhaust device 8, an embedded Control system 9, closed cooling tower inlet air wet and dry bulb temperature sensor 10, dry coil module inlet water temperature sensor 11, dry coil module outlet water temperature sensor 12, closed cooling tower fan frequency converter 22, closed cooling tower circulation Water pump inverter 23 and multiple electric valves 13-21.

[0034] See figure 1, the tap water pipe and the first water outlet of the cold water tank (3) are connected to the water supply port of the closed cooling tower (1) through the pipeline respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com