Nonthermal plasma air treatment system

An air treatment system and air technology, applied in the direction of gas treatment, separation methods, gasification substances, etc., can solve problems such as complex external mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

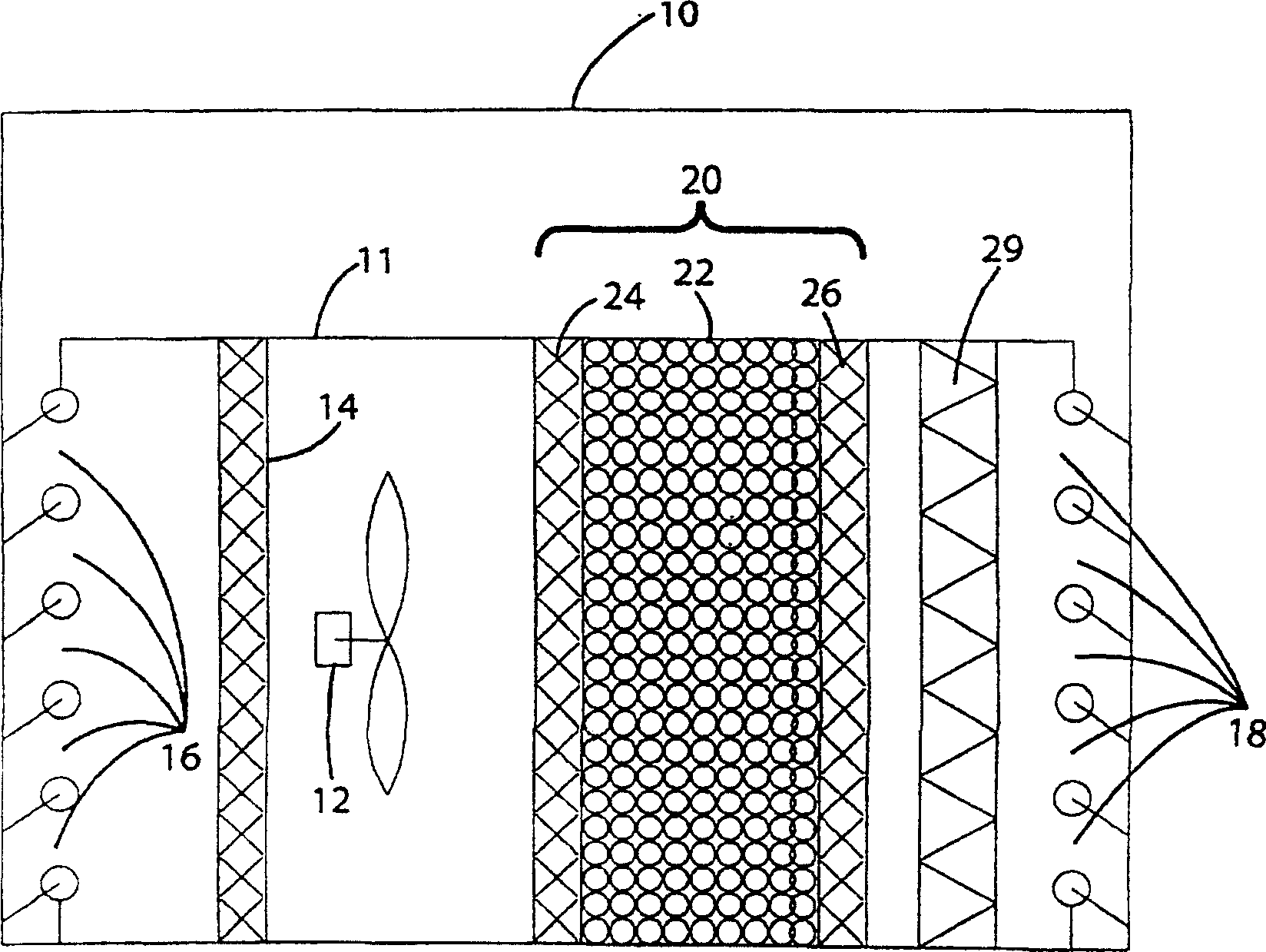

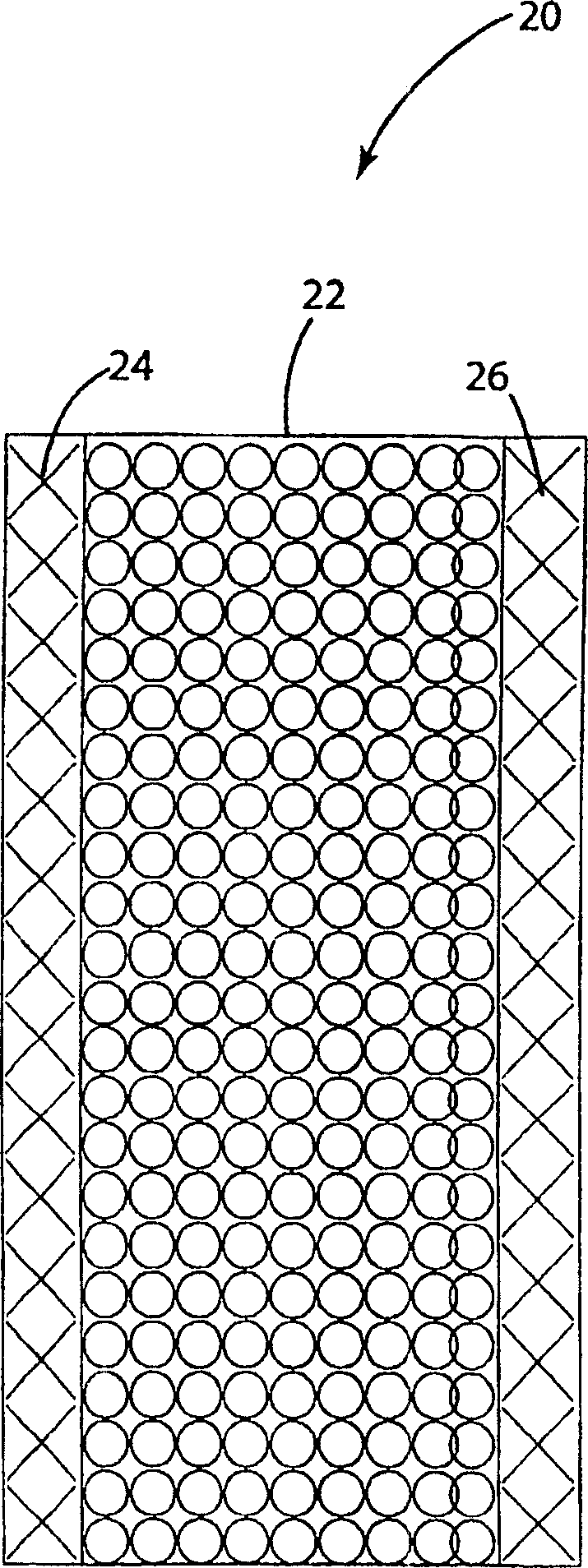

[0039] figure 1 is an embodiment of the present invention. The air treatment system 10 includes a housing 11 and an athermal plasma reactor 20 including a bed of adsorbent material 22 positioned between two opposing electrodes 24 and 26 . Optionally, the air handling system 10 also includes a fan 12 , a set of inlet vanes 16 , a set of outlet vanes 18 , a pre-filter 14 and a HEPA filter 29 .

[0040] A typical operating cycle for air handling system 10 includes two operating phases: an adsorption phase and a desorption / regeneration phase. During the adsorption phase, the vane sets 16 and 18 are turned on and the fan 12 is turned on so that air first passes through the opened vane set 16 and then through the pre-filter 14 into the athermal plasma reactor 20 . Those skilled in the art will appreciate that fan 12 can easily be replaced by a blower or other airflow mechanism known in the art. To provide power to fan 12 and blade sets 16 and 18 using power, power conversion syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com