Heat-resisting and low expansion double capacity compound material core aluminum twisted wire and its making method

A composite material core and composite material technology, applied in the direction of cable/conductor manufacturing, conductors, power cables, etc., can solve the problems of high thermal expansion coefficient, no increase in the filling rate of the conductive layer, and the inability to achieve a significant increase in electrical conductivity, etc., to achieve thermal expansion Low coefficient, improved operational safety, and the effect of preventing major accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

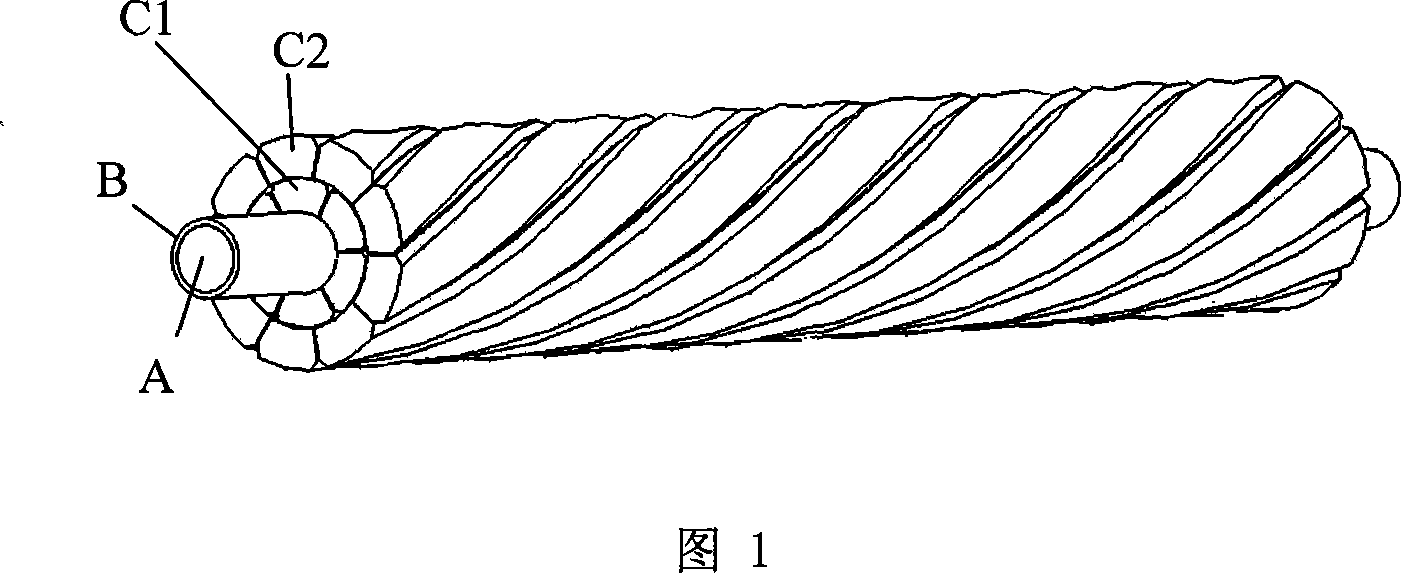

[0040] Embodiment: 226 / 33 composite material cored aluminum stranded wire and its preparation method (226 directs the electric outer layer cross-sectional area to be 226mm 2 , 33 refers to the cross-sectional area of the composite material core is 33mm 2 )

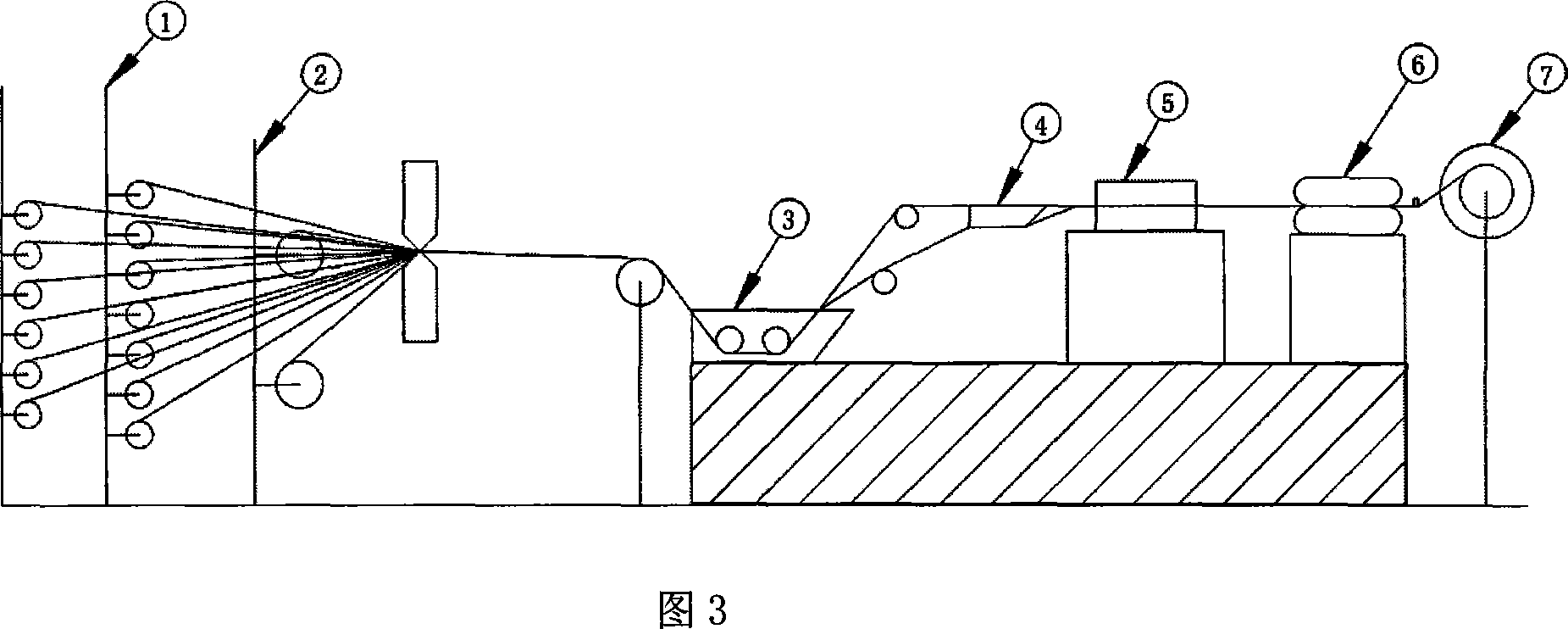

[0041] Step 1: Composite wire core preparation

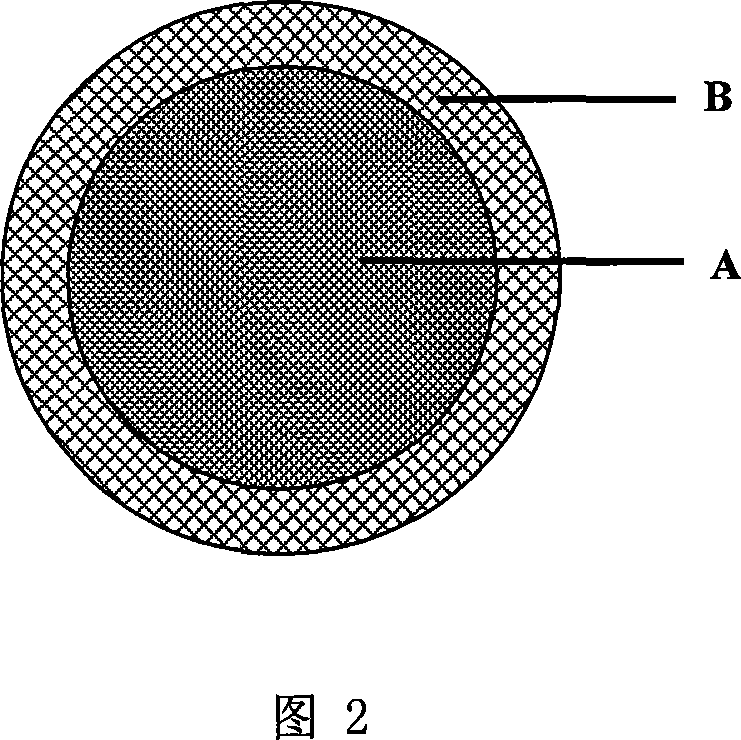

[0042] The high-strength ultra-long continuous fiber reinforced material with high-strength carbon fiber as the inner layer of the composite material core, the low elastic modulus ultra-long continuous fiber reinforced material with glass fiber as the outer layer of the composite material core, and the heat-resistant resin matrix contains rings The heat-resistant epoxy resin of structural unit, the method for producing composite wire core of the present invention is as follows:

[0043] As shown in Figure 3, the modulus is 230GPa, the tensile strength is 3300MPa, and the coefficient of thermal expansion is 1.0×10 -6 25 bundles of 12K carbon fiber (single filament diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com