Preparation method of piezoresistance type linear flexibility stress sensor

A stress sensor and stress-sensitive technology, which is applied in the measurement of the property and force of piezoelectric resistance materials, etc., can solve the problems of complex manufacturing process and high cost of carbon-based flexible stress sensors, and achieve small size, low cost, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

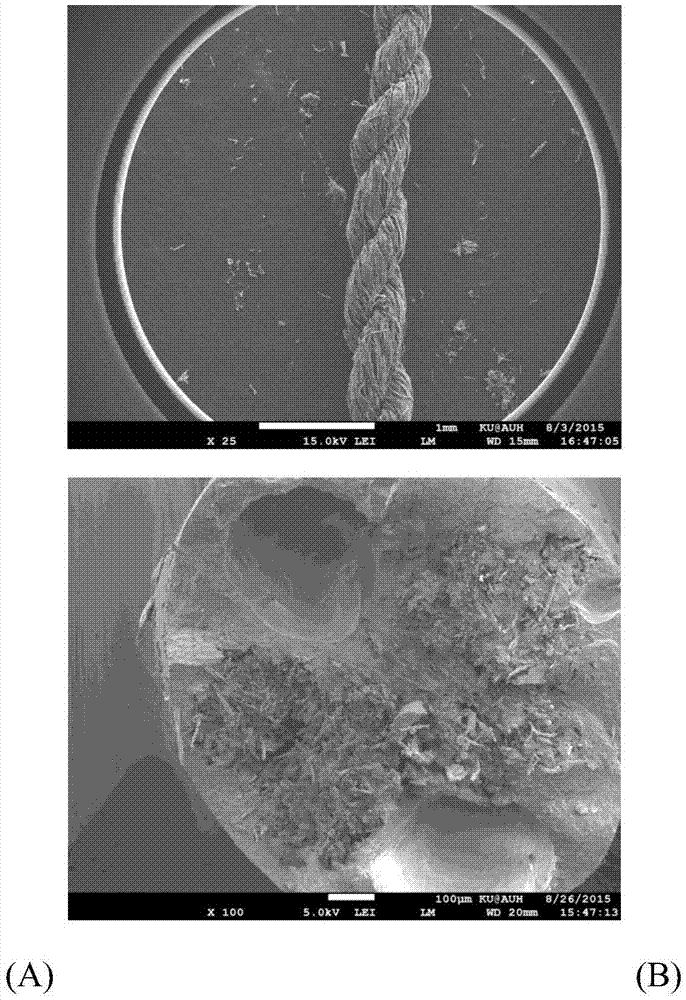

[0024] ①Thin threads woven from cotton fibers with a diameter of about 1mm were cracked at 800°C for 1 hour under the protection of nitrogen to obtain linear carbon materials.

[0025] ② Cut the linear carbon material prepared in step ① into a 3cm-long line segment, and connect the two ends of the line segment to a metal copper wire with a diameter of 0.1mm with conductive silver glue as electrodes.

[0026] ③ The surface of the line segment connected with the copper wire electrode in step ② is dipped and coated with PDMS resin (Sylgard184, DowCorning), vacuum degassed, and the resin is cured to obtain a linear flexible stress sensor.

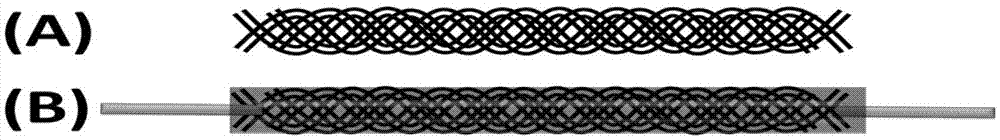

[0027] figure 1 The schematic diagram of the linear flexible stress sensor prepared for the present invention, wherein (A) indicates that the carbonized biomass line is composed of a large number of fine fibers; (B) indicates that the sensor is composed of three parts: stress-sensitive material-carbon fiber, PDMS resin and electrode . figure...

Embodiment 2

[0029] ①Thin threads woven from silk with a diameter of 0.2mm were cracked under the protection of argon at a high temperature of 700°C for 5 hours to obtain linear carbon materials.

[0030] ② Cut the linear carbon material prepared in step ① into a 0.5cm-long line segment, and connect the two ends of the line segment to a metal silver wire with a diameter of 0.1 mm as electrodes.

[0031] ③ The surface of the line segment connected with the silver wire electrode in step ② is dipped and coated with PDMS resin, vacuum degassed, and the resin is cured to obtain a linear flexible stress sensor.

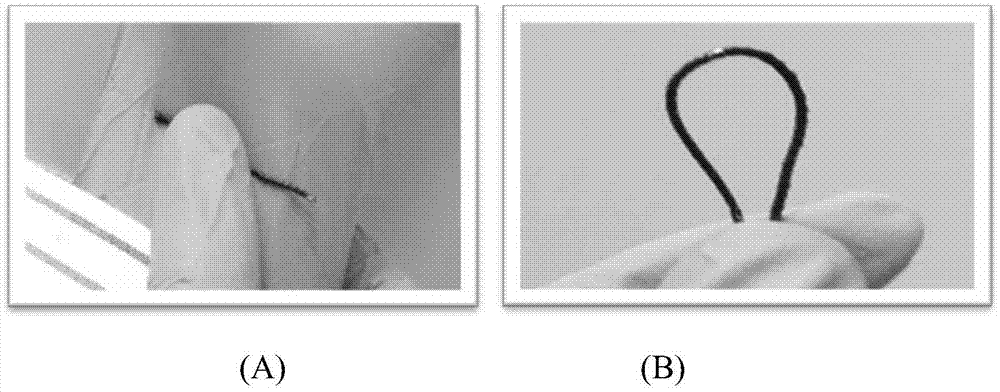

[0032] The diameter of the linear carbon material prepared by the method provided by the invention is about 0.1mm, and the conductivity is 0.09Sm -1 . The prepared linear stress sensor has good flexibility and can be bent at any angle. The sensor has good response to stress changes with a sensitivity of 55MPa -1 , The service life can reach more than 1000 cycles. Sensors can be used...

Embodiment 3

[0034] ① A thin thread woven from hemp fiber with a diameter of about 5mm is cracked at a high temperature of 1000°C for 0.5 hour under the protection of helium to obtain a linear carbon material.

[0035] ② Cut the linear carbon material prepared in step ① into a 10cm-long line segment, and connect the two ends of the line segment to a metal gold wire with a diameter of 0.03 mm as electrodes.

[0036] ③ The surface of the line segment connected with the gold wire electrode in step ② is dipped and coated with PDMS resin, vacuum degassed, and the resin is cured to obtain a linear flexible stress sensor.

[0037] The diameter of the linear carbon material prepared by the method provided by the invention is about 2.5mm, and the conductivity is 1.22Sm -1 . The prepared linear stress sensor has good flexibility and can be bent at any angle. The sensor has good response to stress changes, with a sensitivity of 28MPa -1 , The service life can reach more than 1000 cycles. Sensors ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com