Low-elasticity-modulus titanium-based jawbone implant and preparation method thereof

A low elastic modulus and implant technology, applied in the direction of bone implants, can solve the problems of complex manufacturing process and inability to complete the preparation at one time, so as to reduce the burden, alleviate the stress concentration and stress shielding problems, and the structure can be control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

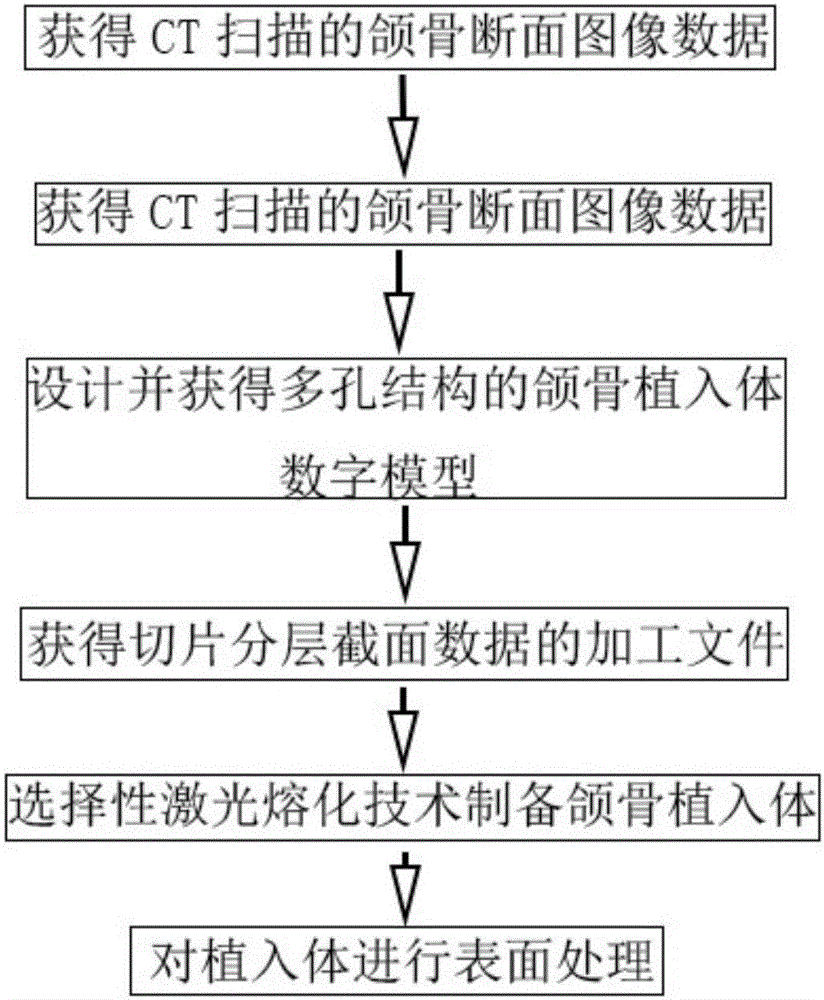

[0053] Such as figure 1 As shown, the preparation method of a low-elastic-modulus titanium-based jaw implant in this embodiment mainly includes 6 steps, namely: obtaining CT-scanned jaw cross-sectional image data, and obtaining a reconstructed three-dimensional digital model of the jaw , Design and obtain the digital model of the porous structure of the jaw implant, obtain the processing file of the sliced layered section data, prepare the jaw implant by selective laser melting technology, and perform surface treatment on the implant. Each step is described in detail.

[0054] 1. Obtain the cross-sectional image data of the jaw from the CT scan

[0055] In this embodiment, CT examination equipment is used to scan the patient's jaw, and the scanning area is from the upper edge of the orbit to 2 mm below the mandibular angle, so as to ensure the integrity of the data. The scanning voltage is 120kV, the scanning current is 170-220mA, and the scanning layer thickness is 1-1.5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com