Biomedical beta-titanium alloy material and preparation method thereof

A biomedical, titanium alloy technology, used in metal processing equipment, medical science, prostheses, etc., can solve problems such as reduced corrosion resistance, and achieve the effect of low elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

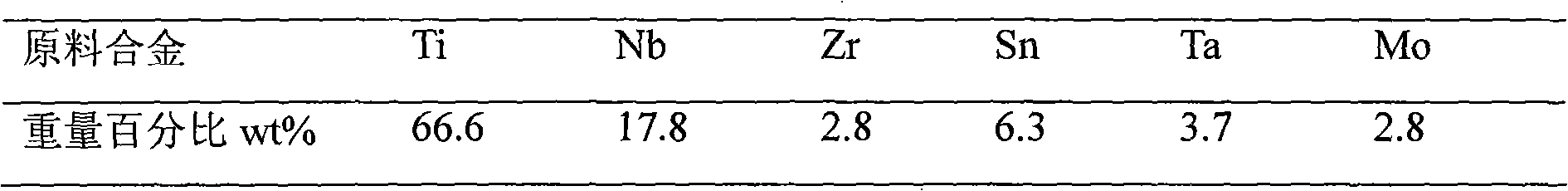

[0050] Take β-titanium alloy material, its raw material chemical composition weight percentage composition according to table 1.

[0051] Table 1 The chemical composition of the raw materials of the β-titanium alloy material in weight percentage composition

[0052]

[0053] Among them, Ti is added in the form of 0 grade sponge Ti and Nb, Mo, Ta and Ti intermediate alloy, Zr is added in the form of sponge Zr; Nb, Mo, Ta refractory metal is added in the form of its intermediate alloy with Ti.

[0054]Take 1874.0g 0 grade sponge Ti, 105.0g sponge Zr, 223.0g pure Sn, and 269.0g Ti-50Ta, 789.0g Ti-80Nb and 226.0g Ti-50Mo master alloy, and press them into electrodes by mixing them on a hydraulic press with a pressure of 150t . The electrode is smelted in a vacuum consumable electric arc furnace, and the vacuum degree before smelting starts is 8.0×10 -3 Pa, the vacuum degree during the smelting process is maintained at 5.0×10 -2 Pa ~ 1.0 Pa, and then remelted twice to obtain an ingot ...

Embodiment 2

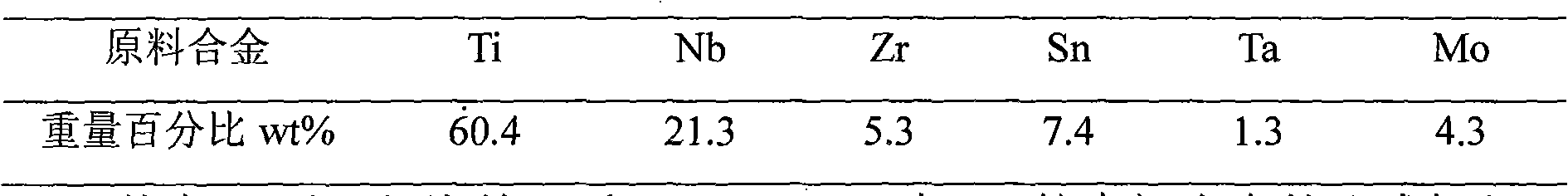

[0061] Take β-titanium alloy material, and its raw material chemical composition weight percentage composition according to Table 2.

[0062] Table 2 The chemical composition of the raw materials of β-titanium alloy materials in weight percentage composition

[0063]

[0064] Among them, Ti is added in the form of 0 grade sponge Ti and Nb, Mo, Ta and Ti intermediate alloy, Zr is added in the form of sponge Zr; Nb, Mo, Ta refractory metal is added in the form of its intermediate alloy with Ti.

[0065] Take 1654.0g grade 0 sponge Ti, 192.0g sponge Zr, 267.0g pure Sn, 98.0g Ti-50Ta, 954.0g Ti-80Nb and 332.0g Ti-50Mo master alloy, and press them into electrodes on a hydraulic press with 170t pressure after mixing. . The electrode is smelted in a vacuum consumable electric arc furnace, and the vacuum degree before smelting starts is 9.0×10 -3 Pa, the vacuum degree during the smelting process is maintained at 5.0×10 -2 Pa ~ 1.0 Pa, and then remelted twice to obtain an ingot of β-tita...

Embodiment 3

[0072] Take β-titanium alloy material, and its raw material chemical composition weight percentage composition according to Table 3.

[0073] Table 3 The chemical composition of the raw material of β-titanium alloy material in weight percentage composition

[0074]

[0075] Among them, Ti is added in the form of 0 grade sponge Ti and Nb, Mo, Ta and Ti intermediate alloy, Zr is added in the form of sponge Zr; Nb, Mo, Ta refractory metal is added in the form of its intermediate alloy with Ti.

[0076] Take 1846.0g 0 grade sponge Ti, 220.0g sponge Zr, 327.0g pure Sn, 42.0g Ti-50Ta, 1034.0g Ti-80Nb and 389.0g Ti-50Mo master alloy, and press them into electrodes by mixing them on a hydraulic press with a pressure of 170t . The electrode is smelted in a vacuum consumable electric arc furnace, and the vacuum degree before smelting is 1.0×10 -2 Pa, the vacuum degree during the smelting process is maintained at 5.0×10 -2 Pa ~ 1.0 Pa, and then remelted twice to obtain an ingot of β-titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com