Nickel-free metastable austenitic stainless steel with TRIP effect

A metastable austenite and stainless steel technology, applied in the field of austenitic stainless steel, can solve the problems of increased raw material cost, low strength, limited application range and sustainable development, and achieve reduced raw material cost, increased strength, and broad room temperature strength range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Stainless steel is smelted by non-vacuum induction furnace single smelting method, die-cast into ingots, forged and hot-rolled into 3.00mm thick hot-rolled plates. Solution annealing, the treatment temperature is 1000~1100℃. The room temperature mechanical properties of the obtained nickel-free metastable austenitic stainless steel were tested, and the room temperature mechanical properties are shown in Table 1.

[0040] Table 1 Tensile properties of hot-rolled and hot-rolled annealed plates at room temperature

[0041]

[0042] The chemical composition of the nickel-free metastable austenitic stainless steel in this embodiment is shown in Table 5.

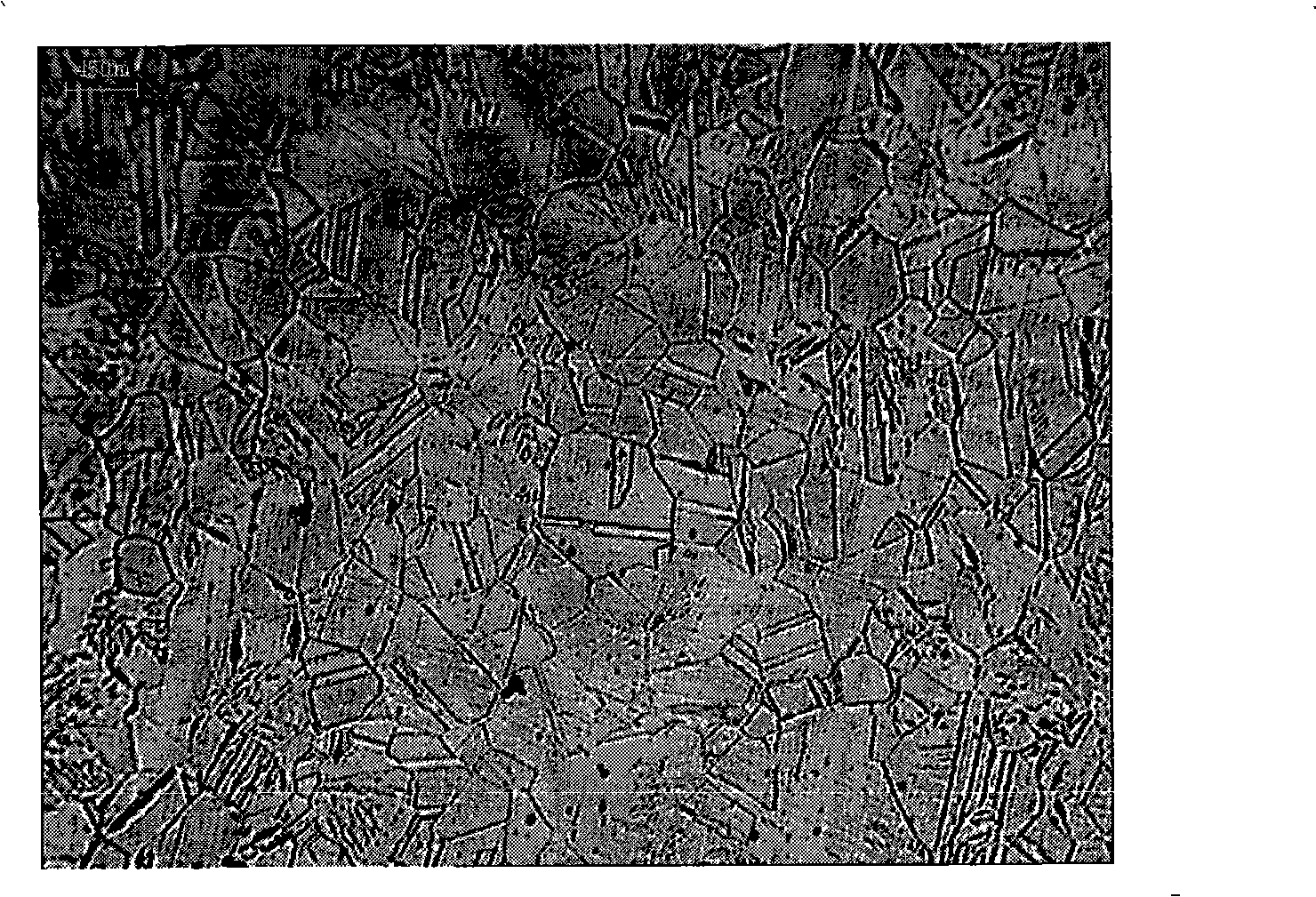

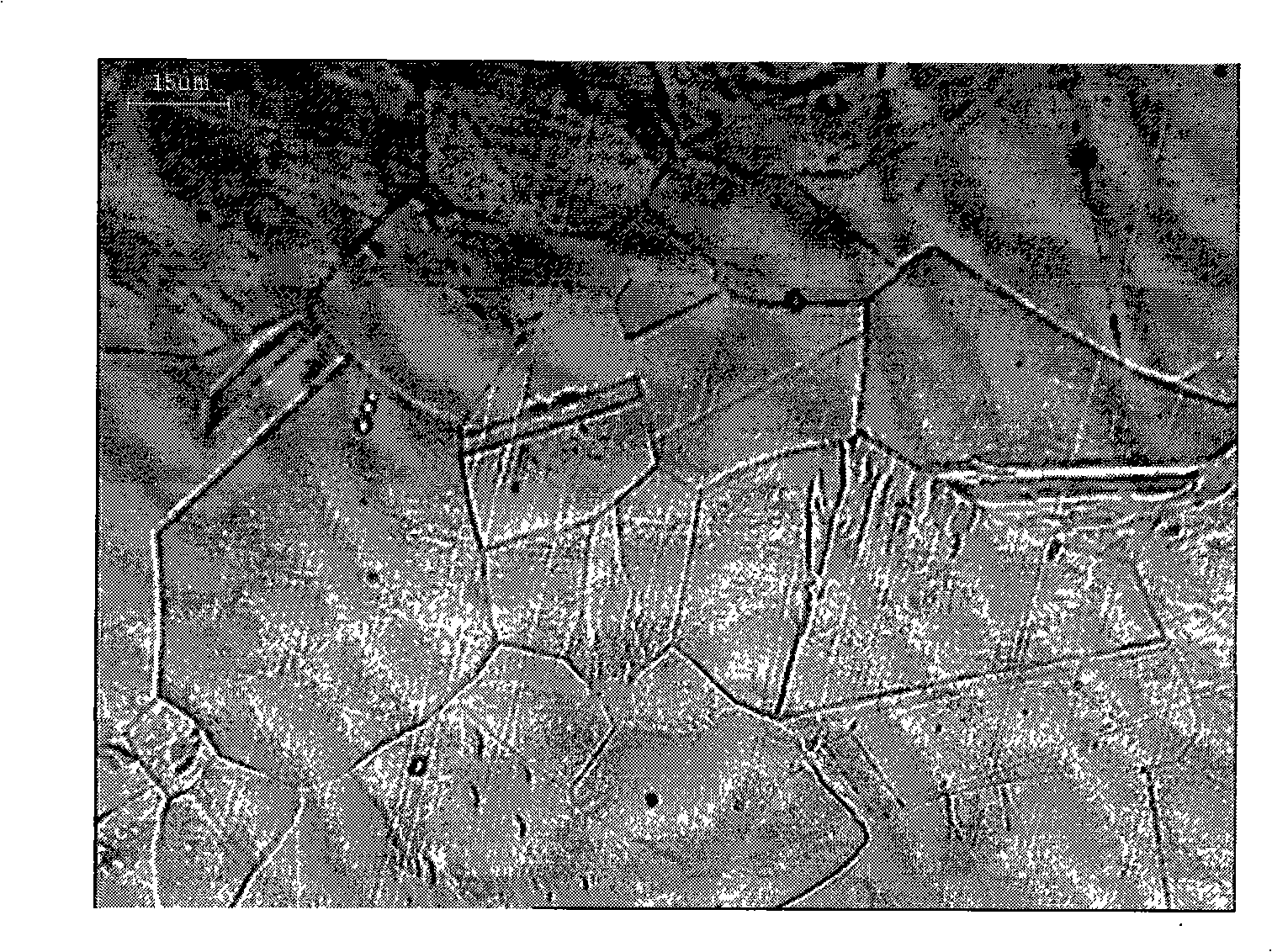

[0043] The room temperature microstructure of the austenitic stainless steel in this embodiment after solution annealing is shown in figure 2 and image 3 ,from figure 2 and image 3 It can be seen that this stainless steel is a single-phase austenite structure, and there are many twine crystals.

Embodiment 2

[0045]Adopt electric arc furnace and AOD two-step method to smelt stainless steel, continuous casting into slab, hot rolling into 3.00mm thick hot-rolled plate. After intermediate annealing, cold rolling with a reduction of 50%. The mechanical properties at room temperature of the obtained nickel-free metastable austenitic stainless steel in the cold-rolled solution annealed state were tested, and the mechanical properties at room temperature are shown in Table 2. The chemical composition of the nickel-free metastable austenitic stainless steel in this embodiment is shown in Table 5.

[0046] Table 2 Tensile properties of cold-rolled solution-annealed sheets at room temperature

[0047]

Embodiment 3

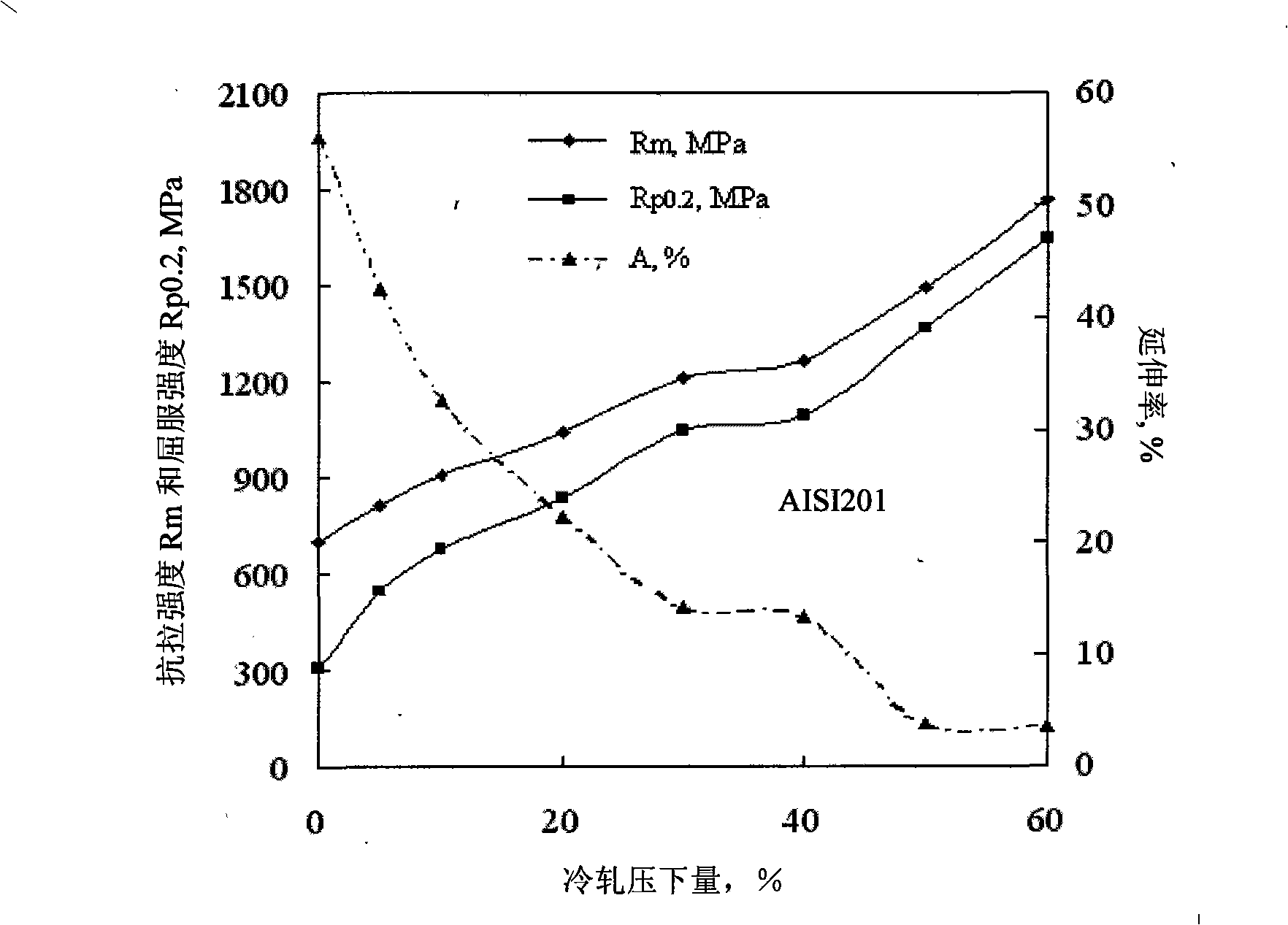

[0049] The stainless steel is smelted by the electric arc furnace single smelting method, continuously cast into slabs, and hot-rolled into 3.00mm thick hot-rolled plates. After intermediate annealing, cold rolling was carried out according to reductions of 7.27%, 11.53%, 15.54%, 20.00%, 22.47%, 28.89%, 29.55%, and 50%, respectively. The mechanical properties of the obtained nickel-free metastable austenitic stainless steel cold-rolled at room temperature are tested. The mechanical properties at room temperature are shown in Table 3. The tensile mechanical properties at room temperature are shown in Table 3. Image 6 .

[0050] Table 3 Mechanical properties of cold-rolled sheets at different reductions

[0051]

[0052] The chemical composition of the nickel-free metastable austenitic stainless steel in this embodiment is shown in Table 5.

[0053] The cold-rolled microstructure of the austenitic stainless steel of this embodiment is shown in Figure 4 and Figure 5 ,fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com