Patents

Literature

76results about How to "Meet the needs of various working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

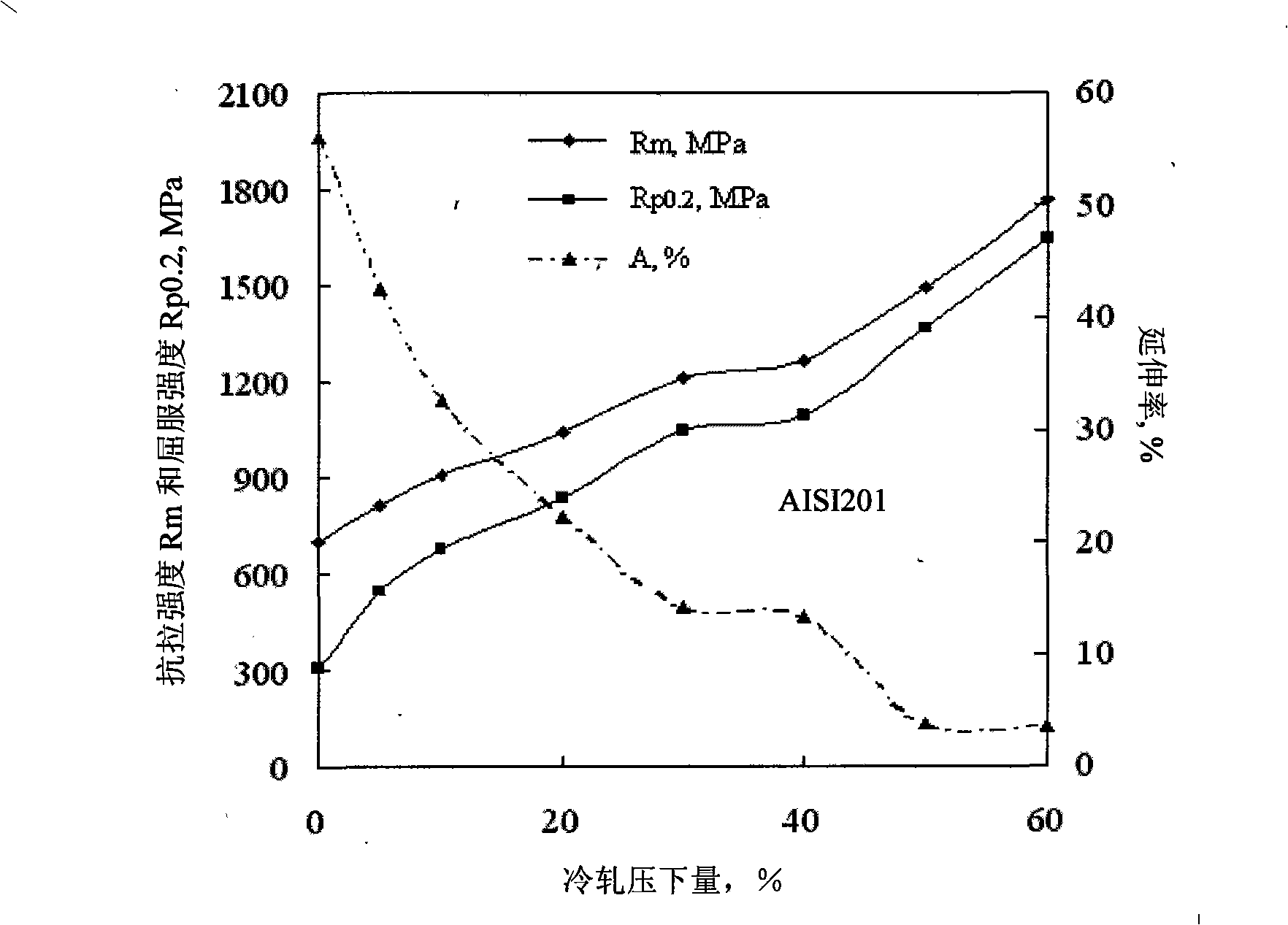

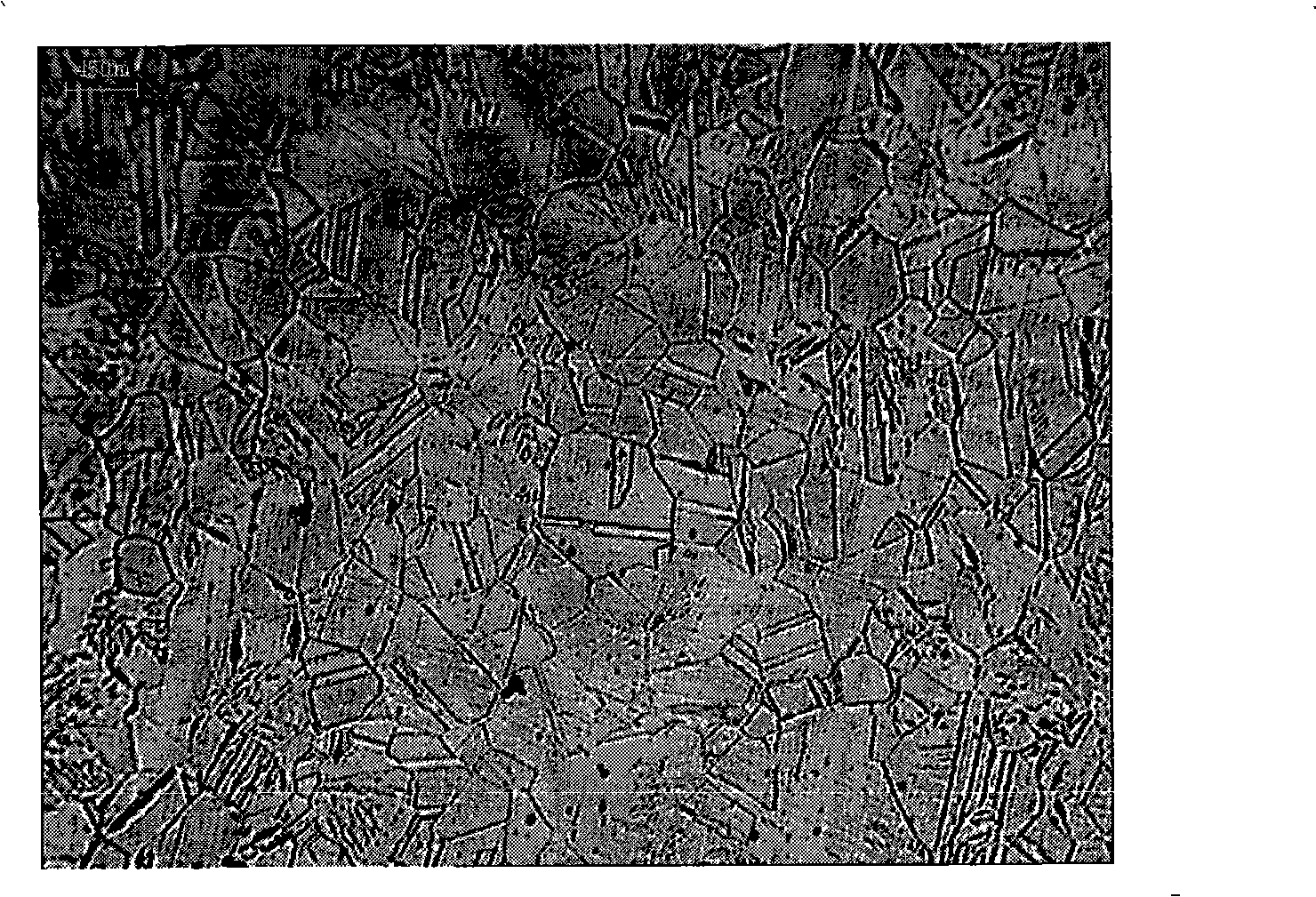

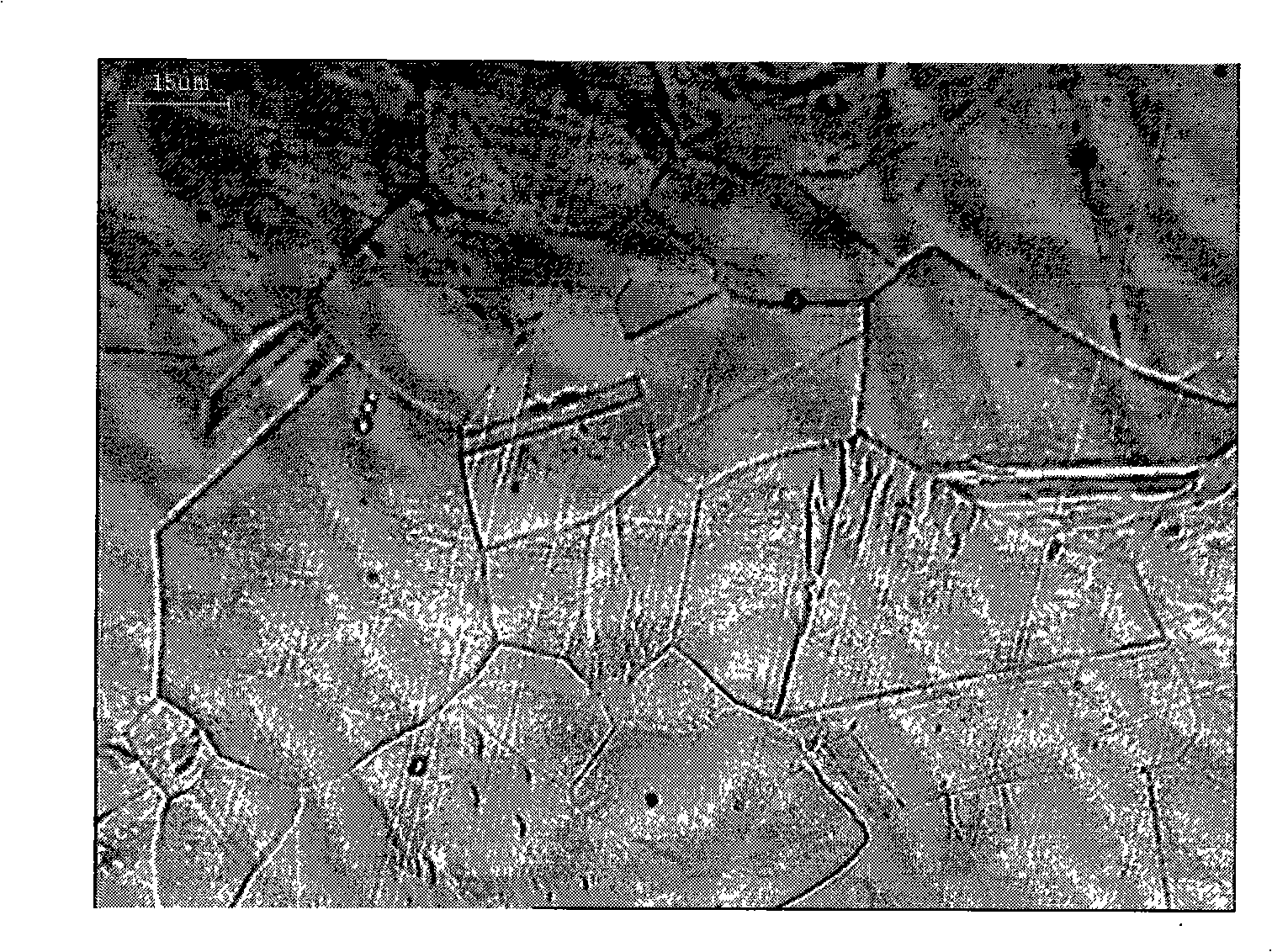

1000MPa grade nickel-saving type metastable austenite stainless steel

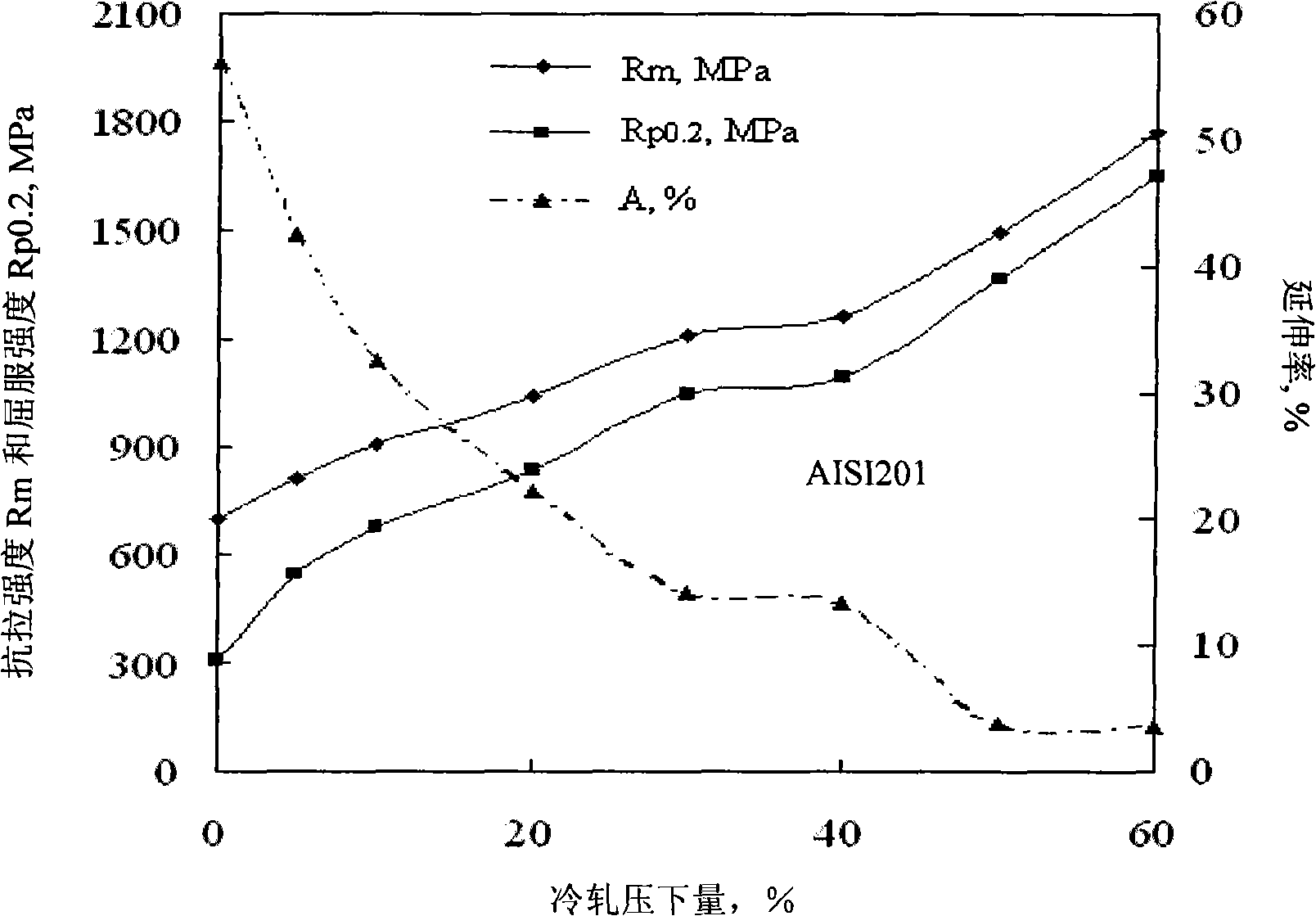

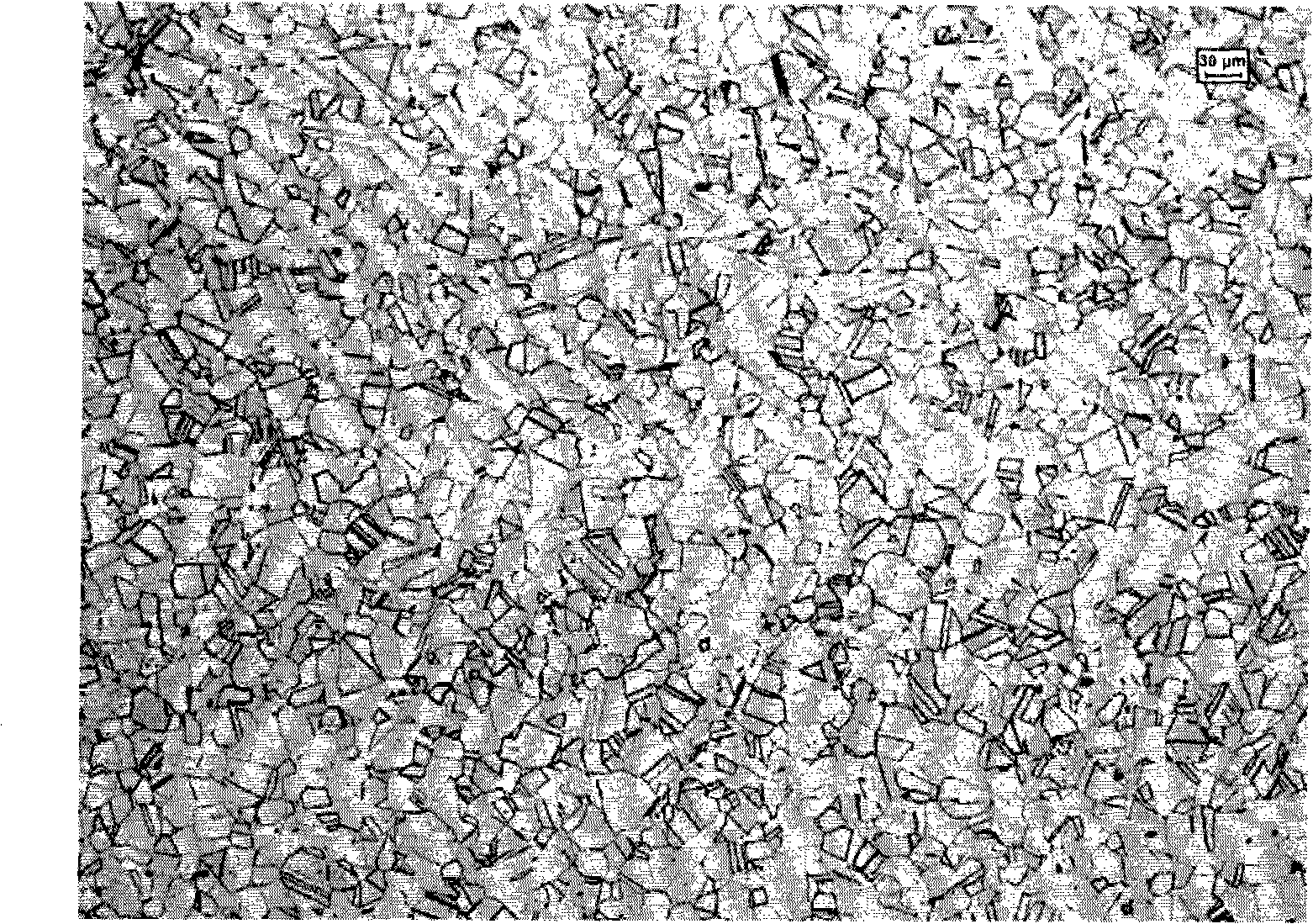

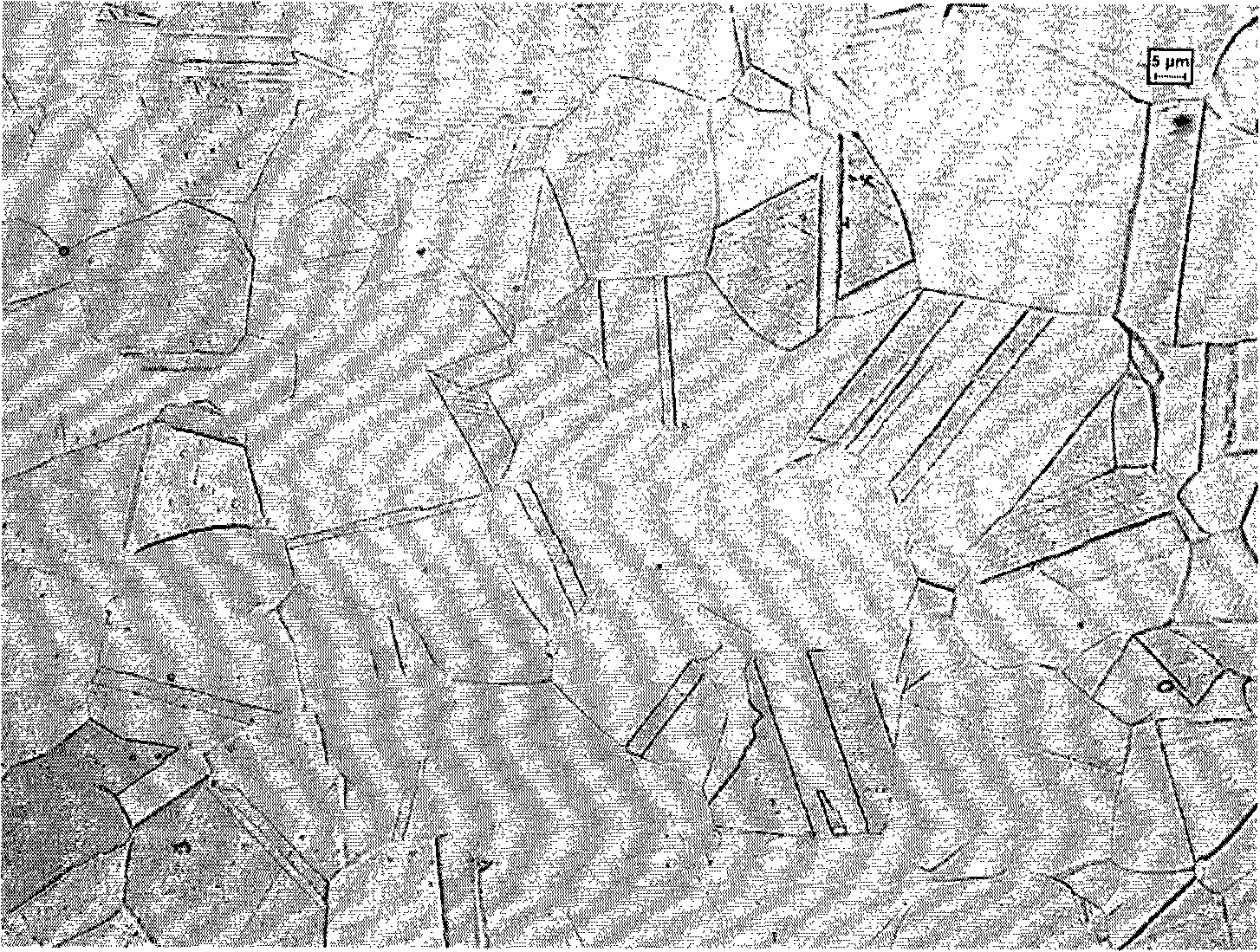

The invention provides 1000MPa class nickel-saving type metastable austenite stainless steel. The chemical components of the nickel-saving type metastable austenite stainless steel of the invention calculated by weight percentage include 0.06 to 0.15 percent of C, less than 1 percent of Si, 8 to 10 percent of Mn, 15 to 17 percent of Cr, 0.5 to 1.2 percent of Ni, 0.15 to 0.30 percent of N, less than 0.03 percent of P, less than 0.02 percent of S and the rest are Fe and unavoidable impurities. The room temperature yield stress of a cold processing state of the invention can reach 1250MPa, the anti-tension intensity can reach 1460MPa and the average room temperature extension rate can be maintained to be 16.8 percent. Under different states, the room temperature yield stress of the material is 370 to 1250MPa and the room temperature anti-tension intensity is 860 to 1460MPa. The room temperature anti-tension intensity of a cold-rolling solid solution state can reach over 1000MPa and the extension rate is larger than 40 percent. The invention has high intensity and excellent plasticity. The excellent room temperature mechanical performance of the 1000MPa class nickel-saving type metastable austenite stainless steel of the invention can be remarkably distinguished from the normal metastable austenite stainless steel and is suitable for weak-corrosion environments such as the fields of traffic, construction and hardware, etc., and can partially replace the austenitic stainless steels with high nickel contents like AISI304, AISI301 and AISI201, etc., so as to save the expensive metal nickel.

Owner:BAOSHAN IRON & STEEL CO LTD

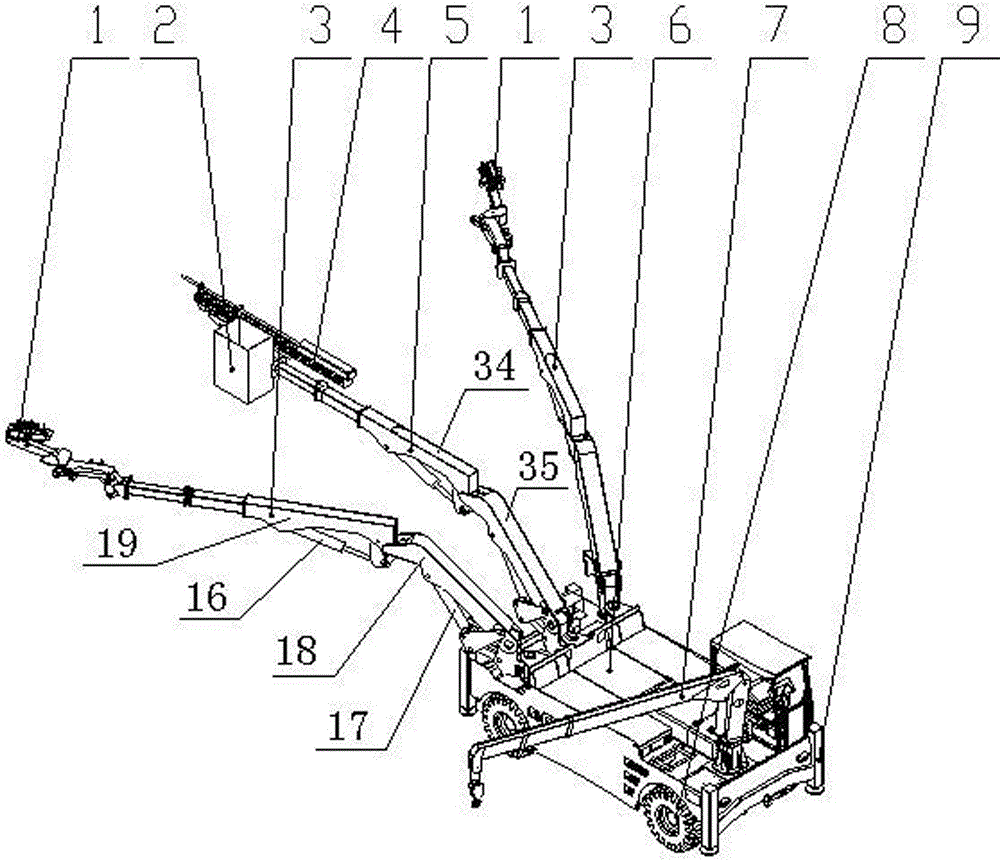

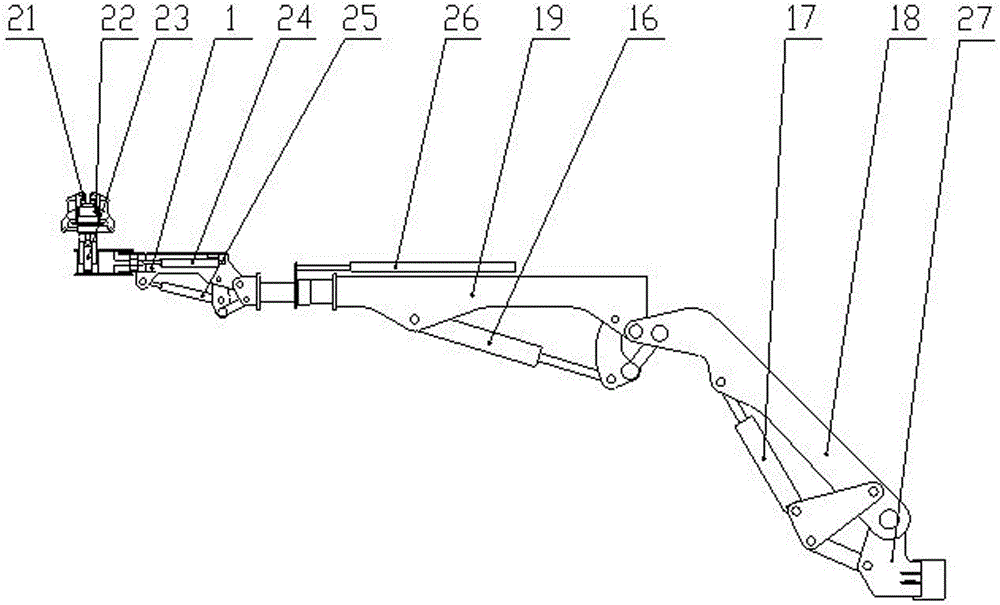

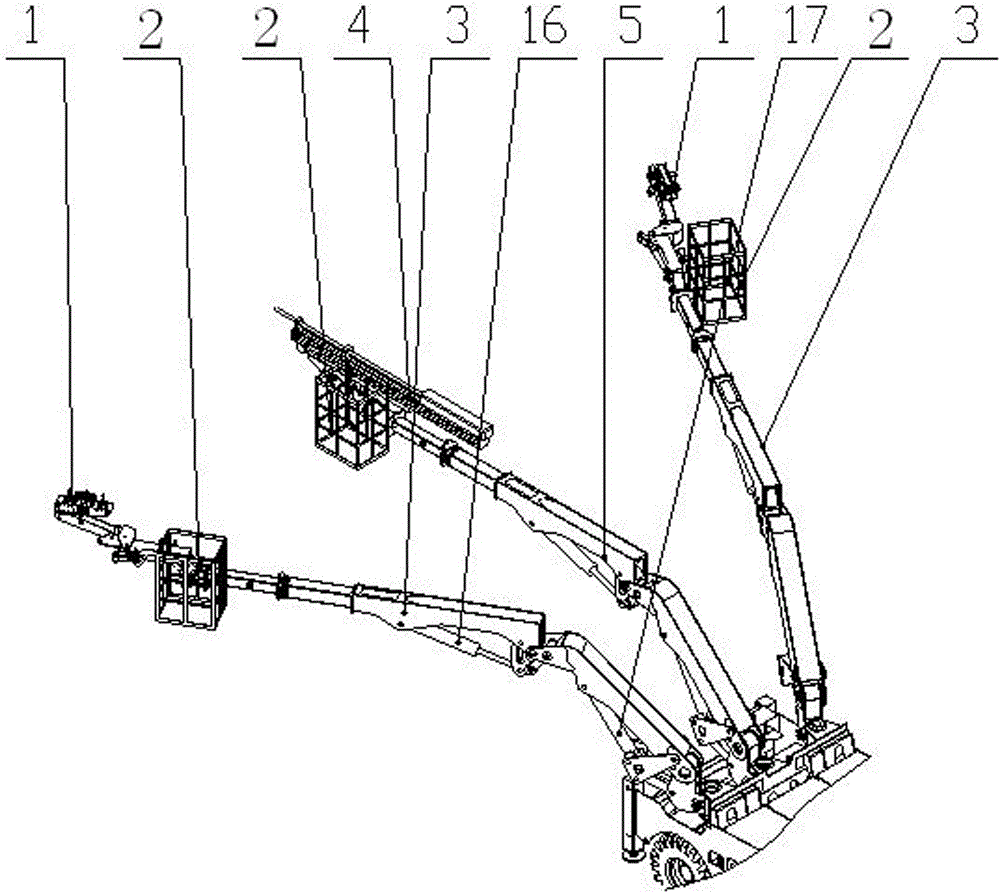

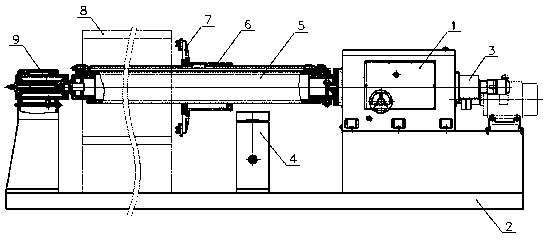

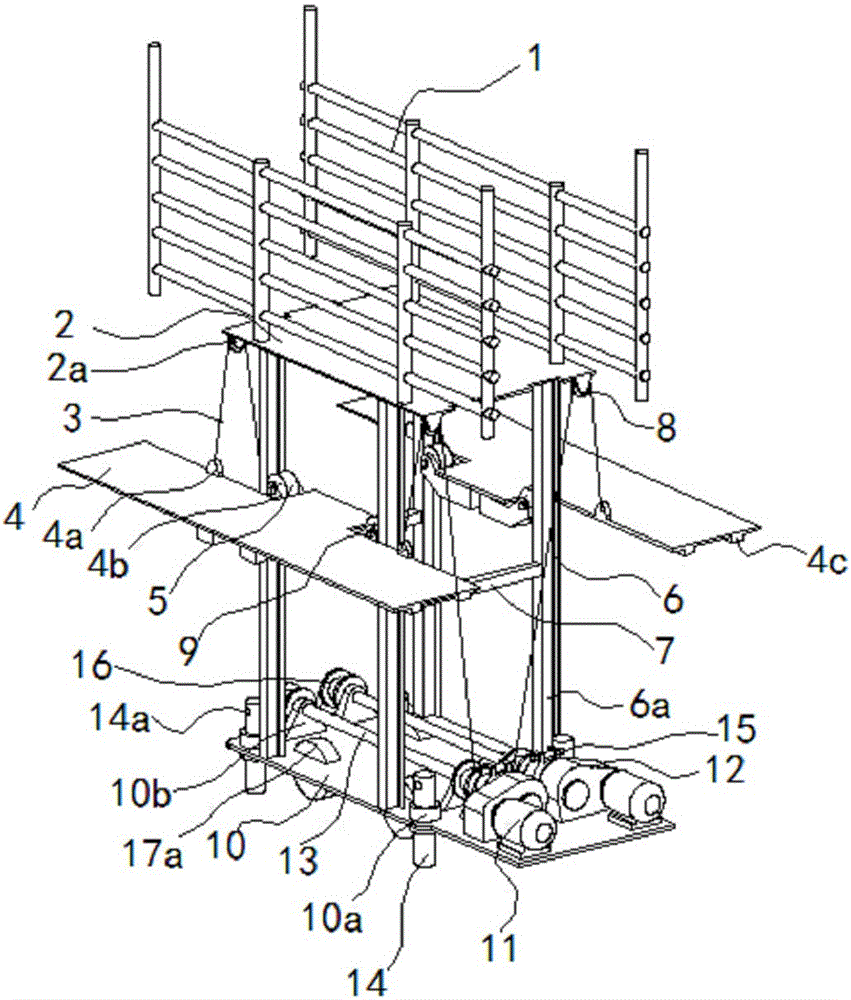

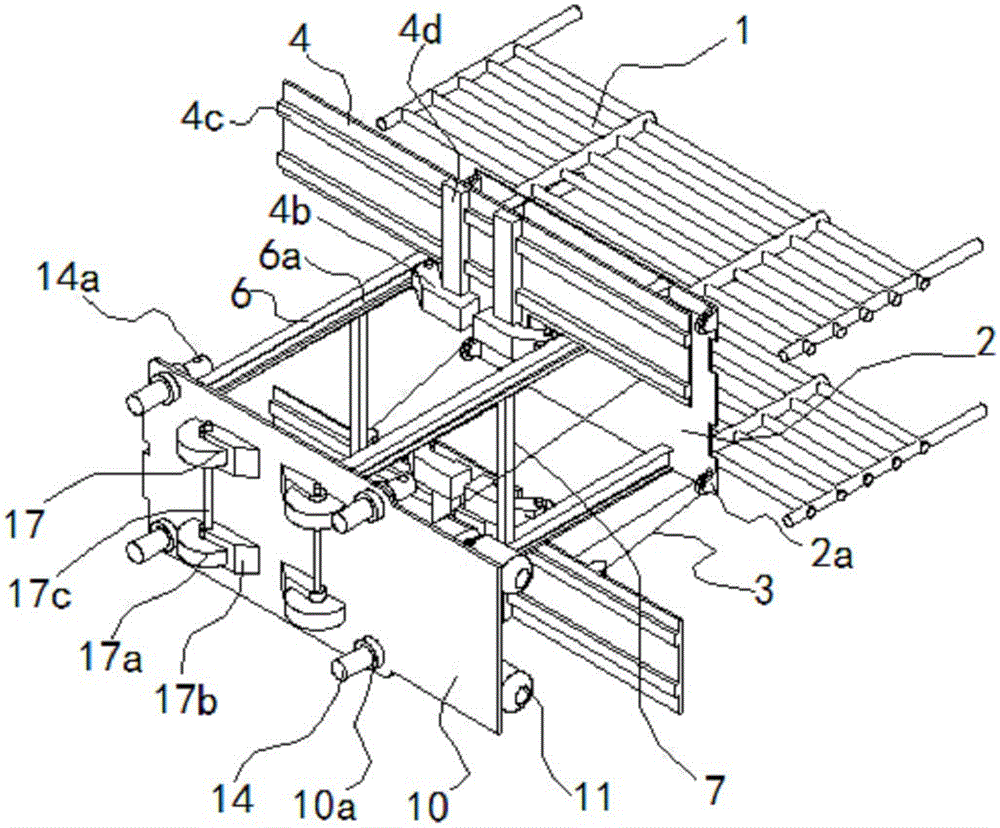

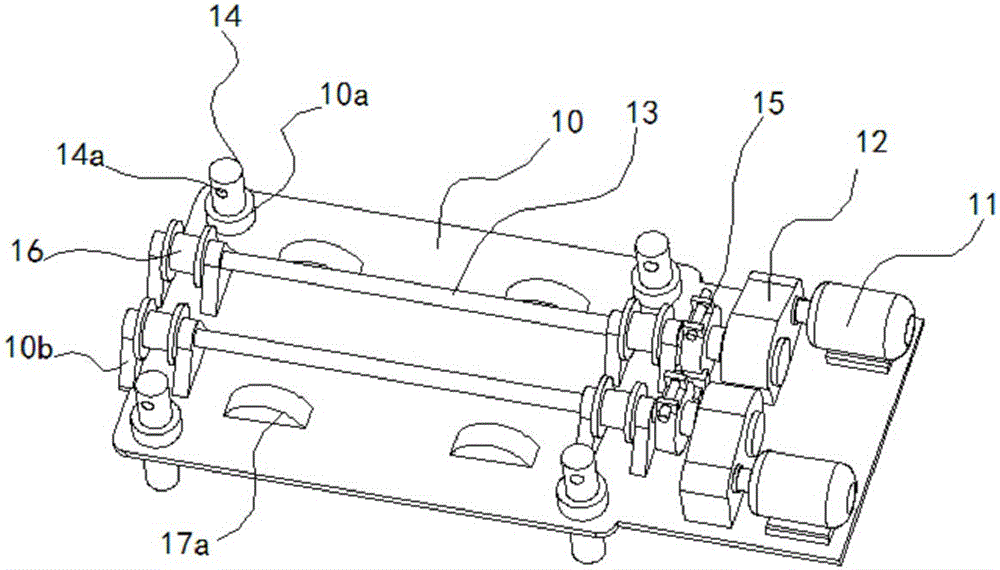

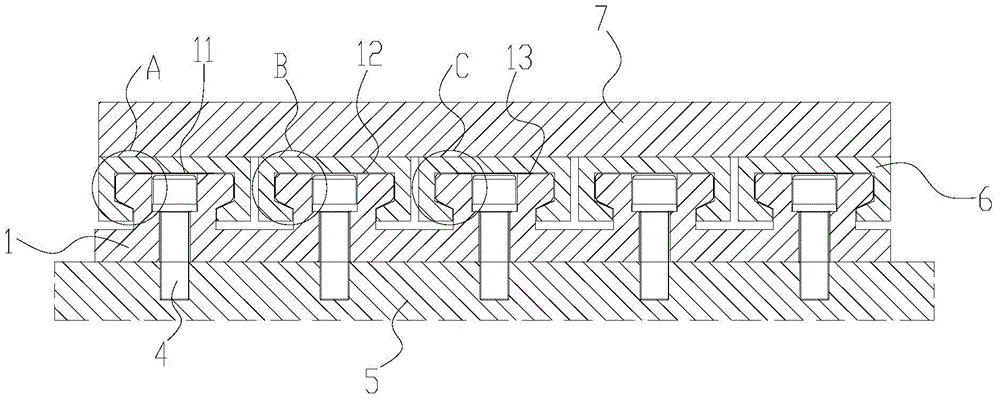

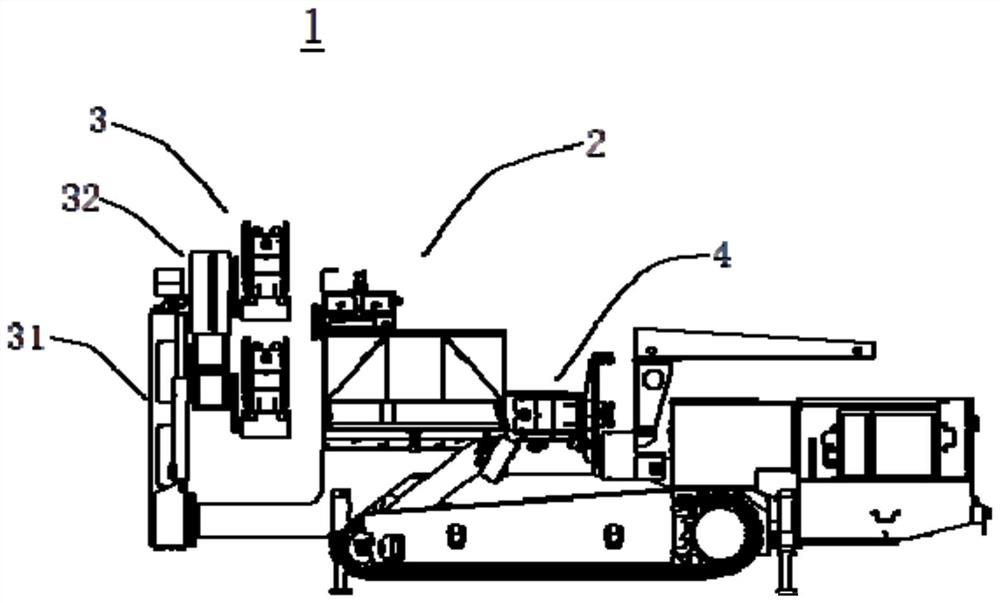

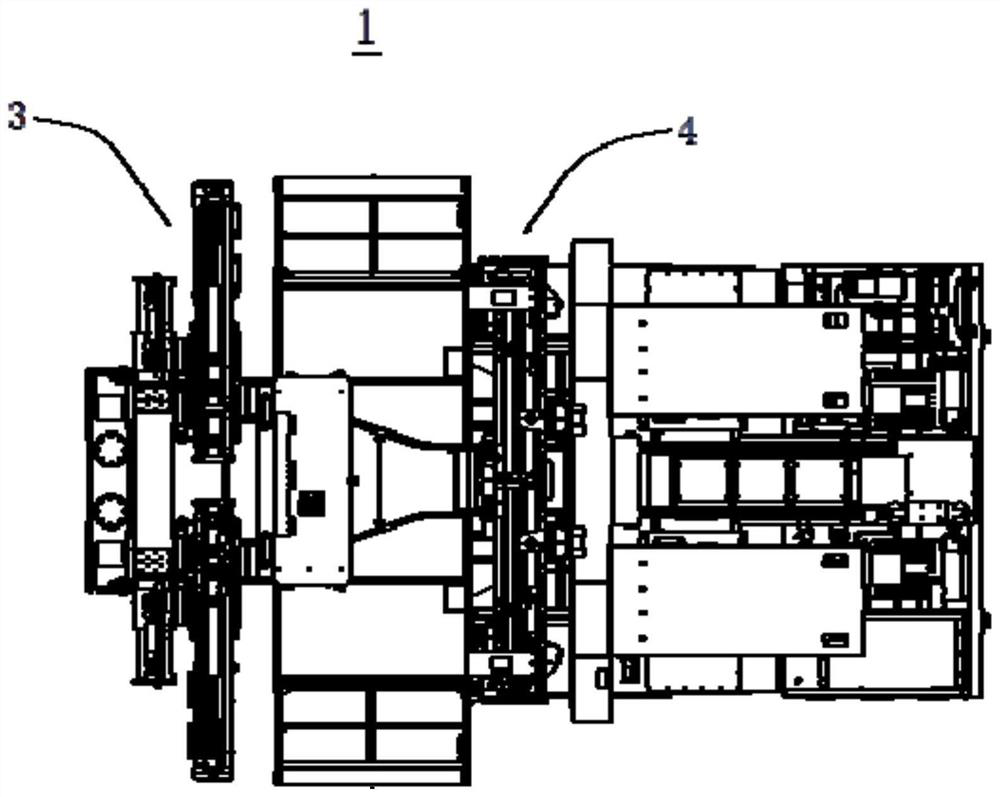

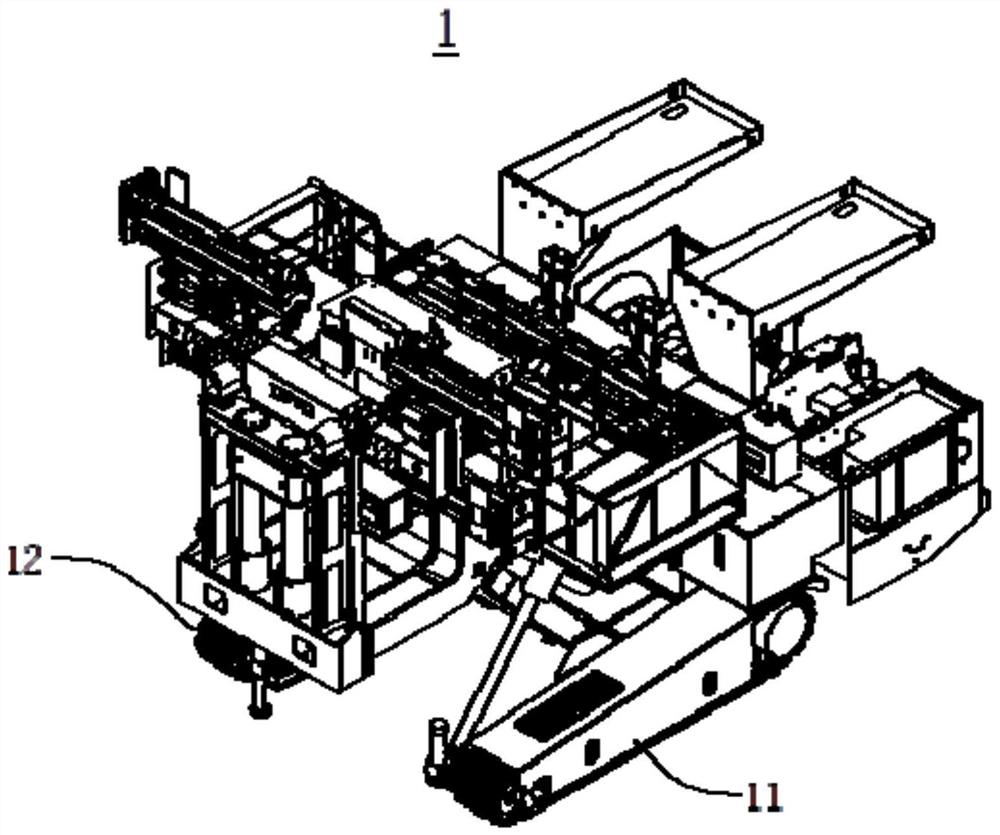

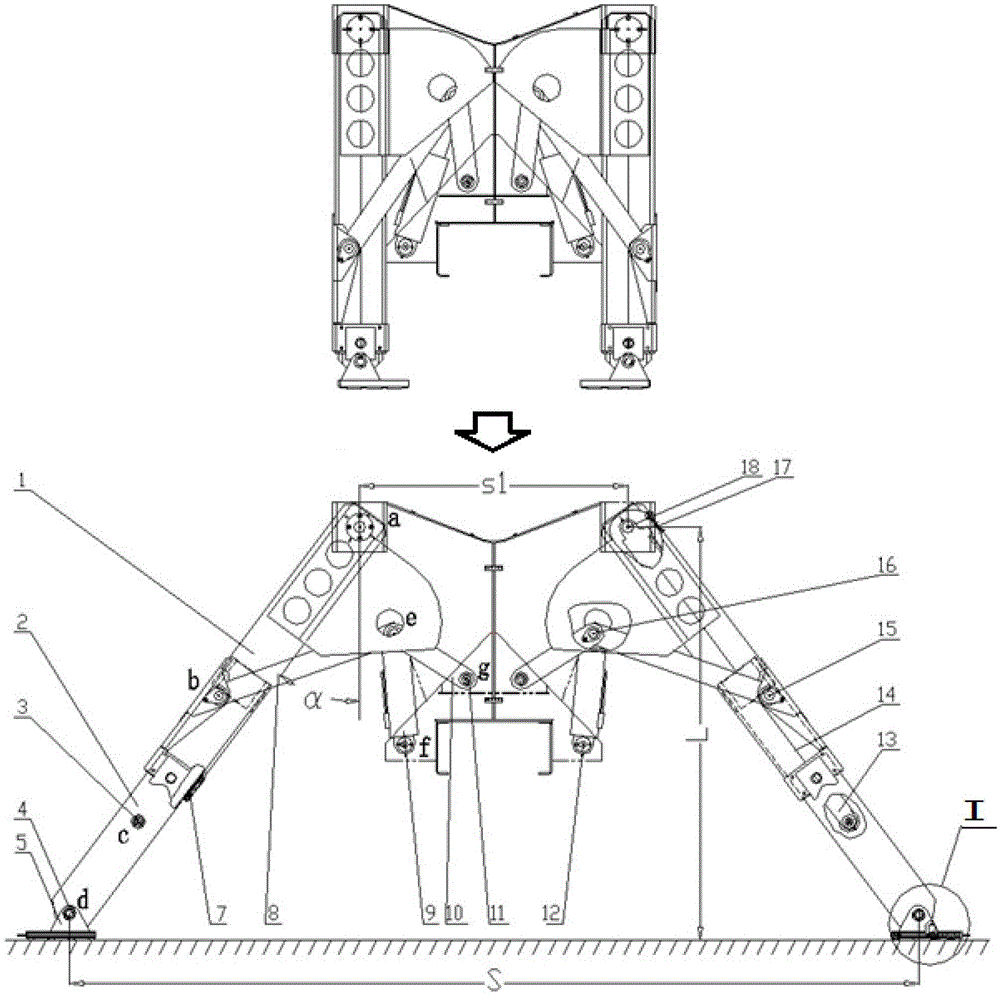

Multifunctional arching drill jambo

ActiveCN106401476AMeet the needs of various working conditionsUnderground chambersDerricks/mastsRobotic armButt joint

A multifunctional arching drill jambo comprises a main machine platform (6). The bottom of the main machine platform is provided with a chassis (8); the two sides of the main machine platform are provided with supporting legs (9); the front portion of the main machine platform is provided with a truck with crane (7) through a slewing bearing; the rear portion of the main machine platform is provided with two parallel mechanical arm racks (3) with mechanical arms (1) and a drill arm rack (5) with a rock drill system (4); the drill arm rack is arranged between the two mechanical arm racks; and the mechanical arms (1) and the rock drill system (4) are provided with quick-dismounting baskets (2). According to the multifunctional arching drill jambo, arch construction can be conducted while three kinds of steps of a tunnel are excavated, all the construction procedures of arch butt joint, bar-mat reinforcement hanging, cross rib welding, anchor rod installation and advance small pipe support can be achieved, and the efficiency of the multifunctional arching drill jambo is far higher than that of manpower.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

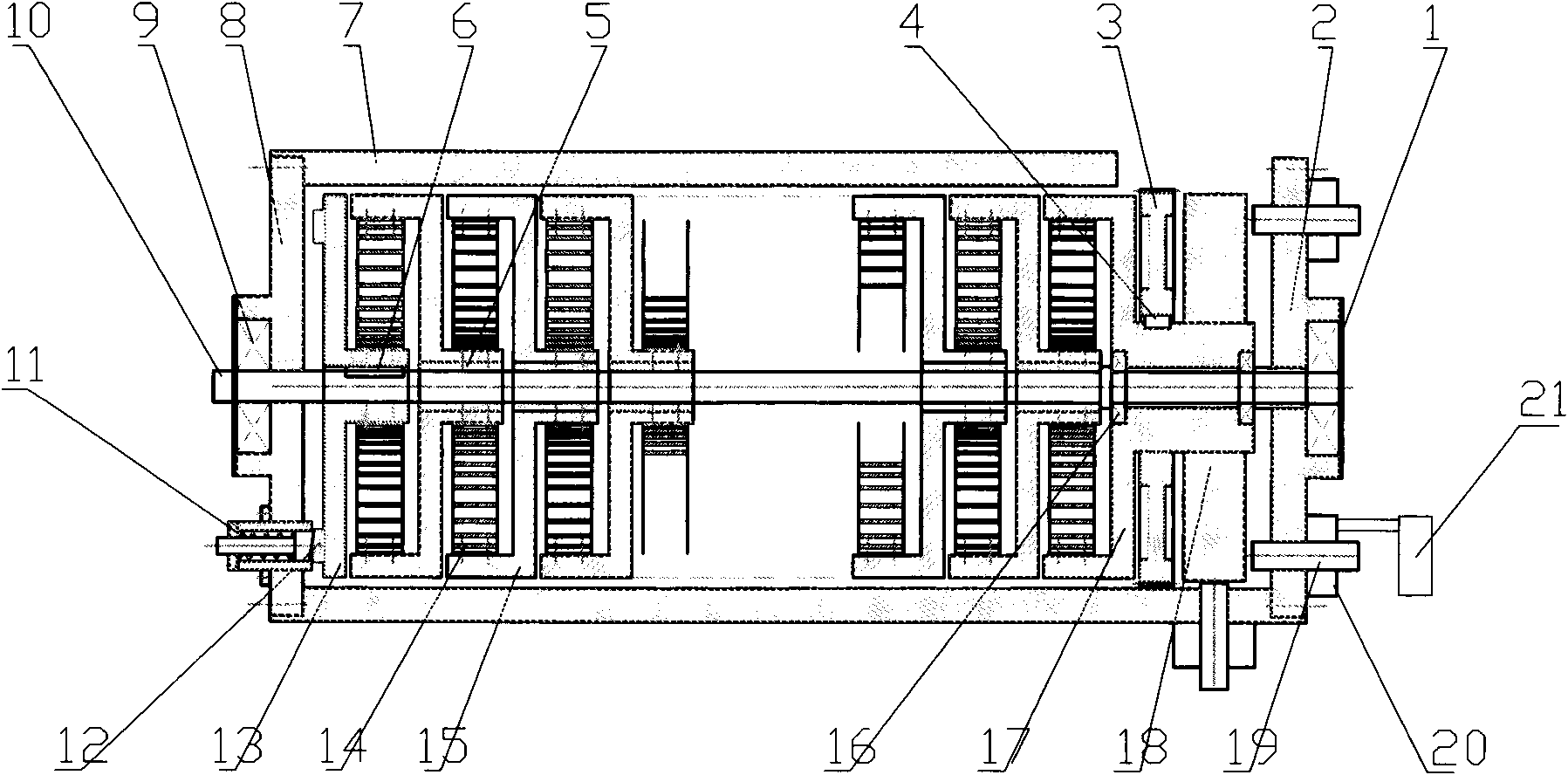

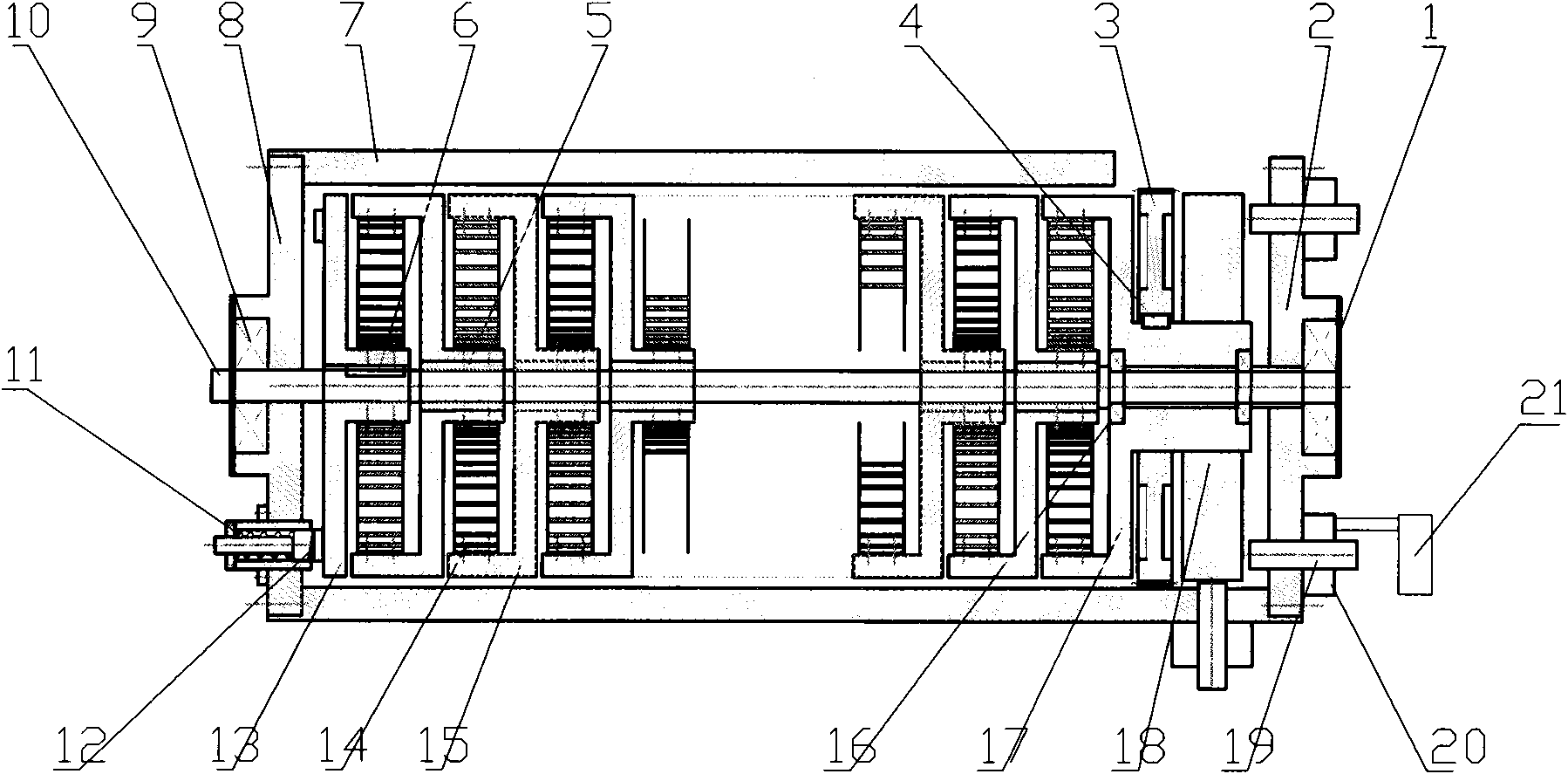

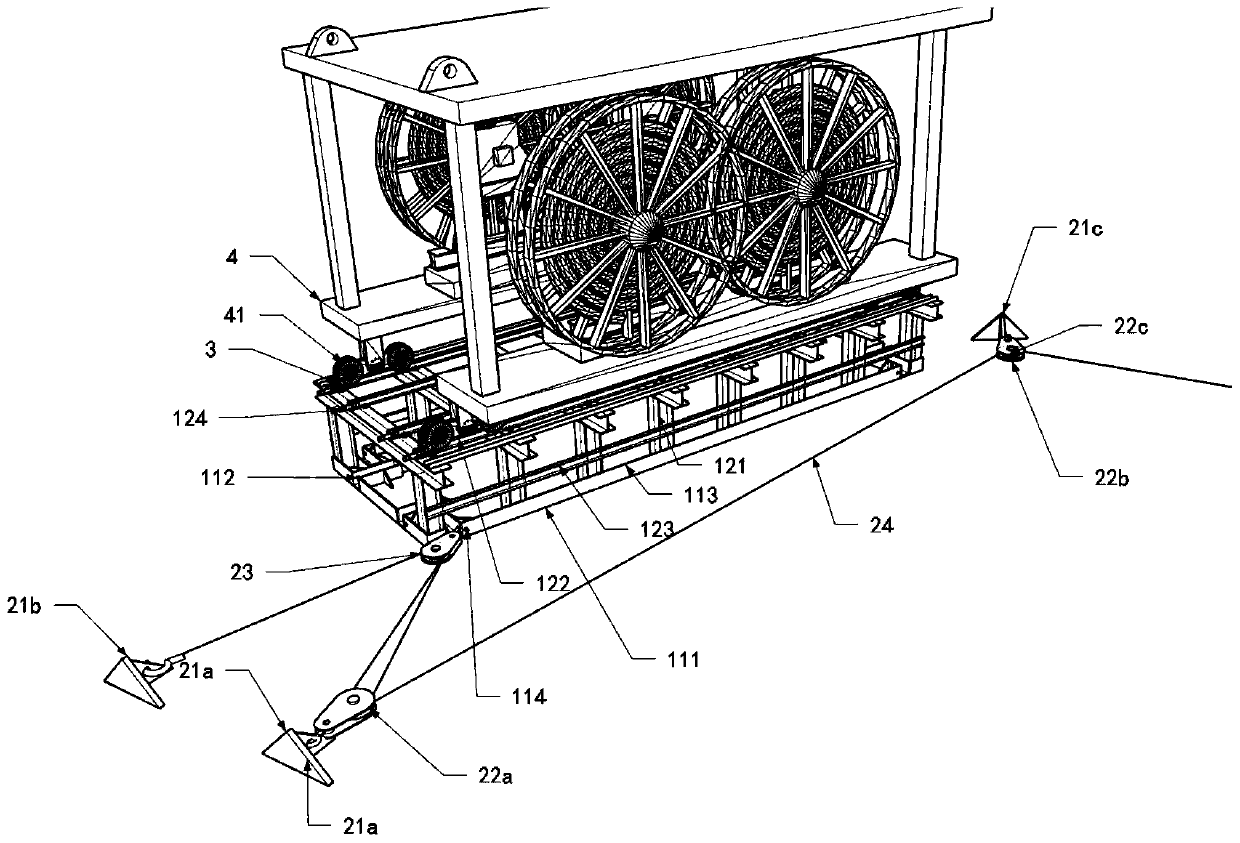

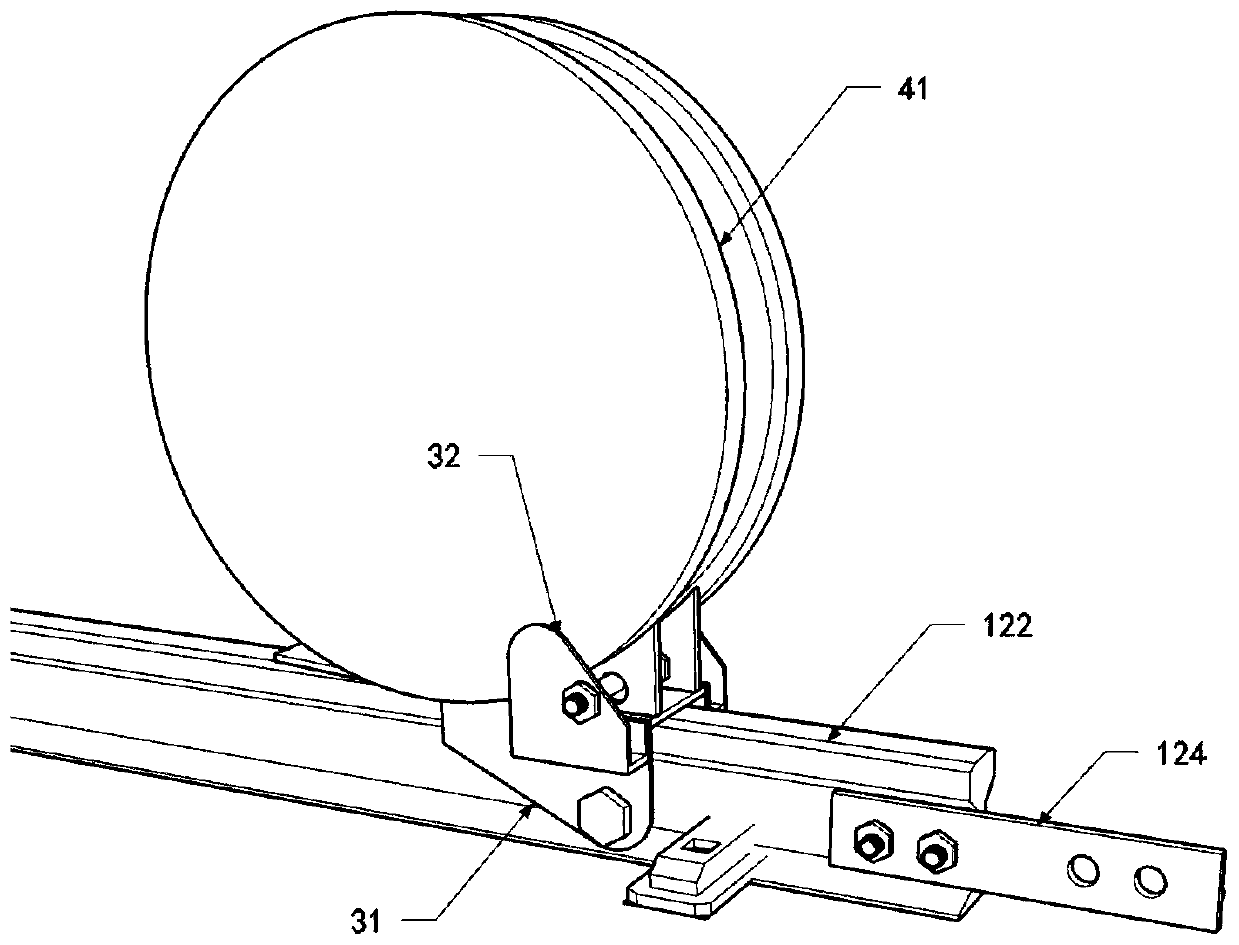

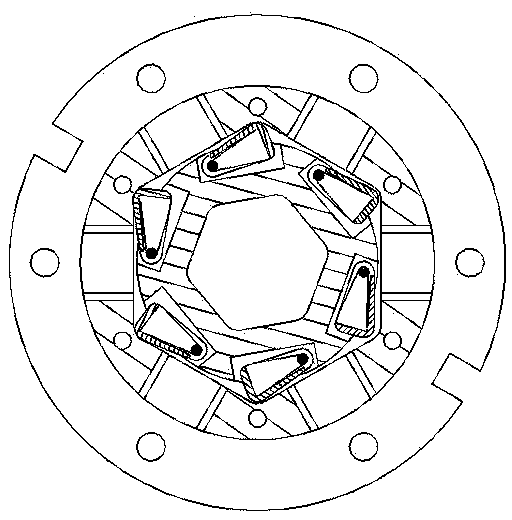

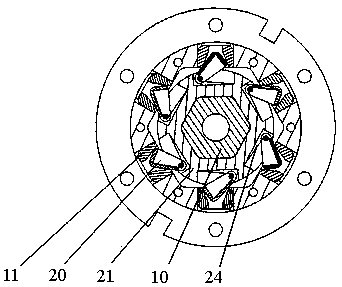

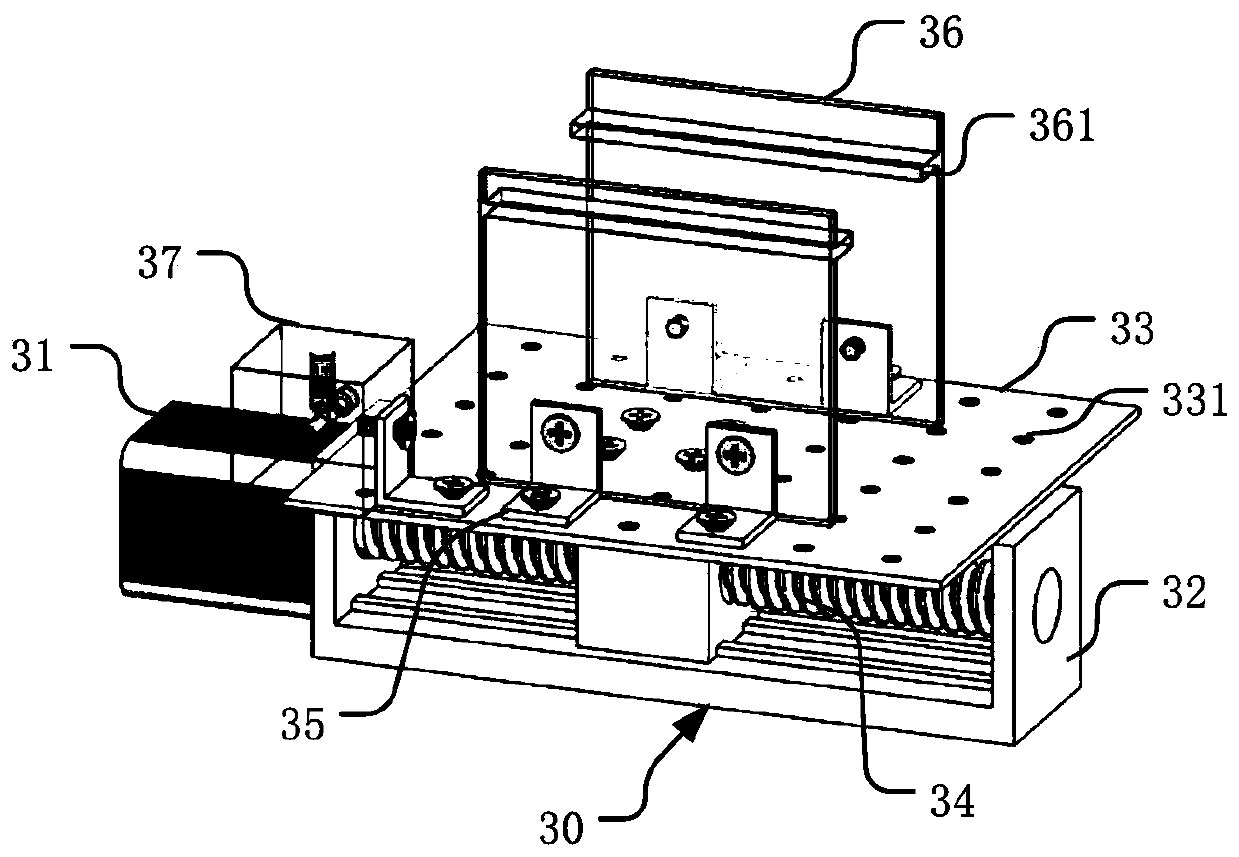

Environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device

InactiveCN101936269ANo pollution in the processNo pollutionSpring motorMachines/enginesDrive wheelEngineering

The invention relates to an environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device. The environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device comprises a box body, an input part, an energy-storing part and an output part, wherein the input part consists of an input shaft and an input driving wheel; the energy-storing part is formed by connecting n clockwork energy-storing units in series; and the output part comprises an output gear and an energy-releasing speed governor. Compared with the priorart, the environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device has the advantages that: a plurality of clockworks are used for storing energy so the energy-storing capacity is large and the defect of deficient energy-storing capacity by a single clockwork is overcome; an energy-releasing speed governor is adopted, so the energy can be released according to the rotating speed required by the load and the requirements of various working conditions can be met; the environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device is simple in structure, easy in manufacturing and low in cost and has a wide application range; and the device does not have any pollution to environments and is a clean energy-storing device.

Owner:李颖超

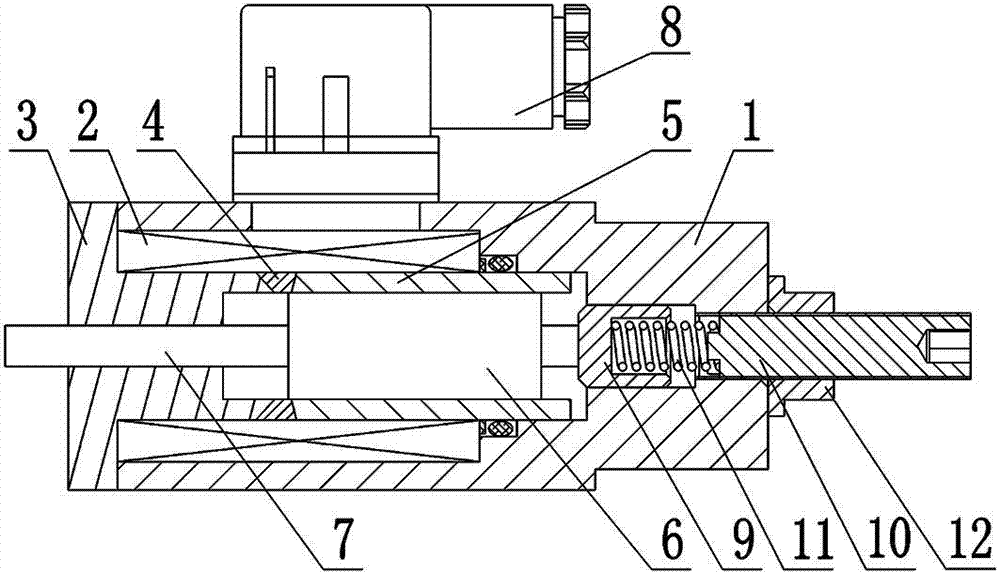

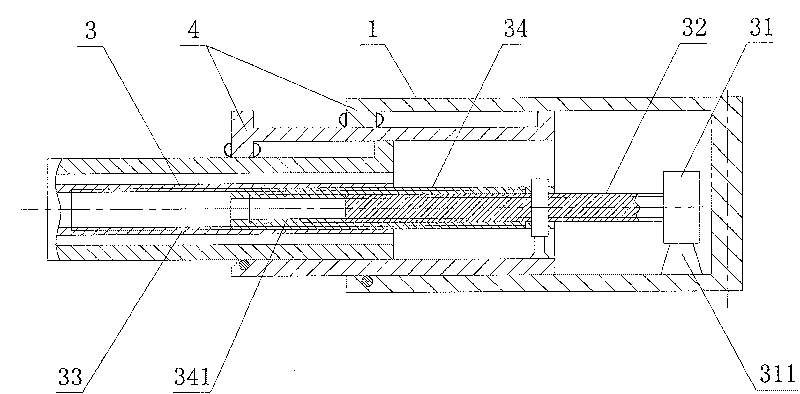

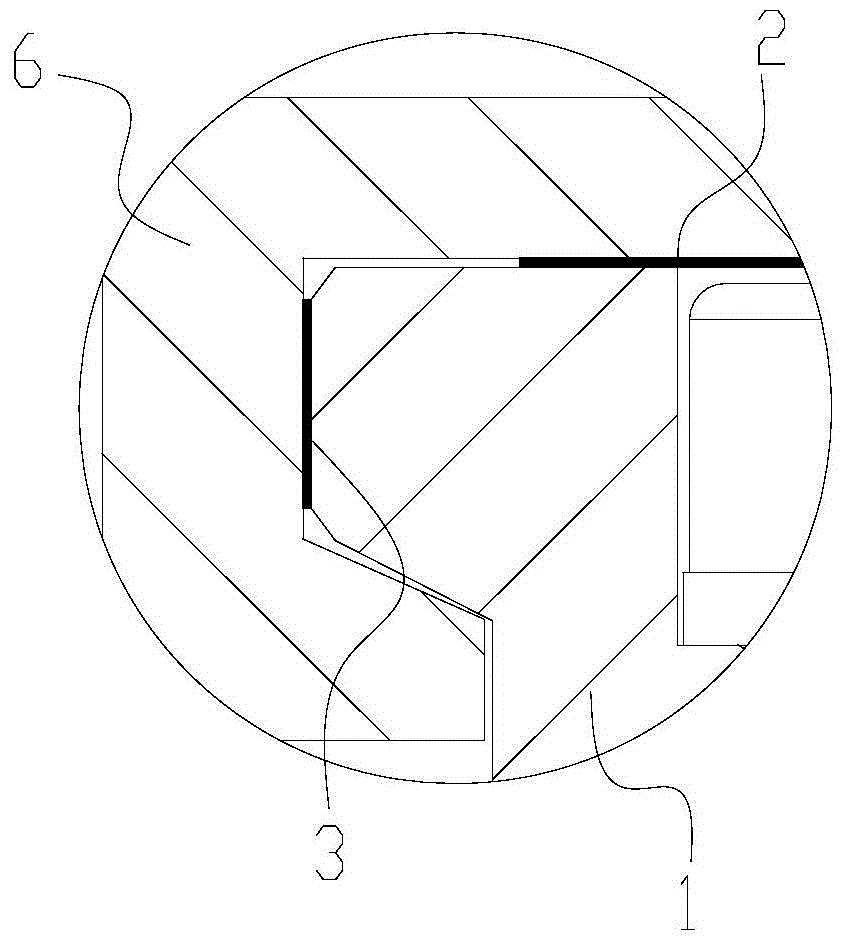

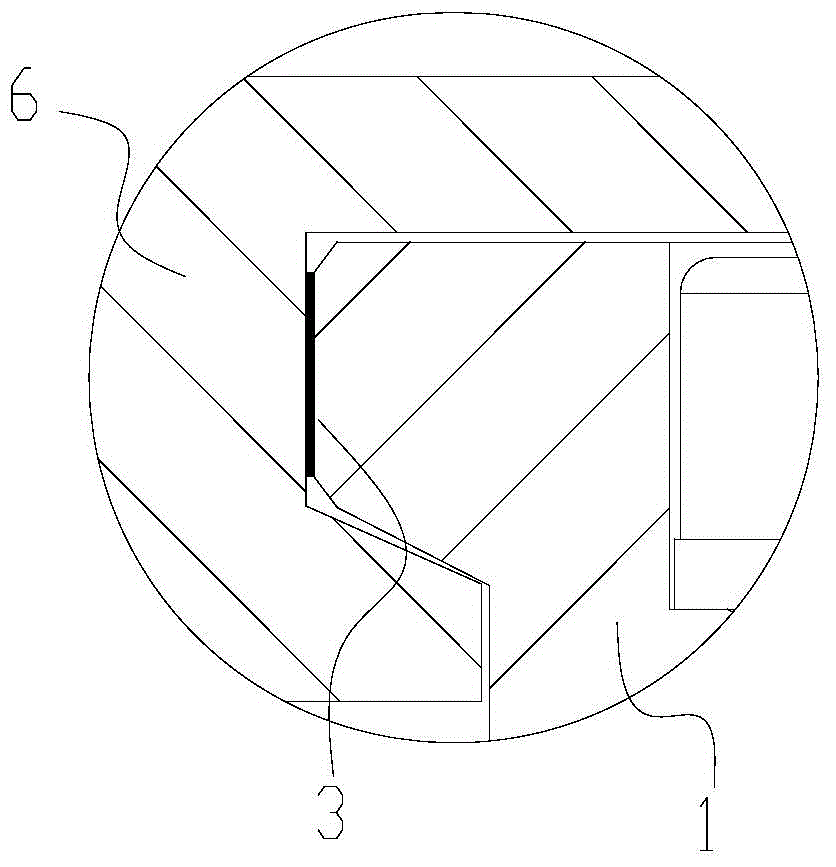

Proportion electromagnet

InactiveCN103117148AAdjustable forceChange preloadElectromagnets with armaturesEngineeringMechanical engineering

The invention discloses a proportion electromagnet which comprises a shell (1), a coil assembly (2), a pole shoe (3), a magnetic shielding ring (4), a guide sleeve (5), an iron core (6) and a push rod (7). A power connector (8) is connected onto the shell (1), a spring seat (9) is fixedly connected to the right end of the iron core (6), a through hole matched with the spring seat (9) is arranged on the right end surface of the shell (1), an adjusting screw (10) is mounted at the right end of the through hole, and a spring (11) is arranged between the adjusting screw (10) and the spring seat (9). The proportion electromagnet has the advantages that the proportion electromagnet is additionally provided with the spring seat, the spring and the adjusting screw, pre-tightening force which is applied on the iron core of an electromagnet by the spring can be conveniently changed by means of adjusting the adjusting screw, accordingly, acting force of the electromagnet at certain current or voltage can be changed, acting force of the proportion electromagnet at the certain current or voltage is adjustable, and the proportion electromagnet is simple and compact in structure, reasonable in design, convenient to adjust and high in practicality.

Owner:四川省宜宾普什驱动有限责任公司

Nickel-free metastable austenitic stainless steel with TRIP effect

The invention provides nickel-free metastable austenitic stainless steel with TRIP effect. The nickel-free metastable austenitic stainless steel comprises the following chemical composition in percentage by weight: 0.08-0.15 percent of C, less than 1 percent of Si, 8-10 percent of Mn, 15-16.5 percent of Cr, 0.15-0.30 percent of N, less than 0.03 percent of P, less than 0.02 percent of S, and the balance being Fe and inevitable impurities. The nickel-free metastable austenitic stainless steel can improve the strength of steel through cold working, ensures that material has wider strength range so as to meet various working condition demands, is especially suitable for weak corrosive environments, such as traffic, construction, hardware and other fields, and can partially replace AISI304, AISI301, AISI201 and other austenitic stainless steel with high nickel content so as to save noble metal nickel.

Owner:BAOSHAN IRON & STEEL CO LTD

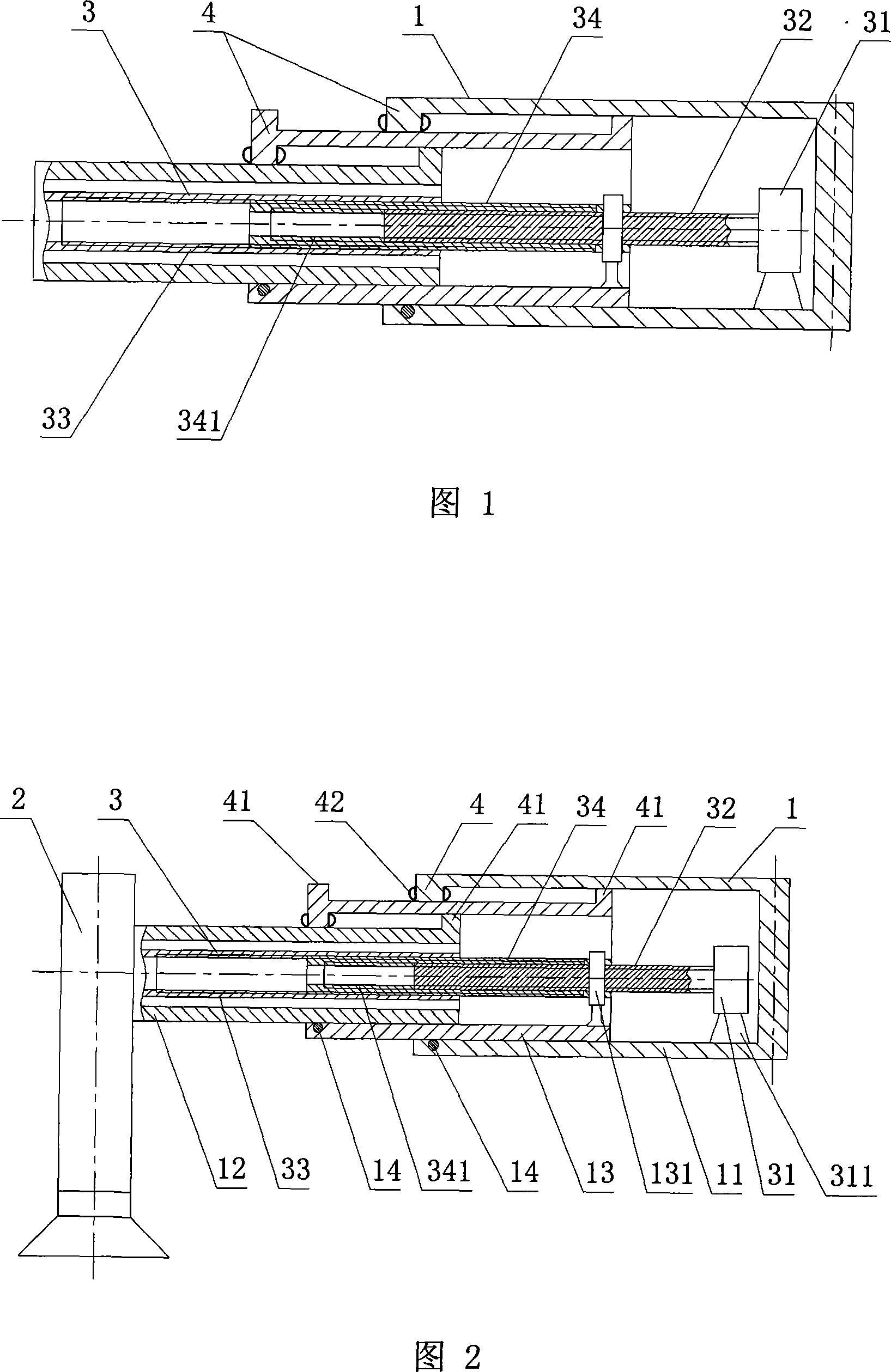

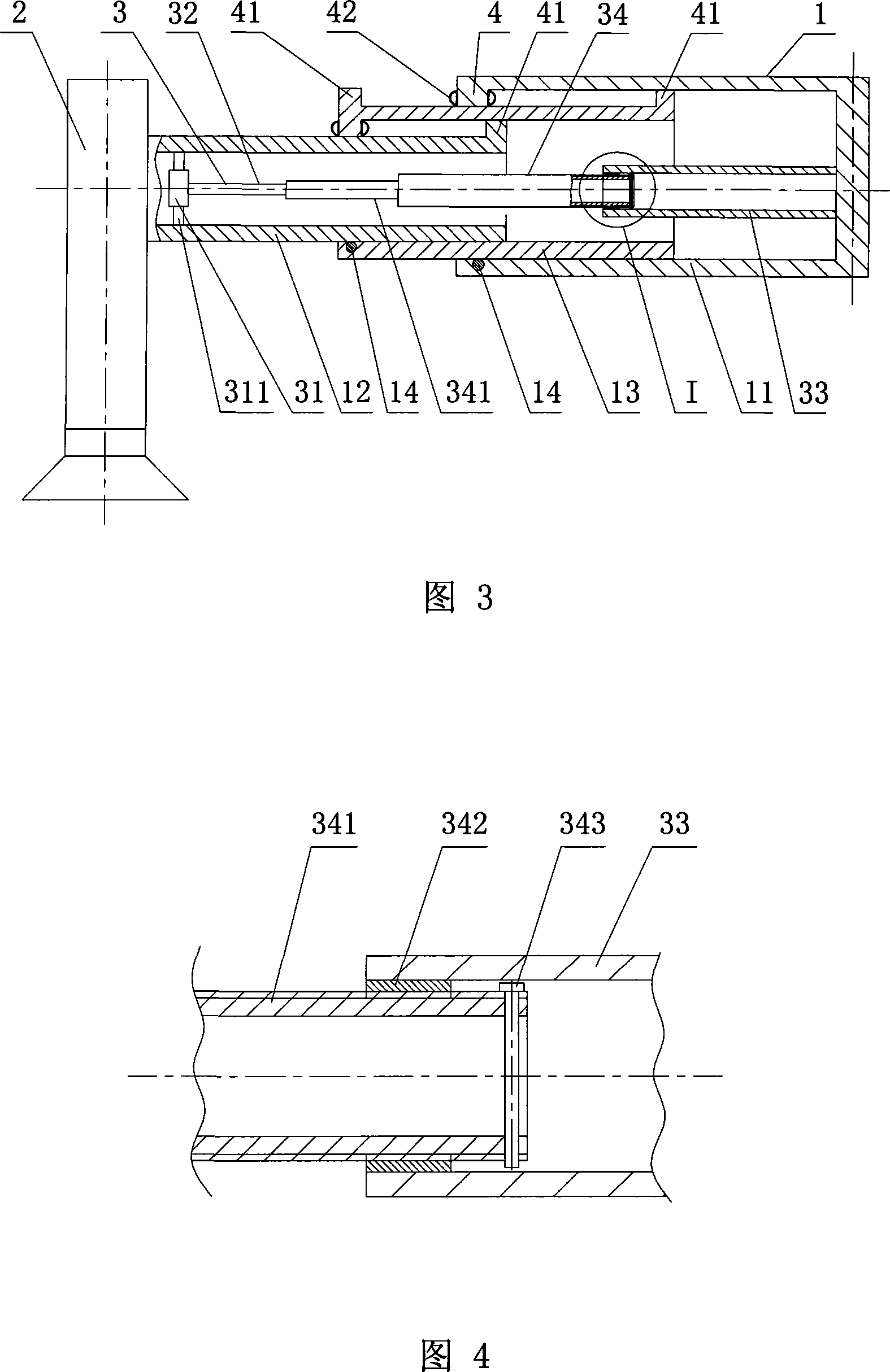

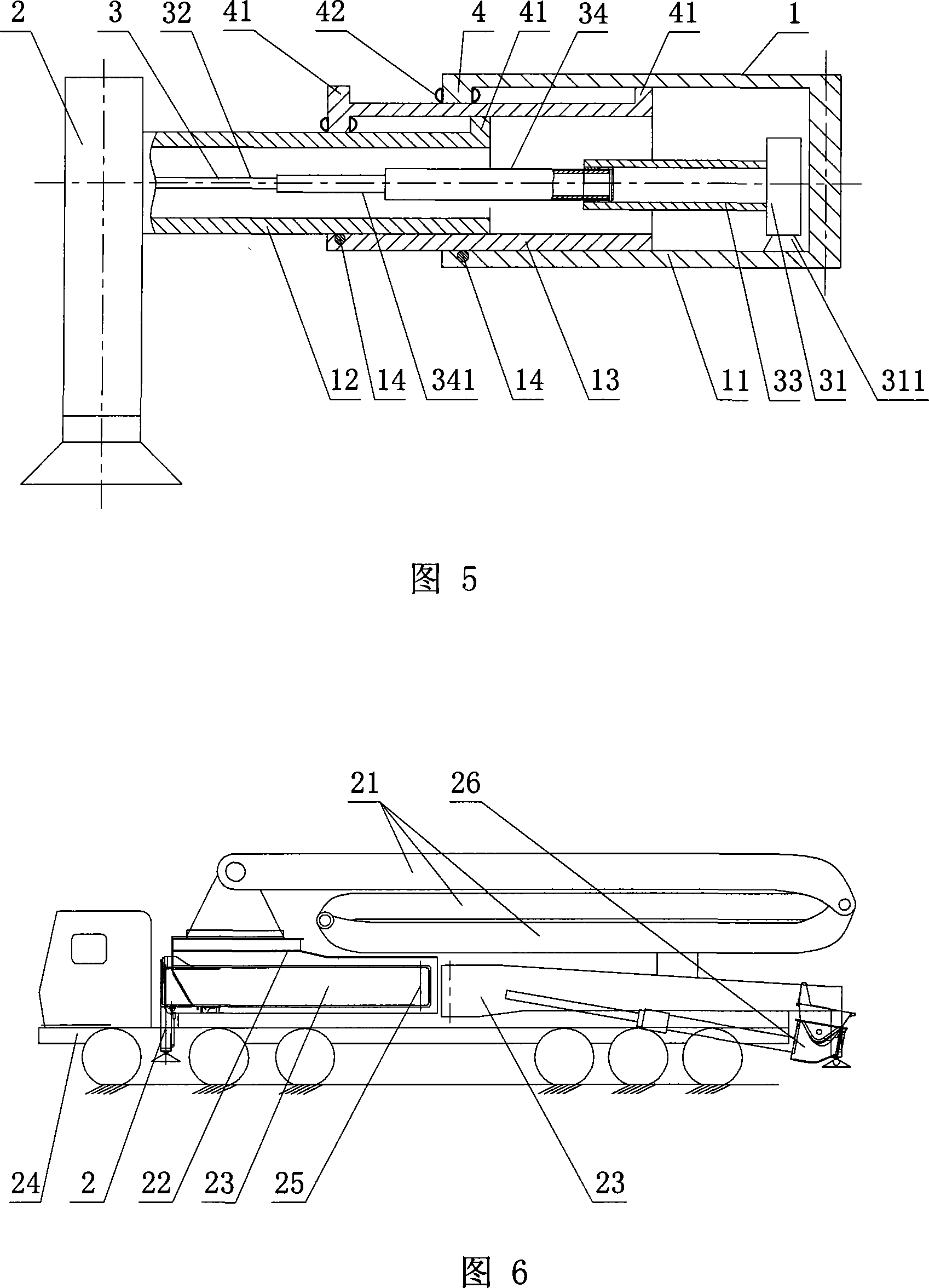

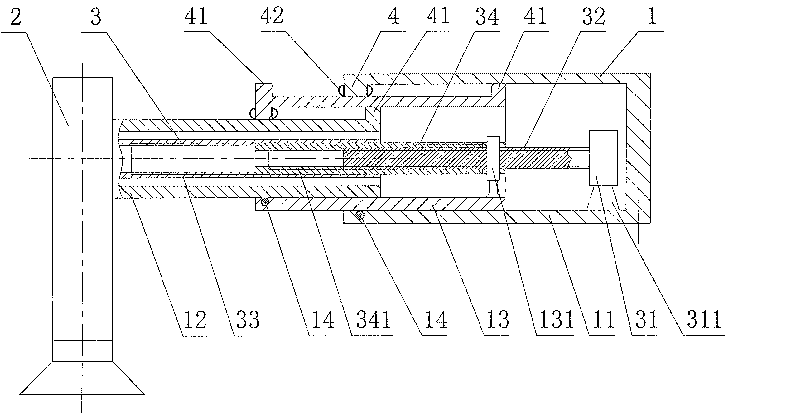

Telescopic component and support for engineering machinery and concrete pump vehicle with the support

InactiveCN101121399ASimple structureEasy to processVehicle fittings for liftingEngineeringScrew thread

A telescopic component used for construction machinery, a telescopic support leg and a concrete pump truck composed of the component. The telescopic assembly includes a telescopic sleeve assembly, and the sleeve assembly is equipped with a screw mechanism and a stop device. The screw mechanism includes a prime mover, a circular shaft and a hollow cylinder, and the circular shaft and the hollow cylinder are threaded, or between the circular shaft and the hollow cylinder Set the middle hollow shaft group, the middle hollow shaft group is composed of the middle hollow shaft with internal and external threads, the two ends of the middle hollow shaft group are respectively screwed with the round shaft and the hollow tube, the prime mover is connected with the end of the round shaft or the hollow tube connection, the prime mover is fixed at one end of the sleeve assembly, and the other end of the sleeve assembly is fixedly connected with the end of the screw mechanism where the prime mover is not installed. The telescopic part of the telescopic outrigger is composed of the telescopic assembly, and one end of the telescopic outrigger is provided with a supporting foot assembly, and the other end is connected with the bracket on the chassis of the construction machine. The telescopic outrigger is installed in the supporting part of the concrete pump truck. The invention has the advantages of simple structure, convenient manufacture and low cost.

Owner:SANY AUTOMOBILE MFG CO LTD

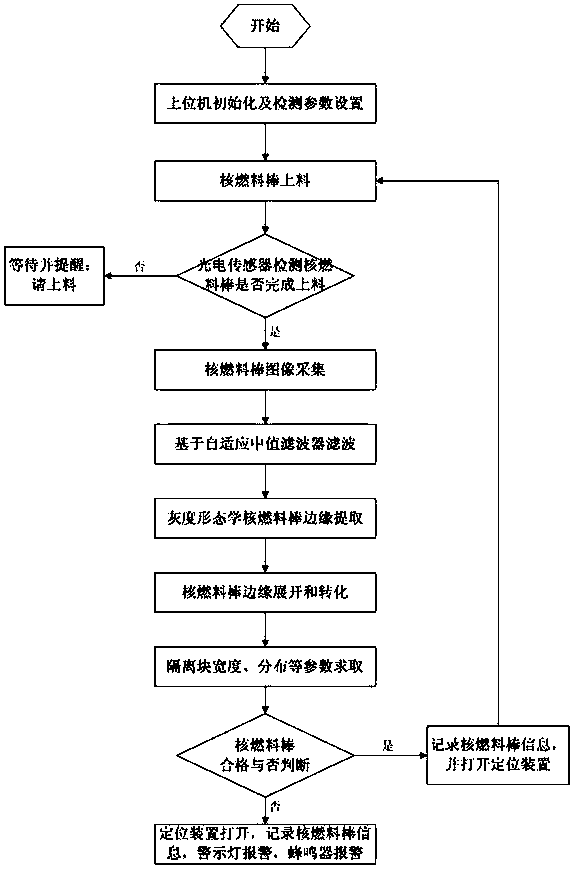

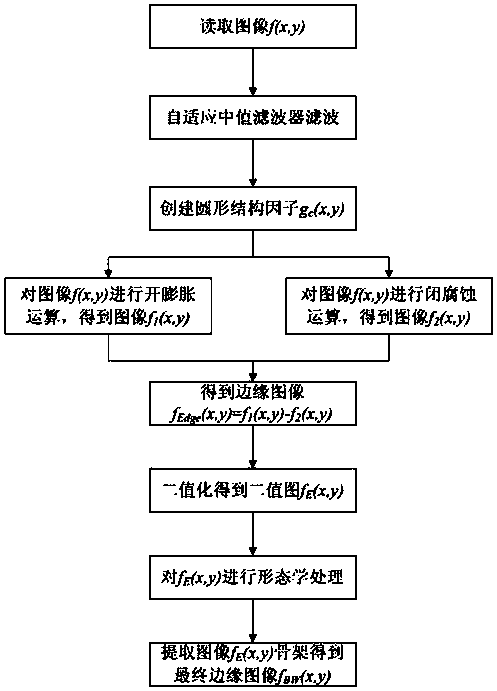

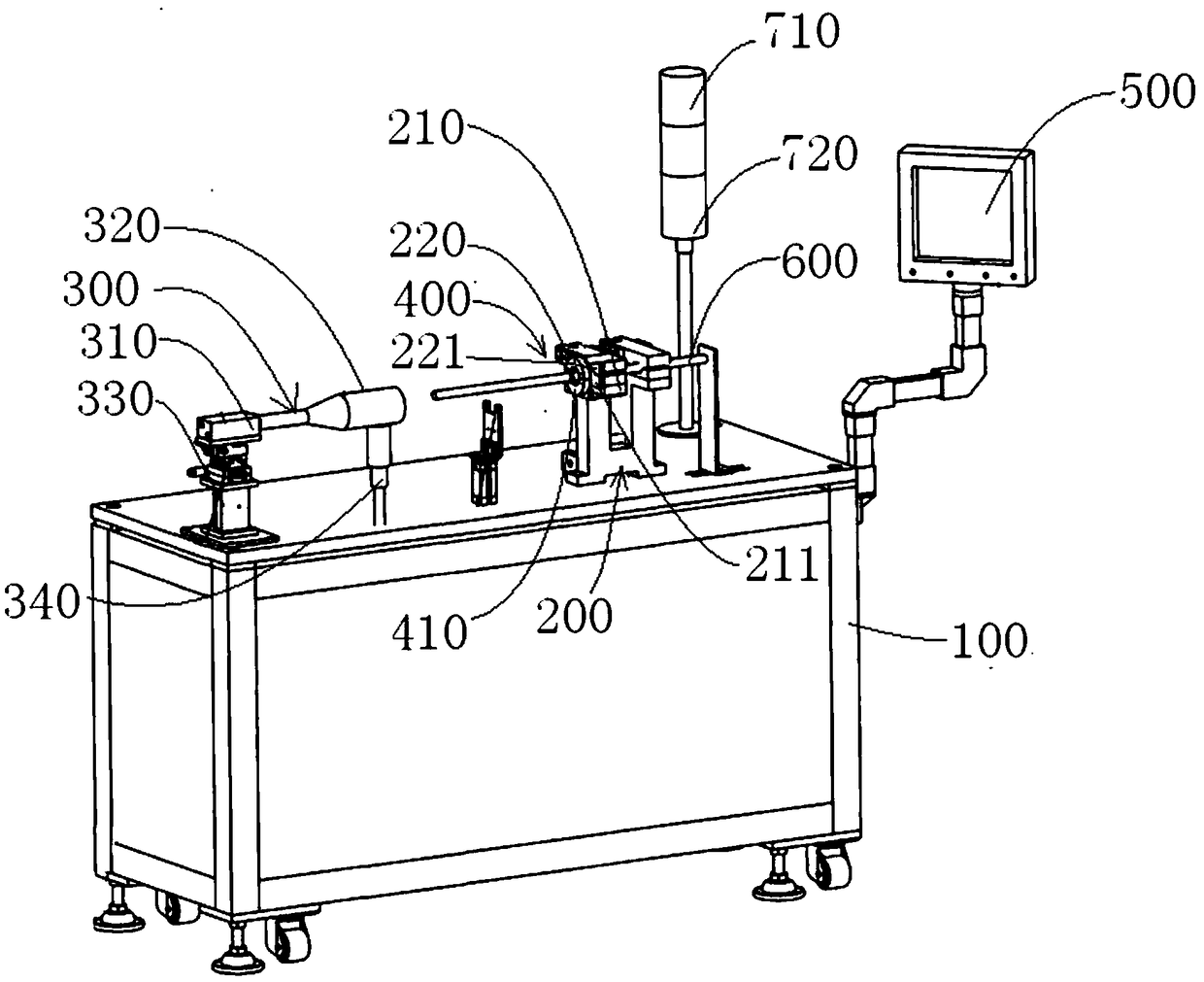

Nuclear fuel rod dimension detecting method and system based on telecentric optics

ActiveCN108759664AImprove noise immunityReduce border blur and distortionUsing optical meansEngineeringDepth of field

The invention discloses a nuclear fuel rod dimension detecting method and system based on telecentric optics. The method comprises filtering an original image by an adaptive median filter and extracting the edge of the filtered image by using an anti-noise grayscale morphology operator, scanning the edge image of the nuclear fuel rod, and unfolding the edge; and detecting the external dimension ofthe nuclear fuel rod by a telecentric imaging system. The nuclear fuel rod dimension detecting system can overcome the far-smallness near-bigness phenomenon of a traditional pinhole imaging system, can clearly acquire the contour shape of an isolation block in the middle part of the nuclear fuel rod, and has the advantages of small distortion, clear edges and a large depth of field. Compared witha conventional edge detection algorithm, the algorithm for detecting the contour edge of the nuclear fuel rod by using dilation-erosion edge detection operator resistant positive and negative pulse noise is good in anti-noise ability and accurate in edge location.

Owner:湖南瑞智健科技有限公司

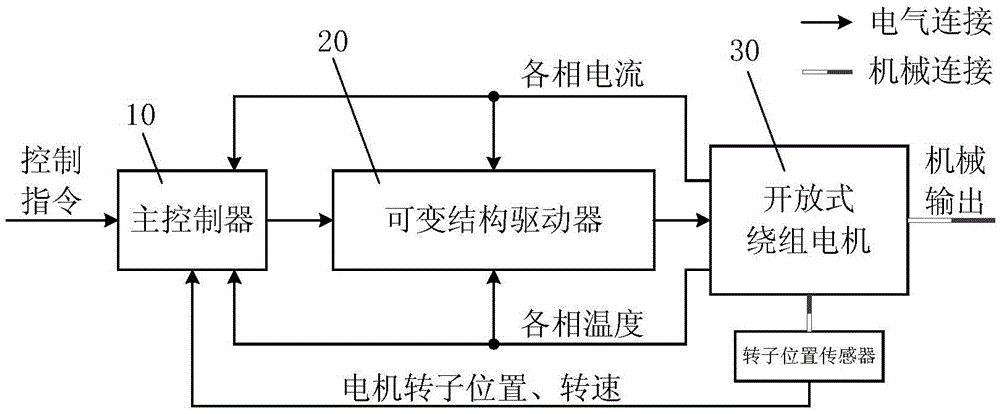

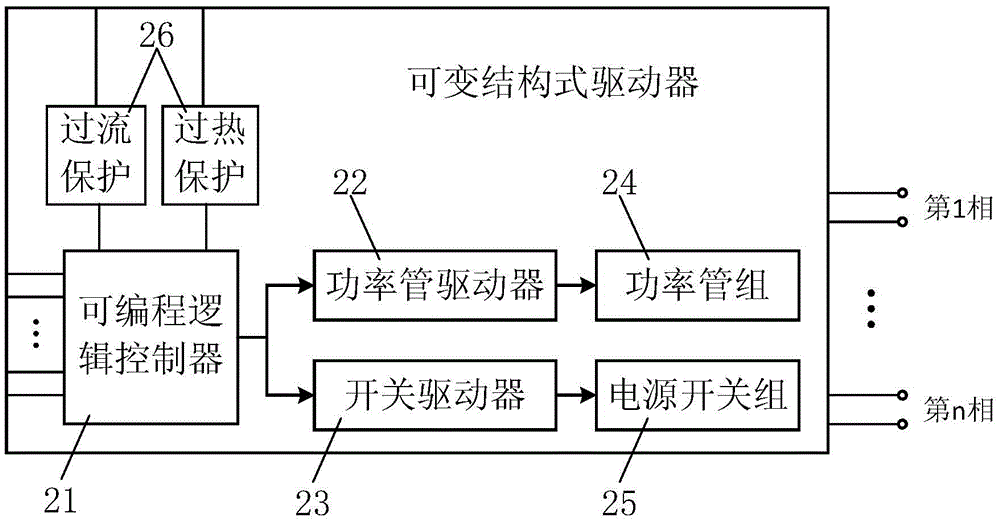

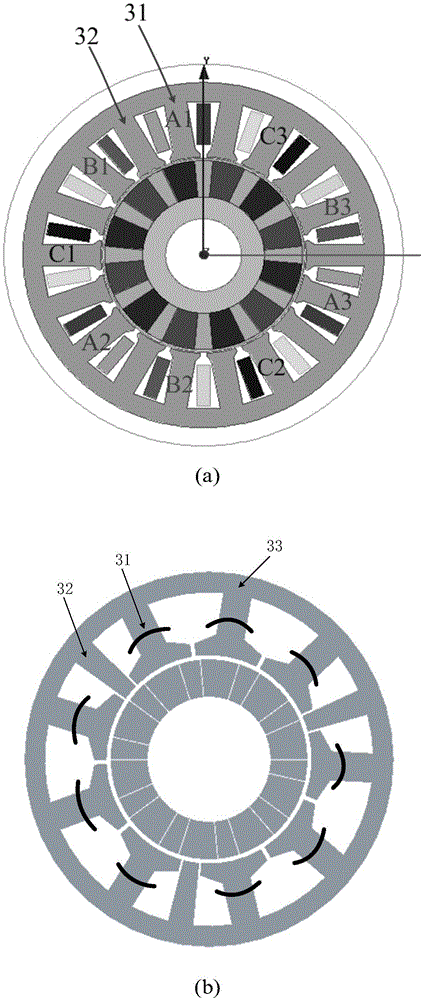

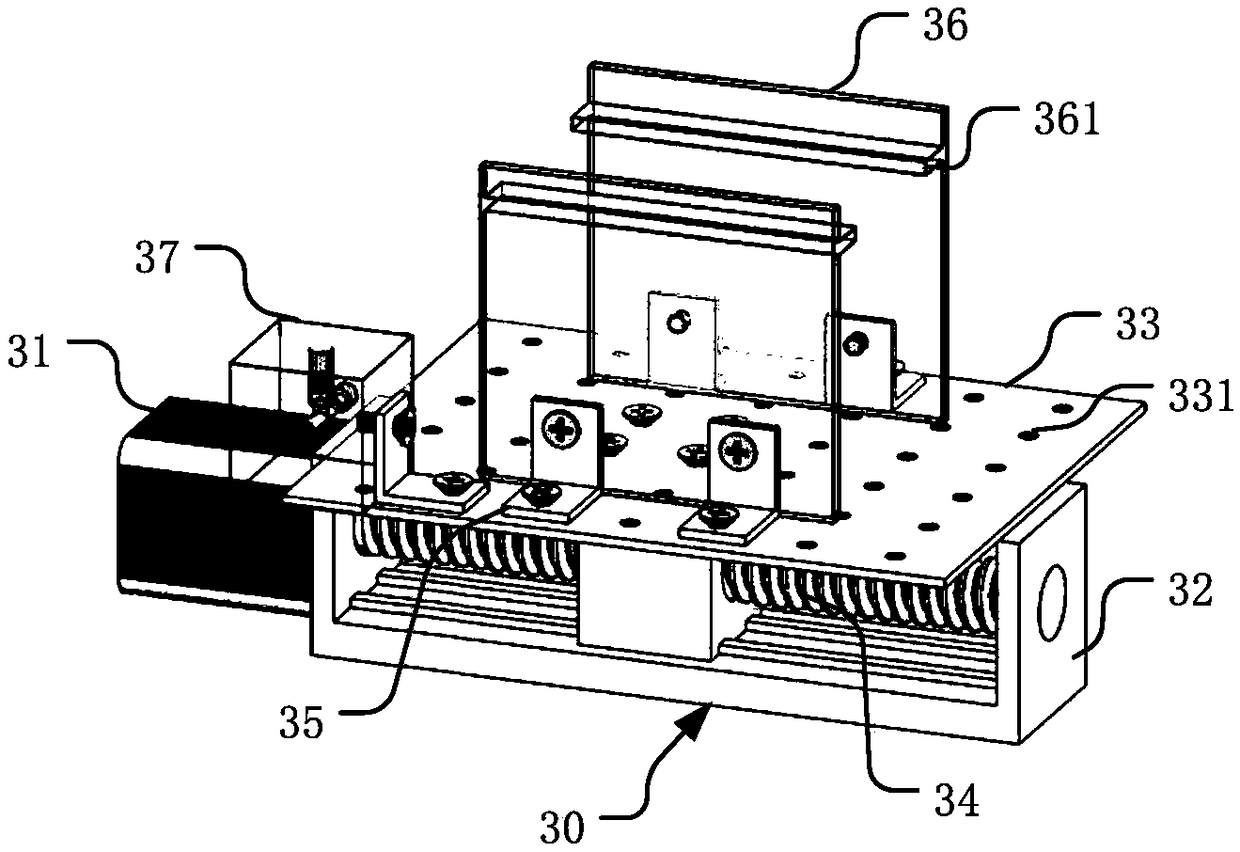

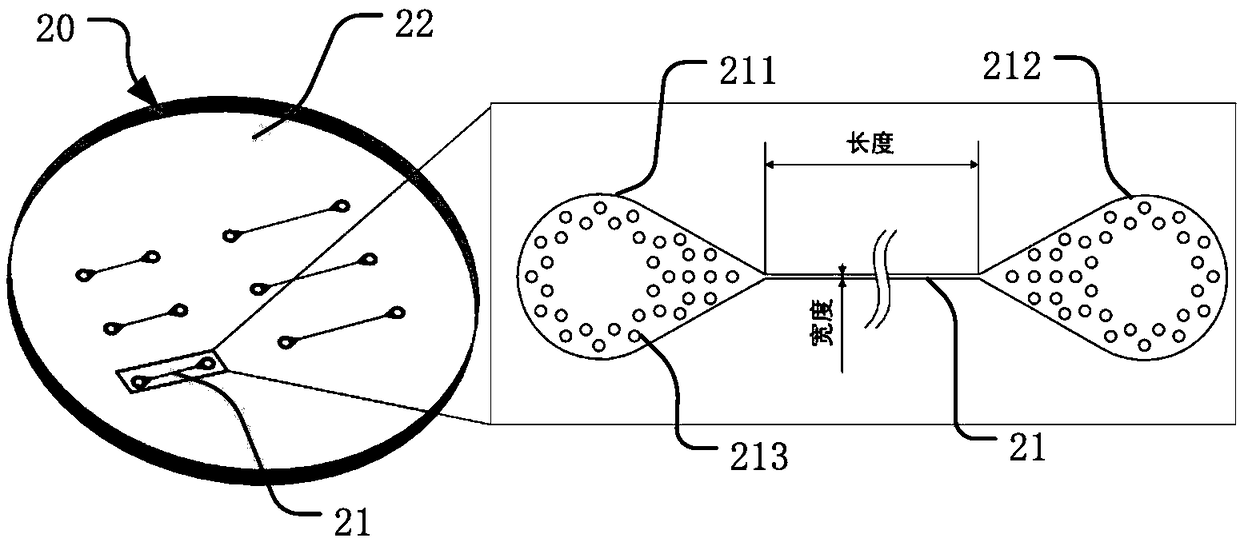

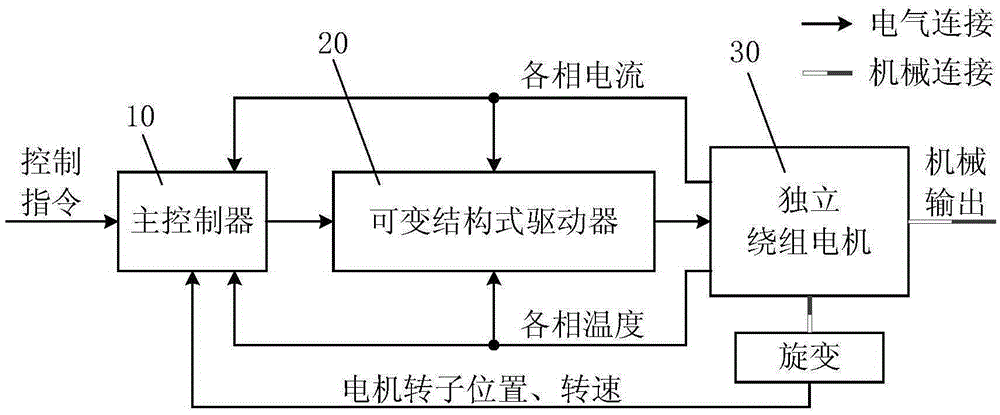

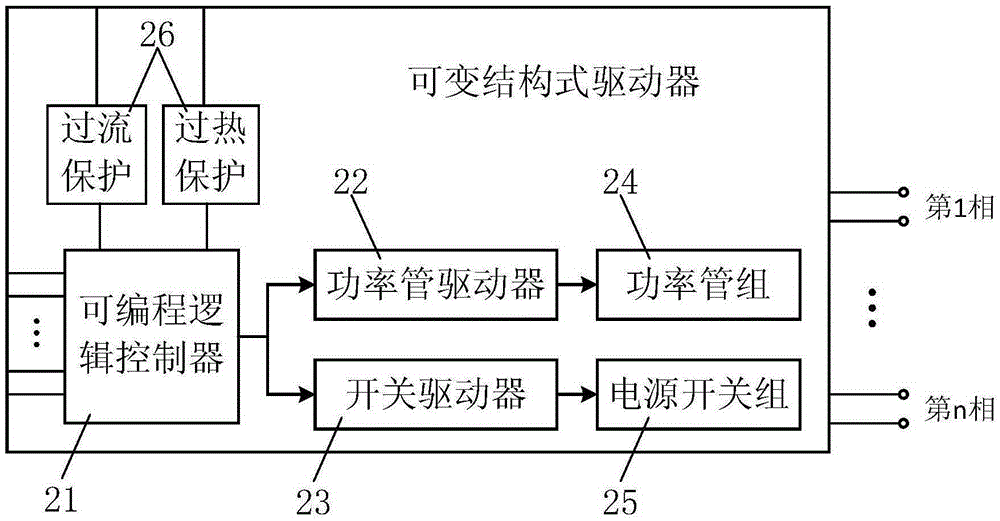

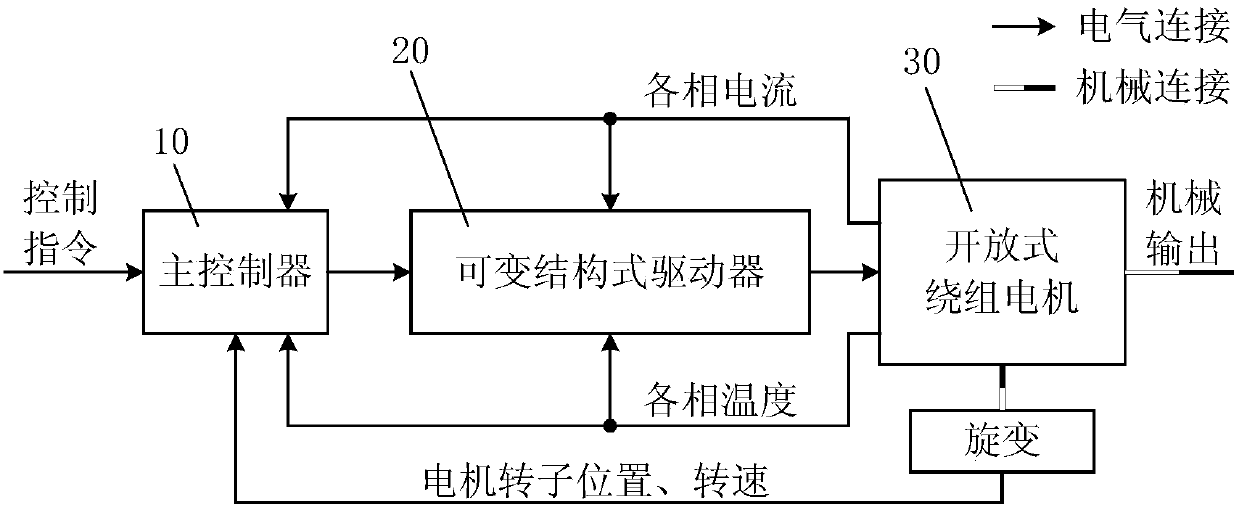

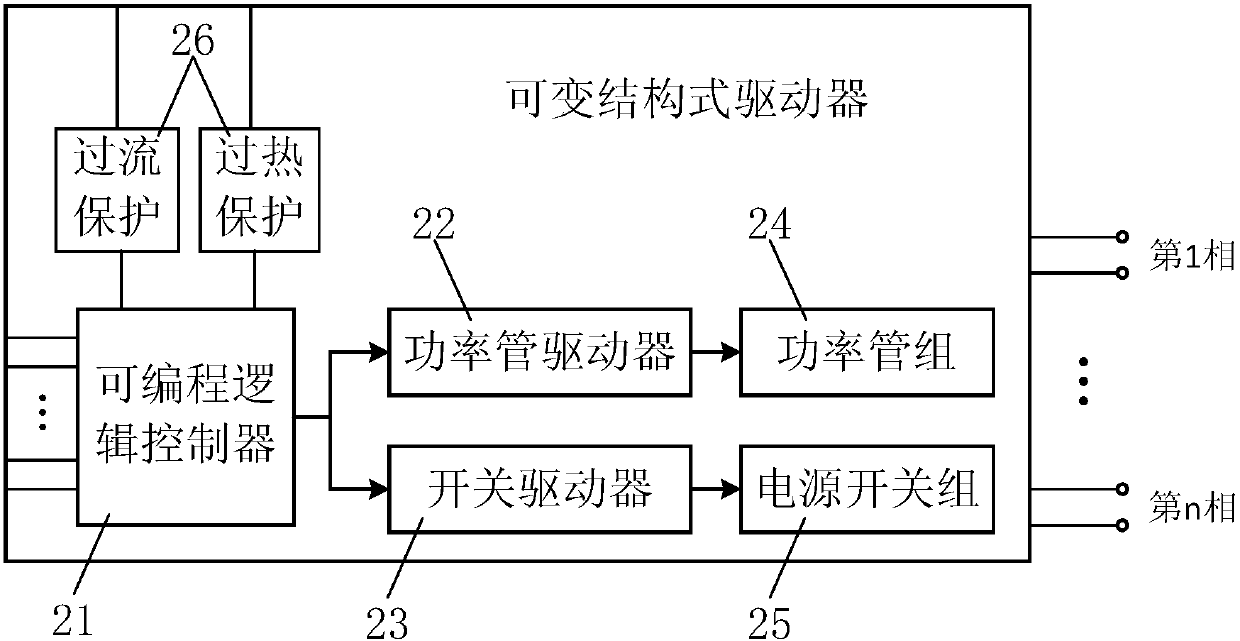

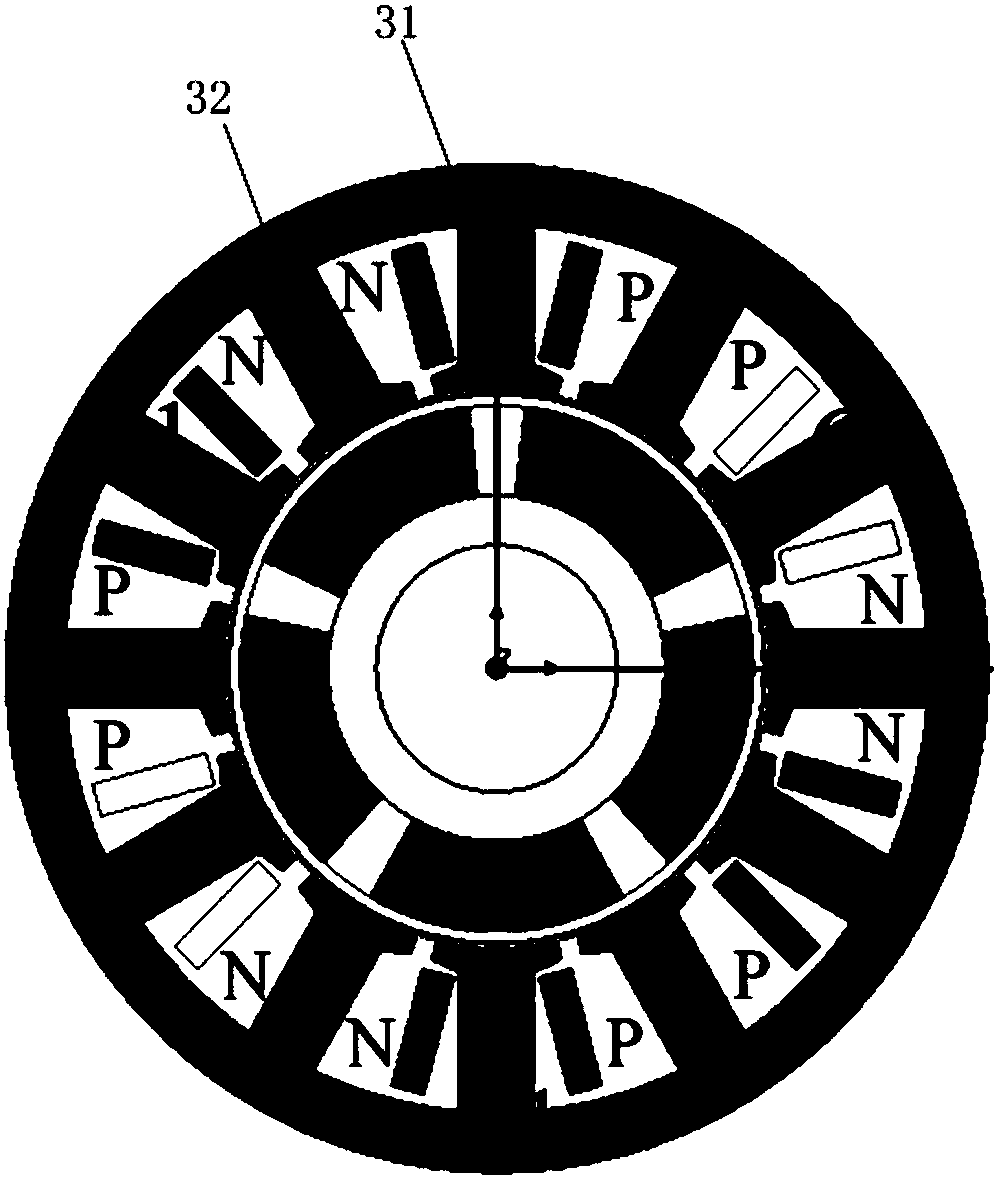

Open winding variable-structure motor system

ActiveCN105610281AReduce weightReduce volumeAssociation with control/drive circuitsHigh power densityClutch

The invention relates to an open winding variable-structure motor system, which comprises a master controller, a variable-structure driver and an open winding motor, wherein the master controller receives a control instruction and feedback information of the open winding motor, and generates a power drive instruction and a drive topology variable-structure instruction; and the variable-structure driver converts a drive topology structure according to the drive topology variable-structure instruction, can connect a plurality of windings of the open winding motor into a new one-phase winding in series and drives the open winding motor according to the power drive instruction. The open winding variable-structure motor system fully utilizes the advantages of variable structures, high power density and high reliability of the variable-structure driver and a multi-phase motor, can meet different work condition requirements, can effectively reduce the weight and the volume of a motor drive system in comparison with a multi-motor and clutch structure, effectively improves the power density and the reliability and eliminates mechanical noise.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

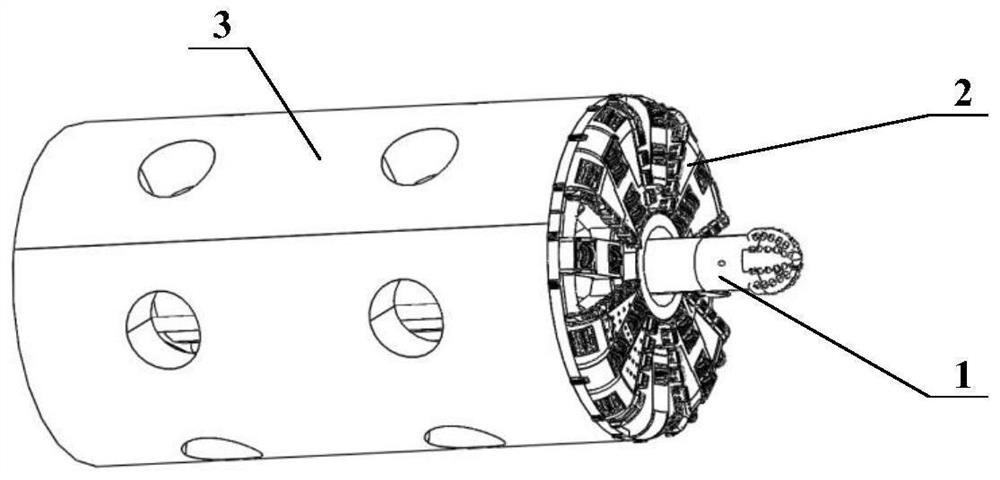

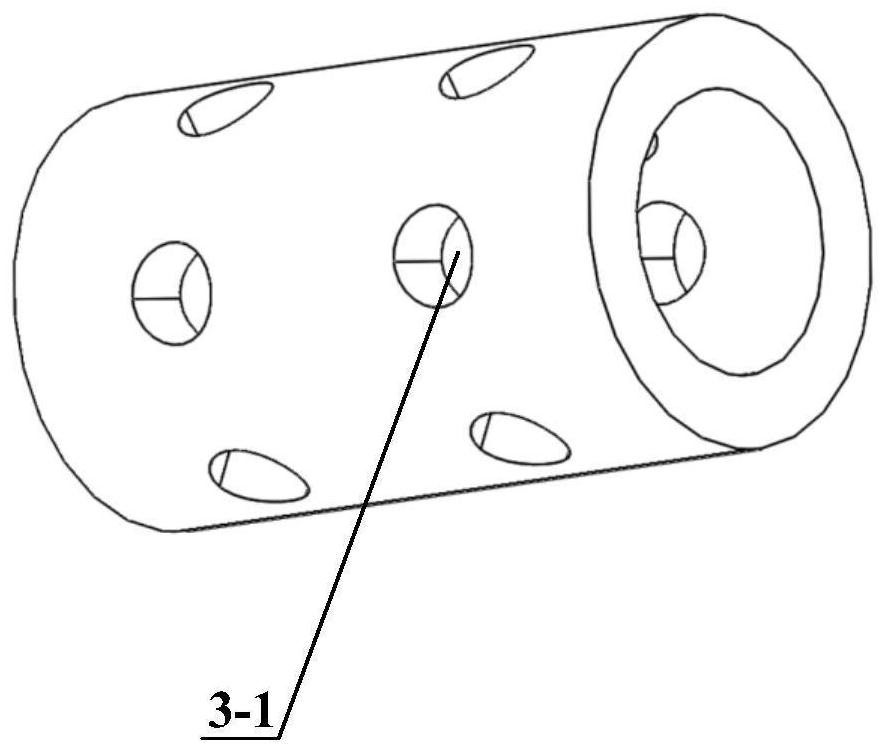

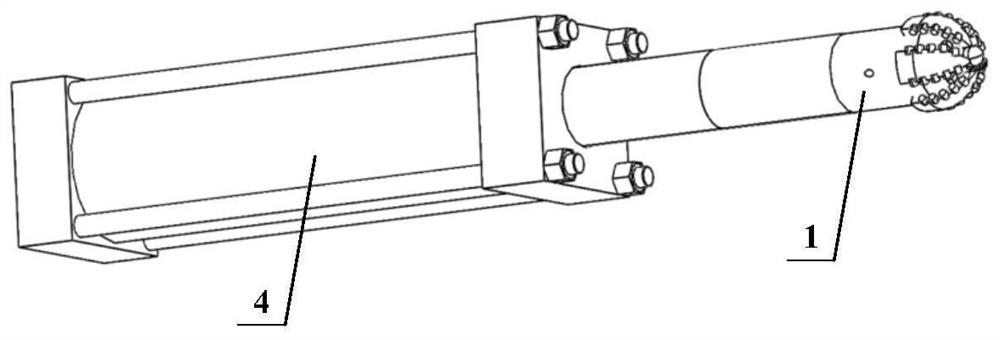

Composite cutterhead device suitable for hard rock crushing and using method of composite cutterhead device

ActiveCN114109380AExpand the scope of workMeet the needs of rock breakingMining devicesTunnelsMechanical engineeringRock breaking

The invention discloses a composite cutterhead device suitable for hard rock crushing and a using method thereof.The device comprises a PDC drill bit body, a hydraulic telescopic device, a TBM cutterhead and a TBM cutter body, the TBM cutterhead is arranged at the end of the TBM cutter body, the hydraulic telescopic device is fixed into the TBM cutter body, the telescopic end of the hydraulic telescopic device can stretch out of the TBM cutterhead, and the telescopic end of the hydraulic telescopic device can stretch out of the TBM cutterhead. The telescopic end of the hydraulic telescopic device is connected with a PDC drill bit body, the structure is compact, the arrangement space of the device is saved, the rock breaking requirement of a complex stratum is met, the TBM cutterhead operation range is enlarged, and the working efficiency can be improved.

Owner:CHINA UNIV OF MINING & TECH +1

System and construction method for head turn and translation of shield trolley

The invention discloses a system and construction method for head turn and translation of a shield trolley. According to the system and construction method for the head turn and translation of the shield trolley, the trolley is pulled to turn a head by using a pulley block device and a limiting device and utilizing an electromobile matched with shield, finally, a jack is used to fine tune, the head turn of the trolley is obtained, construction efficiency is greatly improved, at the same time, safety of construction is increased, and a head turn path is more accurate; and according to the system, structures of all related devices are simple, mechanical equipment used in construction is conventional associated equipment of shield construction, implementation is high, and the devices can be circulated.

Owner:中建三局城建有限公司 +1

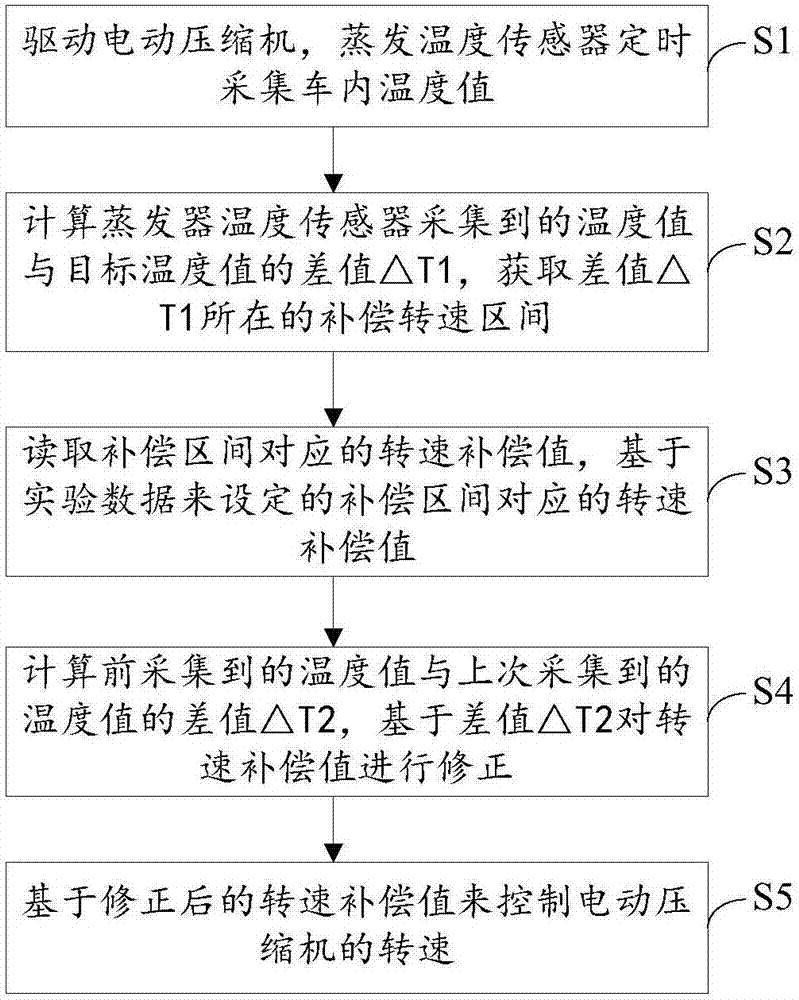

Speed adjusting method of motor compressor

ActiveCN108005881APrevent sudden changes in speedGuaranteed smooth descentPump testingPositive displacement pump componentsEvaporation temperatureTemperature drop

The invention is suitable for the technical field of car air conditioners, and provides a speed adjusting method of a motor compressor. The method comprises following steps: the motor compressor is driven, and an evaporation temperature sensor collects the temperature value in a car in a timing manner; the difference value delta T1 between the temperature value collected by the evaporation temperature sensor and the target temperature value is calculated, and the compensation rotating speed field of the delta T1 is obtained; the rotating speed compensation value corresponding to the compensation field is read; the difference value delta T2 between the pre-collected temperature value and the temperature value collected last time is calculated, and on the basis of the delta T2, the rotatingspeed compensation value is corrected; on the basis of the corrected rotating speed compensation value, the rotating speed of the motor compressor is controlled. Adjusting speeds of different compensation fields are set on the basis of the compensation field, the adjusting speeds are gradually reduced along with decreasing of the compensation field value, the condition that rotating speed suddenlychanges can be prevented wholly, in the compensation field, on the basis of the temperature descend range, the adjusting speed in the compensation field is subject to fine adjustment, and it is ensured that the temperature stably descends to the greatest extent.

Owner:BONAIRE AUTOMOTIVE ELECTRICAL SYST

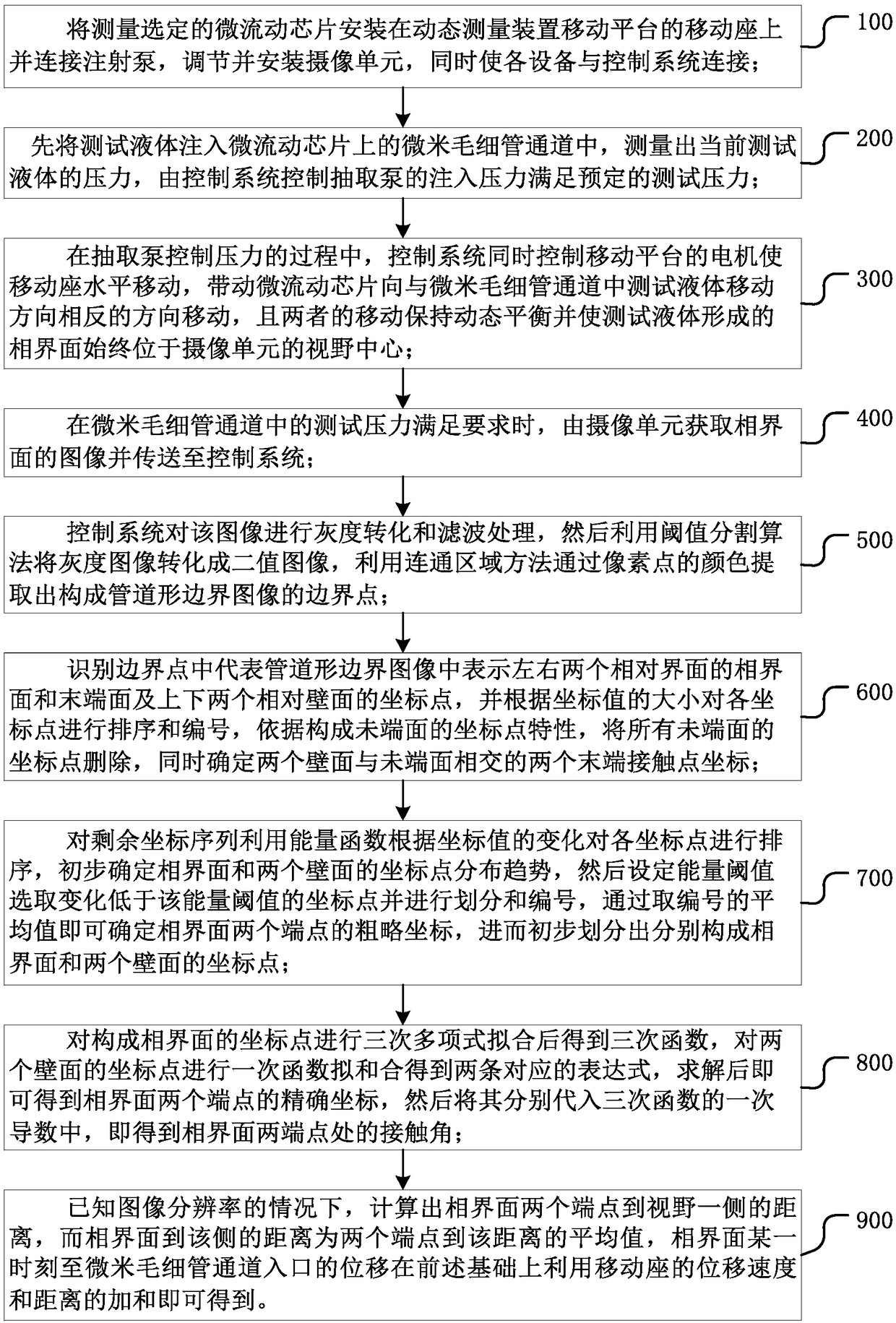

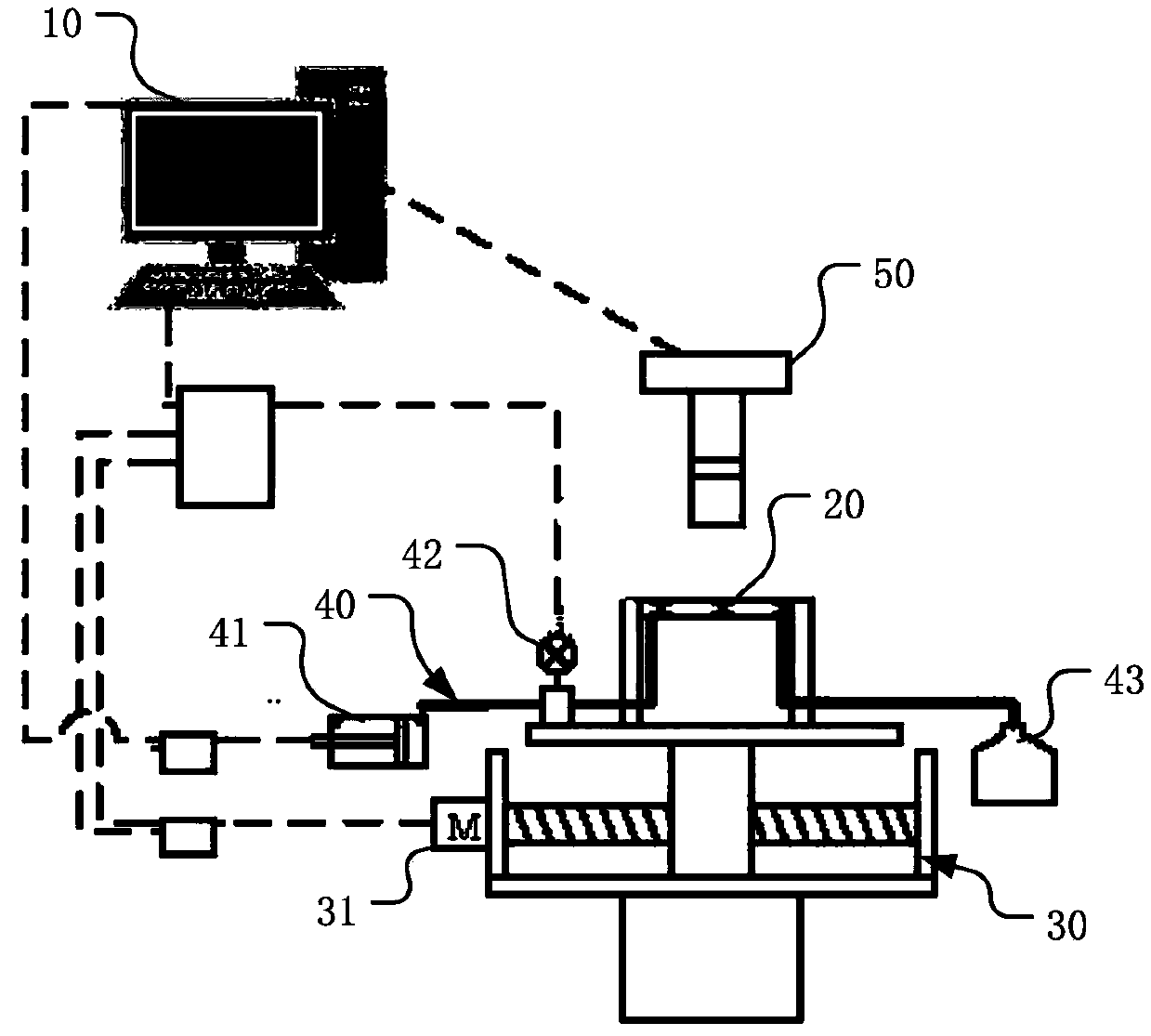

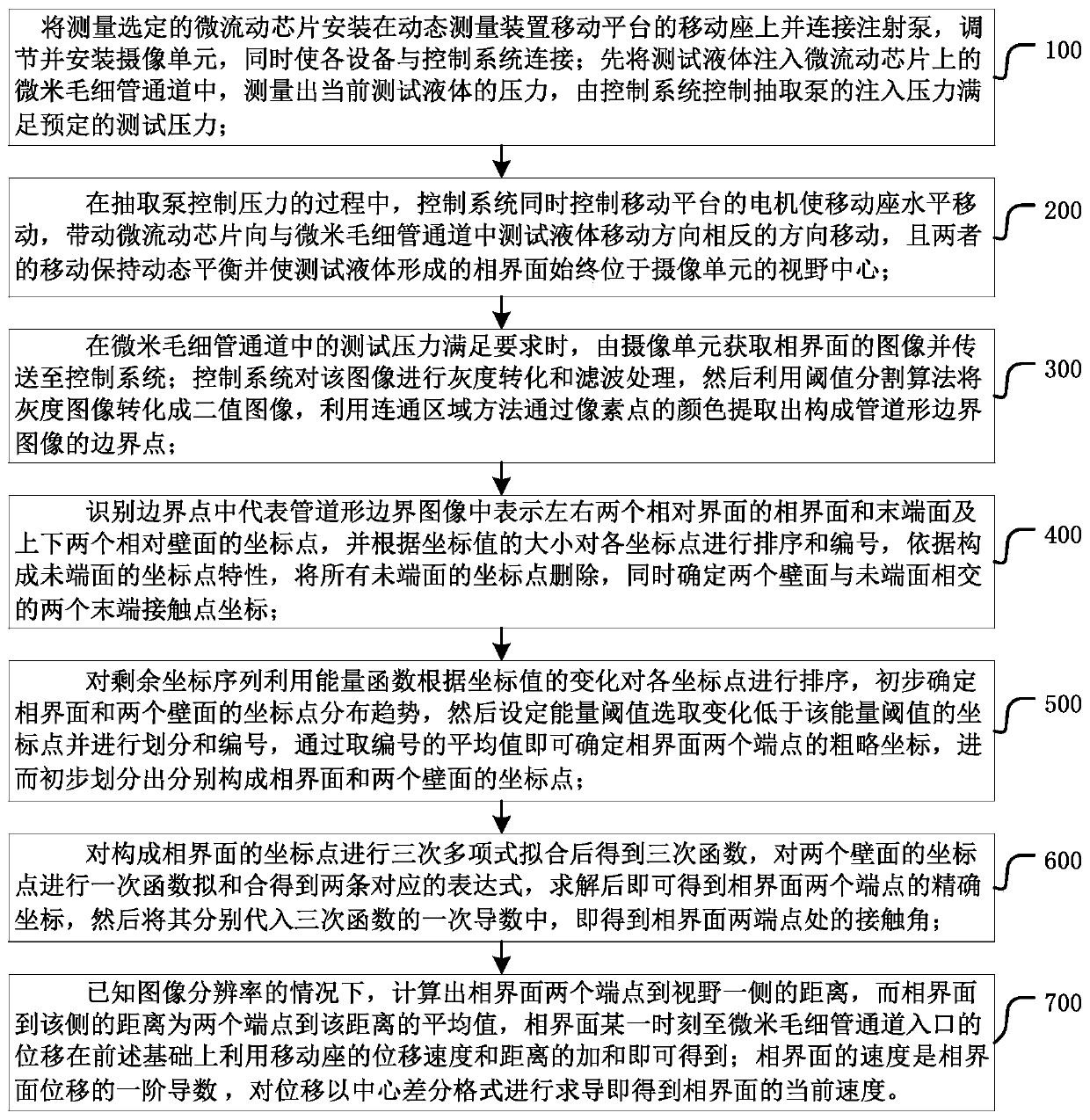

Acquiring method for moving distance of gas-liquid phase interface in micrometer capillary passage

ActiveCN109187277AImprove efficiencyHigh measurement accuracyInvestigating moving fluids/granular solidsLaboratory glasswaresBond numberGas phase

The invention provides an acquiring method for a moving distance of a gas-liquid phase interface in a micrometer capillary passage. The pressures or flow speeds of flowing processes of a gas phase anda liquid phase in a micrometer-scale capillary are controlled by using a dynamic testing device, a method for acquiring a phase interface and the displacement thereof is given, and the interface shape acquisition in the states of small capillary number and small Bond number is realized for the first time. Phase interface shape calculation and displacement calculation based on an image processingmethod are firstly adopted, so that the data processing efficiency and the measuring precision are greatly improved. The invention further provides various algorithms for controlling the pressures oftwo-phase flows and the speed of an electric platform, so that the flexibility during actual operation is improved, and furthermore, demands under various working conditions are met.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

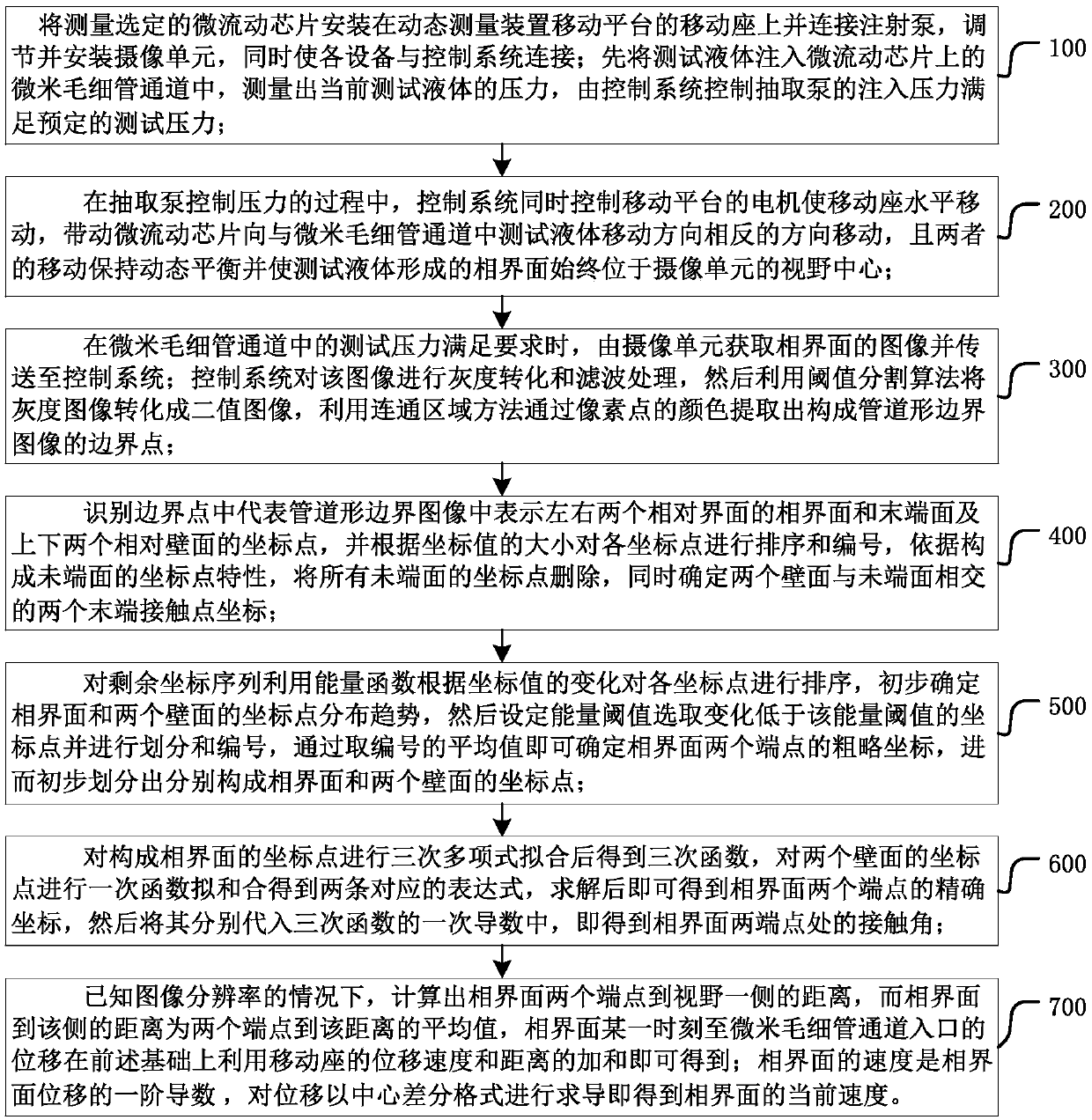

Method for obtaining movement speed of gas-liquid phase interface in micron capillary channel

ActiveCN108918348AImprove efficiencyHigh measurement accuracySurface/boundary effectCapillary channelEngineering

The invention provides a method for obtaining the movement speed of a gas-liquid phase interface in a micron capillary channel. According to the method provided by the invention, the control of pressure or flow velocity of a gas-liquid two-phase flow process in a micrometer-scale capillary vessel is realized through a dynamic testing device; a method for obtaining the phase interface and the phaseinterface velocity is given; the obtaining of the phase interface shape is realized for the first time under the conditions of low capillary number and low bond number; image processing method basedphase shape calculation and velocity calculation are adopted for the first time to ensure that the data processing efficiency and the measurement accuracy are greatly improved; and various algorithmsfor controlling the pressure control of the two-phase flow and the speed of an electric platform are also provided to improve the flexibility in actual operation and meet the requirements of various working conditions.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

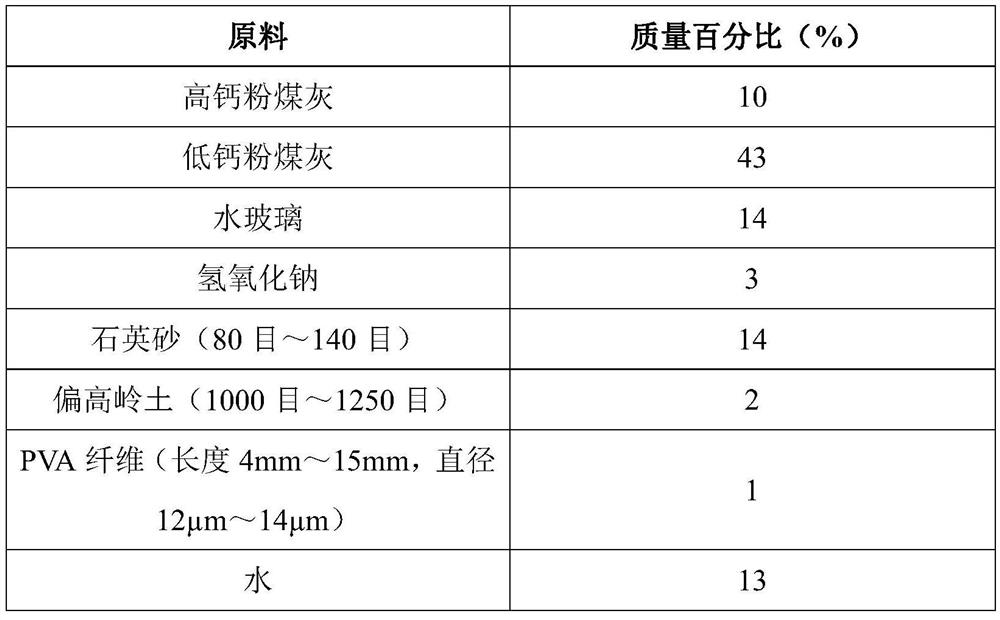

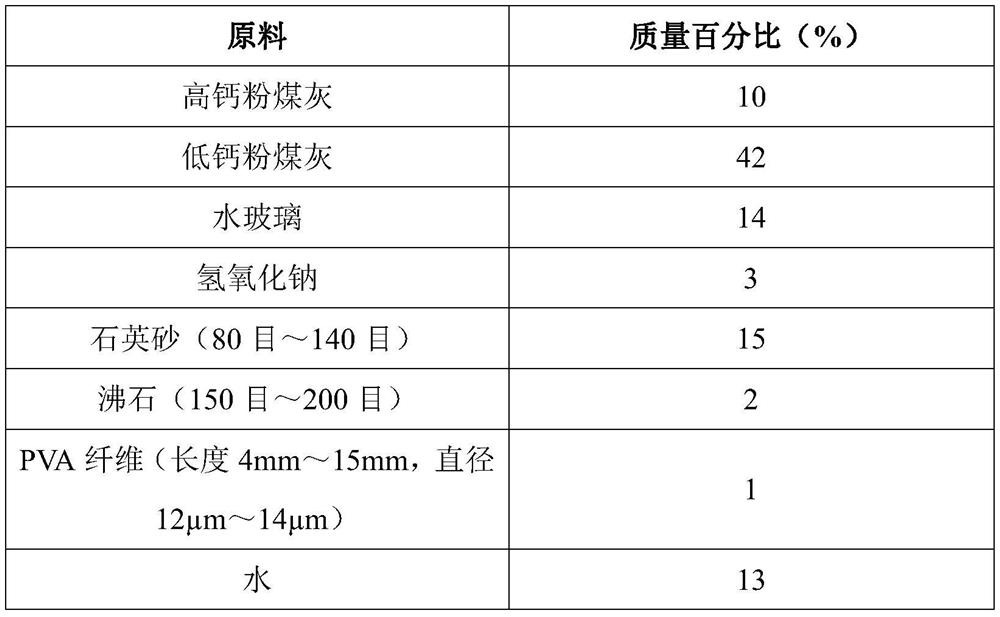

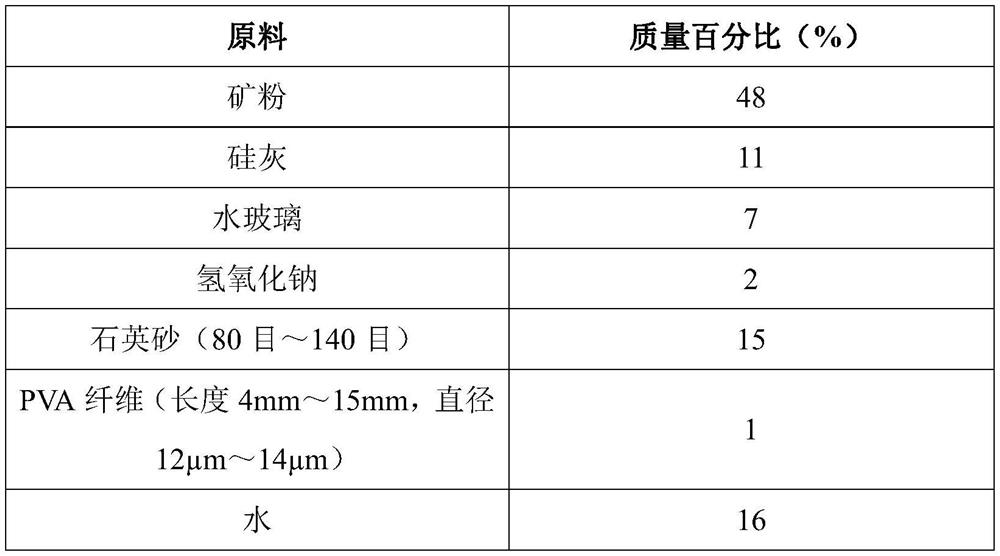

Building coating and preparation method thereof

The invention discloses a building coating and a preparation method thereof. The building coating is composed of a cementing material, water glass, sodium hydroxide, quartz sand, metakaolin, zeolite, fibers and water. The preparation method comprises the following steps: mixing the cementing material, the quartz sand, the metakaolin and the zeolite, stirring, adding the water glass, the sodium hydroxide and the water, stirring, adding the fibers, and stirring to obtain the building coating. A coating layer formed by the building coating has ultrahigh toughness and excellent strain hardening characteristics, can still provide protection for a structure or a component matrix after being subjected to large deformation, is high in anti-permeability grade and excellent in bonding performance, and can be widely applied to surface protection of various building structures and components thereof; and the coating can also be used for reinforcing and maintaining aged and damaged building structures.

Owner:SOUTH CHINA UNIV OF TECH

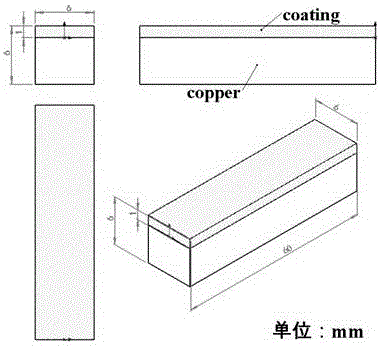

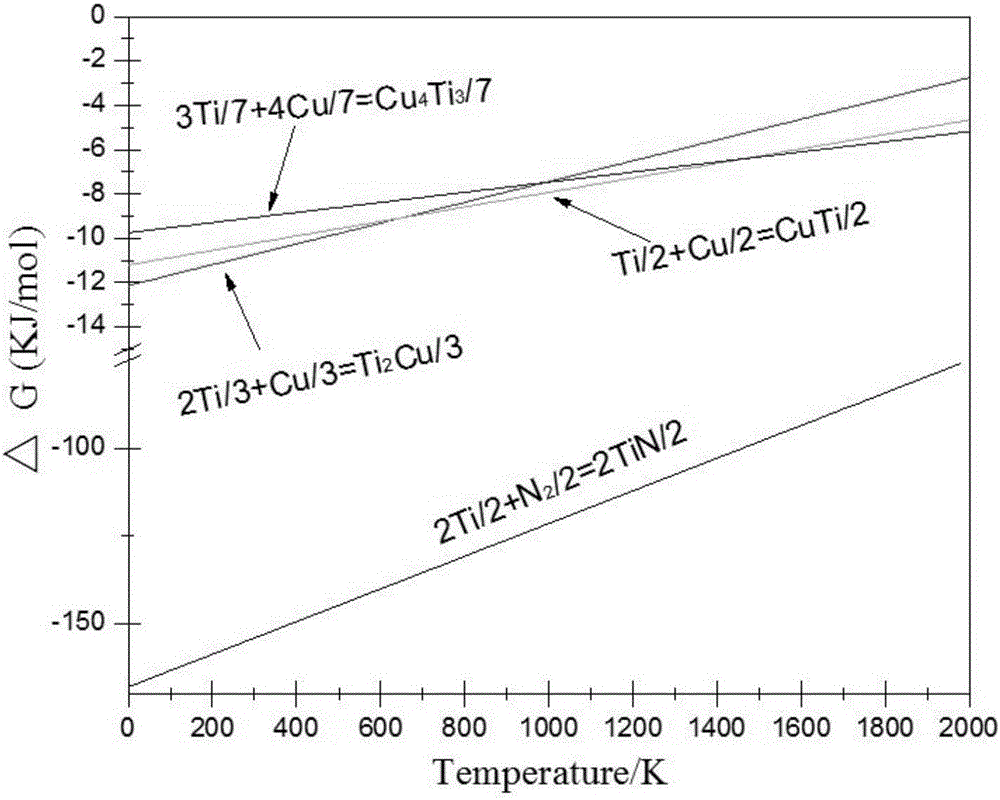

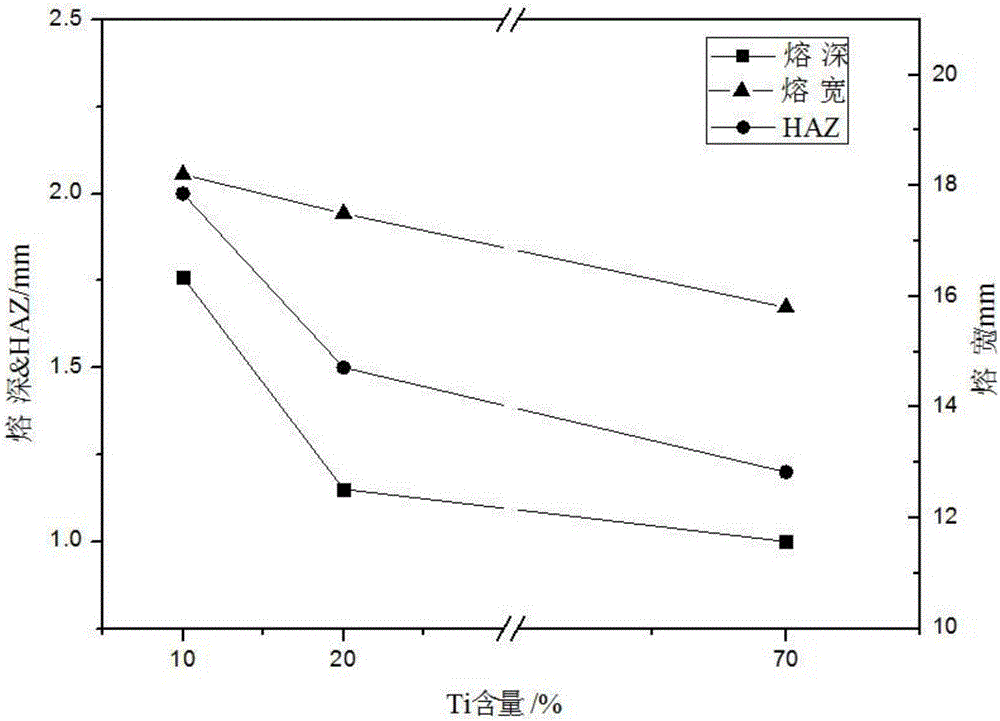

Titanium nitride/copper-titanium intermetallic compound reinforced coating for surface of red copper

ActiveCN106400003AImprove the wear resistance and hardness of copper surfaceHigh utility valueMetallic material coating processesNitrogen gasHardness

The present invention provides a wear-resistant coating material with titanium nitride and a copper-titanium intermetallic compound as an reinforcement phase that is formed on the surface of red copper through nitrogen arc fusion cladding. The degradation of the thermal conductivity and the electrical conductivity due to the use of an integrated composite instead of the red copper is avoided, and the hardness and the frictional wear resistance of the surface are also enhanced; as a result, the surface properties and the integrated electrical and thermal conductivity of the material can meet the use requirements, and the material can be used for repair and reproduction of the red copper. A tungsten electrode nitrogen arc welding machine is used; the red copper is pre-coated with a titanium powder, a copper powder and a desoxidant powder in a certain ratio; under the action of a nitrogen arc heat source, the powders are reacted on the surface of the red copper to generate a titanium nitride / copper-titanium intermetallic compound reinforced copper-based composite coating. The existence form and quantity of the titanium nitride and the types and quantity of copper and titanium reactants in the cladding layer may be effectively controlled by adjusting the ratio of the copper and titanium powders and the ratio of argon and nitrogen gases; thus, the purposes of changing the hardness of the cladding layer and adjusting the friction coefficient are achieved to meet the requirements of various operating conditions.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Telescopic component and support for engineering machinery and concrete pump vehicle with the support

InactiveCN101121399BSimple structureEasy to processVehicle fittings for liftingPrime moverScrew thread

An extension component for the engineering plant, an extension landing leg formed by the component and a concrete-pump car are provided. The extension component includes a telescopic bushing component on which a helix mechanism and an arresting device are arranged. The helix mechanism contains a prime mover, a circular shaft and a hollow barrel. The circular shaft is connected with the hollow barrel via a thread or a middle hollow shaft group is arranged between the circular shaft and the hollow barrel, the middle hollow shaft group comprising a middle hollow shaft which has an internal thread and an outside thread. The both sides of the middle hollow shaft group are connected respectively with the circular shaft and the hollow barrel via the thread and the prime mover is connected withthe end of the circular shaft or the hollow barrel, the prime mover fixed on one end of the bushing component and the other end of the bushing component fixed and connected with the end of no prime mover in the helix mechanism. The extension part of the extension landing leg comprises the extension component and one end of the extension landing leg is provided with a supporting component while theother end is connected with a bracket on an underpan of the engineering plant. A supporting part of the concrete-pump car is provided with the extension landing leg. The invention has the advantagesof simple structure, convenient manufacture and low cost.

Owner:SANY AUTOMOBILE MFG CO LTD

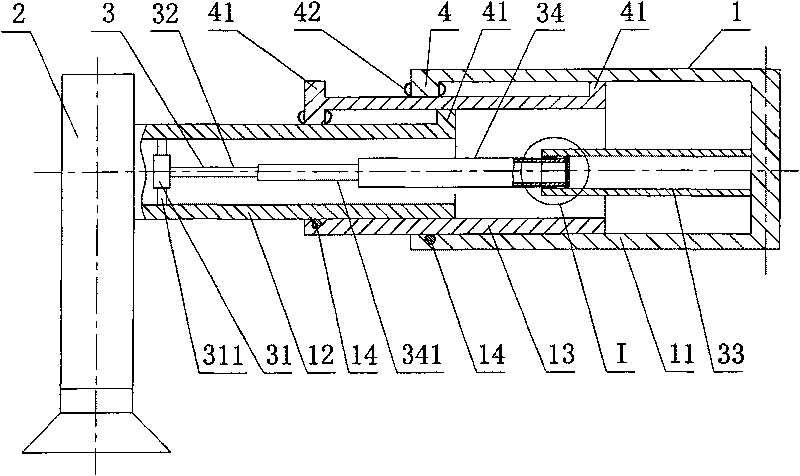

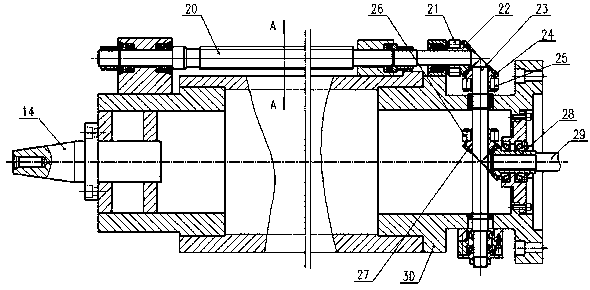

Large-specification deep hole boring device

PendingCN107900412ACompact structureReduce manufacturing costBoring/drilling machinesDrive shaftEngineering

The invention relates to a large-specification deep hole boring device. The large-specification deep hole boring device comprises a bottom plate, a feeding device, a boring rod box, a boring rod bracket, a boring rod, a sliding body, a cutterhead, a workpiece and a tailstock, the boring rod penetrates through an inner hole of the workpiece, one end of the boring rod is connected with the boring rod box, the other end of the boring rod is connected to the tailstock, the boring rod bracket is positioned at the lower part of the boring rod, a feeding screw rod and the sliding body are installed above the boring rod, the sliding body is installed on the feeding screw rod, and the sliding body integrally moves forwards and backwards on the boring rod along the feeding screw rod; and the cutterhead is arranged on the sliding body, a transmission shaft is arranged in the boring rod box, one end of the transmission shaft is connected with the feeding device, the other end of the transmission shaft is connected with the end of the boring rod, the transmission shaft can drive the boring rod to rotate integrally, the boring rod can drive the feeding screw rod to rotate when rotating, so thatthe sliding body arranged on the feeding screw rod moves forwards and backwards relative to the boring rod under the rotation of the feeding screw rod. The large-specification deep hole boring deviceis compact in overall structure and low in manufacturing cost; and the cutterhead is replaced, boring rods with different specifications are used in a certain range, so that machining precision is high, the application range is wide, and the requirements of various working conditions can be met.

Owner:德州普利森机床有限公司

Multifunction rotary tool assembly

The invention discloses a multifunctional rotary tool assembly. The multifunctional rotary tool assembly comprises a multifunctional tool head and corresponding locking heads. The multifunctional tool head is provided with two gear groups, and the two gear groups are the same in reduction ratio and are connected with a key and a lock catch respectively. The two gear groups are connected through a clutch, and synchronous rotation of the key and the lock catch and single rotation of the key are realized. Main components matched with the locking heads are the lock tongue and the lock tongue rotation shaft, a spring sheet is arranged in the lock tongue, and locking and separation of the locking heads can be realized by rotating the lock tongue rotation shaft through single rotation of the key. Due to the fact that the key and the lock catch rotate synchronously, corresponding tools can be driven to rotate through the locking heads. The multifunctional rotary tool assembly has the advantages that the locking heads are compact in structure and can be installed on multiple tools to be used in cooperation with the tool head for working. The multifunctional tool head is simple in structure and simple in operation and can be used for conducting real-time monitoring by being integrated with a visual device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Automatic lifting scaffold

ActiveCN105155833AImprove stabilityNo transgender distortionScaffold accessoriesBuilding support scaffoldsReducerRotating drum

The invention provides an automatic lifting scaffold, and belongs to the technical field of building engineering. A body structure of the scaffold is a cuboid structure consisting of an upper pull plate platform, four stand columns and a base; a lifting structure of the scaffold consists of a motor, a rotating drum, a steel wire rope, a fixed pulley, a platform and a stand column; the platform is mounted on the stand column; a power device is mounted on the base, and consists of a motor, a speed reducer, an electromagnetic brake, a shaft and a rotating drum; and one end of the steel wire rope is fixedly wound on the rotating drum, and the other end is fixedly connected with a hanging lug of the steel wire rope of the platform after bypassing through the fixed pulley. The platforms at the two ends of the automatic lifting scaffold are respectively provided with power by independent power systems to achieve lifting demands, that is, the two platforms do no interfere with each other in the working process to satisfy the demands of various working condition environments.

Owner:CHINA CONSTR EIGHTH ENG DIV

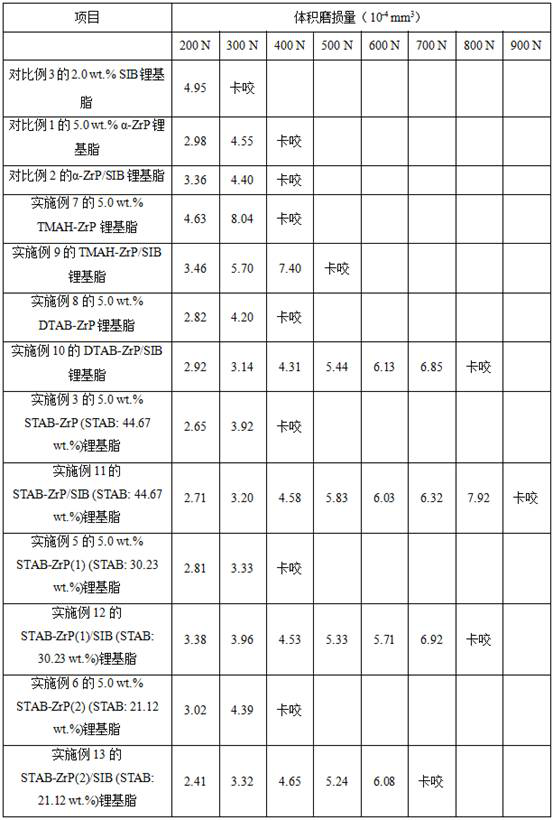

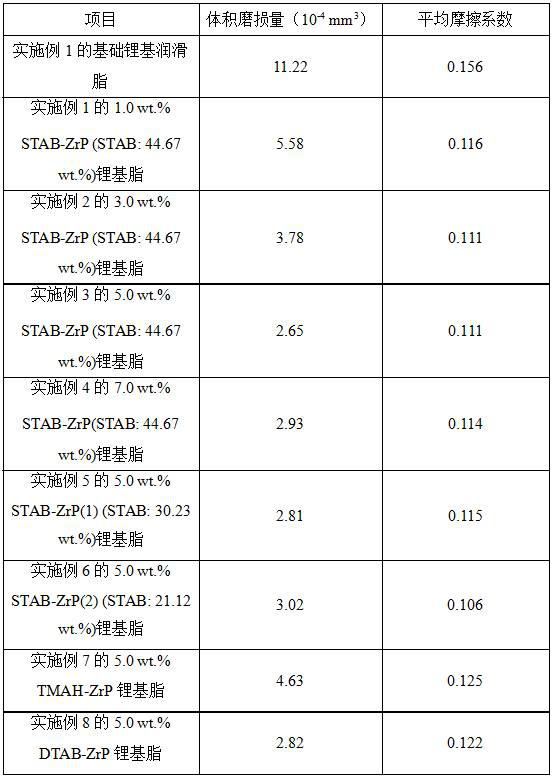

Lubricating grease compound additive and lubricating grease composition prepared from lubricating grease compound additive

PendingCN114426898AImprove extreme pressure performanceStable anti-wear performanceAdditivesOrganic baseAnoxomer

The invention discloses a lubricating grease compound additive and a lubricating grease composition prepared from the lubricating grease compound additive. The lubricating grease compound additive comprises an organic alkali intercalation zirconium phosphate compound and an extreme pressure agent, the organic base intercalation zirconium phosphate compound comprises one or two of organic amine intercalation zirconium phosphate, single-long-chain organic ammonium intercalation zirconium phosphate or double-long-chain organic ammonium intercalation zirconium phosphate. The lubricating grease composition comprises the following components in parts by weight: 90.0 to 98.0 parts of base grease, 1.0 to 7.0 parts of an organic alkali intercalation zirconium phosphate compound, 0 to 3.0 parts of an extreme pressure agent and 0.5 to 1.0 part of an antirust agent, and 0.5 to 2.0 parts of an antioxidant. The additive composition disclosed by the invention combines the advantages of a solid additive and an organic extreme pressure agent, and dual protection of a submicron-sized intercalated zirconium phosphate physical protective film and a nano-sized extreme pressure agent chemical protective film exists on the surface of a friction pair at the same time, so that the extreme pressure property of the lubricating grease is improved, the stable wear resistance is ensured, and the service life of the lubricating grease is prolonged. And the service life of the equipment is effectively prolonged.

Owner:TAIYUAN UNIV OF TECH

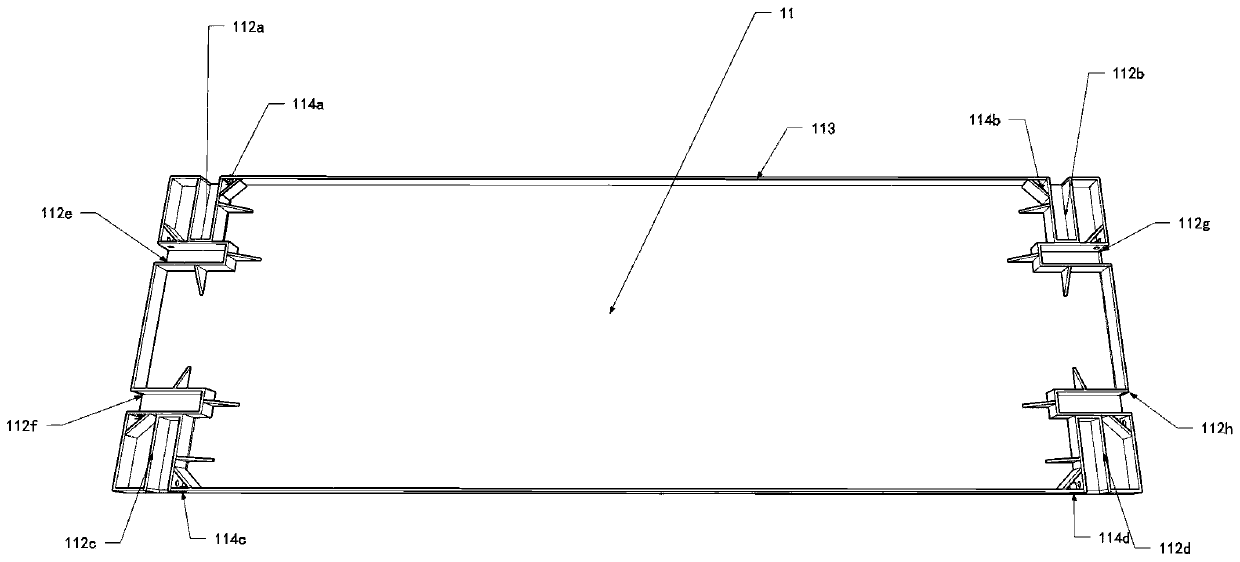

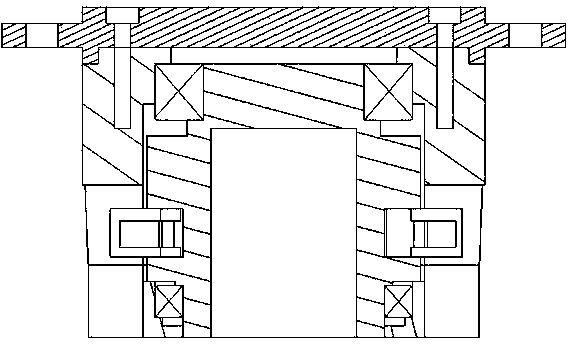

Combined heavy sliding linear guide rail

InactiveCN104653616AMeet the needs of various working conditionsSolve the low moment capacity of anti-overturning abilityLinear bearingsBearing componentsLinear motionEngineering

The invention discloses a combined heavy sliding linear guide rail which comprises a plurality of guide rail bodies, a guide block and a mounting bottom plate, wherein the guide rail bodies are fixedly connected with the mounting bottom plate by virtue of fastening screws, and guided objects perform linear motion along the surfaces of the guide rail bodies; each guide rail body comprises an upper end surface and two side surfaces; the side surfaces are provided with anti-turning inclined surfaces which incline inwards; the guide block comprises upper guide blocks and side guide blocks; the guide rail bodies are respectively provided with the upper guide blocks or the side guide blocks or the upper guide blocks and the side guide blocks; the upper guide blocks are arranged on the upper end surfaces of part of the guide rail bodies and are higher than the upper end surfaces of the guide rail bodies; the side guide blocks are arranged on the two side surfaces of part of the guide rail bodies and are higher than the side surfaces of the guide rail bodies. By virtue of adjustment of a functional module, combined guide rails with different functions can be formed so as to meet different needs. The combined heavy sliding linear guide rail is high in operability, high in precision, good in controllability, good in reliability and can meet requirements of any working condition.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

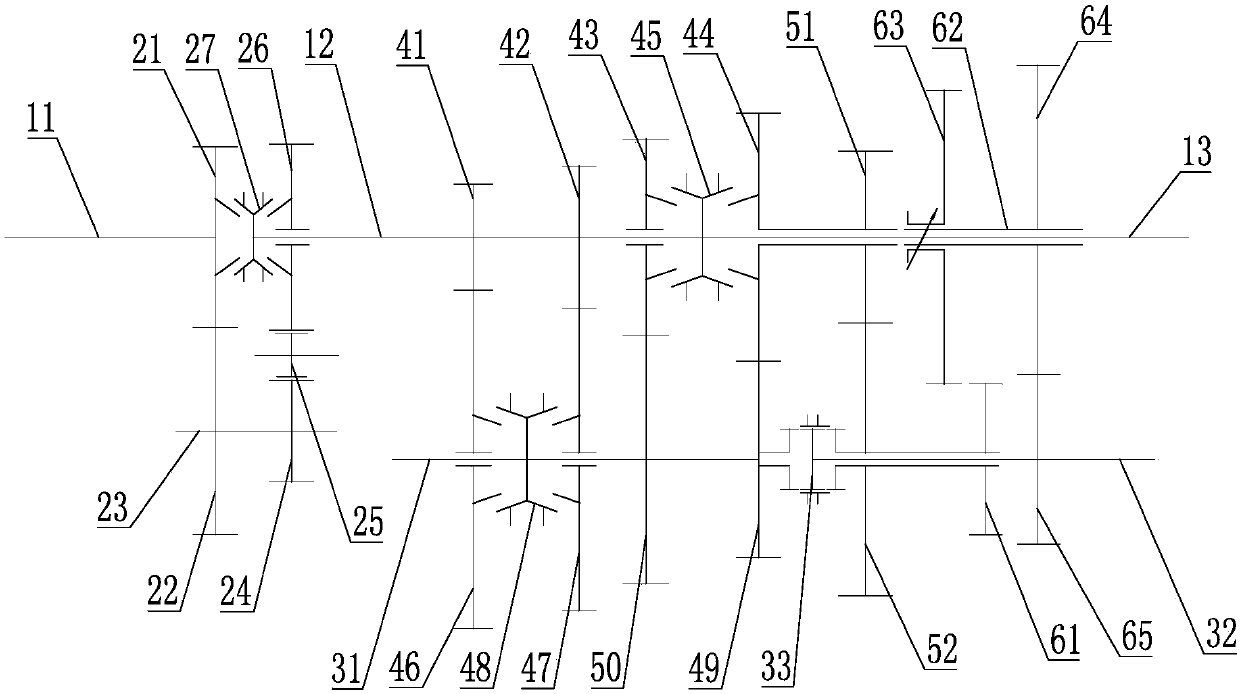

Transmission case of 16+16-gear hillside tractor

PendingCN107701696ACompact structureMeet the needs of various working conditionsToothed gearingsTransmission elementsAgricultural engineeringWorking environment

The invention discloses a transmission case of a 16+16-gear hillside tractor. The transmission case comprises a power input shaft, a shaft I and a power output shaft which are coaxial, wherein the shaft I is fixedly connected with the power output shaft; a reverse gear mechanism is mounted between the power input shaft and the shaft I; the transmission case further comprises a front shaft II and arear shaft II which are parallel to the shaft I; the front shaft II and the rear shaft II are coaxial; a field road gear meshing sleeve is mounted between the front shaft II and the rear shaft II; amain speed change mechanism is mounted between the shaft I and the front shaft II; the main speed change mechanism is connected with a field gear mechanism in a transmission manner; the field gear mechanism is connected with a crawling gear mechanism in a transmission manner; the field gear mechanism and the crawling gear mechanism are mounted between the power output shaft and the rear shaft II in sequence; and the reverse gear mechanism, the main speed change mechanism, the field gear mechanism and the crawling gear mechanism cooperate to totally output 16 forward gears and 16 reverse gears.A transmission is compact in structure, simple and practical, so that the tractor can be applicable to different working environments and engineering working scopes.

Owner:ZHEJIANG UFO AUTOMOBILE MFG CO LTD +1

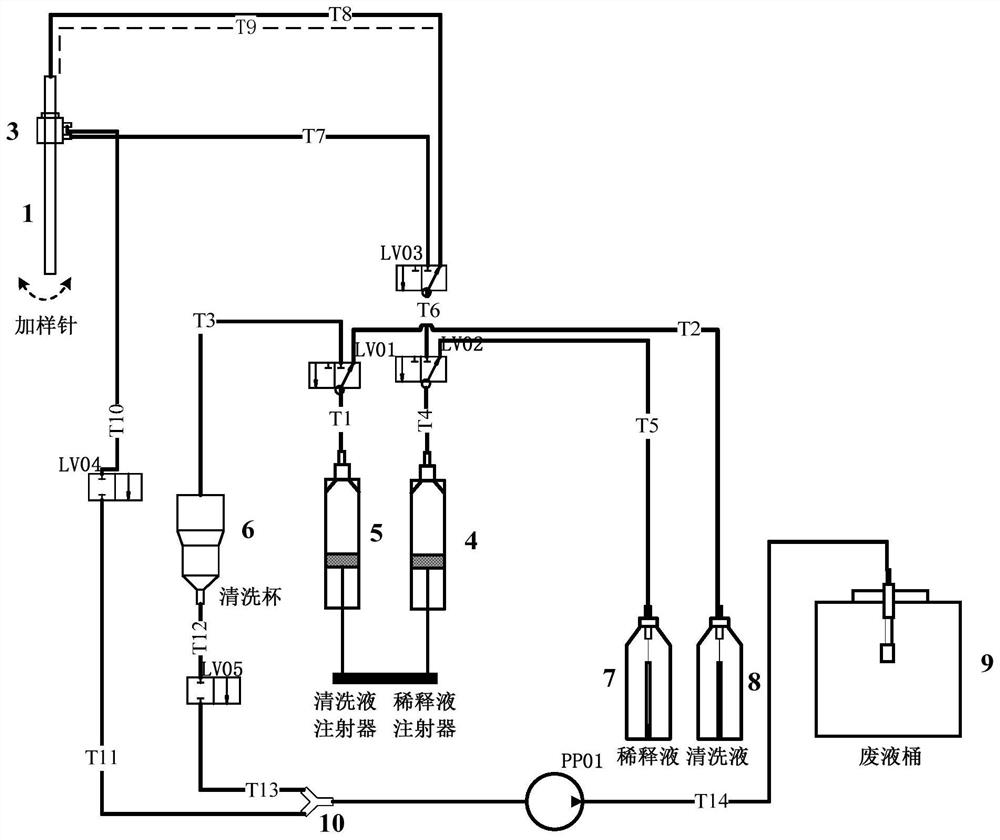

Sample adding needle cleaning fluid path and blood detection instrument

PendingCN112881722ADetection speedLow costHollow article cleaningMaterial analysisDiluentEngineering

The invention provides a blood detection instrument and a sample adding needle cleaning fluid path, the sample adding needle cleaning fluid path is used for cleaning the inner wall and / or the outer wall of a sample adding needle, and the sample adding needle cleaning fluid path comprises a fluid power device, a gating valve, a first fluid suction pipeline, a first fluid pushing pipeline, a second fluid pushing pipeline, a sixth pipeline and a cleaning swab; the first liquid suction pipeline is connected with the liquid power device through a reversing valve; the first liquid pushing pipeline is connected with the sampling needle through the gating valve; the second liquid pushing pipeline is connected with the liquid inlet end of the cleaning swab through the gating valve; the sixth pipeline is connected with the liquid outlet end of the cleaning swab; the liquid power device is used for sucking diluent through the first liquid sucking pipeline; a diluent is transmitted to the sample adding needle through the first liquid pushing pipeline so as to clean the inner wall of the sample adding needle; and diluent is transmitted to the liquid inlet end of the cleaning swab through the second liquid pushing pipeline so as to clean the outer wall of the sampling needle.

Owner:SHENZHEN DYMIND BIOTECH

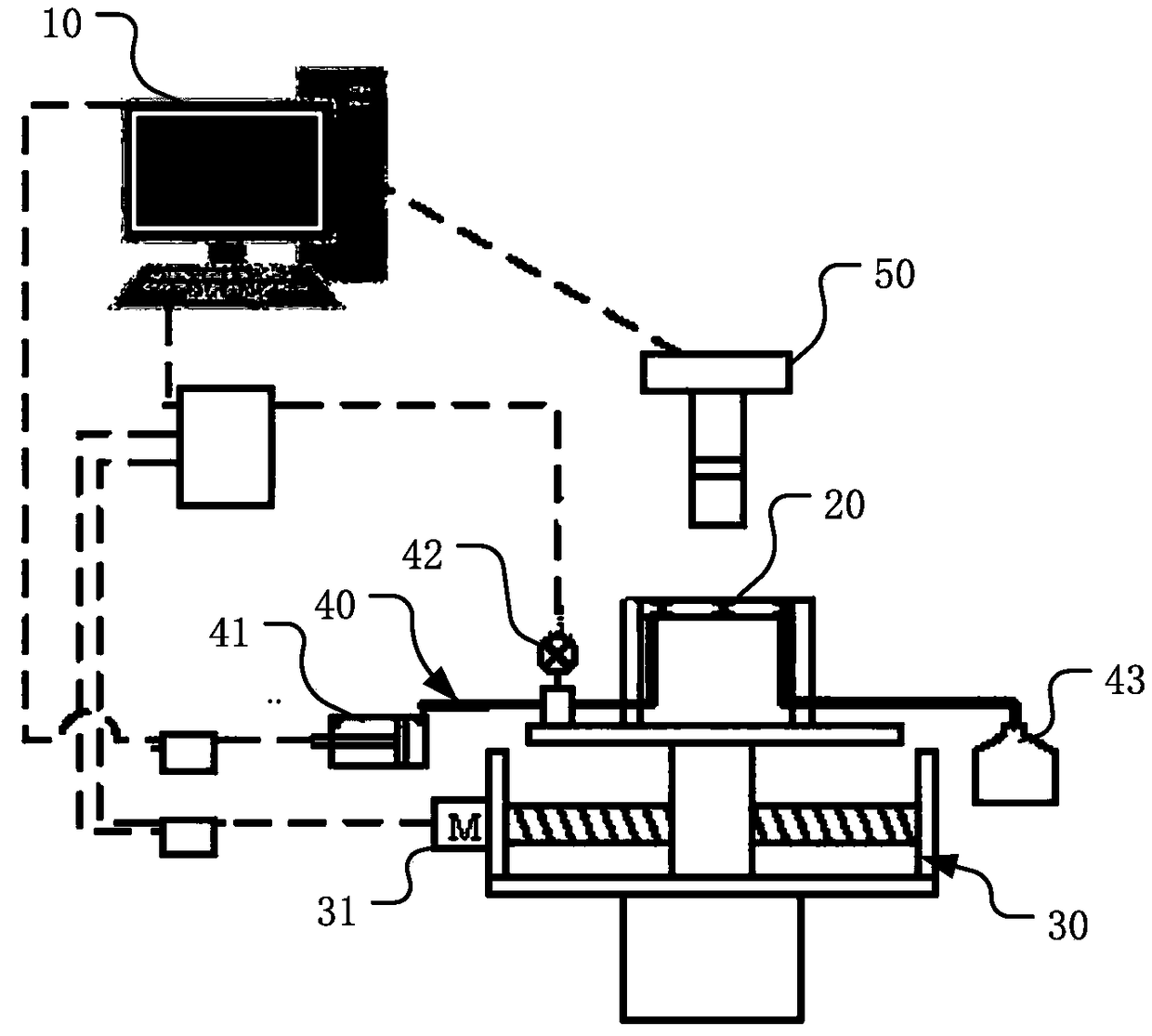

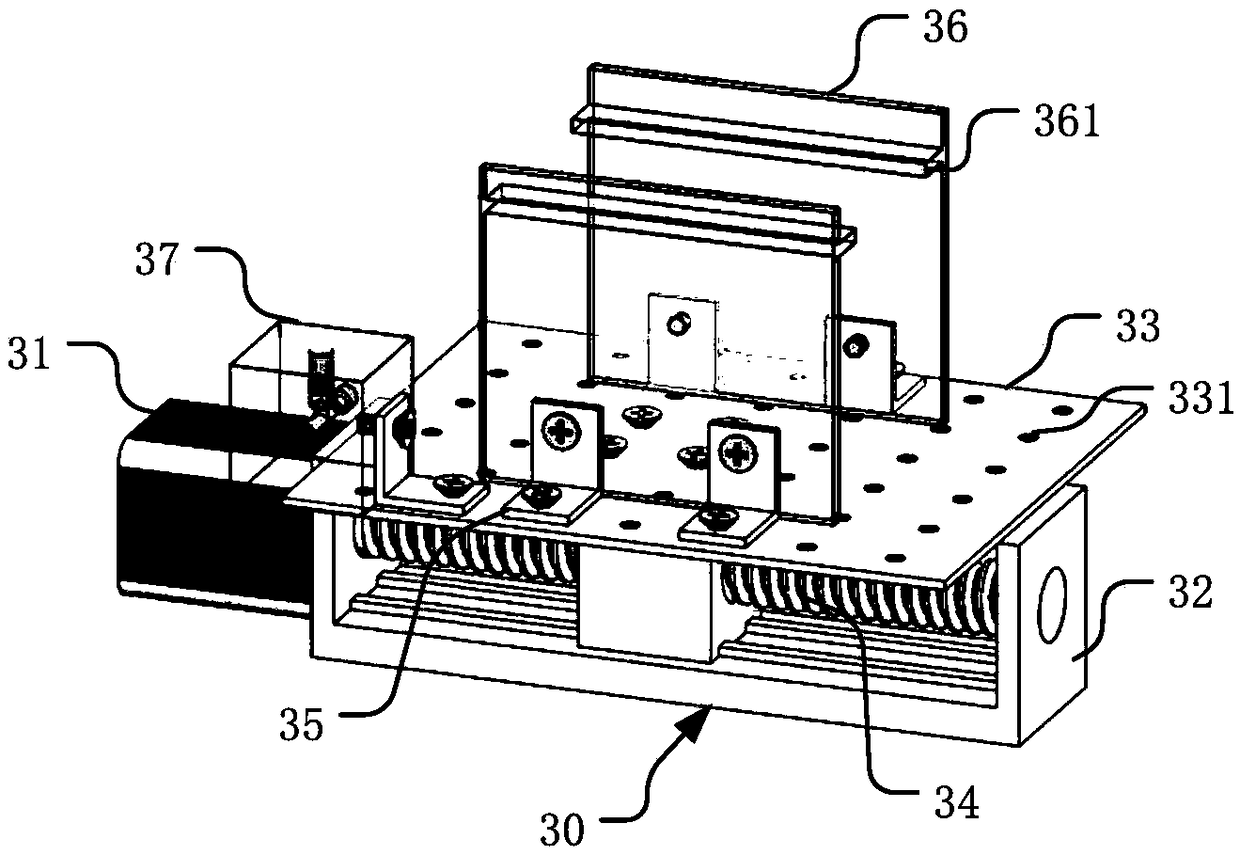

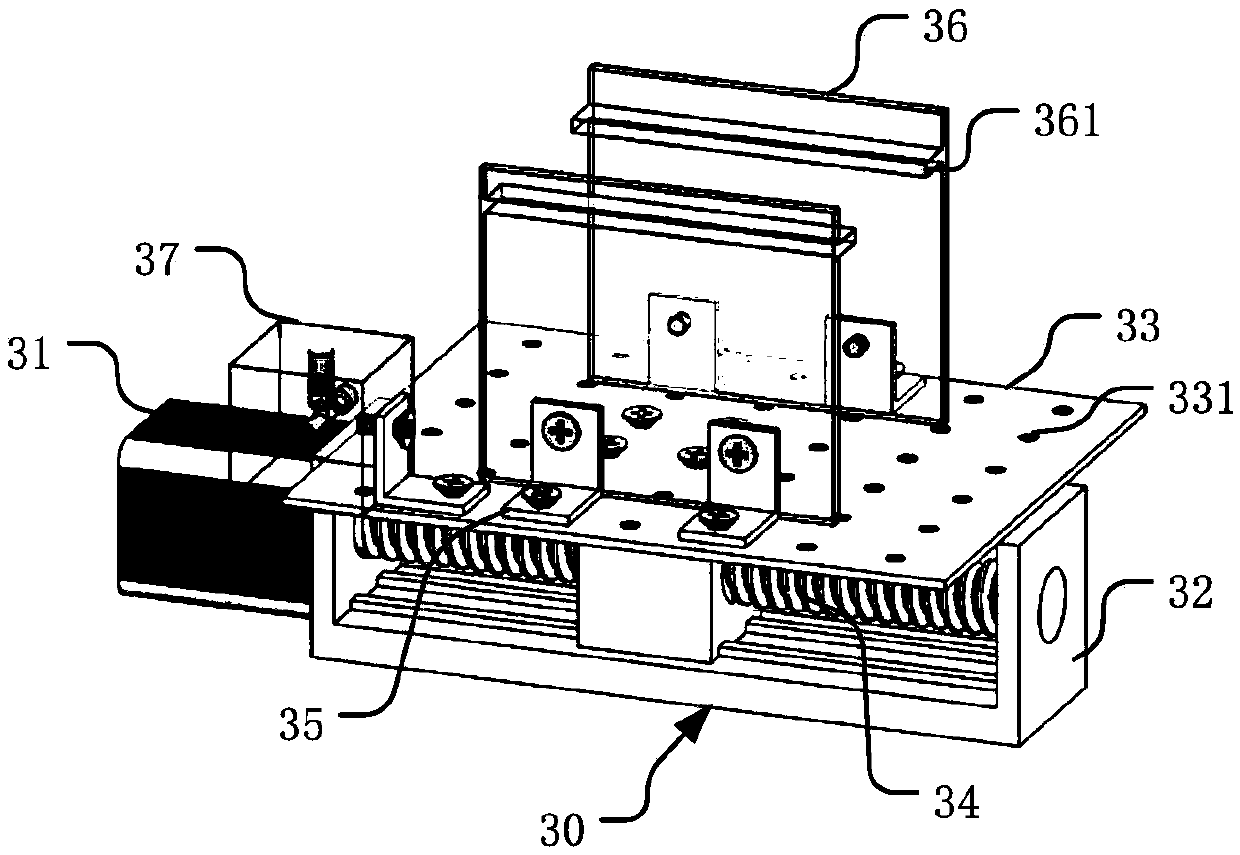

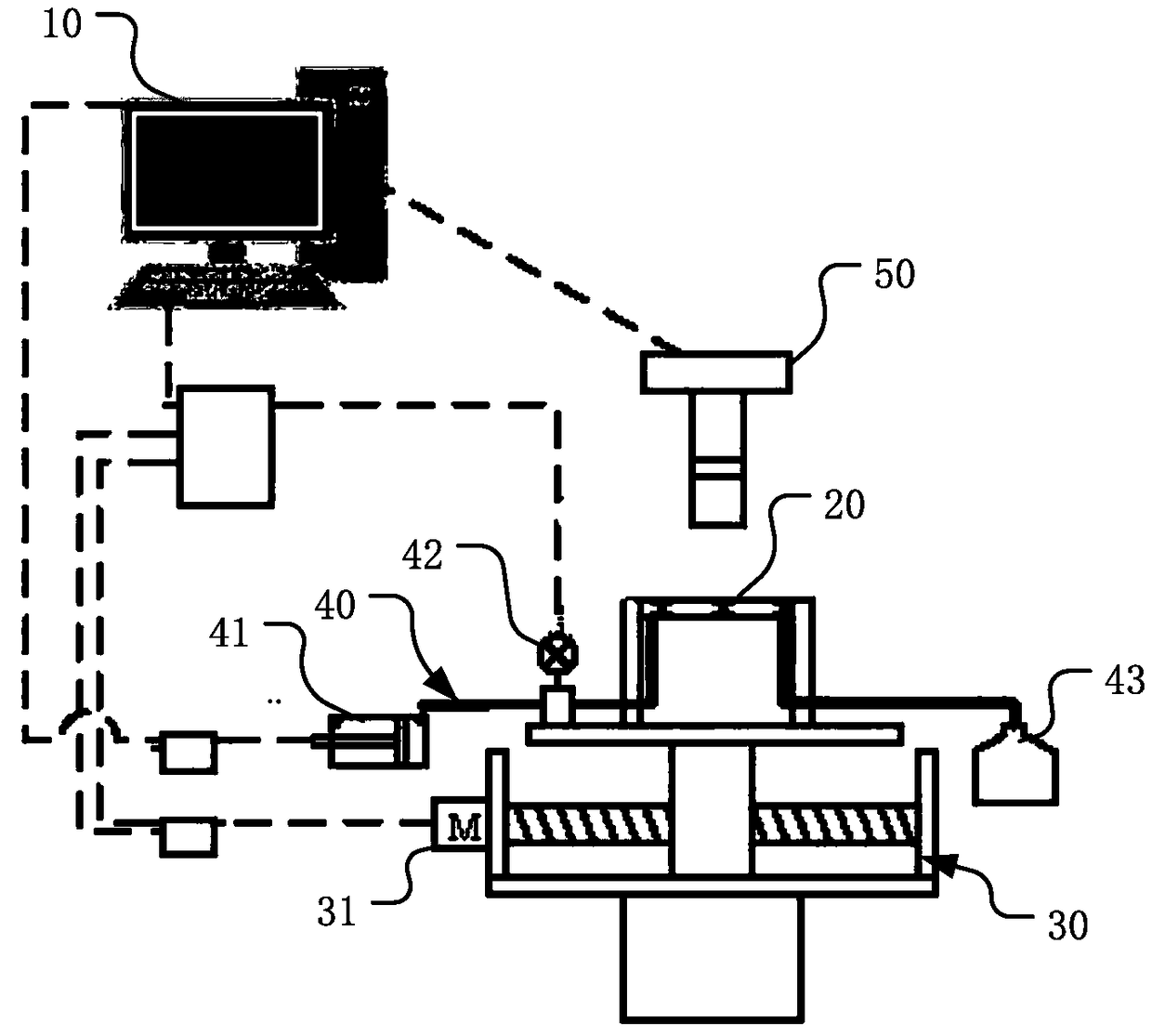

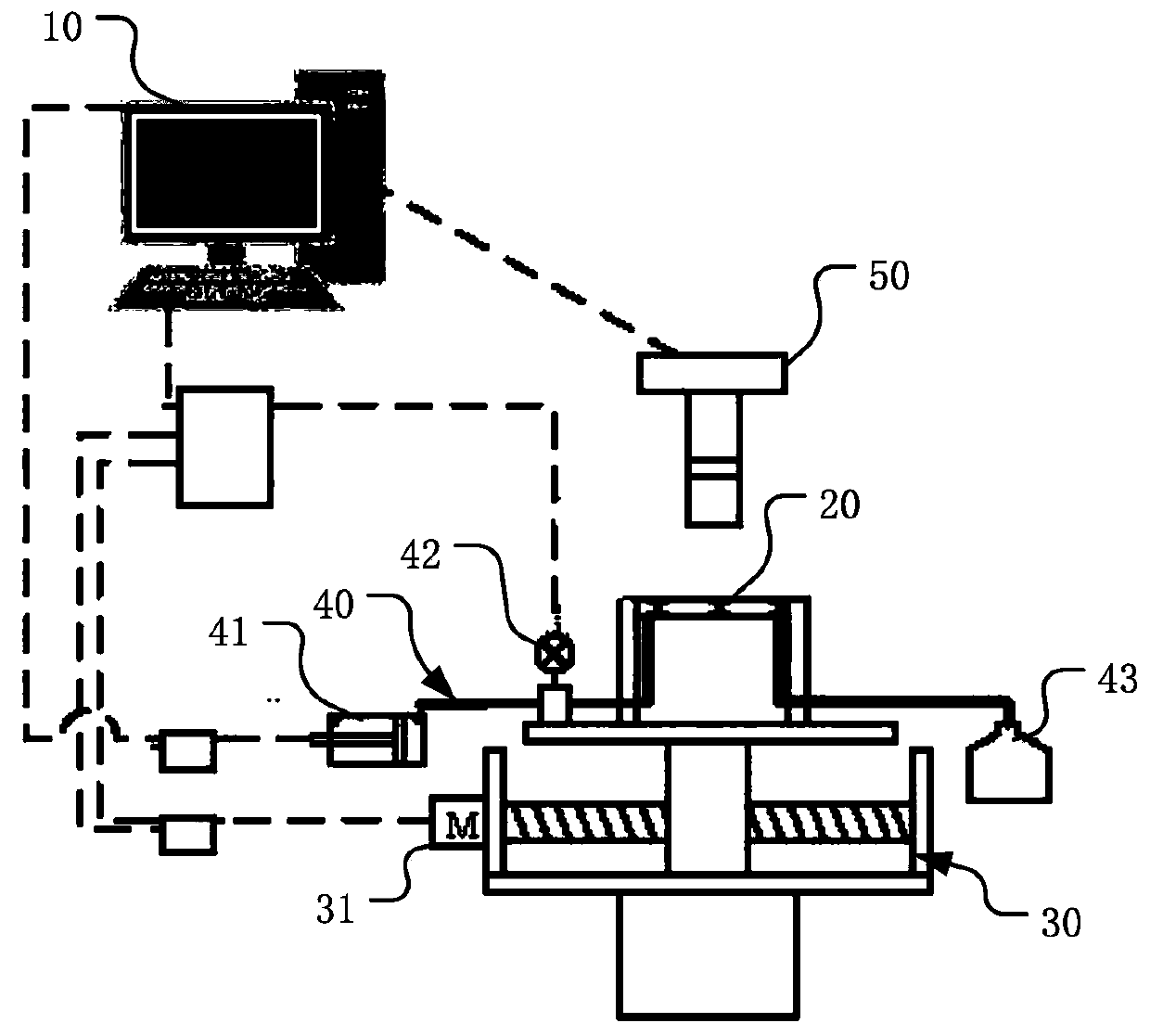

Micron capillary gas-liquid dynamic phase interface testing device

ActiveCN109142675AImprove efficiencyHigh measurement accuracyEarth material testingLiquid dynamicsCapillary channel

The invention provides a micron capillary gas-liquid dynamic phase interface testing device. The device comprises a micro-flow chip provided with a micron capillary channel, a pressure control pipeline with a syringe pump and a pressure sensor, a mobile platform for controlling movement of the micro-flow chip and a camera shooting unit which obtains and outputs a phase interface image of testing liquid, an injection process of the syringe pump is controlled according to information of a pressure sensor, and a horizontal movement speed of the micro-flow chip and the movement speed of the testing liquid in the micro-flow chip are the same and in the opposite direction, so that the phase interface formed by the testing liquid is always maintained in a control system within the field of view of the camera shooting unit. The device achieves the control of the pressure or flow velocity of the gas-liquid two-phase flow process in micrometer-scale capillaries, achieves the dynamic contact angle measurement under the condition of low capillary number and low bond number for the first time, and greatly improves the data processing efficiency and measurement accuracy.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Structure-changeable motor system

ActiveCN105391366AReduce weightReduce volumeElectronic commutation motor controlVector control systemsHigh power densityClutch

The invention relates to a structure-changeable motor system. The structure-changeable motor system comprises a main controller, a structure-changeable type driver and an independent winding motor; the main controller receives a control instruction and feedback information of the permanent magnet independent winding motor and generates power drive and drive topologic structure change instructions; the structure-changeable type driver changes a drive topologic structure based on the drive topologic structure change instruction; the structure-changeable type driver changes the winding drive mode of the independent winding motor into N star-shaped structures or independent H-bridge structures; when the independent H-bridge structures are adopted, multiple windings of the motor are connected in series; and the structure-changeable type driver drives the independent winding motor based on the power drive instruction. The structure-changeable motor system can satisfy different working condition demands; and compared with a structure comprising multiple motors and a clutch, the structure-changeable motor system can reduce weight and volume of a motor drive system efficiently, can increase power density efficiently and can remove mechanical noise.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Anchor bolt support construction device and crawler-type multi-arm side anchor bolt jumbo

ActiveCN112963184AImprove the anchor support speedSolve the problem of low side support efficiencyDerricks/mastsAnchoring boltsArchitectural engineeringRock bolt

The invention provides an anchor bolt support construction device. The device comprises a base, a first anchor bolt assembly located on the front side of the base and a second anchor bolt assembly located on the rear side of the base, wherein drilling frames in the first anchor bolt assembly and the second anchor bolt assembly can be used for conducting side anchor support operation and roof anchor support operation before and after rotation. According to the anchor bolt support construction device and a crawler-type multi-arm side anchor bolt jumbo applying the same, support construction of multiple side anchors can be conducted at the same time, so that the side anchor support speed is increased, and the problem that the side anchor support efficiency is relatively low under the condition that the roof and side conditions are relatively good and the roof anchor support is completed is solved; and part of the drilling frames can rotate to replenish and drive roof anchors, so that the application range of the anchor rod support construction device is widened, and the requirements of various working conditions can be met.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

An Open Winding Variable Structure Motor System

ActiveCN105610280BReduce weightReduce volumeAssociation with control/drive circuitsEmergency protective circuit arrangementsElectric machineControl engineering

The invention relates to an open winding variable-structure motor system, which comprises a master controller, a variable-structure driver and an open winding motor, wherein the open winding motor comprises N groups of windings; each group of windings comprise a first winding and a second winding; N is greater than or equal to 2; the master controller receives a control instruction and feedback information of the open winding motor, and generates a power drive instruction and a drive topology variable-structure instruction; and the variable structure driver converts a drive topology structure according to the drive topology variable-structure instruction, can connect each group of two windings of the open winding motor into a new one-phase winding in series, and can also be converted into a light load mode or a heavy load mode. The open winding variable-structure motor system fully utilizes the advantages of variable structures, high power density and high reliability of the variable-structure driver and a multi-phase open winding motor, can meet different work condition requirements, can effectively reduce the weight and the volume of a motor drive system, effectively improves the power density and the reliability and eliminates mechanical noise.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

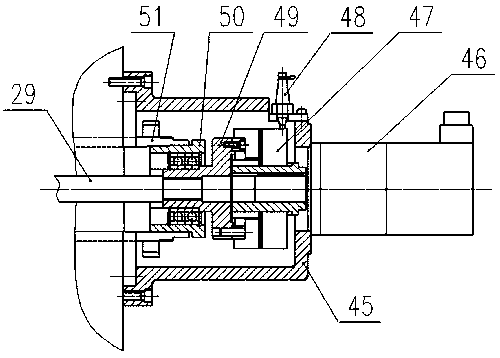

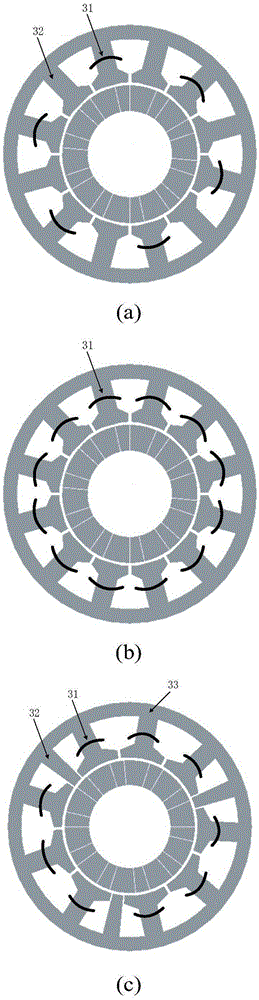

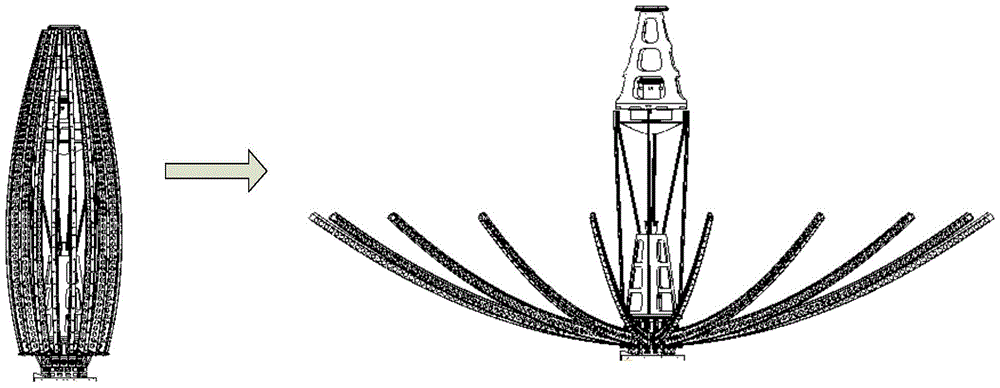

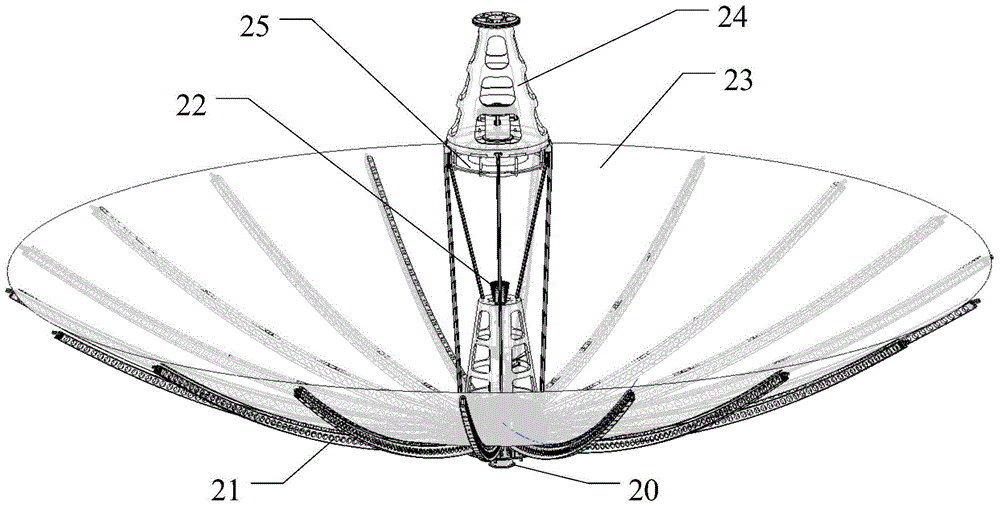

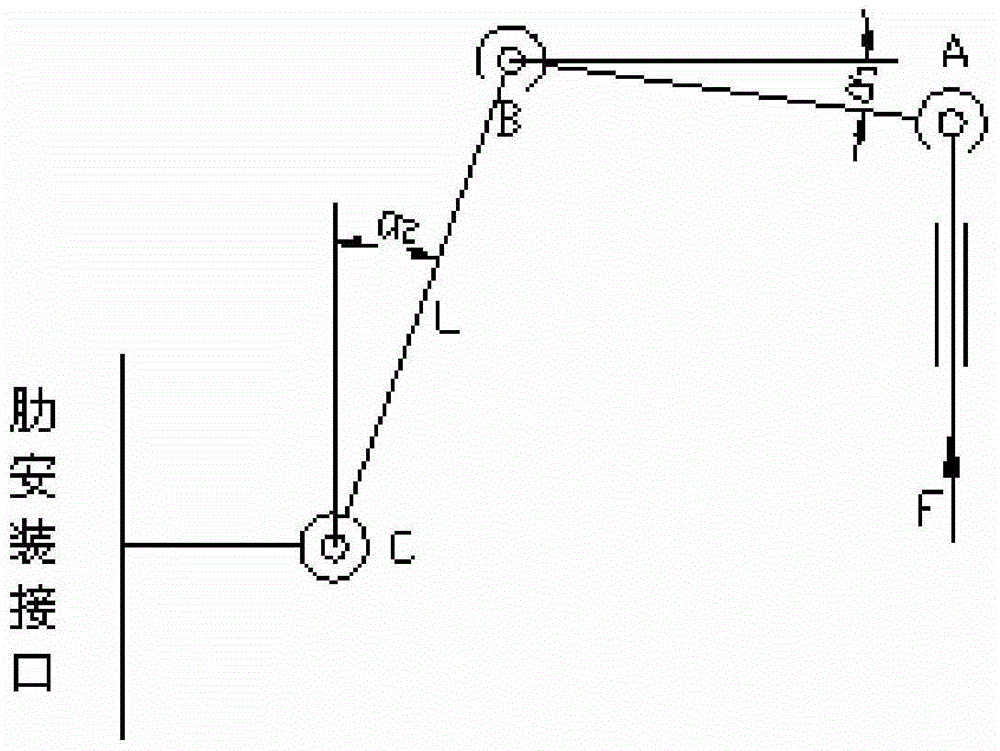

A New Rib Expanding Mechanism for High Precision Umbrella Antenna

ActiveCN104617369BMeet the needs of various working conditionsEasy to controlAntenna supports/mountingsGearingLinear motionCoupling

A new type of high-precision umbrella-shaped antenna rib expansion mechanism, the motor and reducer provide power for the rib expansion mechanism; the screw is connected to the reducer through the coupling block, and rotates itself under the drive of the reducer, and the nut is set on the screw. The rotating motion of the lead screw is converted into the up and down linear motion of the nut; the sliding plate is set on the guide sleeve, connected with the nut through a limit screw, and moves up and down together with the nut; one end of the connecting rod is hinged to the sliding plate through a rotating shaft, and the other end It is hinged with the locking arm; the umbrella-shaped antenna rib is installed on the H surface of the locking arm, and the locking arm is driven by the connecting rod to rotate, and then drives the antenna rib to complete the unfolding or retracting action; the locking device in place is used for the antenna rib to be unfolded in place. Locking, so that the antenna rib has sufficient rigidity; the invention realizes the smooth deployment and retraction of the high-precision umbrella antenna and the process is controllable, and has the characteristics of high repeated deployment accuracy and small thermal deformation.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

A method for obtaining the moving velocity of the gas-liquid phase interface in a micron capillary channel

ActiveCN108918348BImprove efficiencyHigh measurement accuracySurface/boundary effectCapillary channelCapillary Tubing

The invention provides a method for obtaining the movement speed of a gas-liquid phase interface in a micron capillary channel. According to the method provided by the invention, the control of pressure or flow velocity of a gas-liquid two-phase flow process in a micrometer-scale capillary vessel is realized through a dynamic testing device; a method for obtaining the phase interface and the phaseinterface velocity is given; the obtaining of the phase interface shape is realized for the first time under the conditions of low capillary number and low bond number; image processing method basedphase shape calculation and velocity calculation are adopted for the first time to ensure that the data processing efficiency and the measurement accuracy are greatly improved; and various algorithmsfor controlling the pressure control of the two-phase flow and the speed of an electric platform are also provided to improve the flexibility in actual operation and meet the requirements of various working conditions.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

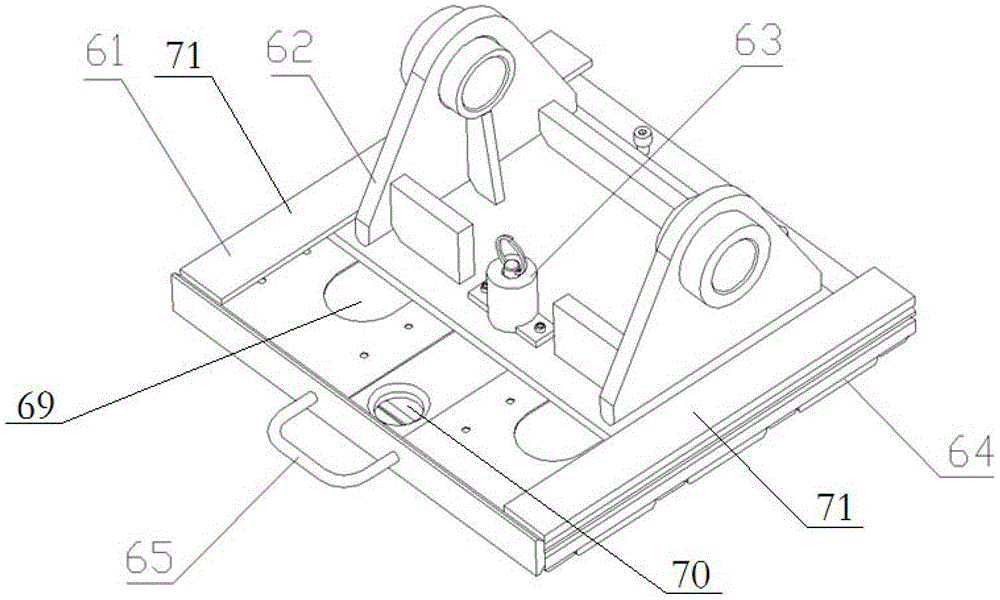

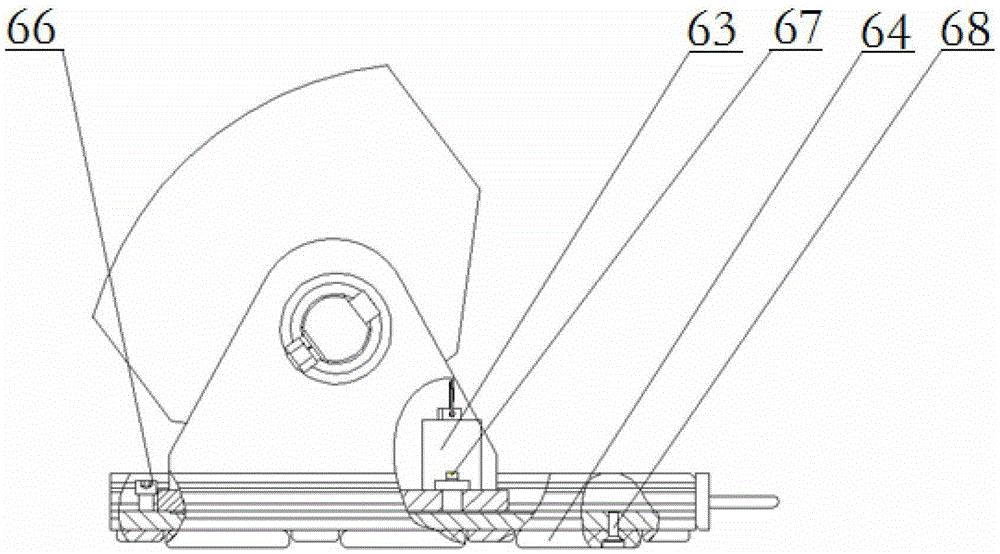

Anti-skid foot device and walking machine

ActiveCN103832410BAvoid technical problems prone to sideslipSolve technical problems that are prone to sideslipVehicle fittings for liftingSoil-shifting machines/dredgersFixed frameEngineering

The invention discloses an anti-skid support foot device and a walking machine, and relates to the technical field of engineering machinery. It solves the technical problem in the prior art that the legs are prone to sideslip. The anti-skid foot device includes a base, a foot, a locking device and a slide rail structure, the slide rail structure is arranged between the foot and the base, and the foot can slide along a predetermined direction on the base through the slide rail structure; the tightener is arranged on the base and the foot On the other hand, when the feet slide along a predetermined direction on the base to a predetermined locking position through the slide rail structure, the locking device can lock the feet on the base. The walking machine includes a fixed frame, an A-shaped outrigger, a telescopic power mechanism, and an anti-slip foot device provided by any technical solution of the embodiment of the present invention. The invention is used to improve the anti-skid performance of the legs.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com