Open winding variable-structure motor system

An open winding and variable structure technology, which is applied in the direction of connecting with the control/drive circuit, can solve the problems of low system power density, large volume and weight, large mechanical vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

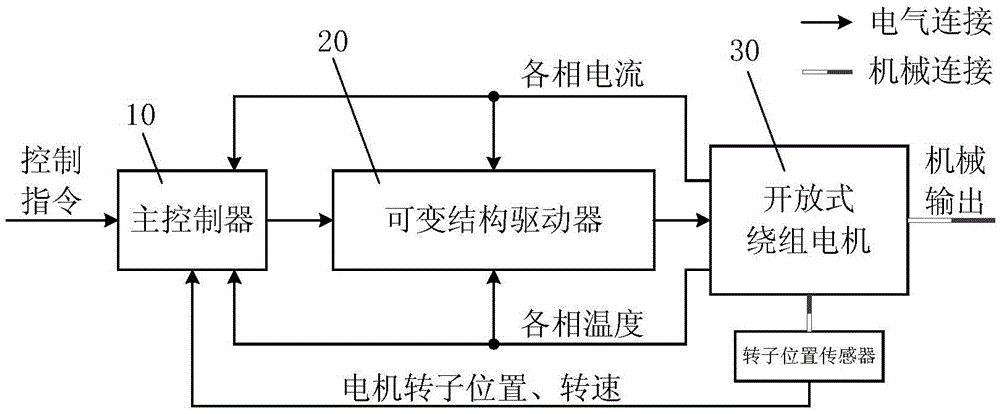

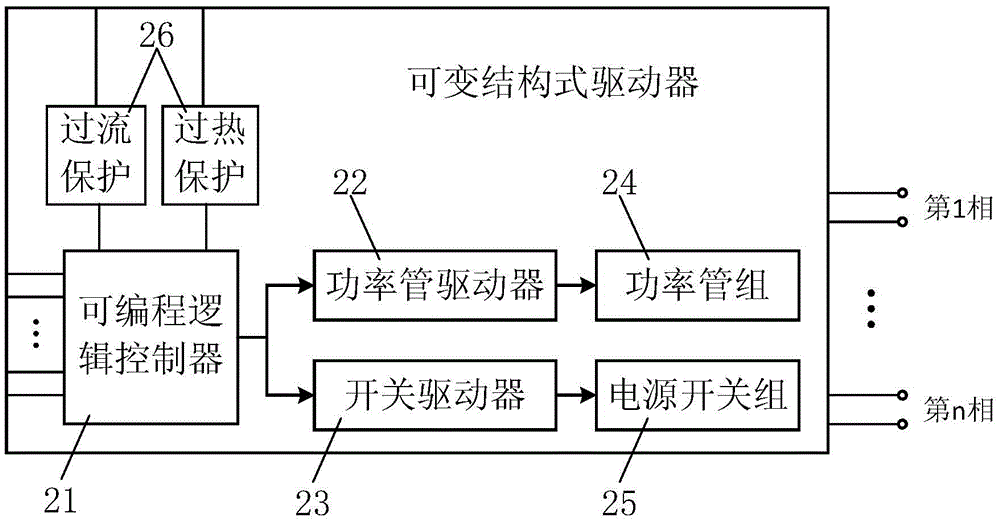

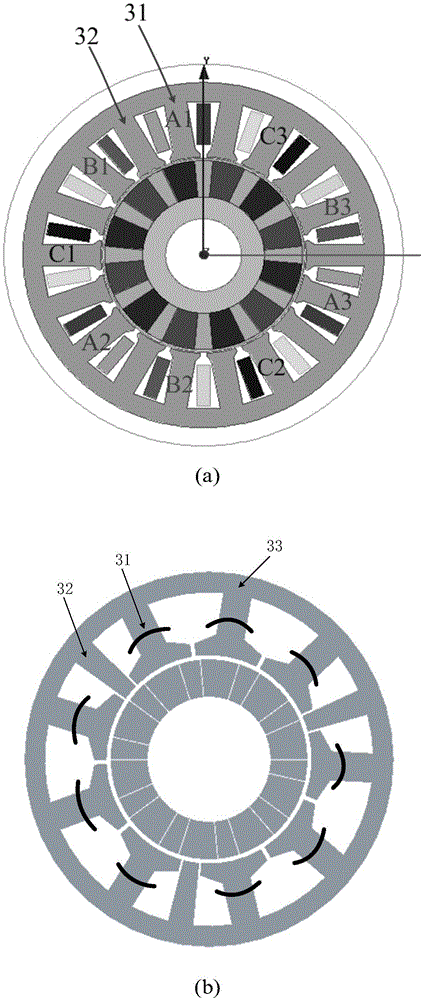

[0067] Such as figure 1 As shown, the main propulsion control of a ship is used to illustrate the variable structure motor system proposed by the present invention. In the present invention, the variable structure motor system includes a main controller 10, a variable structure driver 20 and an open winding motor 30. The main controller 10 receives control instructions and feedback information from the open winding motor 30, and generates Power drive and drive topology variable structure instructions. According to different operating conditions, the variable structure driver 20 transforms the drive topology structure according to the drive topology variable structure instruction. The variable structure driver 20 converts the open winding motor Multiple windings of 30 are connected in series to become a new one-phase winding. When the number of phases is 3×N+3, it is driven by 3×N+3 of the H bridge 42. After the control command is changed, it can be changed to N The new N+1 pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com