Large-specification deep hole boring device

A large-scale, deep-hole technology, applied in the field of large-scale deep-hole boring devices, can solve the problem that the deep-hole boring head is difficult to process discontinuous holes and soft material holes, the boring diameter of the deep-hole boring head cannot be adjusted arbitrarily, and the processing hole diameter is difficult. Large and other problems, to achieve the effect of compact coaxial installation structure, wide processing range and easy finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

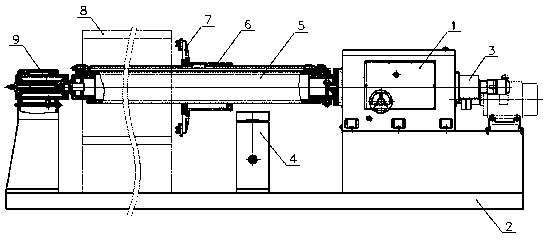

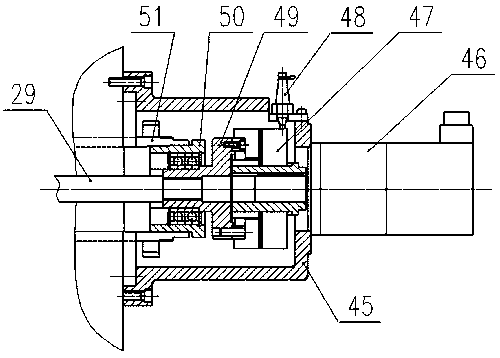

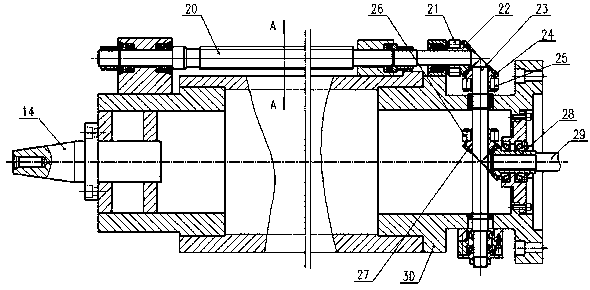

[0032] As shown in the figure, the large-scale deep hole boring device adopts a fairly rigid boring bar 5 as a whole, which passes through the inner hole of the workpiece 8, and one end of the boring bar 5 is installed in the boring bar box through a flange. On the main shaft 51, the power input is realized, and the other end is connected to the tailstock 9, so as to realize the simply supported state at both ends of the boring bar; The frame 31 is a long structure, the sliding body 6 moves along the boring bar 5 as a whole, and is guided relative to the boring bar 5 through the screw bracket 31; the cutter head 7 is installed above the sliding body 6, and the cutter head 7 is installed symmetrically A pair of cutters 44, the size of the cutters 44 is corrected according to the machining aperture, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com