Patents

Literature

37results about How to "Easy finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron casting online automatic finishing device and iron casting online automatic finishing method

ActiveCN104190912ARealization of online automatic finishingAvoid damageCasting plantsMaterials scienceTemporary storage

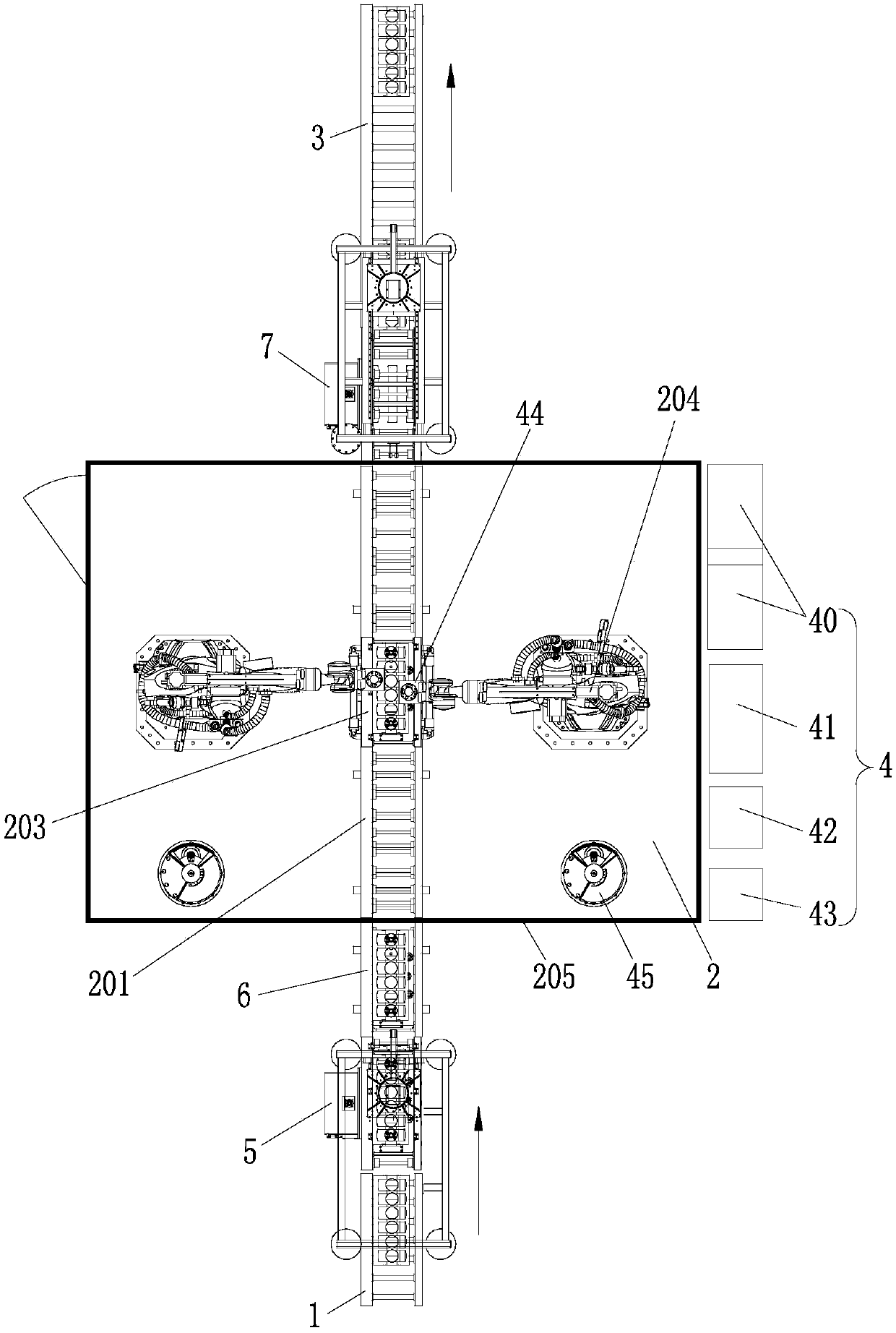

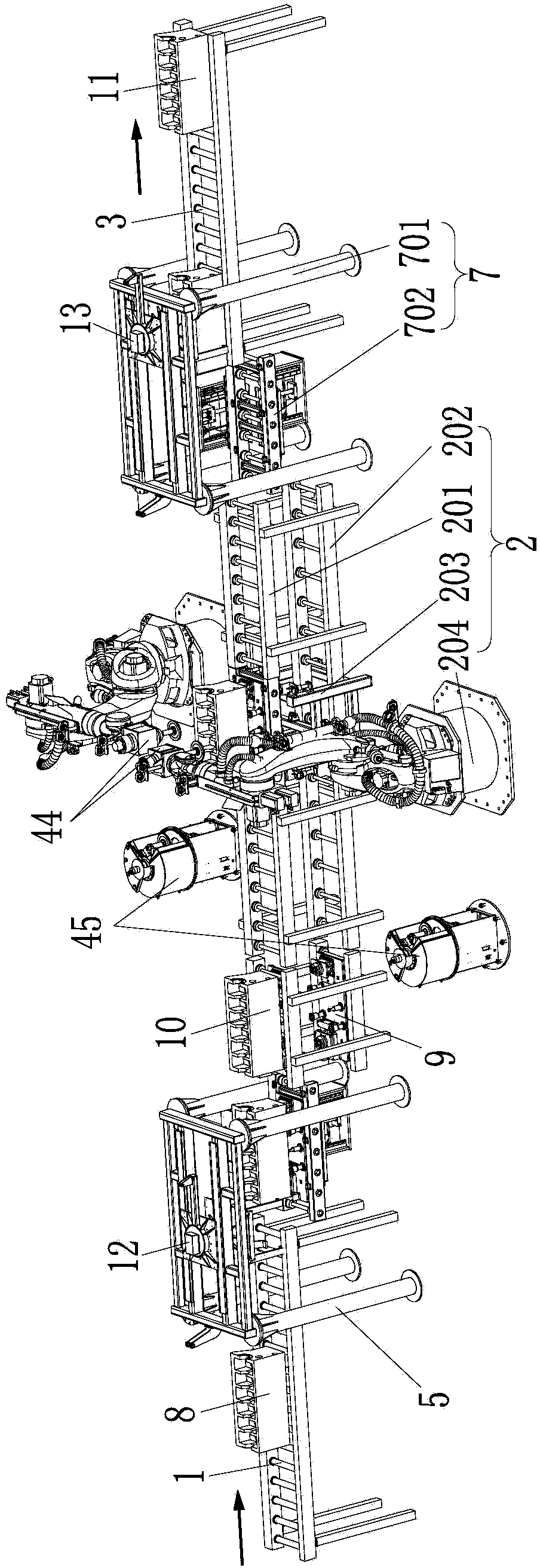

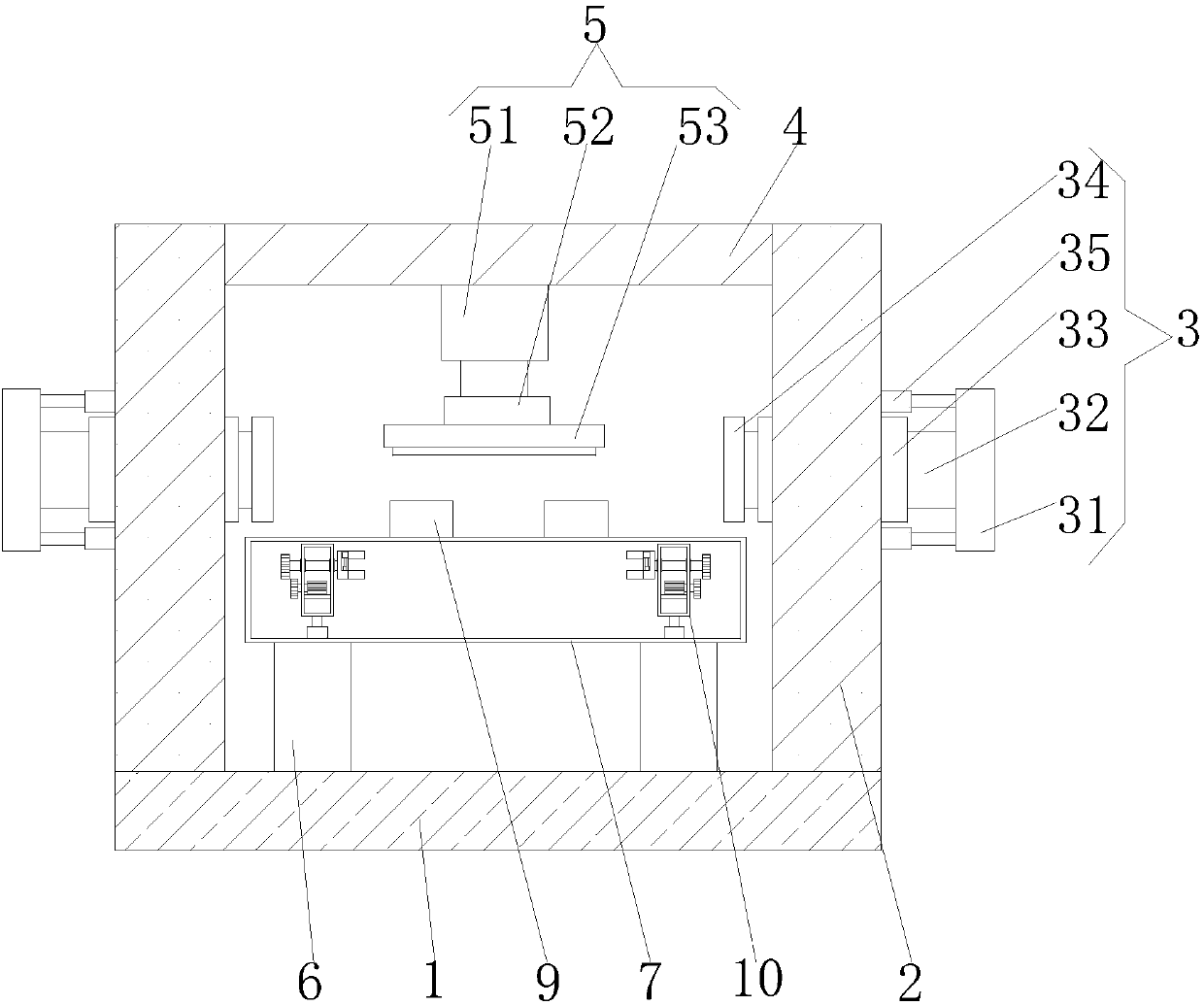

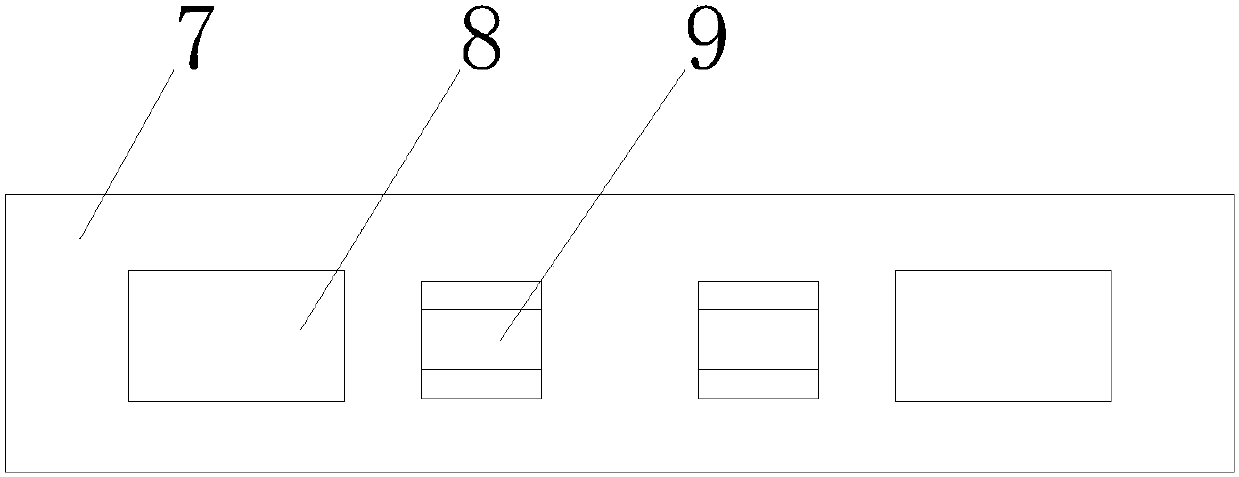

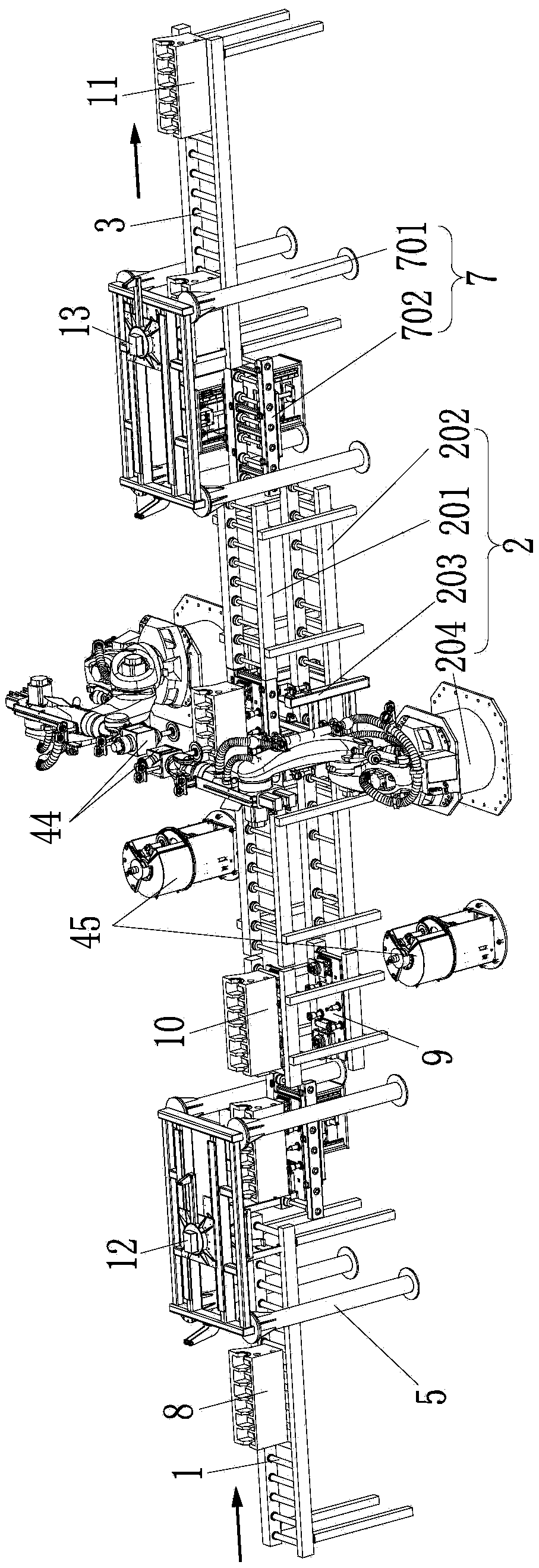

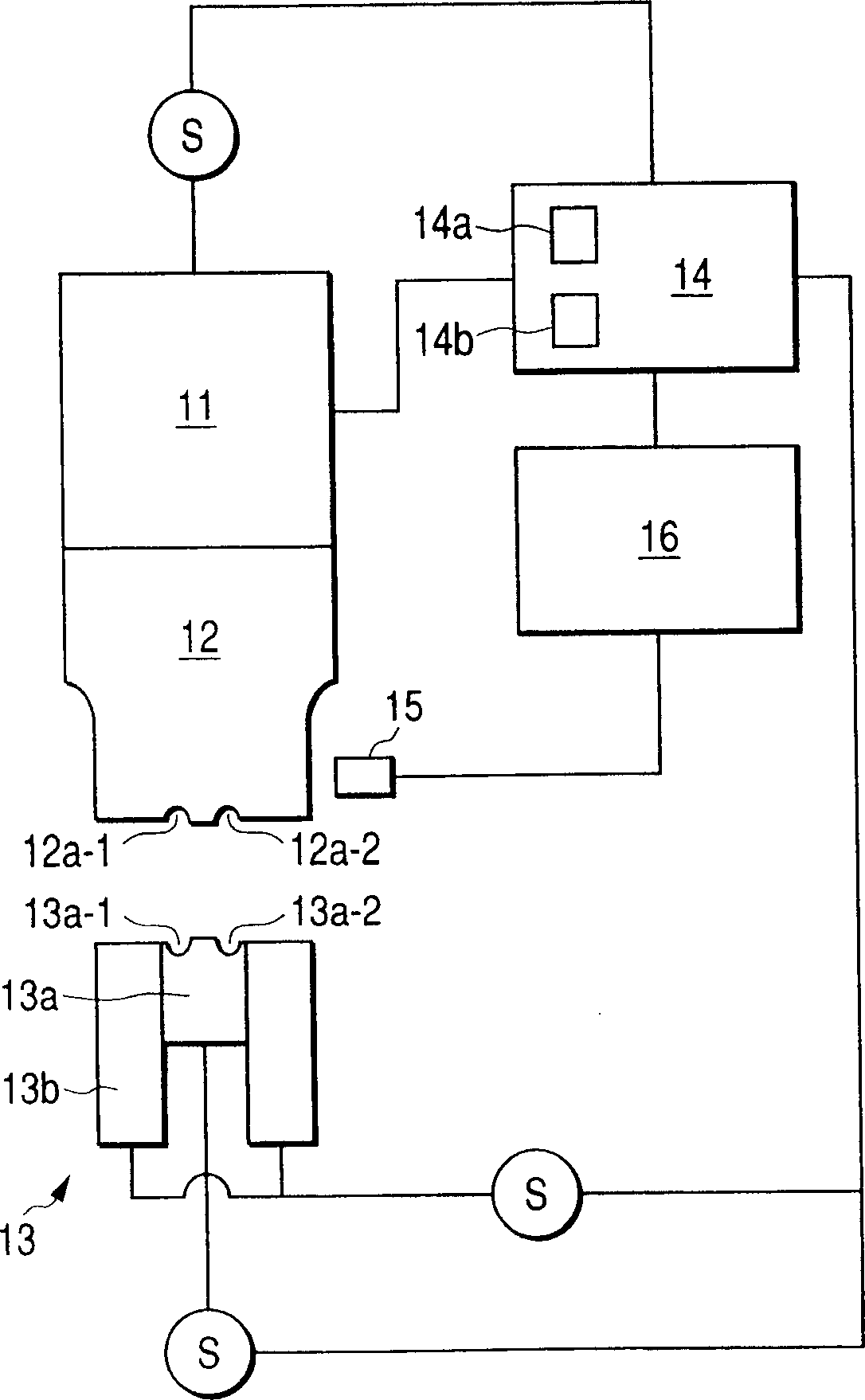

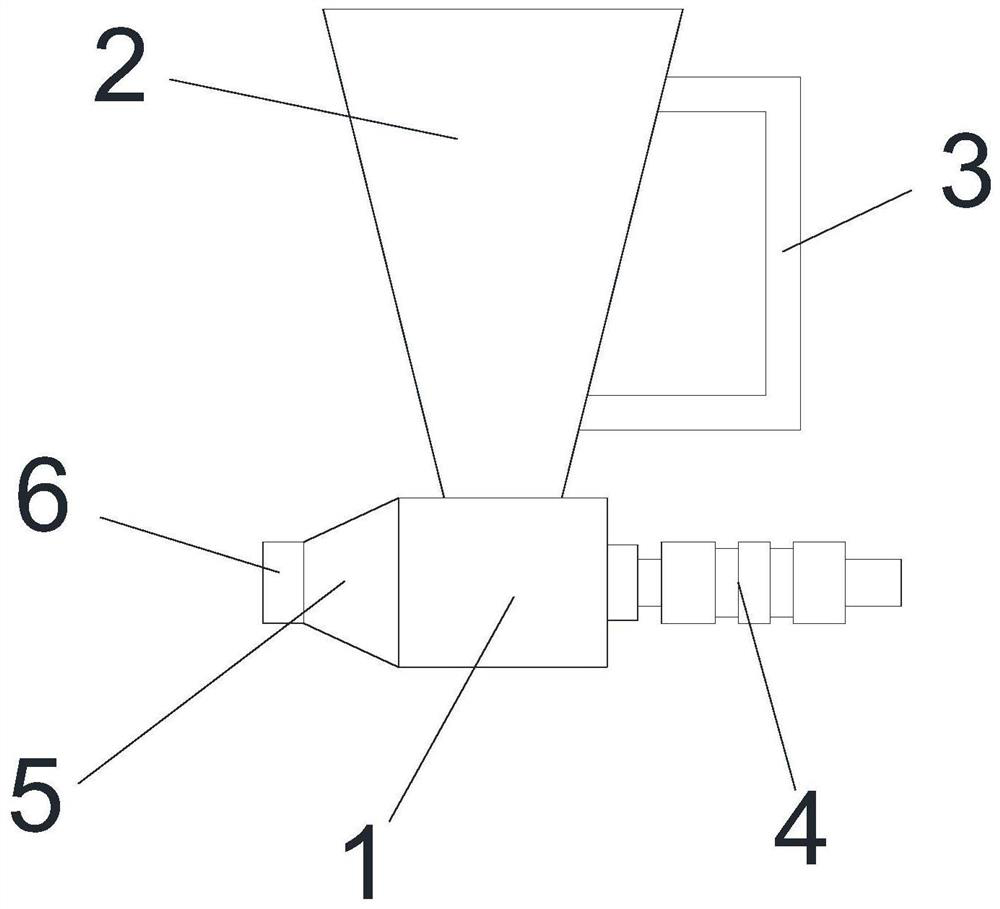

The invention discloses an iron casting online automatic finishing device and an iron casting online automatic finishing method. The iron casting online automatic finishing device comprises a supplied material conveying line, a safety chamber used for finishing of iron castings, a discharge conveying line used for conveying and storing the iron castings machined through finishing, and a centralized controller used for online automatic finishing control. A first lifting table used for assembling iron casting materials on an empty tray to form a load-bearing tray is arranged between the supplied material conveying line and the safety chamber. A temporary storage table used for temporarily storing the load-bearing tray conveyed to the safety chamber and temporarily storing the empty tray supplied to the first lifting table is arranged between the first lifting table and the safety chamber. A second lifting table used for separating the iron castings where finishing is completed from the load-bearing tray and sending the iron castings to the discharge conveying line is arranged between the safety chamber and the discharge conveying line. It is ensured that finishing of the iron castings is conducted in order, and online automatic finishing of the iron castings is achieved by conducting transferring through the lifting tables.

Owner:CHANGSHA CTR ROBOTICS

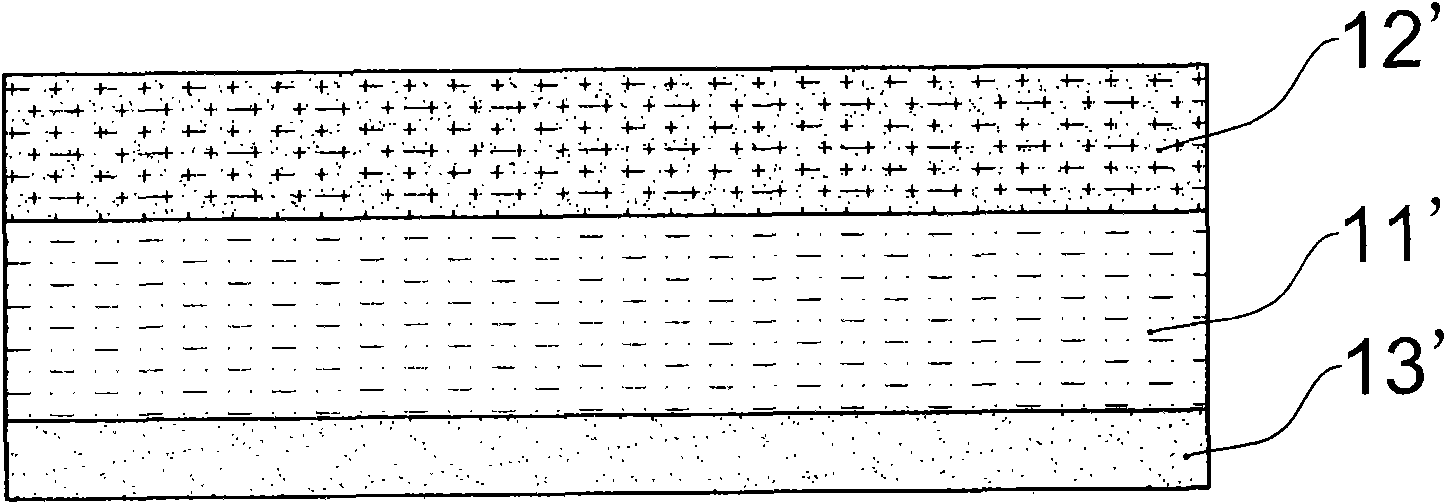

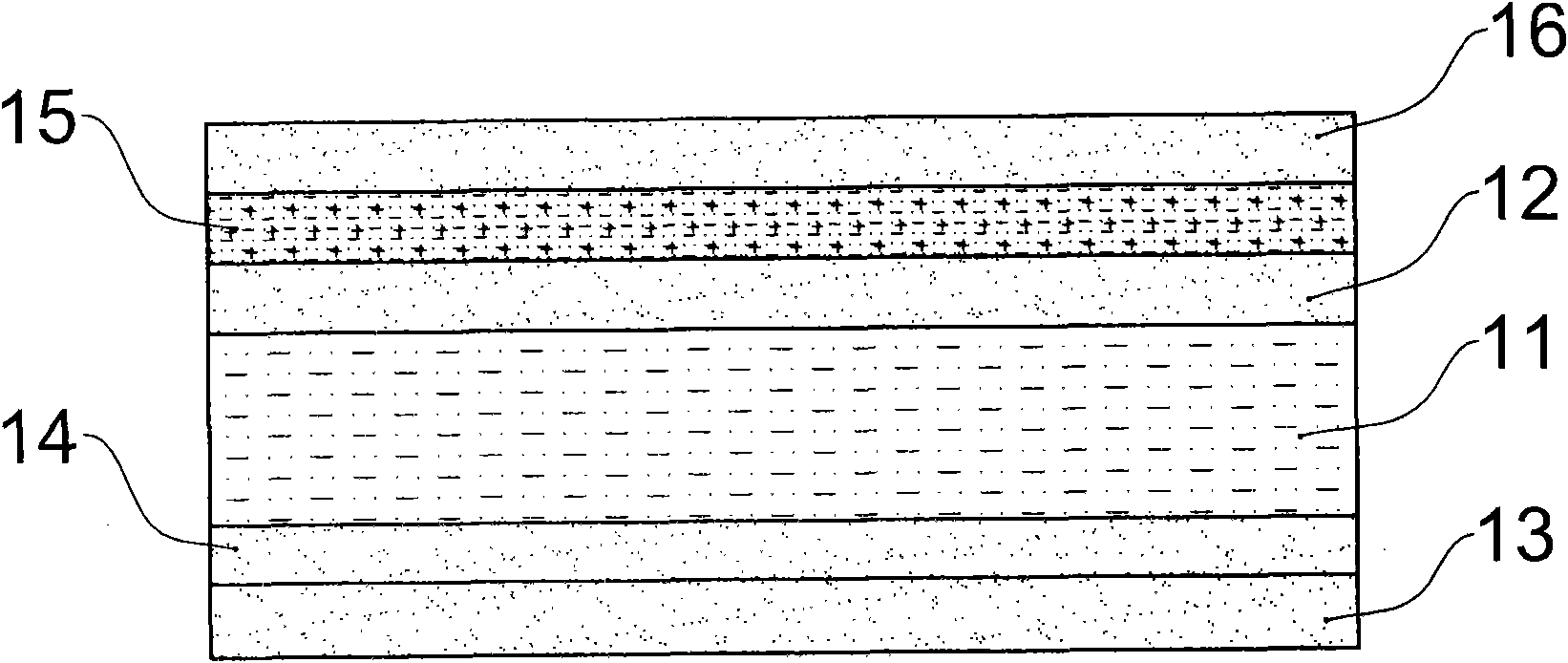

Dry spraying decorative paper and manufacturing technology thereof

InactiveCN101608417AImprove wear resistanceThe decorative effect is clear and realisticPaper coatingPaper/cardboard layered productsFlocculationManufacturing technology

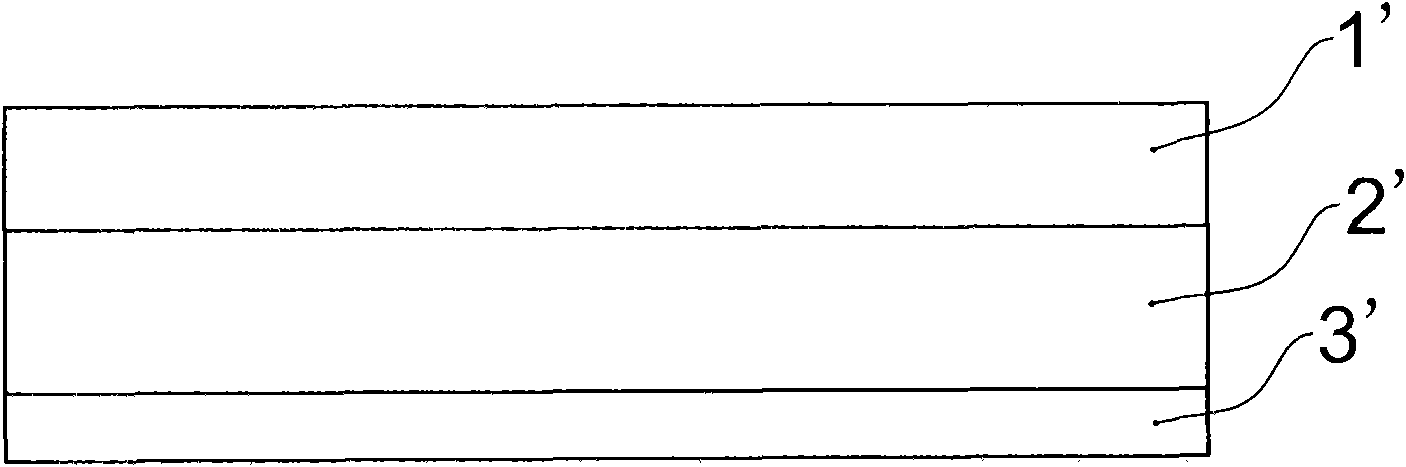

The invention provides dry spraying decorative paper for manufacturing a wood floor and a manufacturing technology thereof. The dry spraying decorative paper comprises printing base paper, wherein the upper surface of the printing base paper is printed with decorative patterns, the upper surface of the printing base paper is coated with an attachment glue layer, the lower surface of the printing base paper is coated with a binding glue layer which is used for binding a floor substrate layer, a wear-proof material layer is formed on the upper surface of the attachment glue layer by a dry powder spraying mode, and a cover glue layer is repeatedly coated on the upper surface of the wear-proof material layer. The dry spraying decorative paper radically solves the problems of distribution uniformity of powder particles, attachment ability, resin coating and melting effect, flocculation and deposition in a use process, not only ensures the wear-proof revolution stability, but also ensures the definition of a woody panel simultaneously. In addition, the scattered wear-proof powder particles also can be recovered and recycled so as to reduce the waste and save the cost.

Owner:CHUZHOU RUNLIN WOOD IND CO LTD

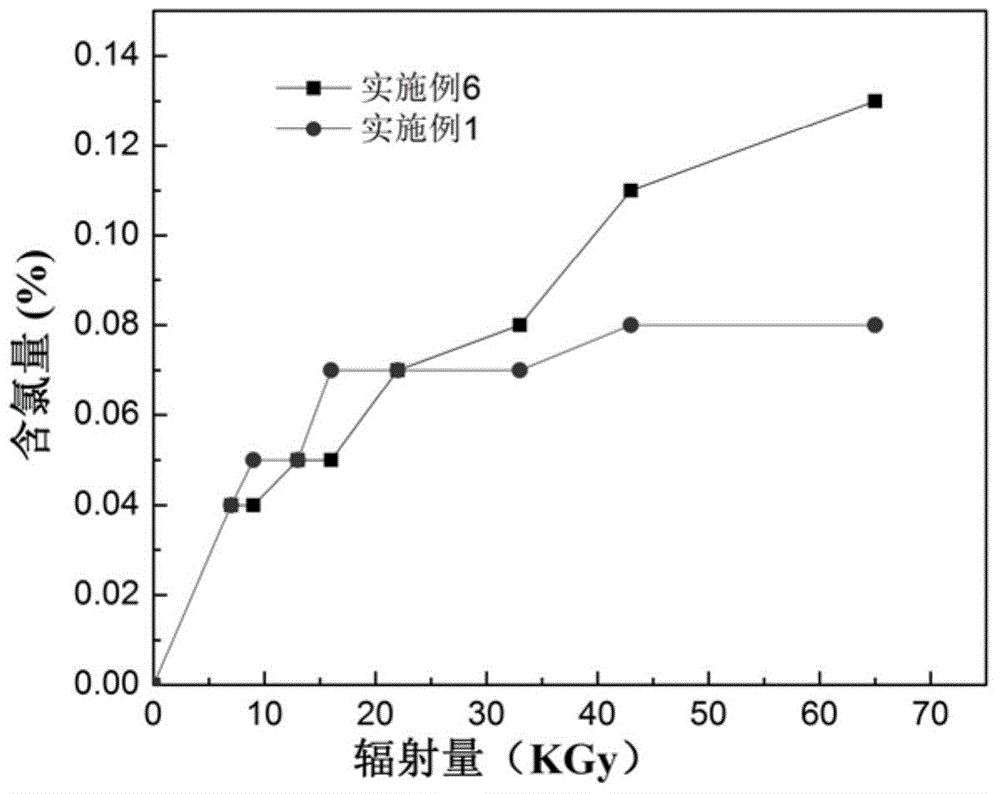

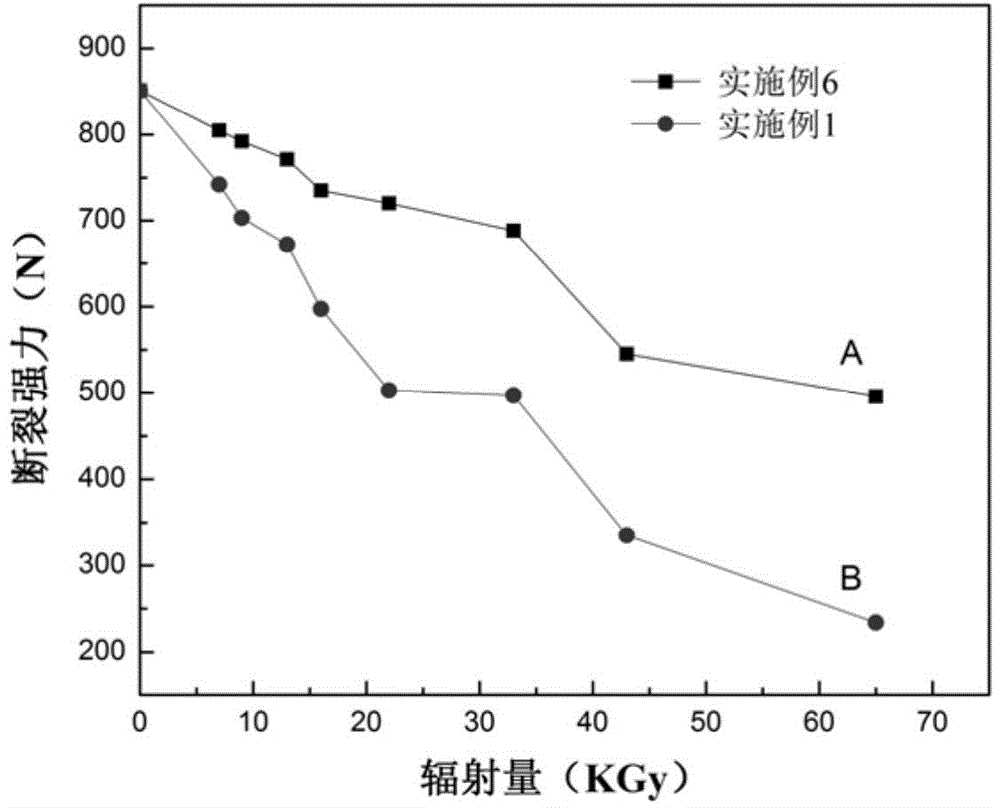

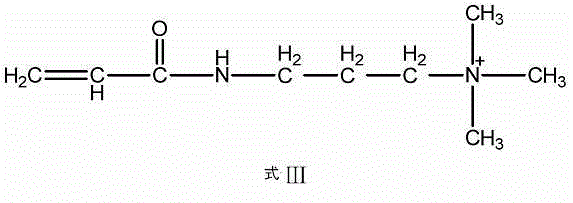

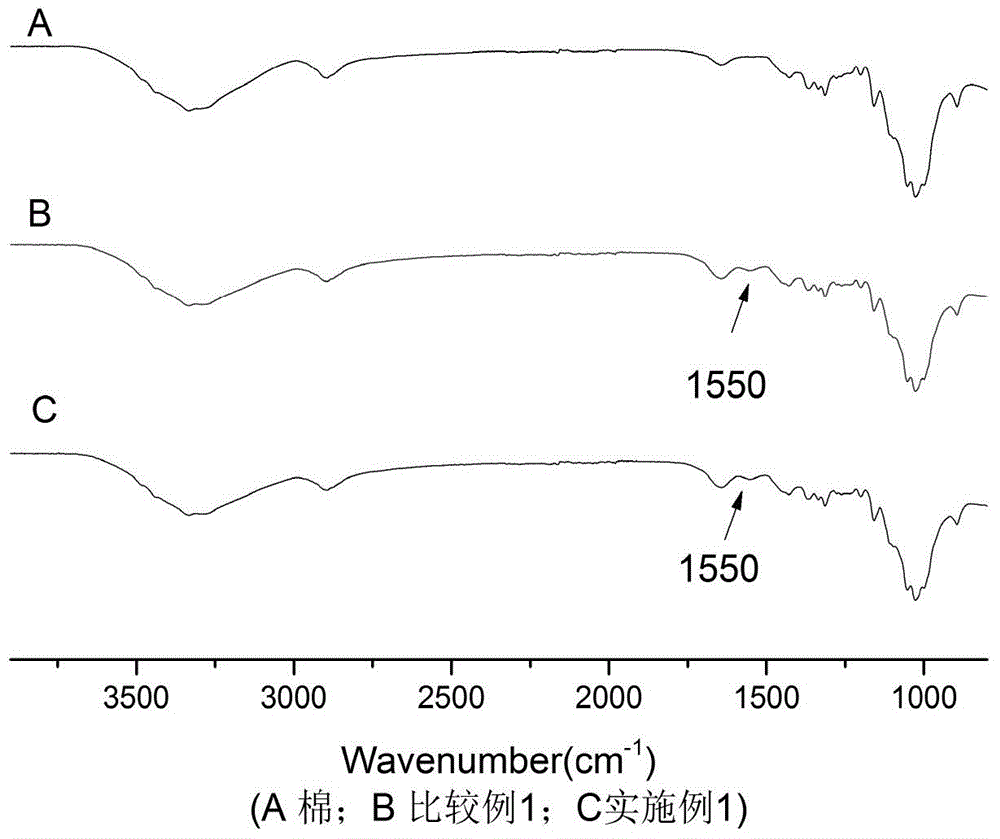

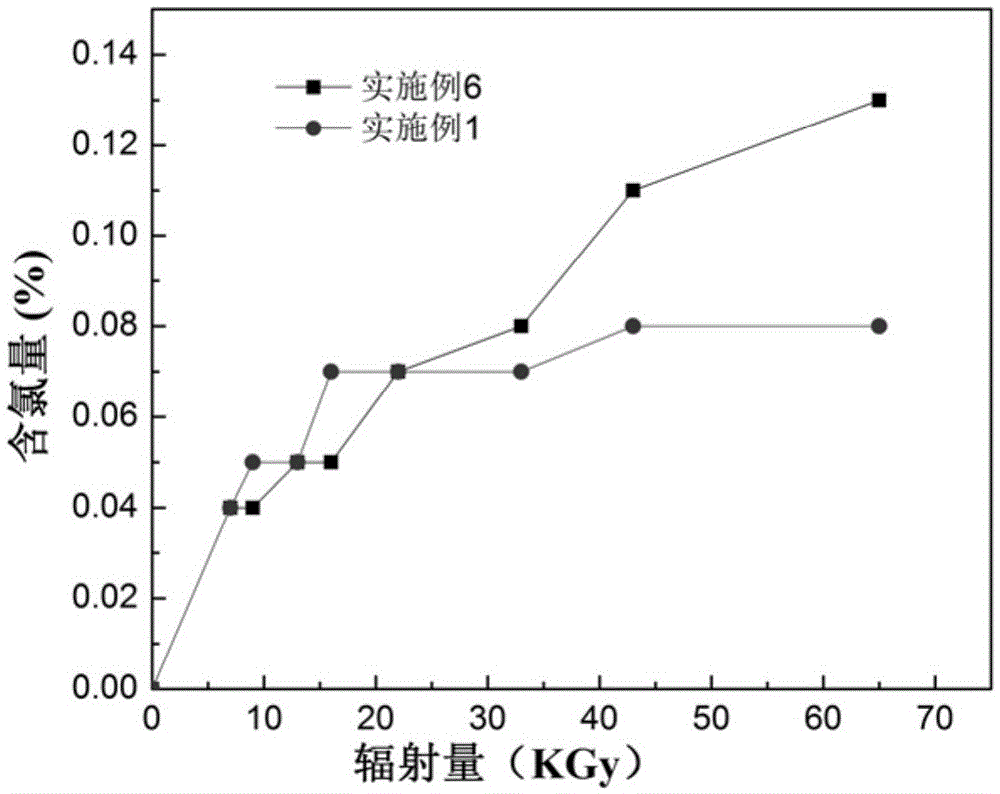

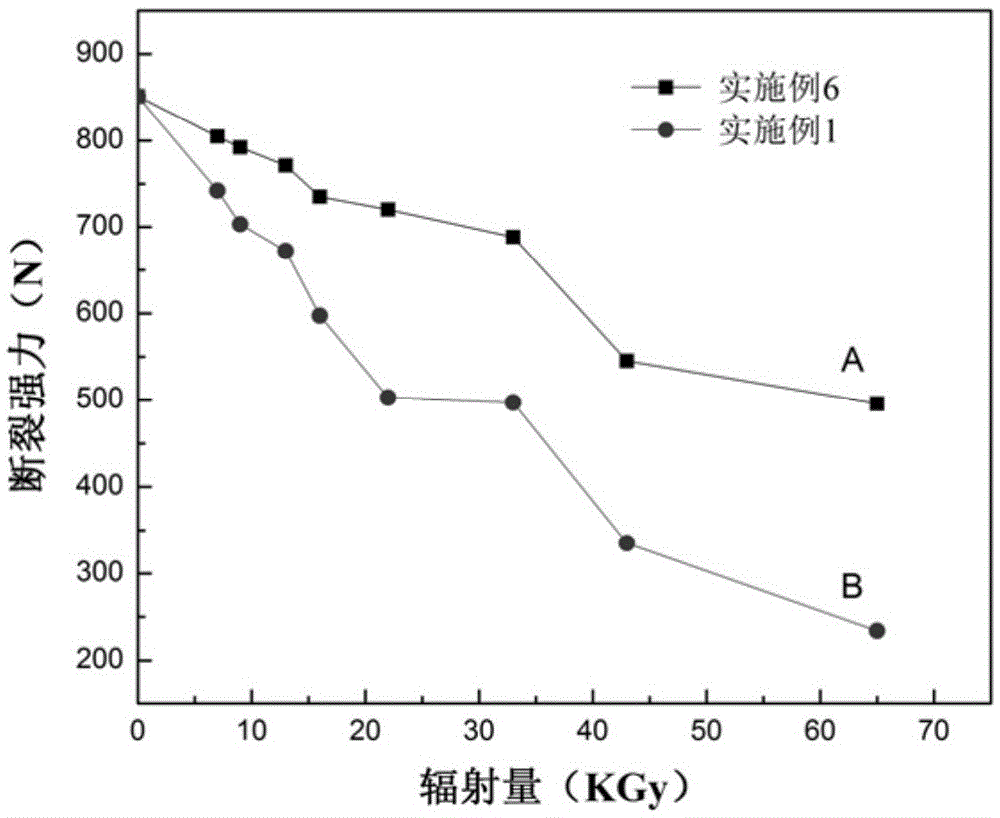

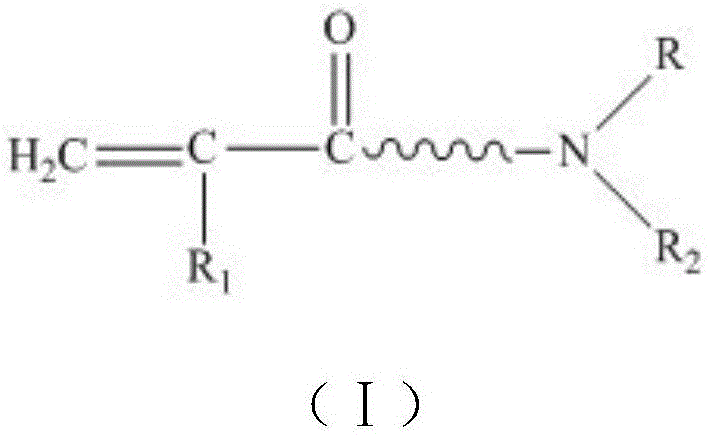

Method for preparing antimicrobial textiles by using electronic radiation technology

ActiveCN104358104AWill not polluteImprove efficiencyPhysical treatmentVegetal fibresAfter treatmentAntibacterial property

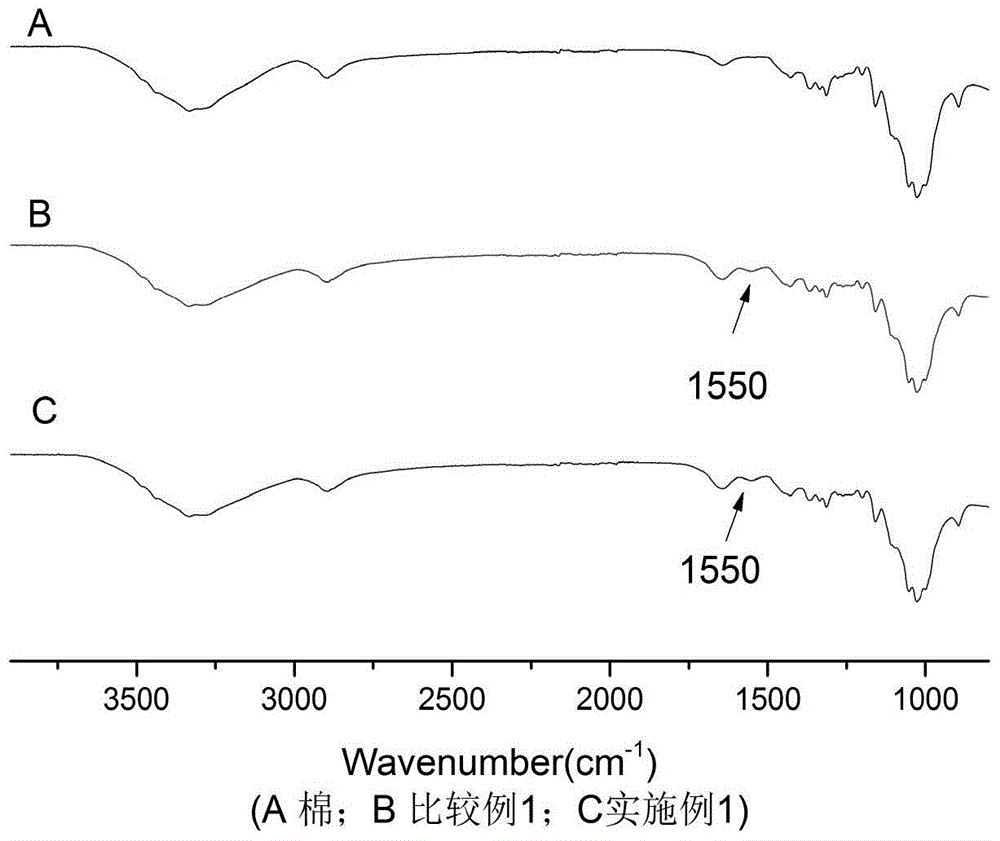

The invention discloses a method for preparing antimicrobial textiles by using an electronic radiation technology. The method comprises the following steps: dipping textiles or coating textiles by antibacterial finishing liquid and then carrying out electronic radiation; or firstly, carrying out electronic radiation on the textiles and then dipping or coating the antibacterial liquid; and baking, washing and carrying out after treatment, so as to prepare antibacterial textiles, wherein the radiation range of electronic radiation is 0-500KGy and corresponding other radiation unit conversion value; an antibacterial agent precursor in the antibacterial finishing liquid can generate free radical through electronic radiation, and can react with other substances through the free radical; and the antibacterial agent precursor can be independently used or used in a mixing manner. According to the method, the reaction can be carried out at normal temperature; the treatment process is simple, and easy to control; the antibacterial agent is high in utilization rate and low in energy consumption; and the antimicrobial textiles prepared by the method are excellent in antibacterial property, and good in wearability.

Owner:JIANGNAN UNIV

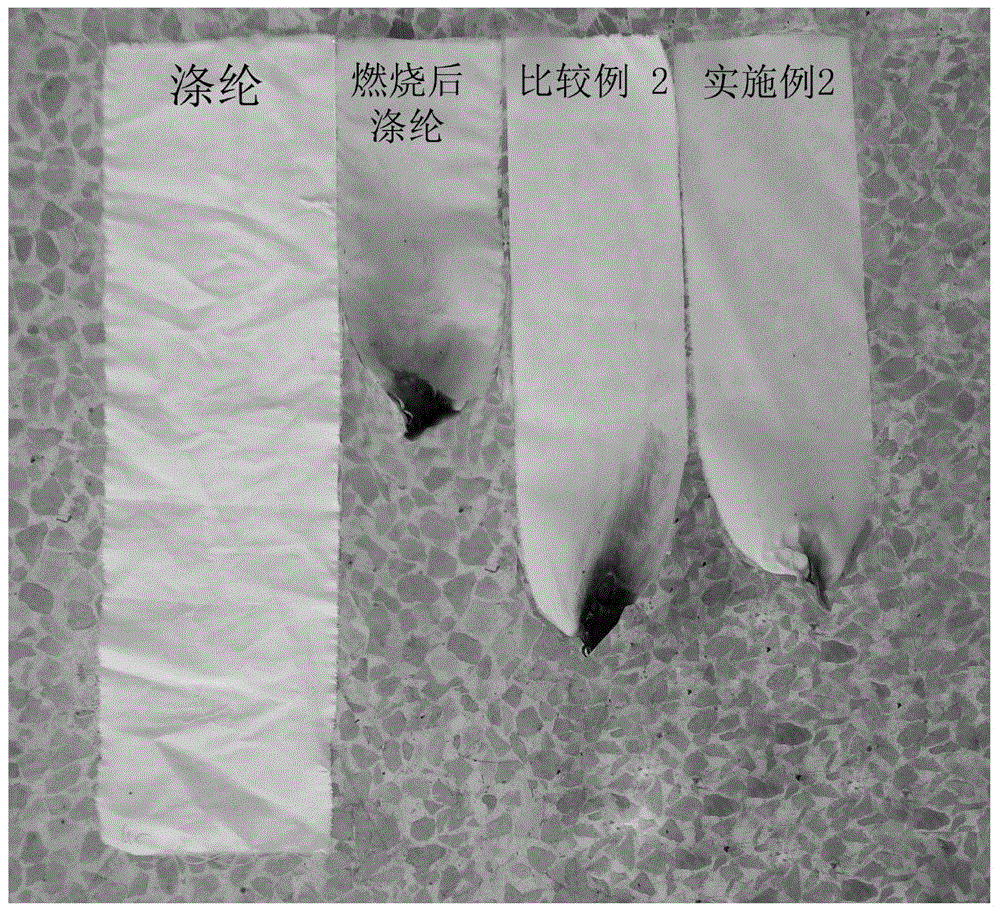

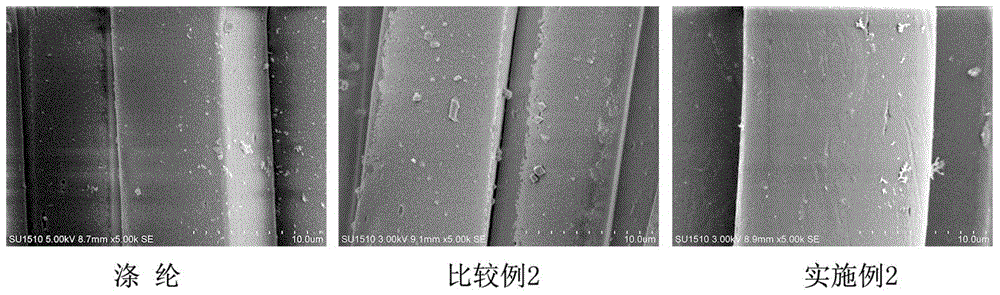

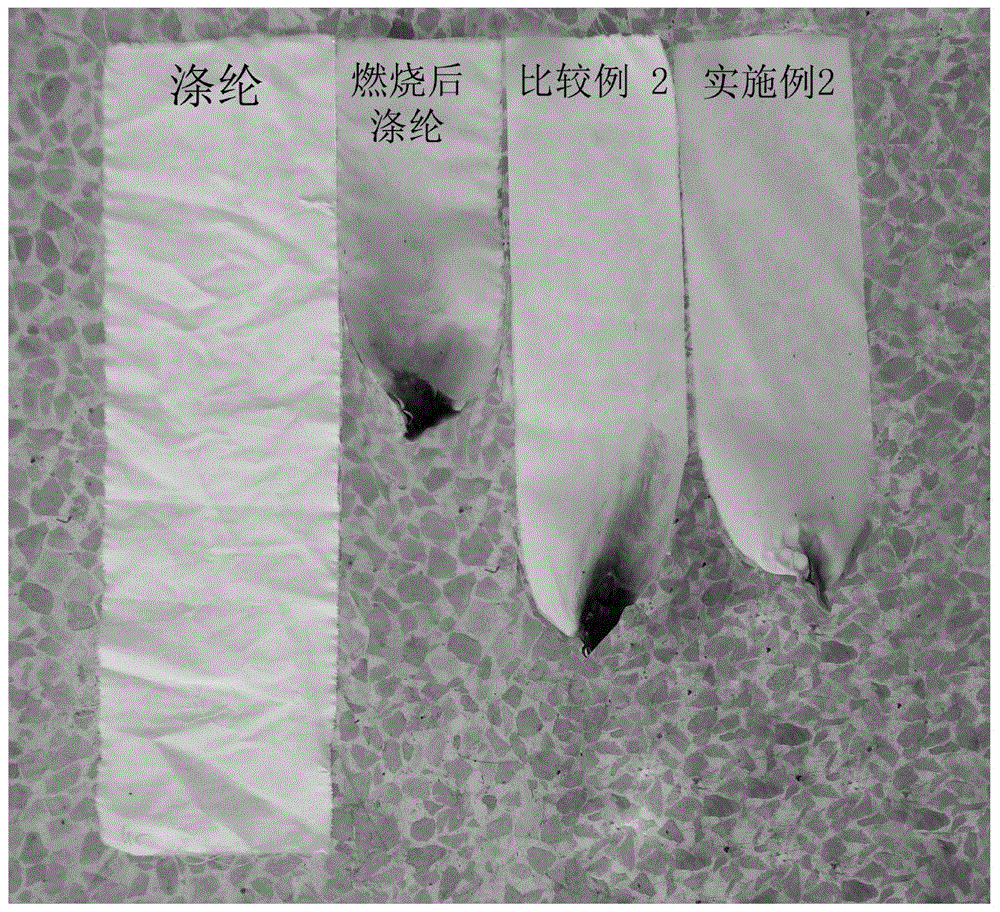

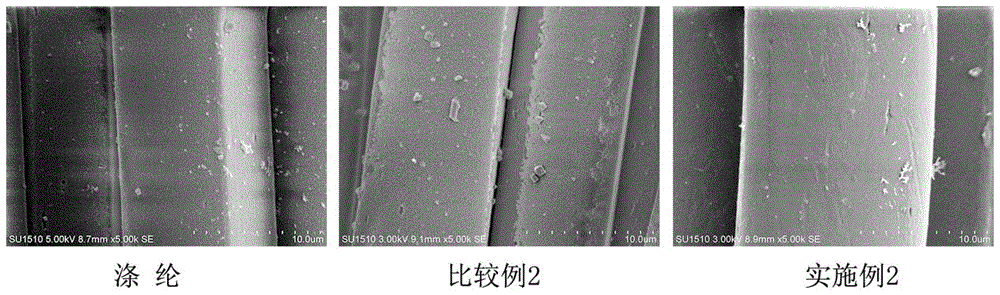

Method of producing flame retardant textile by electronic radiation technology

ActiveCN104818607ALower reaction energyIncrease profitPhysical treatmentEngineeringElectron beam radiation

A method of producing flame retardant textile by the electronic radiation technology is characterized in that after textile is pad-rolled or coated with flame retardant finishing liquid, and drying or baking is performed after electronic beam radiation to obtain the flame retardant textile; the flame retardant fishing liquid comprises resin cross-linking agent and organophosphorus flame retardant. The method has the advantages that the technical operation is simple and the flame retardant textile has performances such as durability, high temperature resistance and non-flammability.

Owner:JIANGNAN UNIV

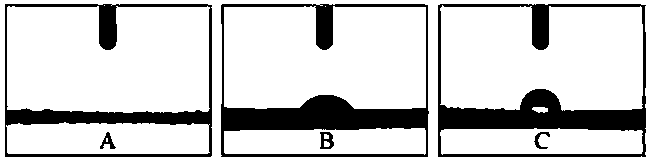

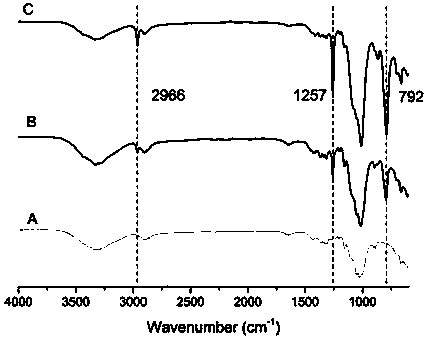

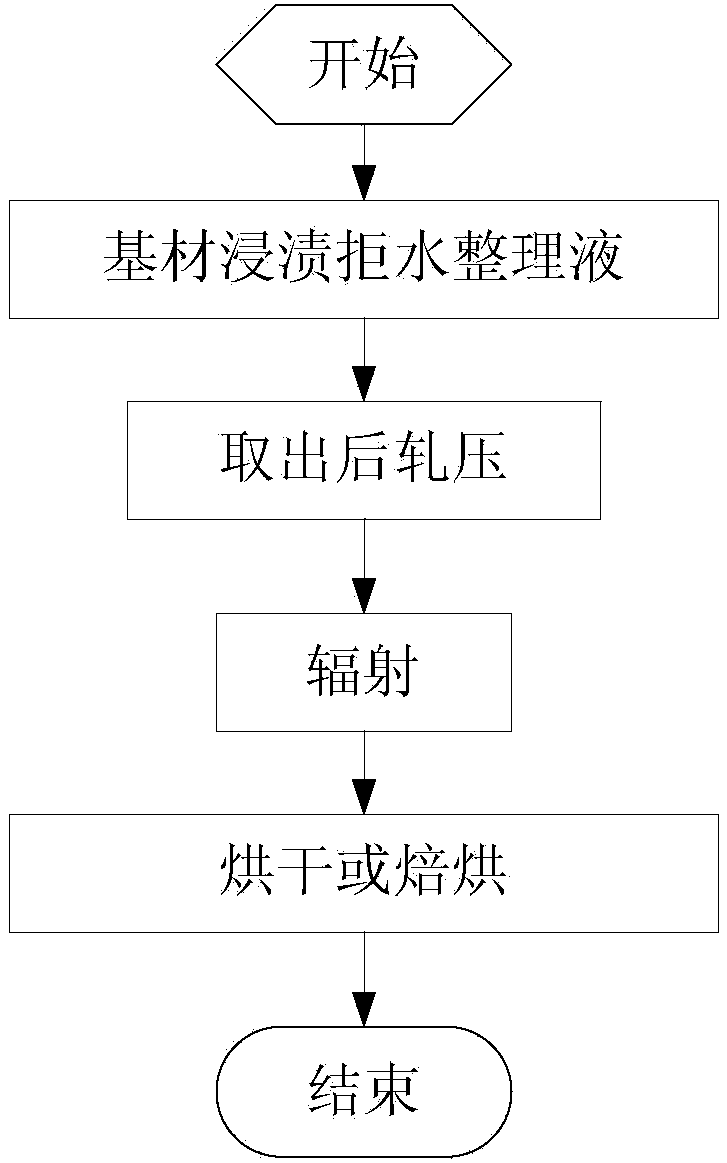

Method for preparing water-repellent textile

InactiveCN104278512AShort processing timeReduce energy consumptionPhysical treatmentAfter treatmentPolymer science

The invention provides a method for preparing a water-repellent textile. An electron radiation technology is adopted, a reactive organic silicon compound is taken as a water repellent, and the textile is subjected to water-repellent treatment. According to the main technical scheme, the method comprises the following steps: padding the textile in a water-repellent or a coating water repellent, radiating, drying or baking, performing after-treatment, thereby obtaining the water-repellent textile. The water-repellent textile prepared by the method disclosed by the invention is excellent in water-repellent performance and can be reacted at normal temperature, the grafting ratio is greatly improved, and the method has the advantages of simple processing technology, simplicity in control and low energy consumption and is worthy of popularization and application.

Owner:HUBEI ERAY NUCLEAR TECH

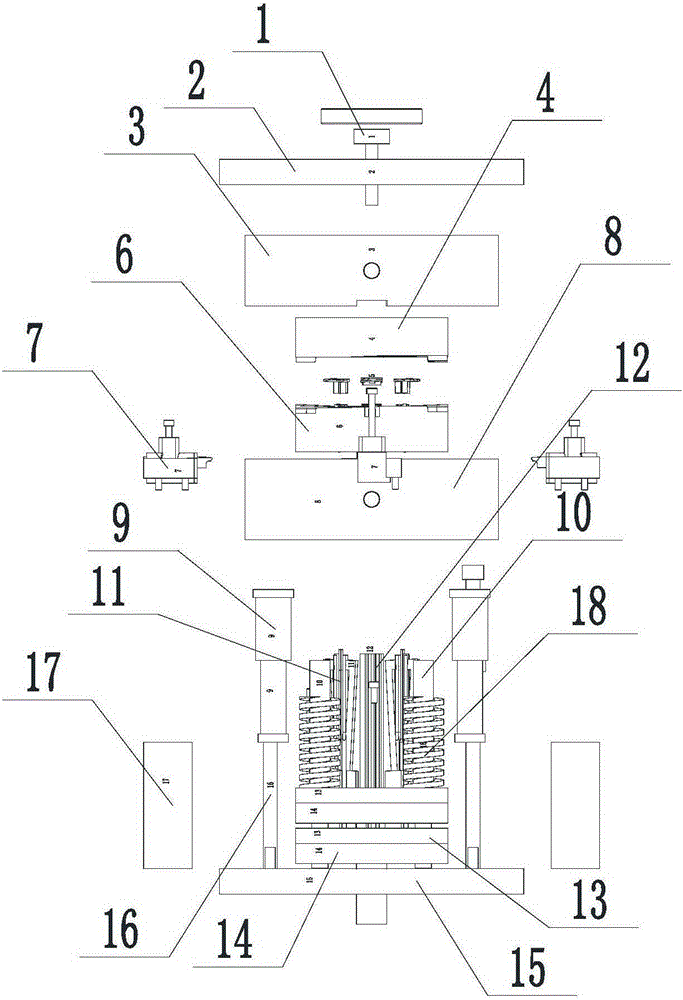

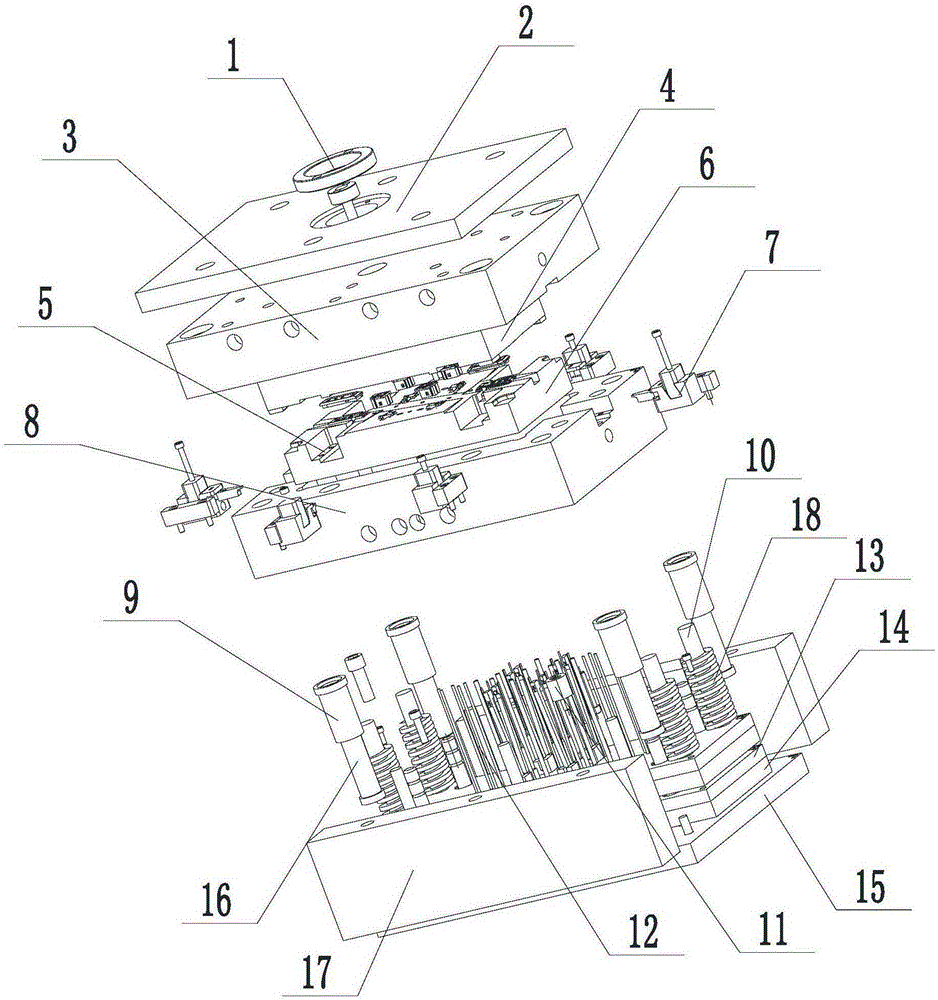

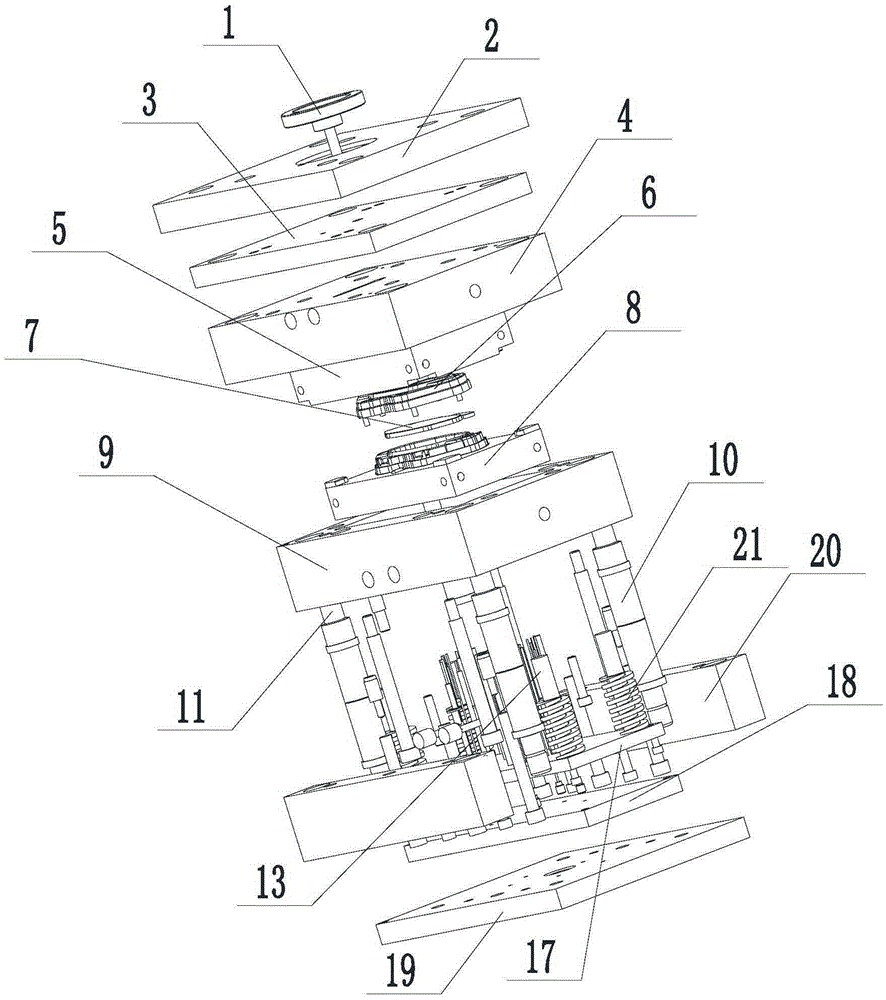

Double-color die and manufacturing technology thereof

The invention discloses a double-color die which comprises a bottom plate. Two sets of ejector pin fixing assemblies composed of ejector pin face plates and ejector pin bottom plates are arranged in the middle of the upper surface of the bottom plate in sequence from top to bottom. Guide pillar holes are formed in the four corners of the upper surfaces of the two sets of ejector pin fixing assemblies respectively. Guide pillars are arranged in the guide pillar holes. Springs are arranged on the guide pillars. A plurality of inclined tops and flat ejector pins which penetrate the two sets of ejector pin fixing assemblies and are fixed are further arranged in the middles of the upper surfaces of the two sets of ejector pin fixing assemblies. Fixing pillars are arranged in the positions, close to the two sets of ejector pin fixing assemblies, on the upper surface of the bottom plate, and the fixing pillars are sleeved with return pins. The double-color die can be well processed, and the processing efficiency of the die is ensured.

Owner:SICHUAN LANGRUN TECH

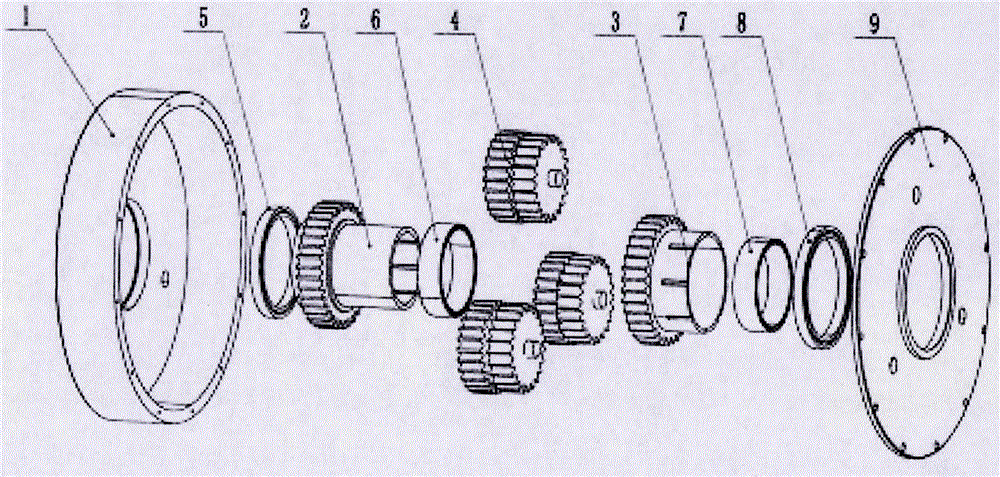

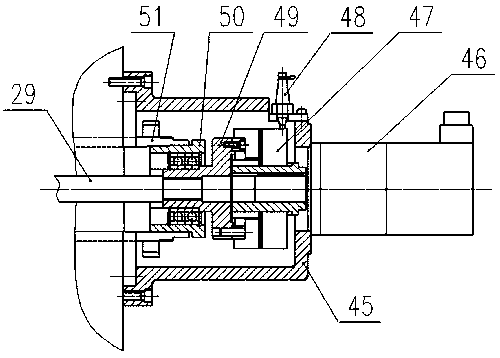

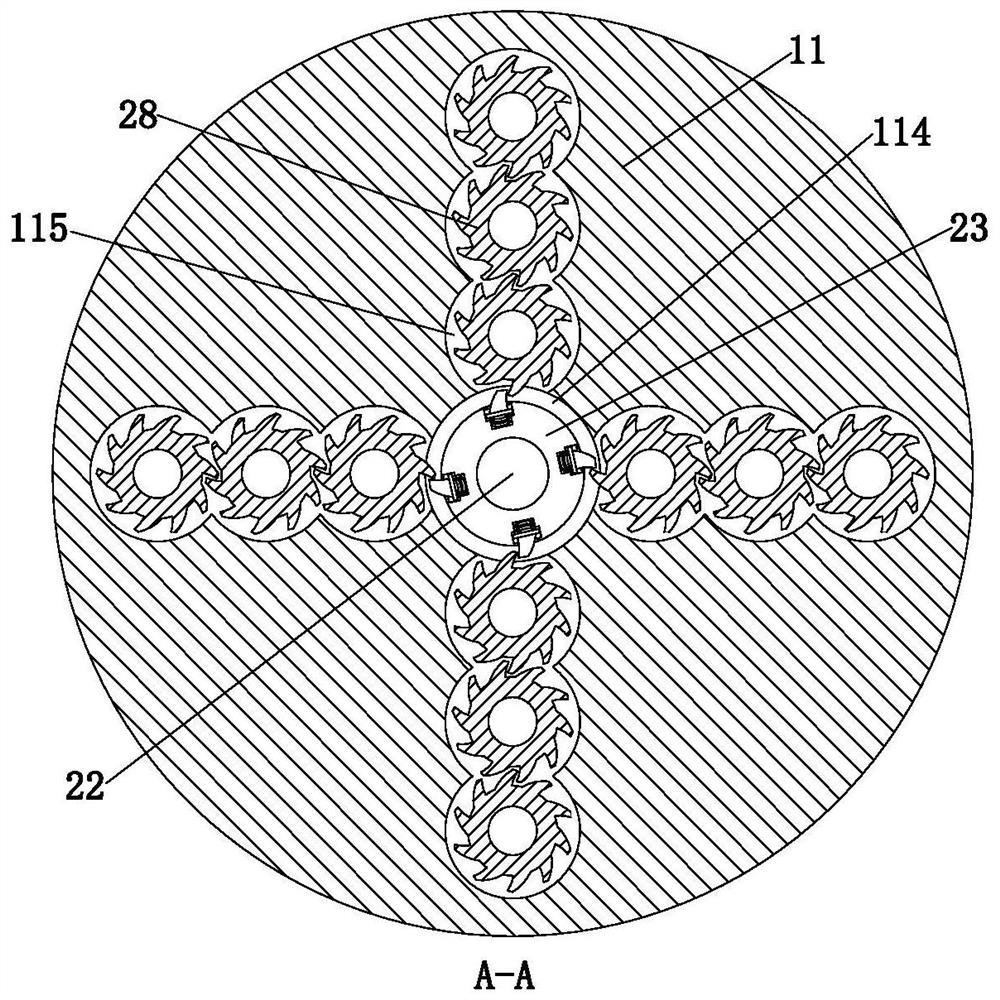

Large-reduction-ratio external meshed hollow shaft planetary reducer

InactiveCN106224453AEasy to installRealize the change of reduction ratioToothed gearingsGearing detailsGear wheelReduction drive

The invention relates to the technical field of precision machinery, in particular to a large-reduction-ratio external meshed hollow shaft planetary reducer. The large-reduction-ratio external meshed hollow shaft planetary reducer comprises an input sun wheel, a fixed sun wheel, duplex planetary wheels, an end cover, a shell, a needle bearing I, a needle bearing II, an end cover supporting bearing and a shell supporting bearing. The working mode is based on the external meshed differential planetary reduction principle; the input sun wheel and the fixed sun wheel are concentrically mounted and are supported by the needle bearing I and the needle bearing II; the three groups of duplex planetary wheels are mounted on the shell and the end cover, and are respectively meshed with the input sun wheel and the fixed sun wheel; the end cover is connected with the input sun wheel through the end cover supporting bearing; and the shell is connected with the fixed sun wheel through the shell supporting bearing. According to the large-reduction-ratio external meshed hollow shaft planetary reducer, all gears are externally meshed, so that finish machining is easy to implement; and due to a hollow shaft structure, the large-reduction-ratio external meshed hollow shaft planetary reducer is easy to mount, and varying of the reduction ratio can be realized.

Owner:金顺日

Mechanical machining surface finishing equipment

InactiveCN106271993AEasy flipSpeed up the processGrinding carriagesGrinding machinesSurface finishMechanical equipment

The invention discloses mechanical machining surface finishing equipment. The mechanical machining surface finishing equipment comprises a base, the top of the base is fixedly connected with support frames, one side of each support frame is fixedly connected with a fixing device, each fixing device comprises a push plate, one side of each push plate is fixedly connected with one end of a push rod, and the other end of each push rod penetrates through a limiting sleeve to be fixedly connected with one side of a fixing plate. According to the machining surface finishing equipment, by cooperatively using second electric telescopic rods, support blocks, motors and first gears, mechanical equipment can be automatically turned over in the finishing process, the problem that the mechanical equipment cannot be automatically turned over when the mechanical equipment surface is finished is solved, and the manual turnover condition is avoided; by cooperatively using mobile rods, fixed blocks, fixed extrusion blocks, movable extrusion blocks, third electric telescopic rods and second gears, the mechanical equipment can be better turned over in the finishing process, and then the working progress is improved.

Owner:张庆荣

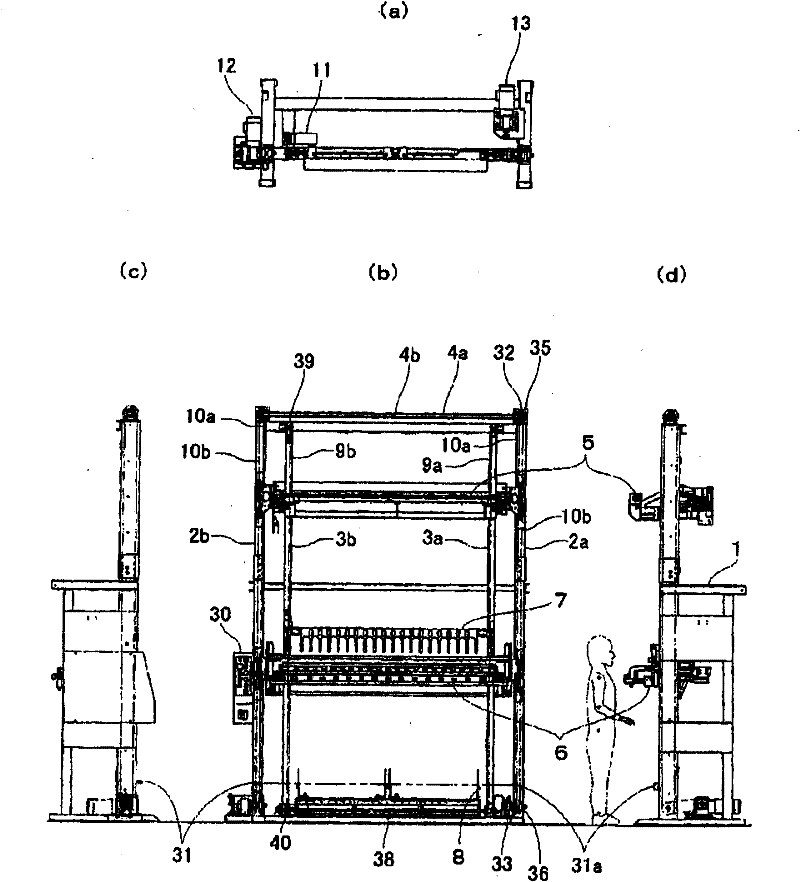

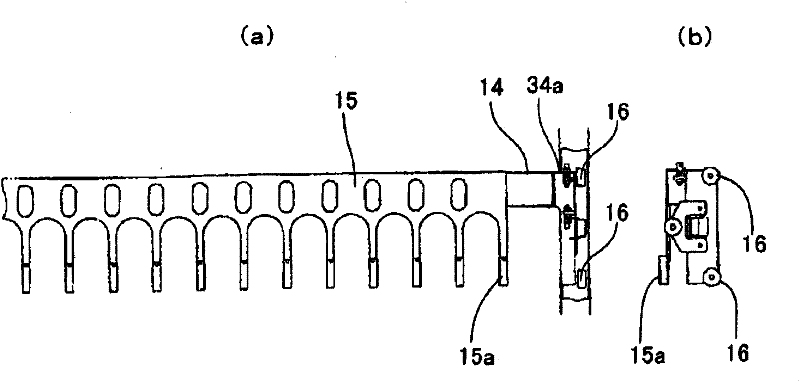

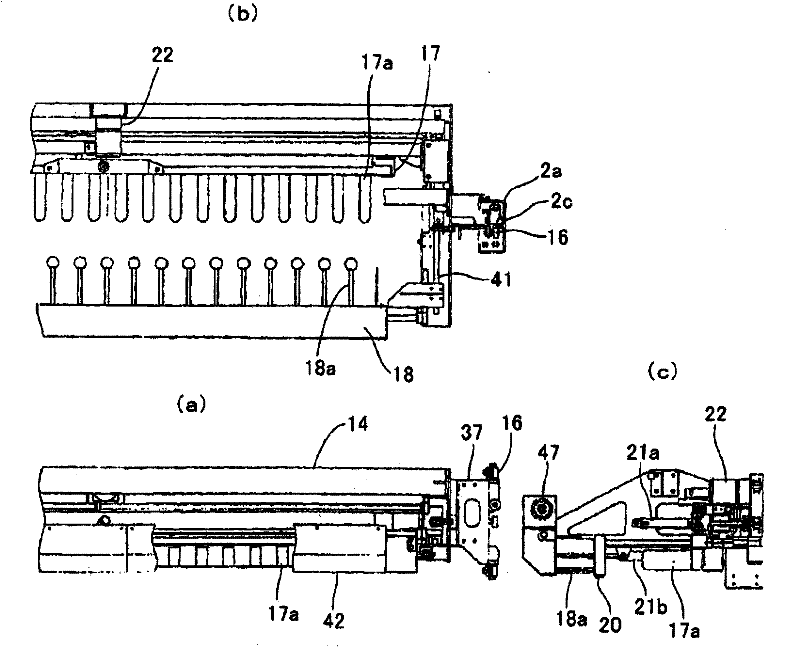

Curtain finisher

InactiveCN102245064AEasy finishingUniform zigzag pleatsCurtain rodsTextile shapingLeading edgeEngineering

Disclosed is curtain finisher that enables heat treatment without shrinkage; easily forms uniform zigzag shapes (pleats) without requiring worker correction, and makes work efficient without applying unnecessary force on curtain fabric when forming zigzag shapes, and easily finishes curtain fabric in line with various curtain specifications (pleat pitches, pleat depths, pleat shapes, accessories, and the like). The curtain finisher is equipped with a hook portion that holds a curtain top; an iron portion containing a heater that rises and lowers between the curtain top and a hem portion while forming curtain pleats; a hem-holding portion composed of a backside-folding portion equipped at equidistant spacing with a folding tool in parallel, and a front-side folding portion disposed at half-pitches to mesh with the backside-folding portion, that rises and lowers between the curtain top and the hem portion; and an edge fastening portion for fastening a curtain edge. The backside-folding portion of the hem portion has a cylinder that houses at a leading edge a heater, and a bottom edge of the cylinder projects downward from the hem-holding portion bottom, excluding the cylinder portion, and the curtain hem when the hem-holding portion is lowered to the curtain hem portion.

Owner:KYOKUTO SANKI CO LTD

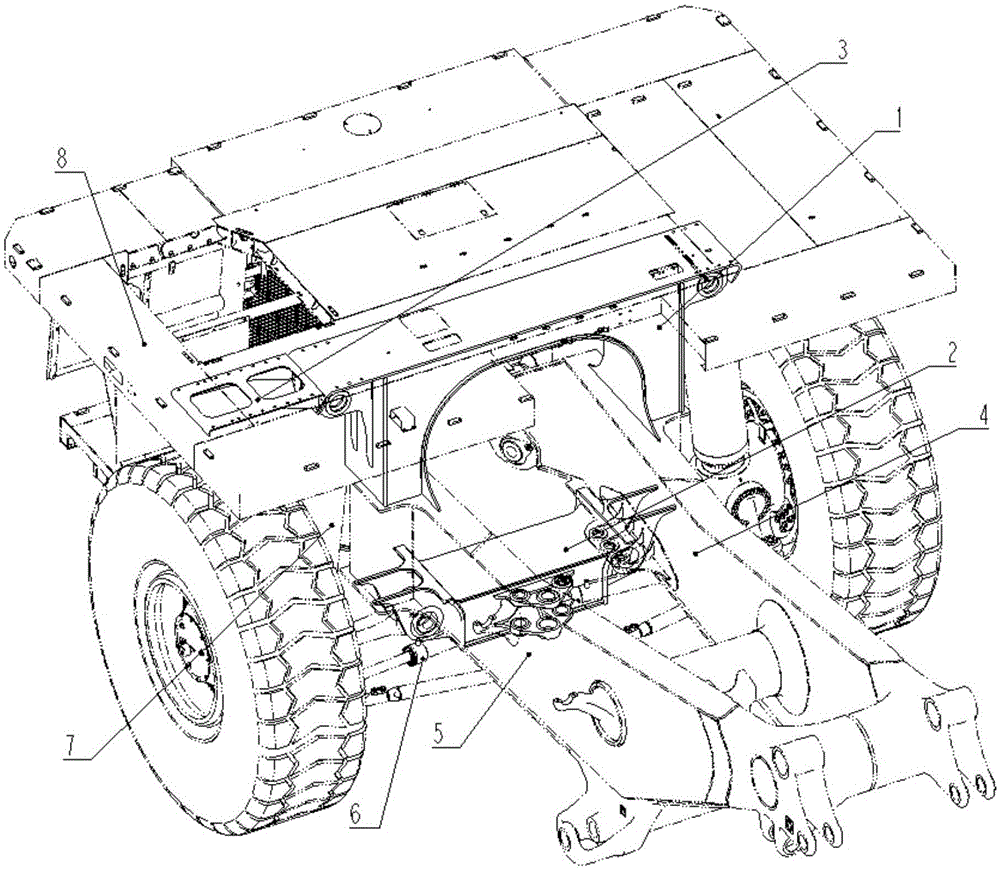

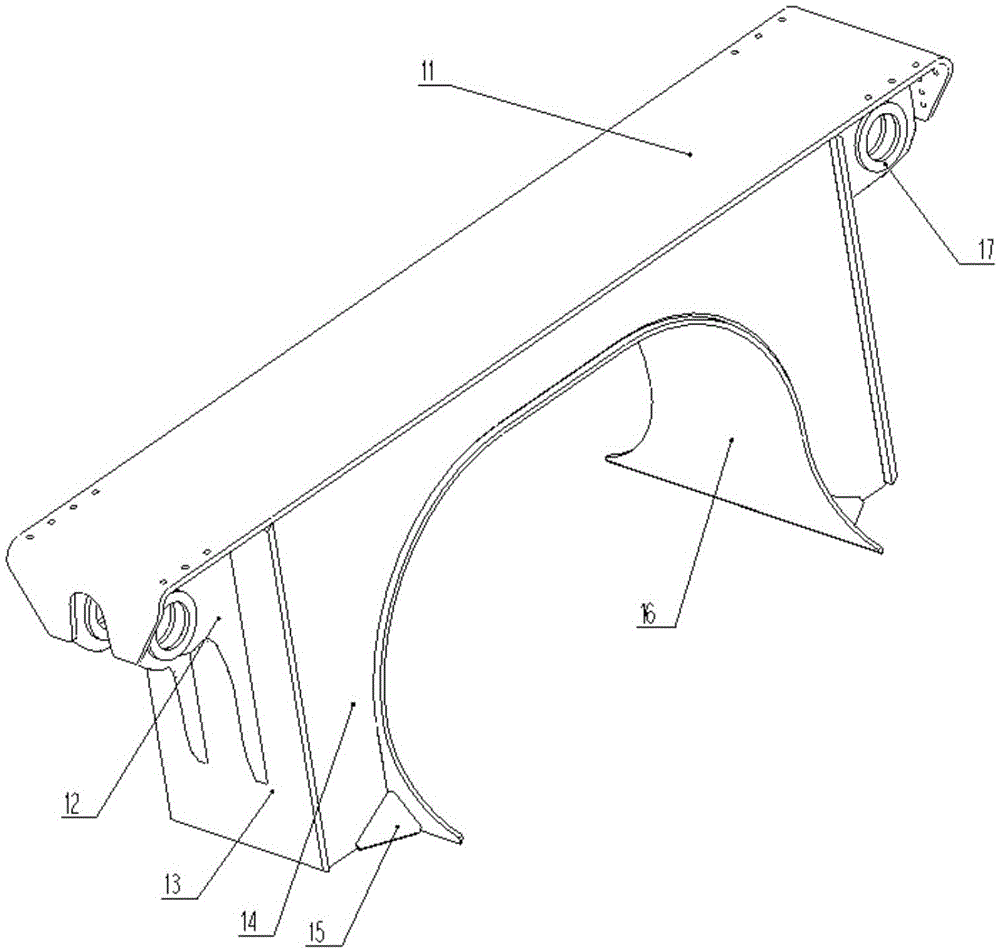

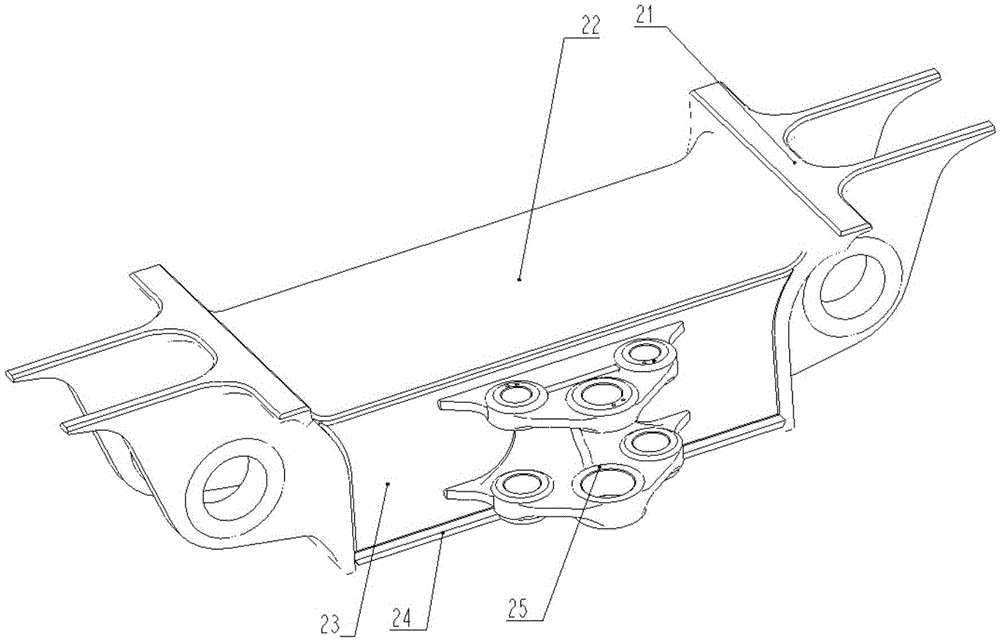

Split type gantry beam for electric drive mining-use dumper frame

ActiveCN105539593AEasy to adjust fitGuaranteed positionUnderstructuresStress concentrationVehicle frame

The invention discloses a split type gantry beam for an electric drive mining-use dumper frame and belongs to the technical field of dumper frames. A split structure of an upper gantry beam body, a lower gantry beam body and a deck support is adopted. The gantry beam structure is simple in positioning and point splicing process, welding formation is easy to control, the attachment situation between the gantry beam and a corresponding longitudinal beam is easy to adjust, and a mounting process is simplified to a great degree; front suspension supports, pull rod seats and steering middle seats are assembled, welded and then machined, and the relative position of a hole is easy to guaranteed, so that positioning parameters of a front axle main pin and a steering trapezoid can be strictly guaranteed; medium machining and finish machining are adopted for small assemblies, machining is easy to conduct, the cycle is short, cost is low, and production is easy to arrange; a casting structure is adopted for the complex stressed position, and a swallow-tail form structure or a stiffened plate is adopted to reduce structural sudden change, so that the gantry beam can bear a large bending load, a twisting load and an impact load, stress concentration of a stress concentrated area is reduced, breakage and damage of a structural piece are avoided, and meanwhile various functional requirements are met.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

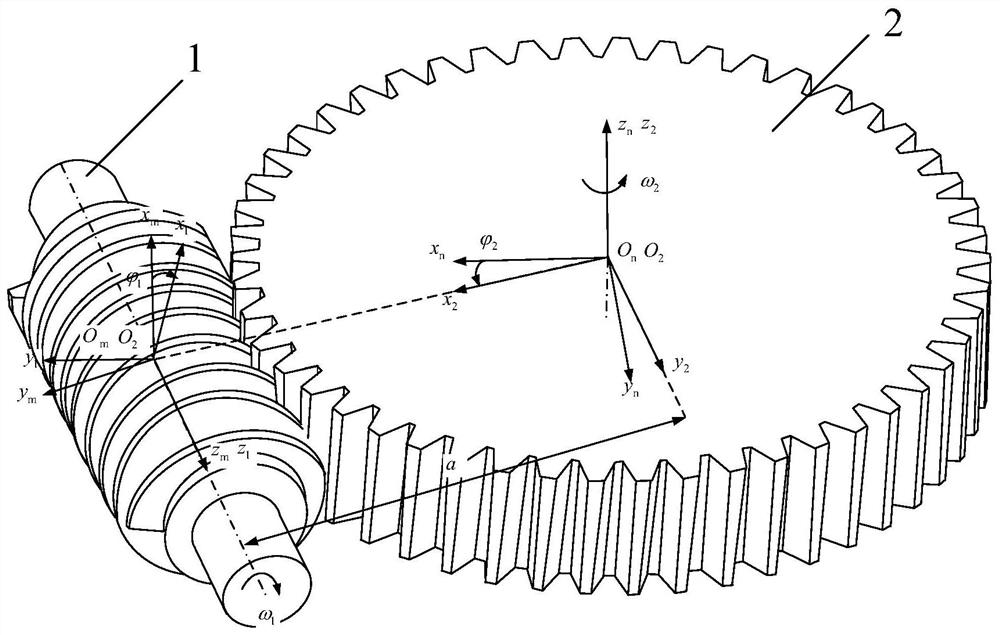

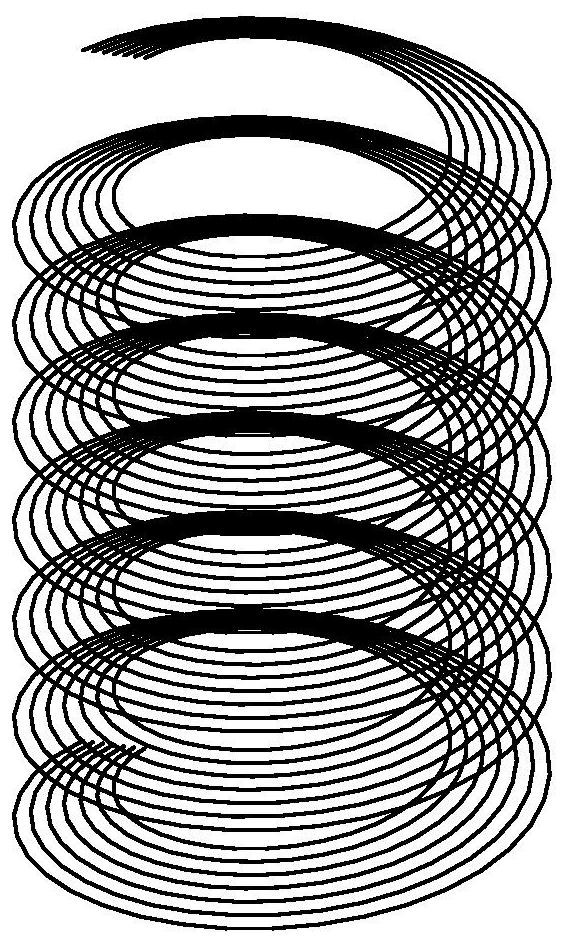

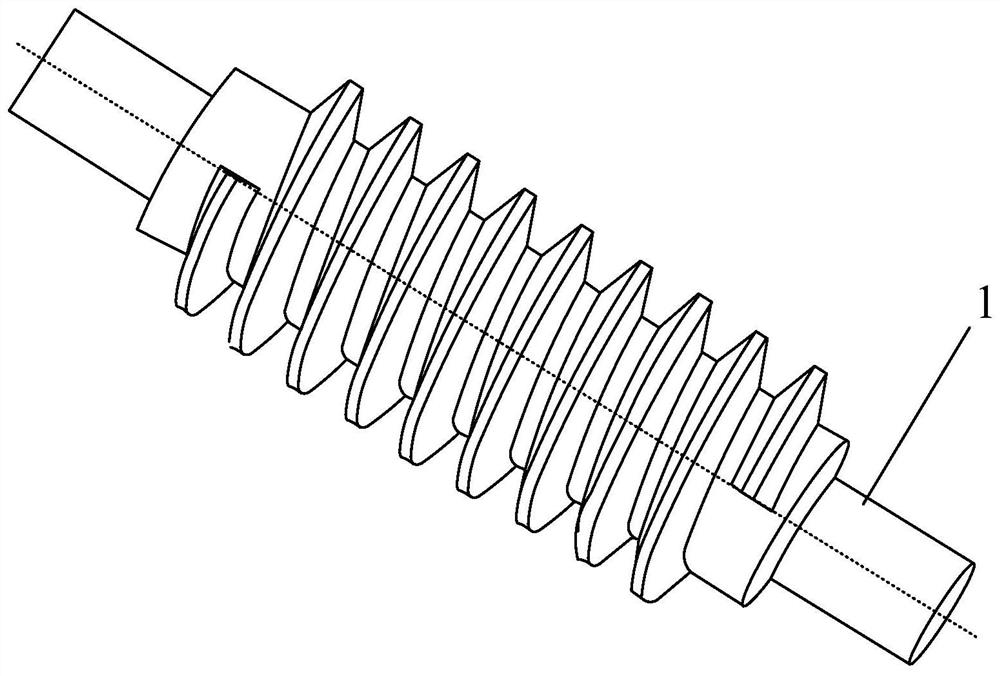

Backlash-adjustable worm helical gear transmission

ActiveCN112052535ALarge transmission ratioGood self-lockingGeometric CADSustainable transportationGear driveInvolute gear

The backlash-adjustable worm helical gear transmission comprises a double-side special-shaped involute worm and a variable-tooth-thickness involute gear, the normal modules of the tooth faces on the two sides of the double-side special-shaped worm and the variable-tooth-thickness involute gear are equal, the end face modules of the tooth faces on the two sides of the double-side special-shaped worm and the variable-tooth-thickness involute gear are unequal, and the tooth faces on the two sides of the double-side special-shaped worm are involute helical faces of which the lead angles are unequal and the leads are equal, the helical angles of the tooth surfaces on the two sides of the variable-tooth-thickness involute gear are unequal and are positive values, so that the gradually-changed tooth thickness is generated, the design of the lead angles of the double-side special-shaped worm is met, and the modeling and meshing analysis method for backlash-adjustable worm helical gear transmission is provided. According to the invention, the characteristics of large transmission ratio, good self-locking performance, low error sensitivity and low cost of a worm helical gear are inherited, the real-time adjustment of the backlash between teeth and the compensation of the abrasion loss can be carried out, and the technical scheme is suitable for various precision light-load equipment.

Owner:CHONGQING UNIV

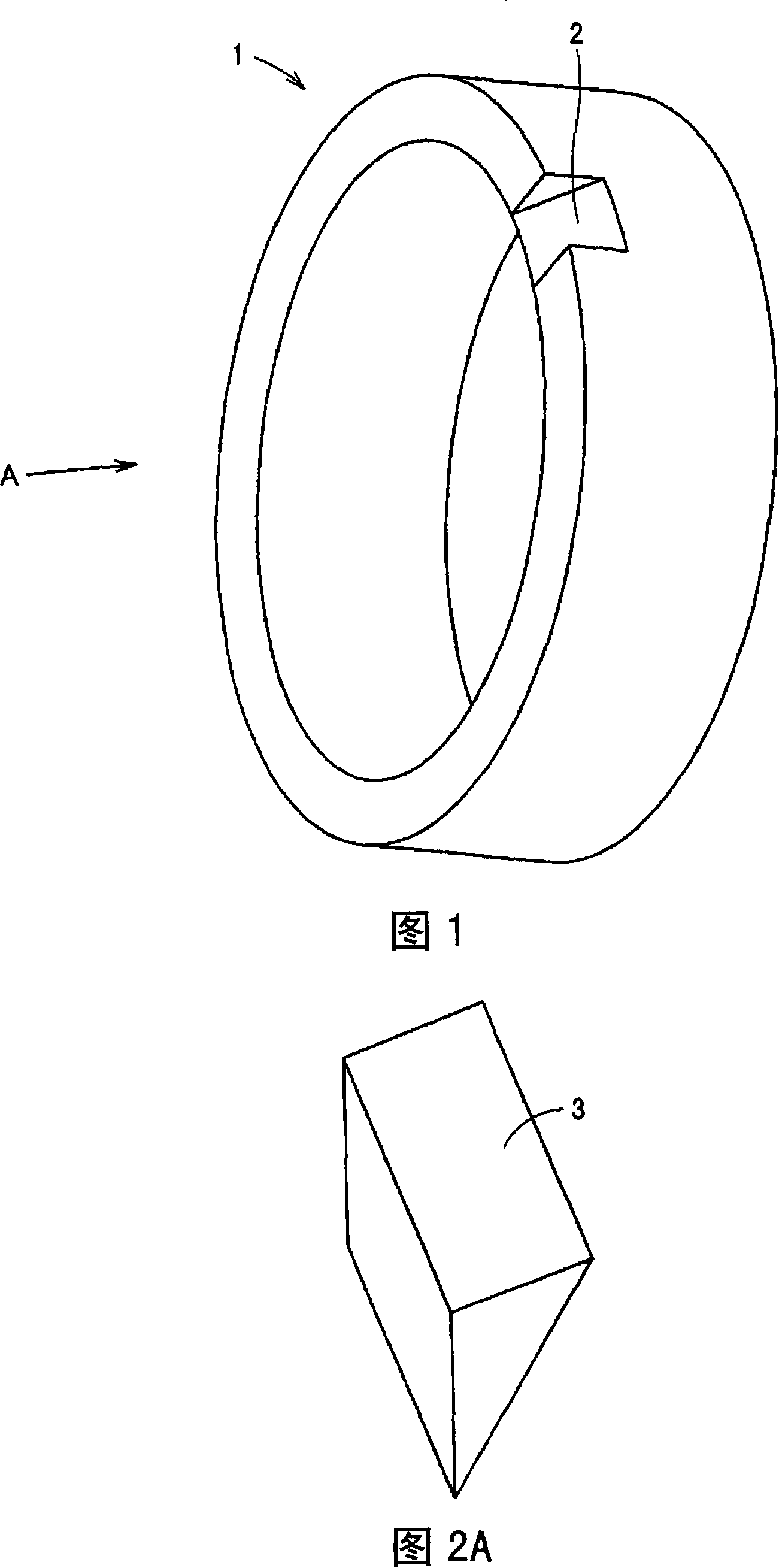

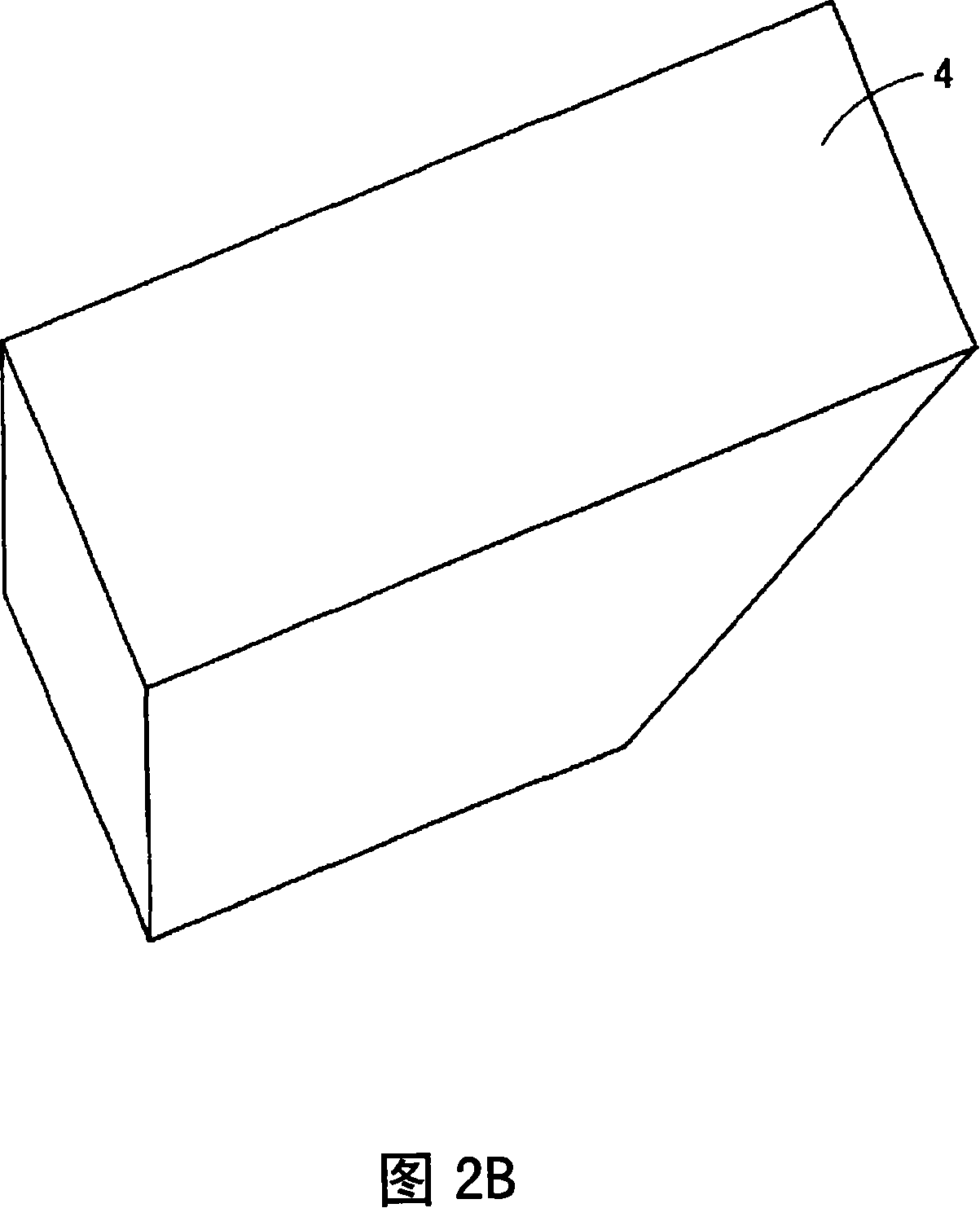

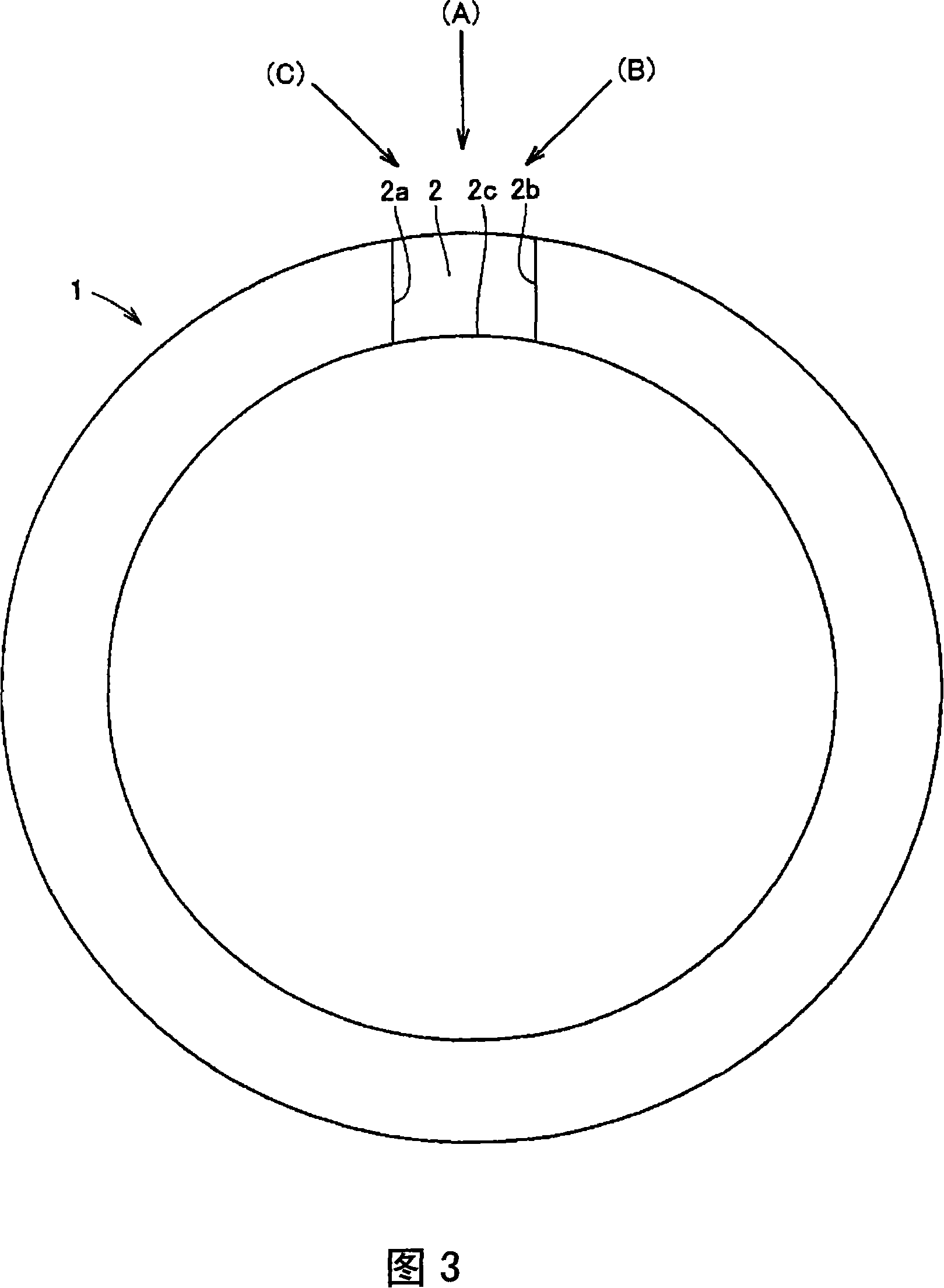

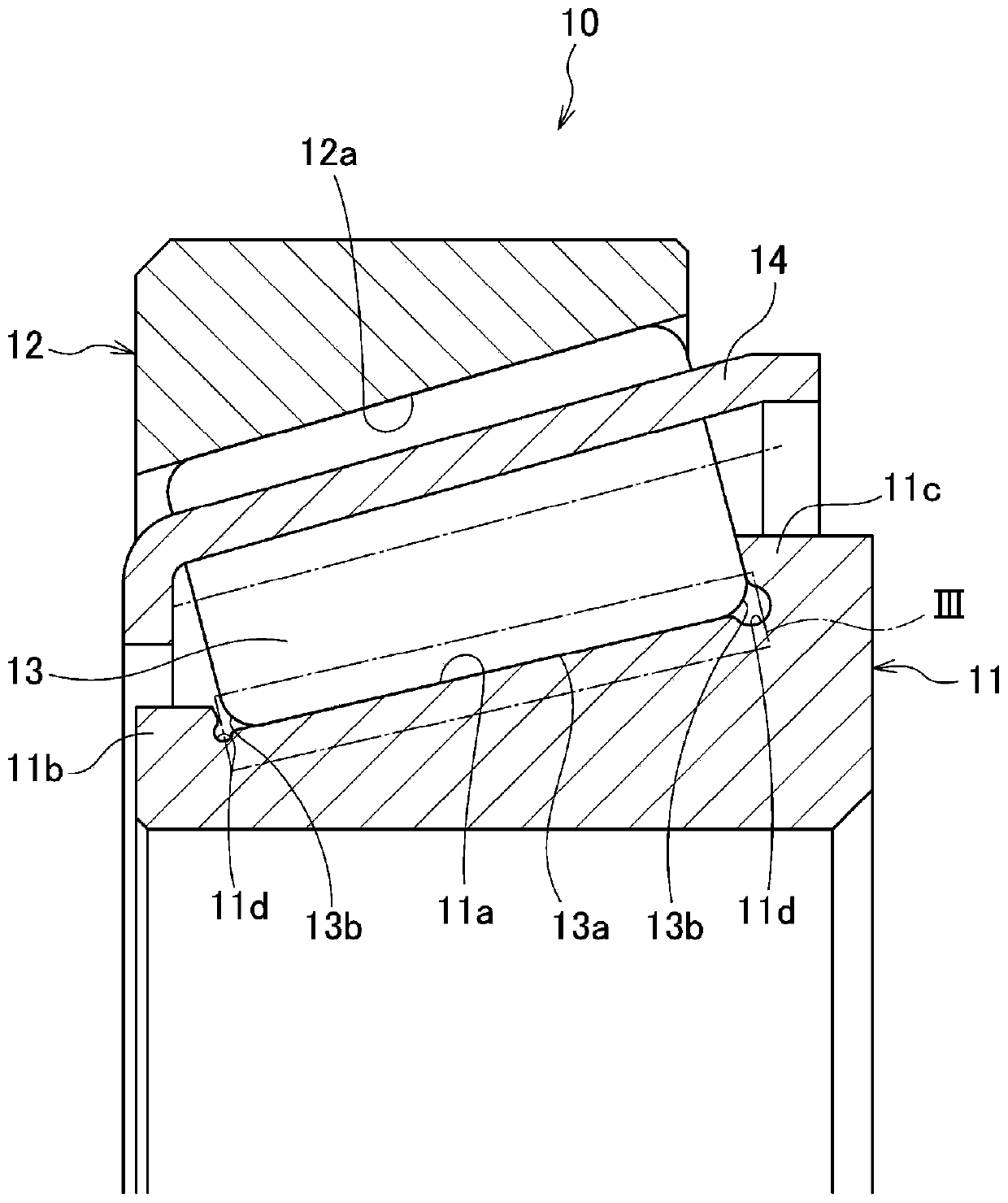

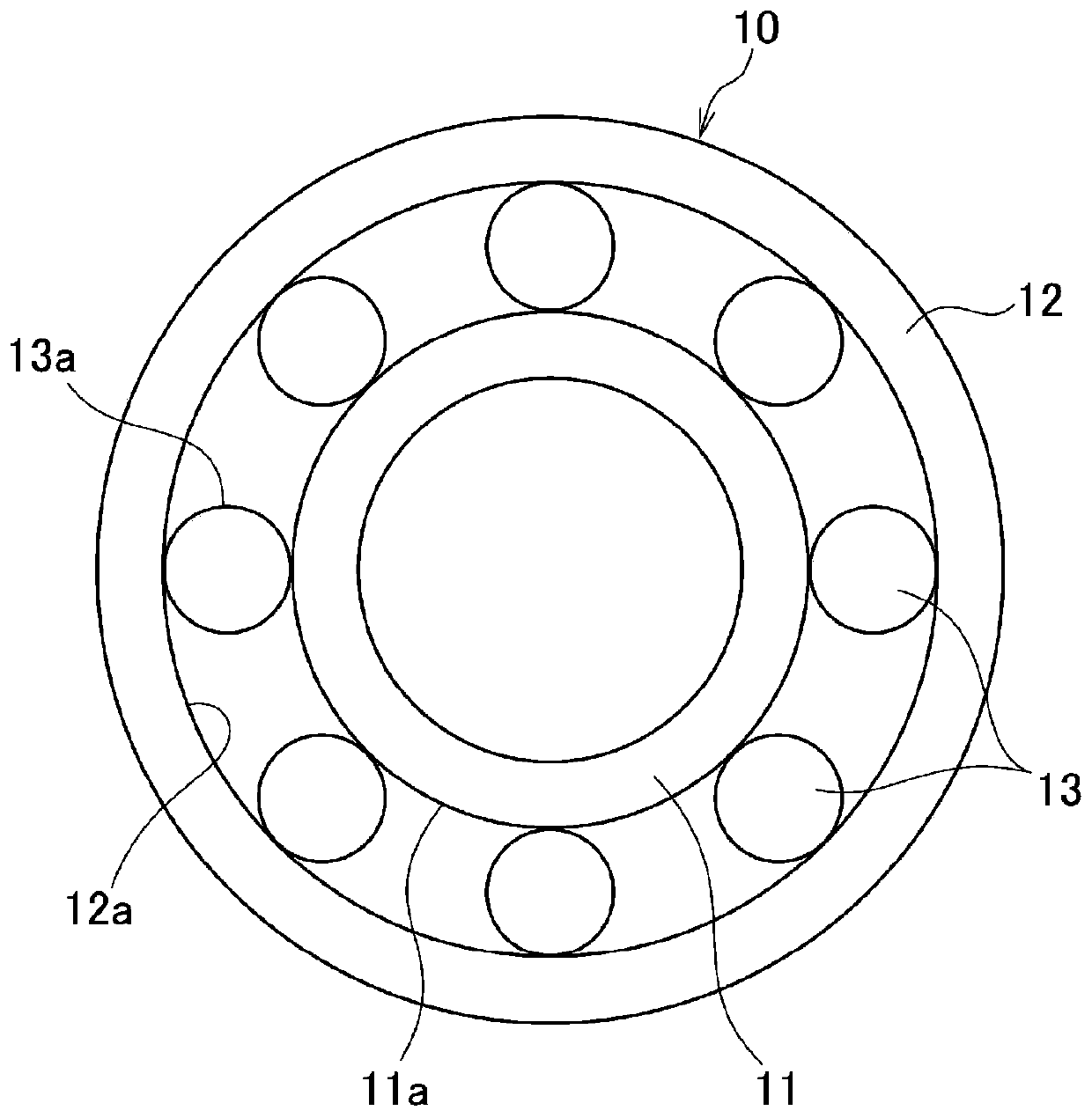

Rolling bearing

InactiveCN101120180AReduce contact stressInhibit wearRoller bearingsBearing assemblyEngineeringMechanical engineering

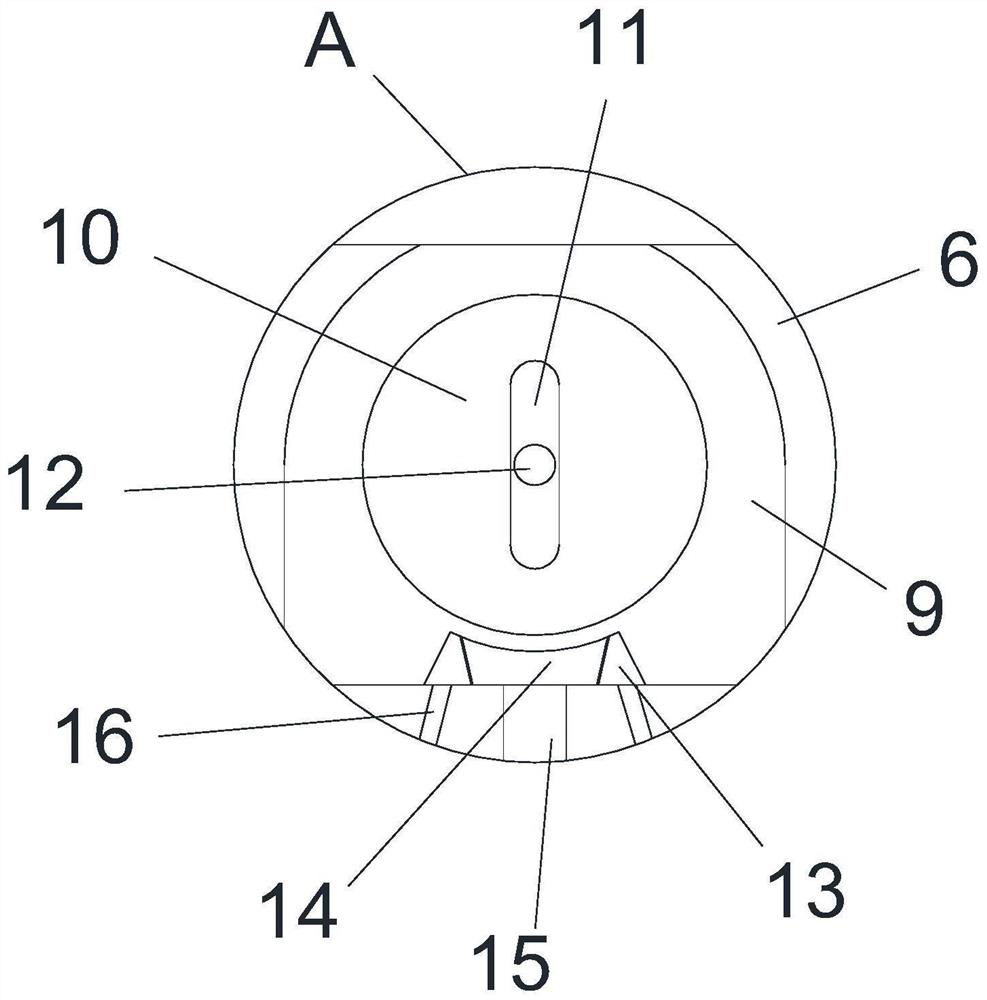

A four-point contact ball bearing (11), comprising an inner ring (12), an outer ring (13), balls (14) disposed between the inner ring (12) and the outer ring (13), and a retainer (15) holding intervals between the balls (14). The outer ring (13) comprises flat surfaces (13a) cut by planes each of which connects any one point on its outer diameter surface to any two points at its end face outer peripheral part.

Owner:NTN CORP

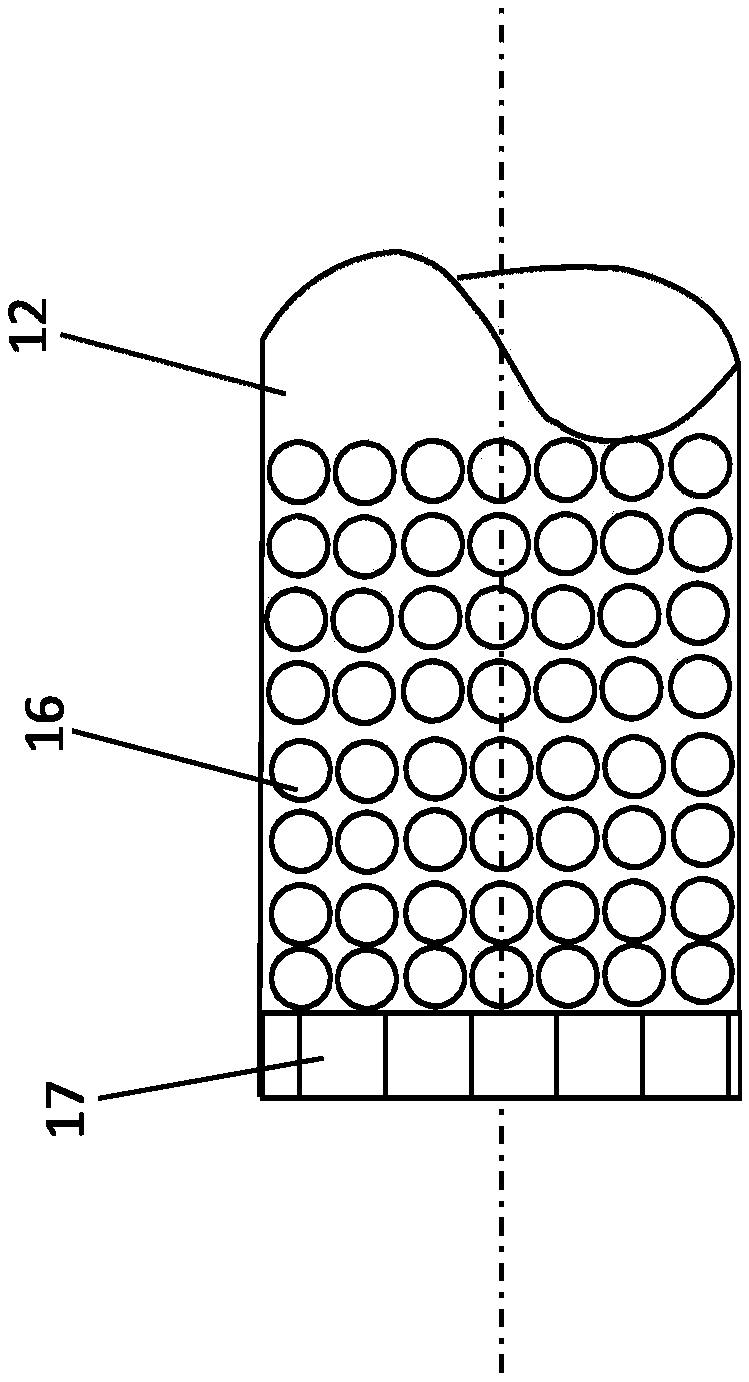

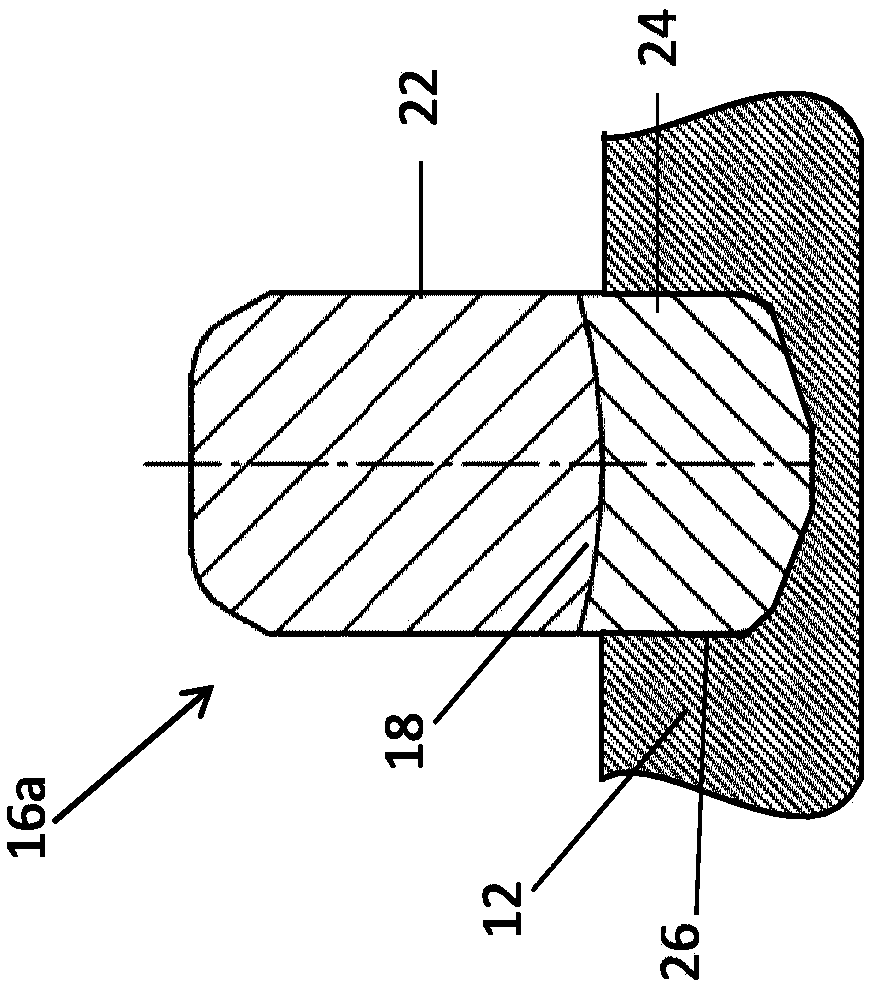

Wear-resistant element for a comminuting device

The invention relates to a wear-resistant element (16c) for partial insertion into a recess on a surface of a wear area of a comminuting device, the wear-resistant element (16c) comprising a fasteningsection (24) which can be connected to the recess on the surface of the wear area and has a wear portion (22) that protrudes at least in part from the surface of the wear area. According to the invention, the fastening section (24) comprises a material that has a lower wear resistance than the material of the wear portion (22), the wear portion (22) extends beyond the fastening section (24) in the vertical direction of the wear-resistant element (16c), and the fastening section (24) is in the form of a sleeve.

Owner:F L SMIDTH & CO AS

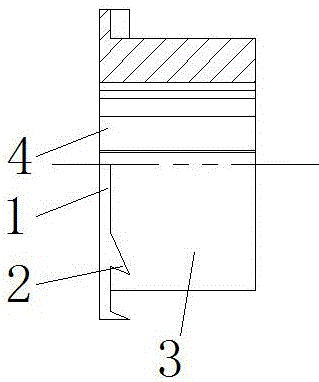

Tapered roller bearing

InactiveCN110494664AEasy finishingLow costRolling contact bearingsShaftsEngineeringPulp and paper industry

Owner:NSK LTD

A method for preparing antibacterial textiles using electron radiation technology

ActiveCN104358104BWill not polluteImprove efficiencyPhysical treatmentVegetal fibresAfter treatmentElectron radiation

Owner:JIANGNAN UNIV

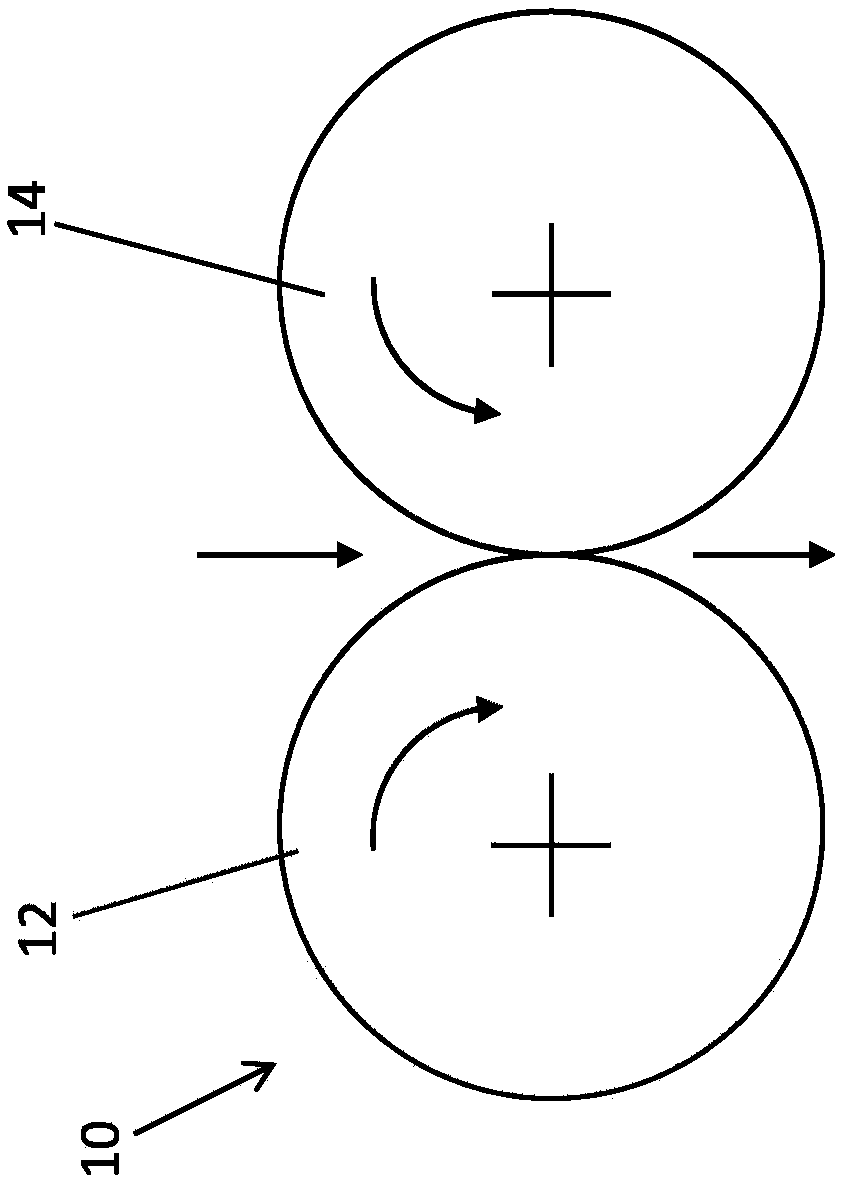

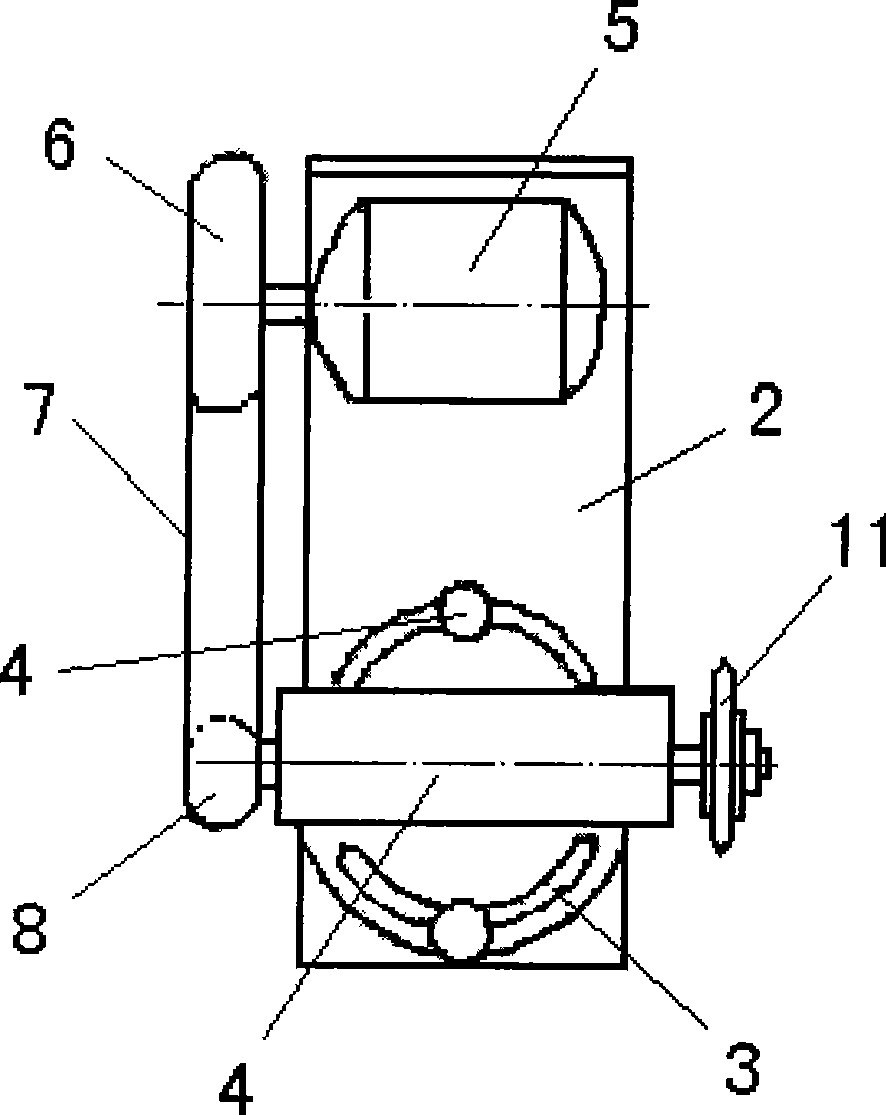

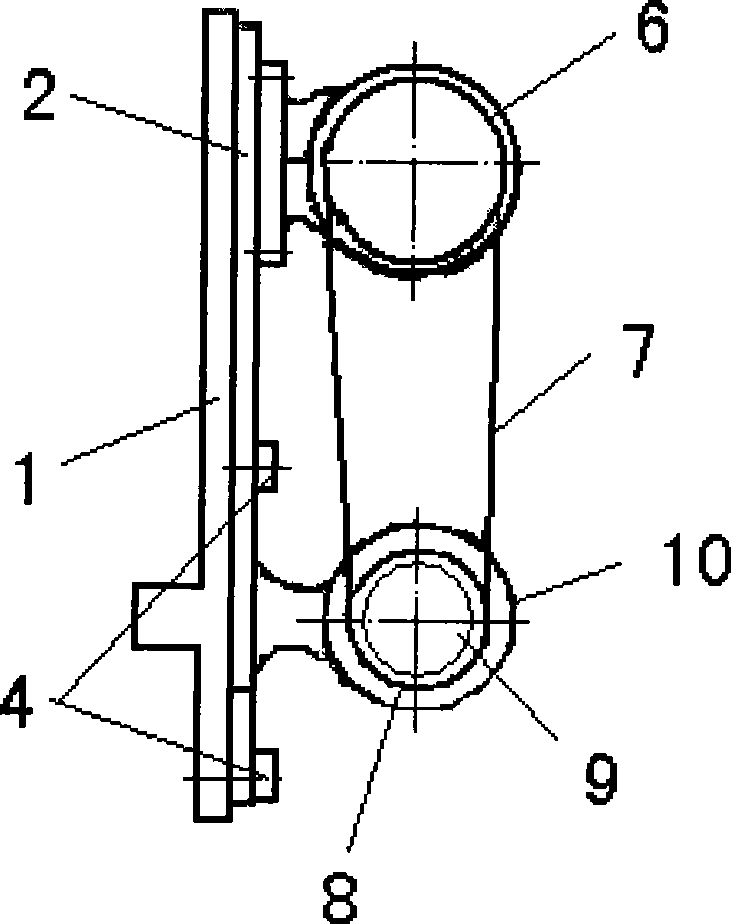

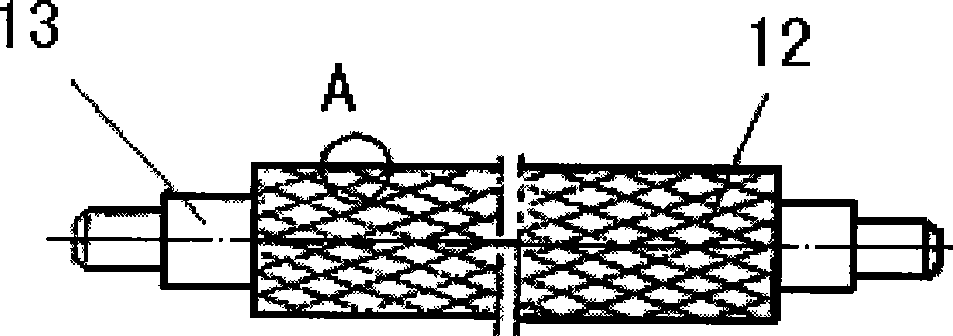

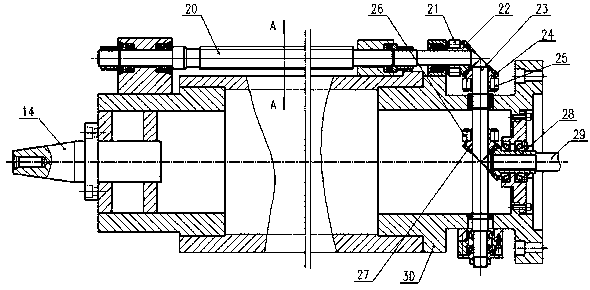

Method for grinding helical burr on soft rubber roller and processing device

InactiveCN101433985AReduce radial forceSmall resilienceThread cutting feeding devicesThread cutting machinesEngineeringScrew thread

The invention relates to a grinding and processing method for screw threads on a soft rubber roller and a processing device. The method is as follows: a main shaft of a machine tool drives the soft rubber roller to rotate, a grinding wheel for grinding the screw threads is arranged in the radial direction of the soft rubber roller at the same time, and the grinding wheel is fixed on a feeding device of the machine tool through a grinding head connected with the grinding wheel; and when the main shaft drives the soft rubber roller to rotate, the feeding device of the machine tool drives the grinding wheel to feed in the direction parallel to the direction of the main shaft, so as to grind and process the driven screw threads on the soft rubber roller. The device comprises a supporting plate on which a rotating plate is arranged, two semicircular arc grooves are arranged on the rotating plate, and a fastening bolt connected with the supporting plate is respectively arranged in the two semicircular arc grooves; and the rotating plate is provided with an electric motor, an output shaft of the electric motor is connected with a driving pulley which is connected with a driven pulley through a belt, the driven pulley coaxially drives a grinding head which is rotationally arranged in a grinding head sleeve fixedly supported on the rotating plate, and an extending end of the grinding head is connected with the grinding wheel. The method has the advantages of high processing efficiency and good processing quality, and can effectively solve problem of processing the screw threads of the soft rubber roller.

Owner:BEIJING NANKOU RAILWAY TRANSIT MACHINERY

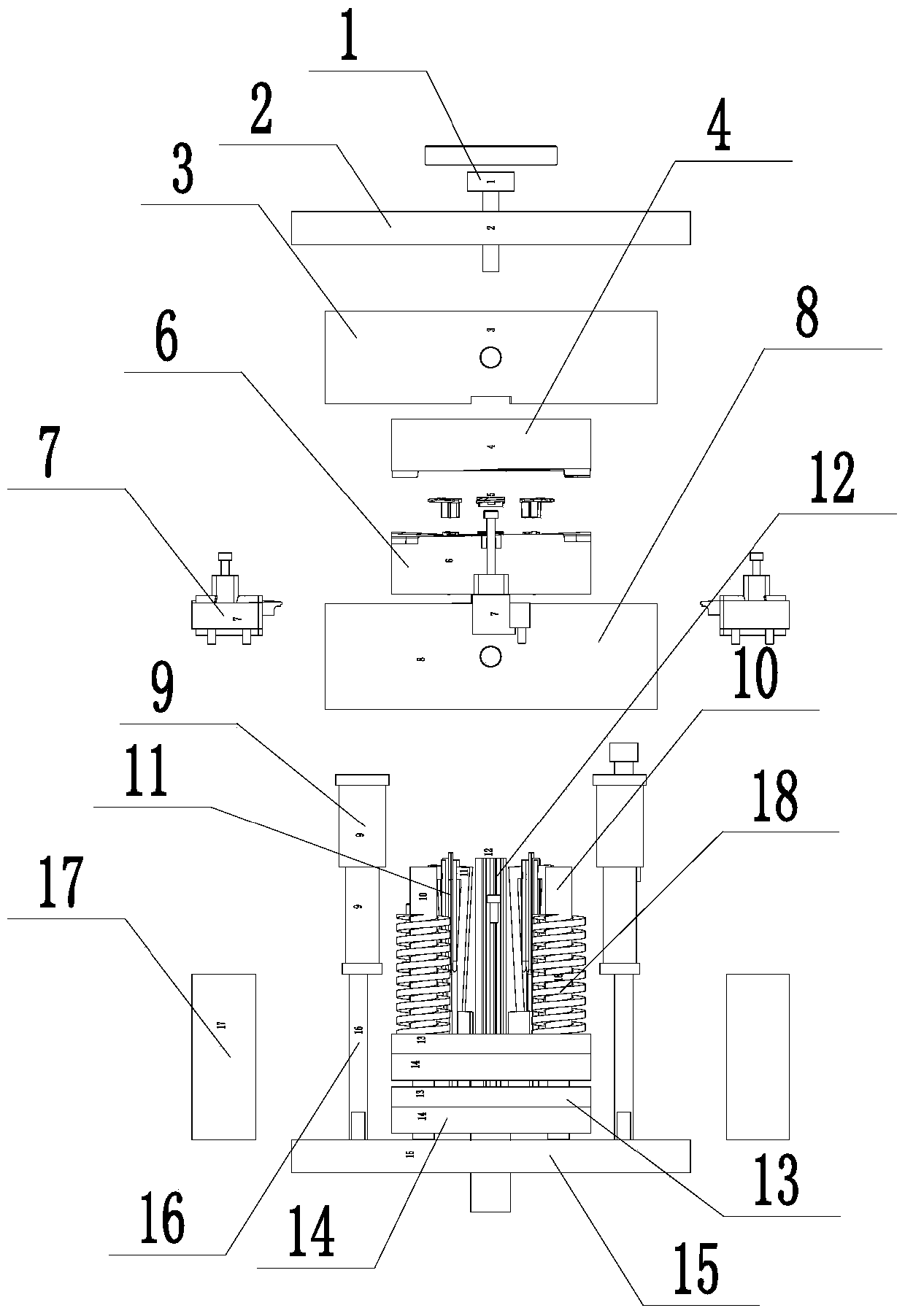

Mirror surface insert mold and preparation technology thereof

ActiveCN105397951AHigh product precisionMeet production needsOptical articlesProcessing accuracyEngineering

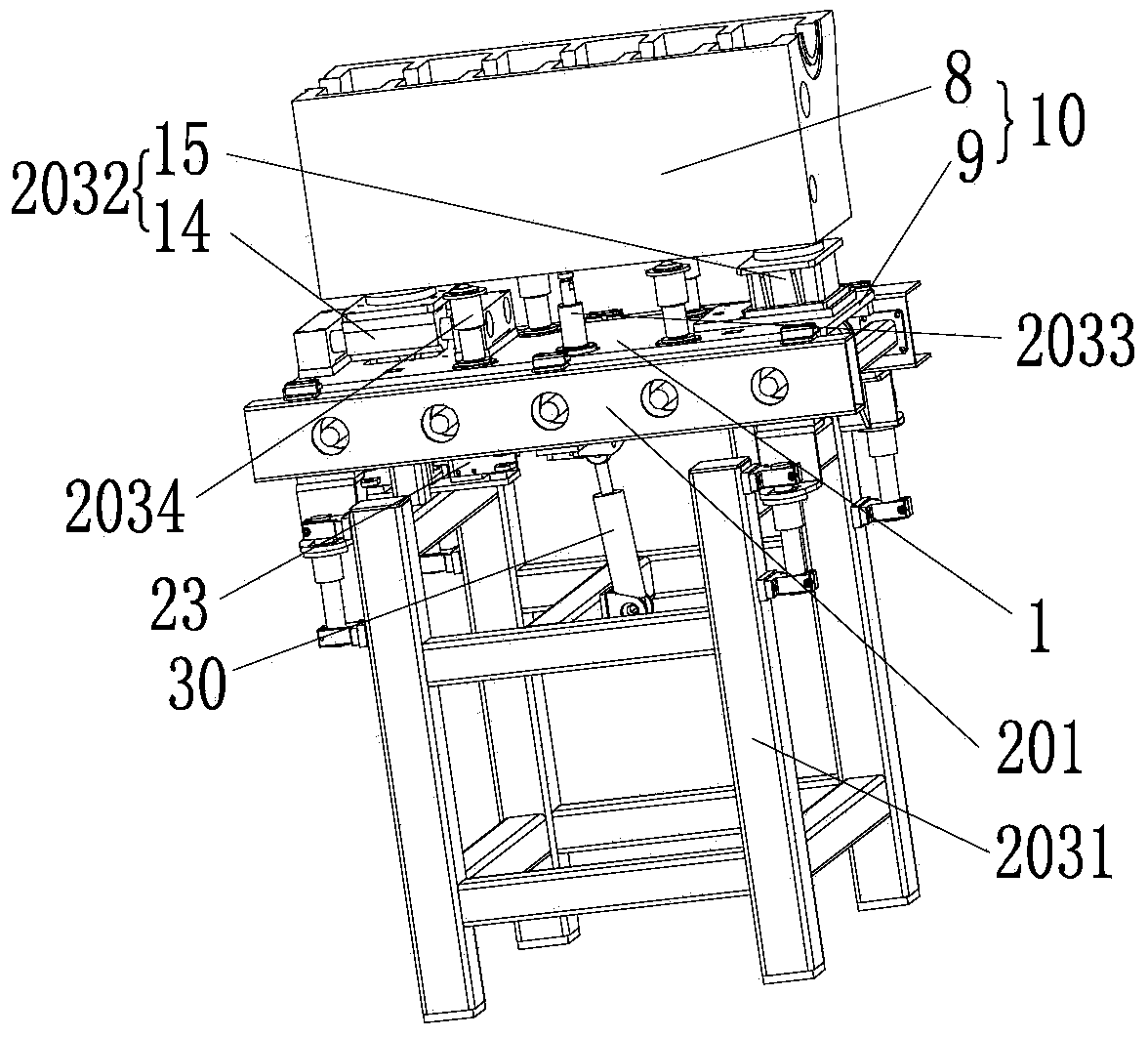

The invention discloses a mirror surface insert mold. The mirror surface insert mold comprises a bottom plate and ejector pin fixing assemblies, wherein the ejector pin fixing assemblies are arranged on the upper surface of the bottom plate and composed of ejector pin bottom plates and ejector pin panels. The four corners of the upper surface of each ejector pin fixing assembly are provided with return pins which are sleeved with springs. The middle of the upper surface of each ejector pin fixing assembly is further provided with a plurality of fixed ejector pins, ejector sleeves and flat ejector pins, wherein the ejector pins, the ejector sleeves and the flat ejector pins penetrate through the two sets of the ejector pin fixing assemblies. Stop bolts are arranged in the position, close to the ejector pin bottom plates, of the upper surface of the bottom plate. Two square irons are symmetrically arranged in the position, close to the stop bolts, of the upper surface of the bottom plate. Guide posts are arranged on the upper surfaces of the stop bolts. The outer surfaces of the guide posts are sleeved with guide sleeves. A B plate is arranged on the tops of the guide posts. The upper surface of the B plate is sequentially provided with a back mold core, a front mold core, an A plate, a top clamp plate and a panel from bottom to top. A vertical downward sprue is arranged on the top of the panel. According to the mirror surface insert mold, the mirror surface insert mold can be well processed and completed, and the processing accuracy of the mold is ensured.

Owner:SICHUAN LANGRUN TECH

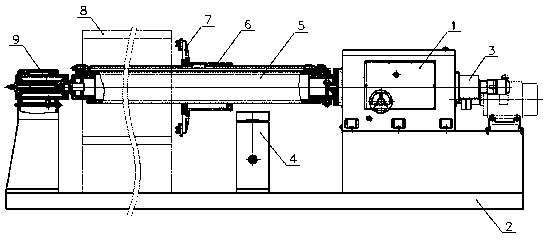

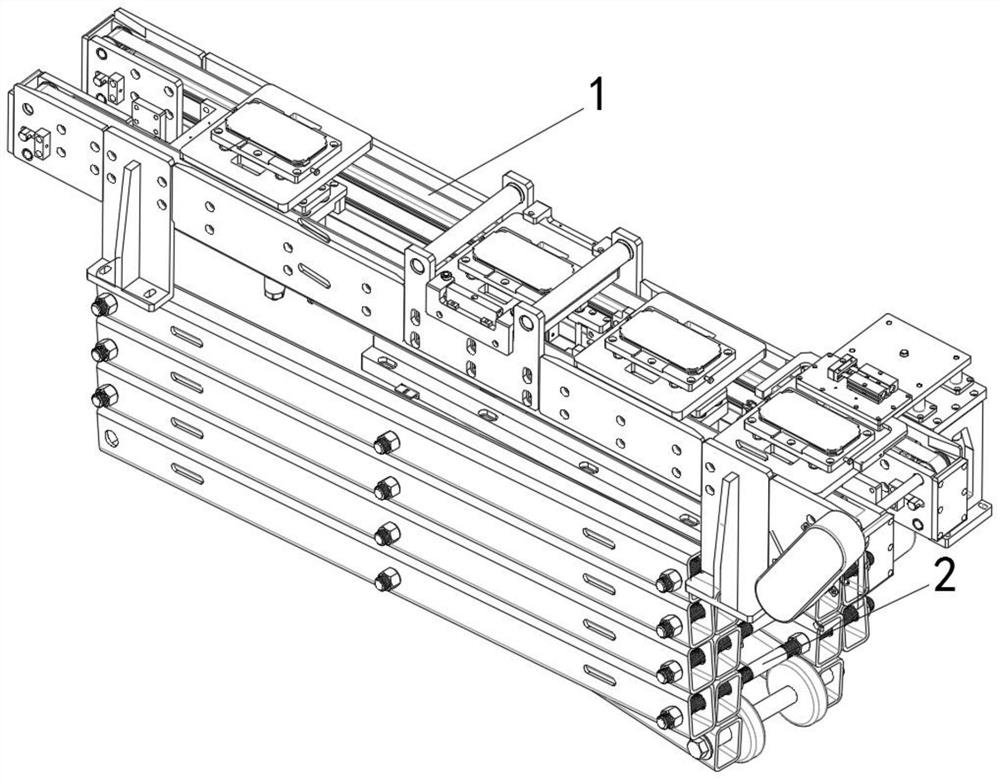

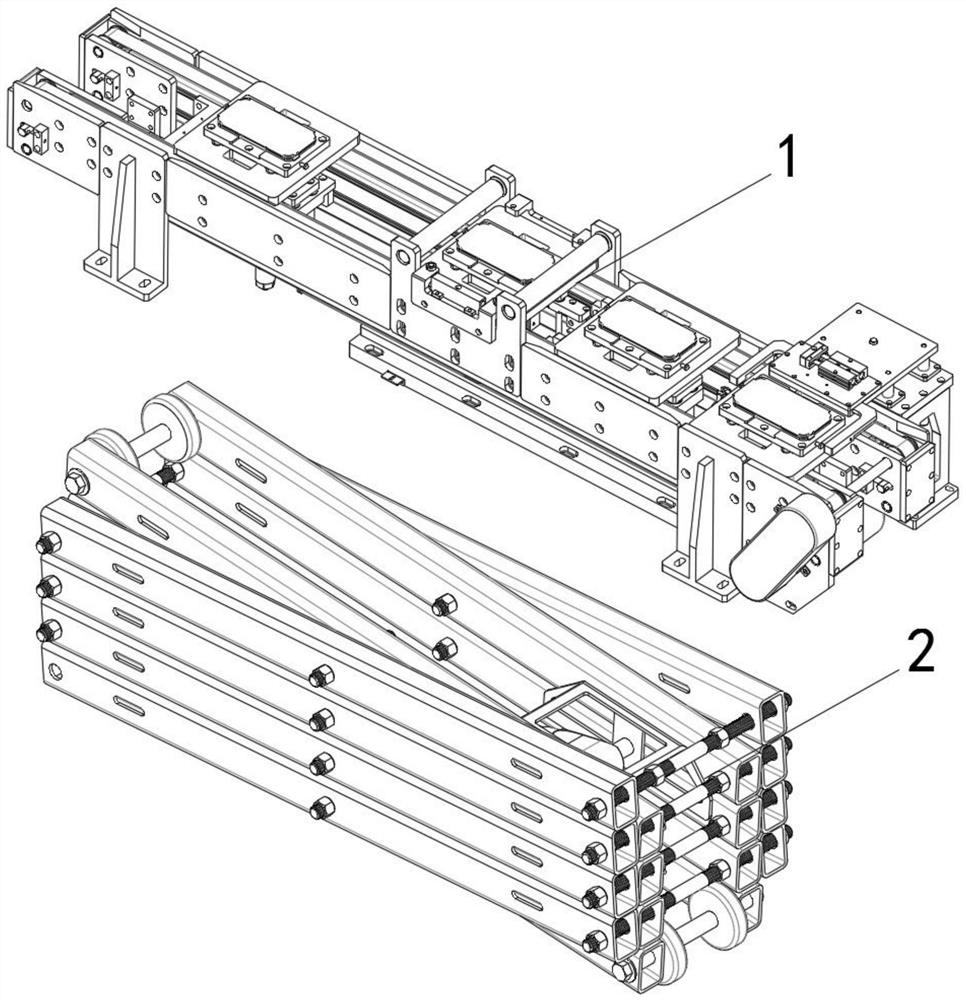

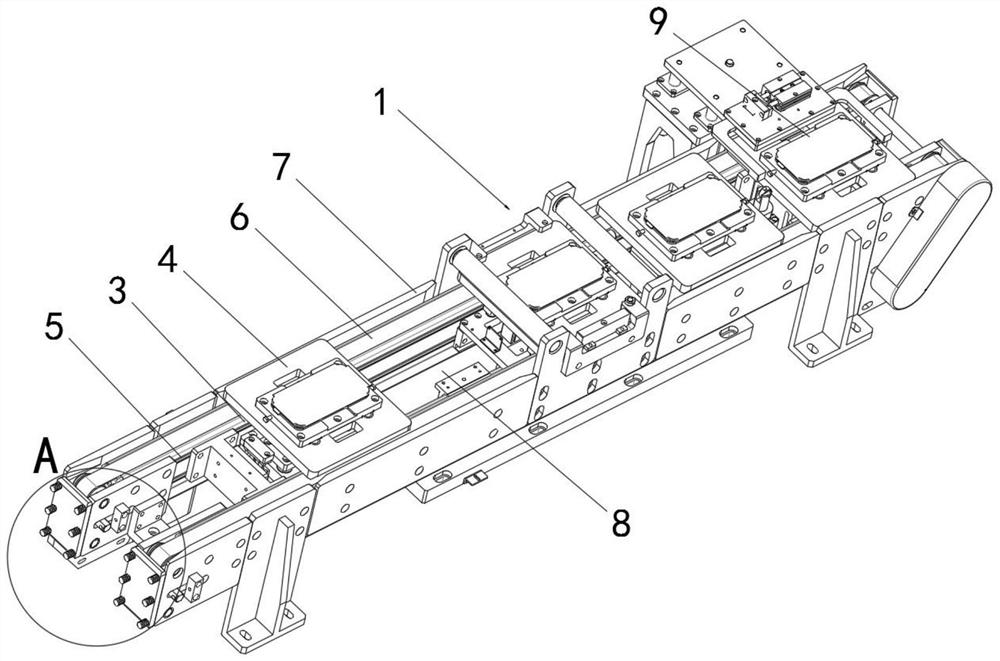

Large-specification deep hole boring device

PendingCN107900412ACompact structureReduce manufacturing costBoring/drilling machinesDrive shaftEngineering

The invention relates to a large-specification deep hole boring device. The large-specification deep hole boring device comprises a bottom plate, a feeding device, a boring rod box, a boring rod bracket, a boring rod, a sliding body, a cutterhead, a workpiece and a tailstock, the boring rod penetrates through an inner hole of the workpiece, one end of the boring rod is connected with the boring rod box, the other end of the boring rod is connected to the tailstock, the boring rod bracket is positioned at the lower part of the boring rod, a feeding screw rod and the sliding body are installed above the boring rod, the sliding body is installed on the feeding screw rod, and the sliding body integrally moves forwards and backwards on the boring rod along the feeding screw rod; and the cutterhead is arranged on the sliding body, a transmission shaft is arranged in the boring rod box, one end of the transmission shaft is connected with the feeding device, the other end of the transmission shaft is connected with the end of the boring rod, the transmission shaft can drive the boring rod to rotate integrally, the boring rod can drive the feeding screw rod to rotate when rotating, so thatthe sliding body arranged on the feeding screw rod moves forwards and backwards relative to the boring rod under the rotation of the feeding screw rod. The large-specification deep hole boring deviceis compact in overall structure and low in manufacturing cost; and the cutterhead is replaced, boring rods with different specifications are used in a certain range, so that machining precision is high, the application range is wide, and the requirements of various working conditions can be met.

Owner:德州普利森机床有限公司

High-heat-conductivity low-density die-cast aluminum silicon rare-earth alloy

The invention relates to the technical field of aluminum alloys, and particularly provides a die-cast aluminum silicon rare-earth alloy which comprises 10.1-15.0 wt% of Si, 0.1-1.0 wt% of rare earth (Ce or La or Ce-La mixture), one or two or three or four additives A and the balance of Al and inevitable impurities. When the number of the additives A is one, the mass content is 0.3-2.0%; and when the number of the additives A is two or three or four, the mass content of each additive is 0.2-1.5%. The additives A can be Fe, Ni, Mn, Mg or mixture thereof. The die-cast aluminum silicon rare-earth alloy has the advantages of favorable heat-conducting property, low density, favorable flowability, favorable die casting performance, easy subsequent finish machining of die casting, high efficiency, high speed, no residual waste slag and high yield, and is a preferable die-cast aluminum alloy for radiators with excellent comprehensive properties.

Owner:朱岳群

A kind of mechanical processing surface finishing equipment

InactiveCN106271993BEasy flipSpeed up the processGrinding carriagesGrinding machinesSurface finishMachined surface

The invention discloses mechanical machining surface finishing equipment. The mechanical machining surface finishing equipment comprises a base, the top of the base is fixedly connected with support frames, one side of each support frame is fixedly connected with a fixing device, each fixing device comprises a push plate, one side of each push plate is fixedly connected with one end of a push rod, and the other end of each push rod penetrates through a limiting sleeve to be fixedly connected with one side of a fixing plate. According to the machining surface finishing equipment, by cooperatively using second electric telescopic rods, support blocks, motors and first gears, mechanical equipment can be automatically turned over in the finishing process, the problem that the mechanical equipment cannot be automatically turned over when the mechanical equipment surface is finished is solved, and the manual turnover condition is avoided; by cooperatively using mobile rods, fixed blocks, fixed extrusion blocks, movable extrusion blocks, third electric telescopic rods and second gears, the mechanical equipment can be better turned over in the finishing process, and then the working progress is improved.

Owner:张庆荣

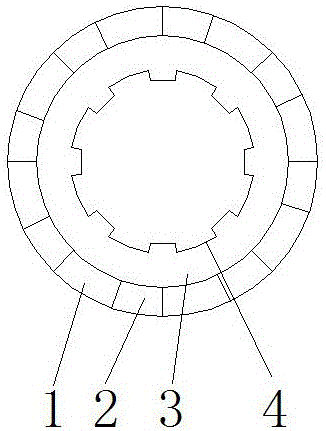

Clutch sleeve of bicycle mini-sized transmission

The clutch sleeve of the bicycle miniature gearbox of the present invention relates to a ratchet. A clutch sleeve for a bicycle miniature gearbox, characterized in that: a clutch ratchet base ring is provided at one end of the sleeve, a clutch ratchet is provided on the clutch ratchet base ring, and a clutch ratchet is provided on the inner hole of the sleeve. spline groove. The clutch sleeve of the bicycle miniature gearbox, the clutch ratchet can be located on the inside of the clutch ratchet base ring, the clutch ratchet is 6-12 teeth, and the clutch ratchet is evenly distributed on the clutch ratchet On the base ring, the outer diameter of the sleeve is 26 mm, the outer diameter of the clutch ratchet base ring is 32 mm, the total length of the sleeve and the clutch ratchet base ring is 16‑18 mm, and the teeth of the clutch ratchet The height is 2 mm. In the present invention, the clutch ratchet and the basic ring of the clutch ratchet are integrated, and the strength of the clutch ratchet is high, which solves the perennial problem that the clutch ratchet often breaks, ensures the reliability of the clutch, and has popularization value.

Owner:石宗泽

A kind of two-color mold and its preparation process

ActiveCN105269762BMeet production needsHigh precisionEngineeringElectrical and Electronics engineering

The invention discloses a double-color die which comprises a bottom plate. Two sets of ejector pin fixing assemblies composed of ejector pin face plates and ejector pin bottom plates are arranged in the middle of the upper surface of the bottom plate in sequence from top to bottom. Guide pillar holes are formed in the four corners of the upper surfaces of the two sets of ejector pin fixing assemblies respectively. Guide pillars are arranged in the guide pillar holes. Springs are arranged on the guide pillars. A plurality of inclined tops and flat ejector pins which penetrate the two sets of ejector pin fixing assemblies and are fixed are further arranged in the middles of the upper surfaces of the two sets of ejector pin fixing assemblies. Fixing pillars are arranged in the positions, close to the two sets of ejector pin fixing assemblies, on the upper surface of the bottom plate, and the fixing pillars are sleeved with return pins. The double-color die can be well processed, and the processing efficiency of the die is ensured.

Owner:SICHUAN LANGRUN TECH

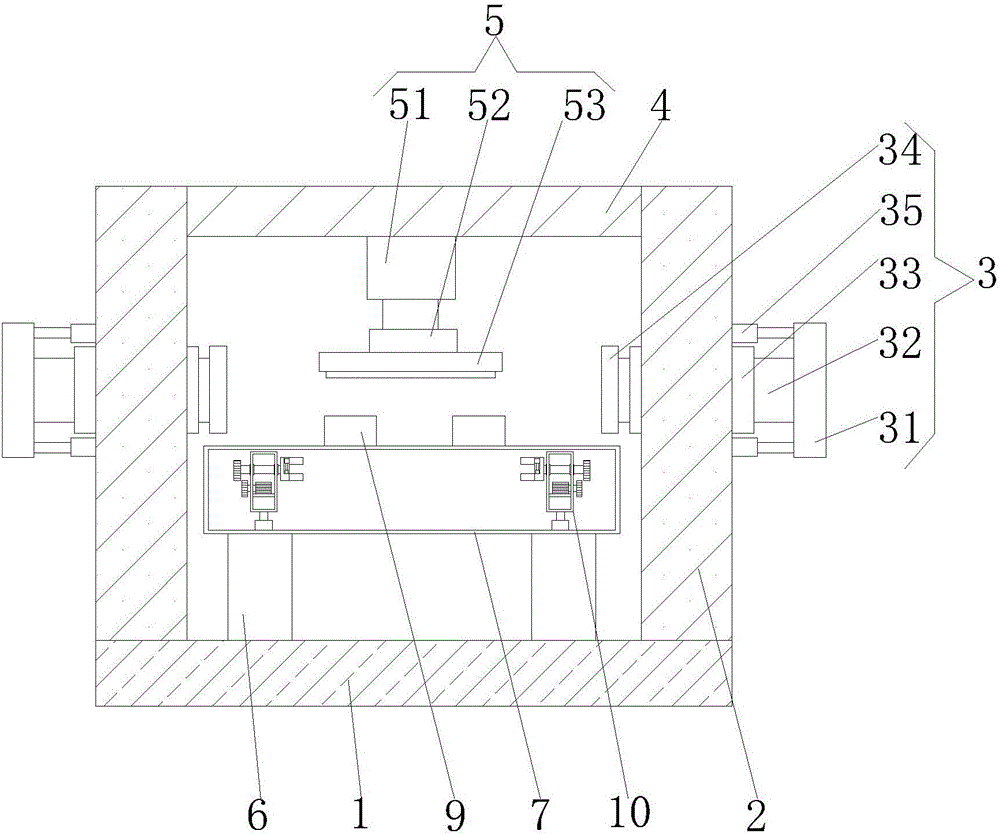

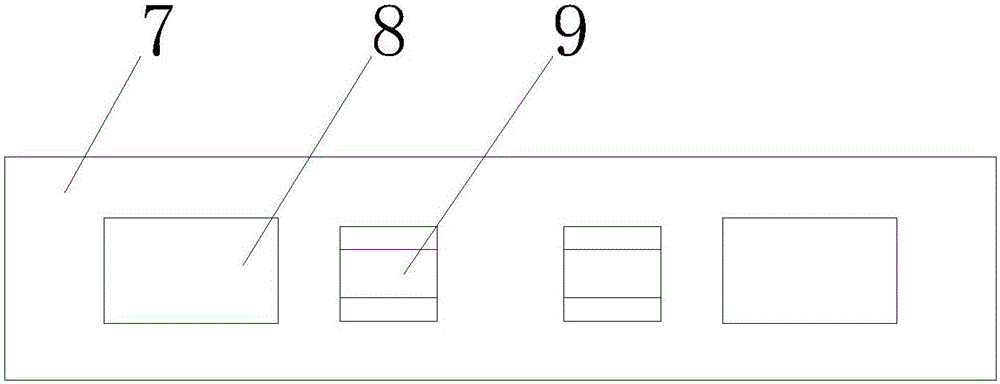

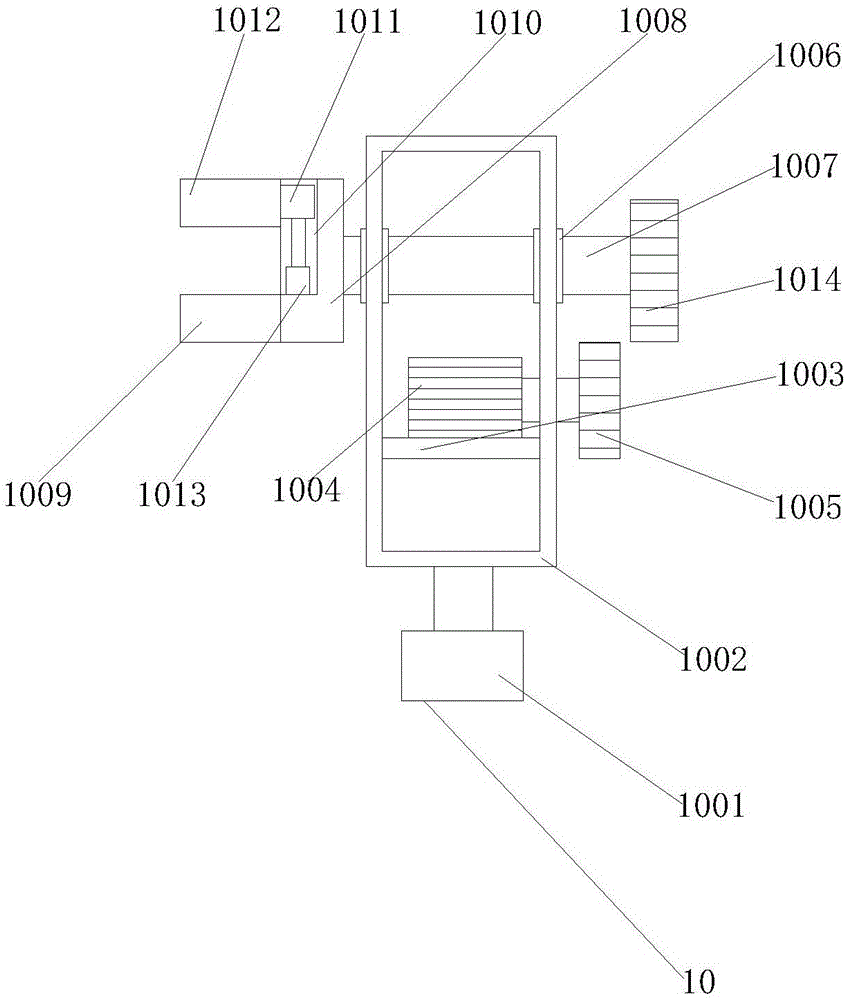

On-line automatic finishing device for iron castings and on-line automatic finishing method for iron castings

ActiveCN104190912BRealization of online automatic finishingAvoid damageCasting plantsCast ironTemporary storage

The invention discloses an iron casting online automatic finishing device and an iron casting online automatic finishing method. The iron casting online automatic finishing device comprises a supplied material conveying line, a safety chamber used for finishing of iron castings, a discharge conveying line used for conveying and storing the iron castings machined through finishing, and a centralized controller used for online automatic finishing control. A first lifting table used for assembling iron casting materials on an empty tray to form a load-bearing tray is arranged between the supplied material conveying line and the safety chamber. A temporary storage table used for temporarily storing the load-bearing tray conveyed to the safety chamber and temporarily storing the empty tray supplied to the first lifting table is arranged between the first lifting table and the safety chamber. A second lifting table used for separating the iron castings where finishing is completed from the load-bearing tray and sending the iron castings to the discharge conveying line is arranged between the safety chamber and the discharge conveying line. It is ensured that finishing of the iron castings is conducted in order, and online automatic finishing of the iron castings is achieved by conducting transferring through the lifting tables.

Owner:CHANGSHA CTR ROBOTICS

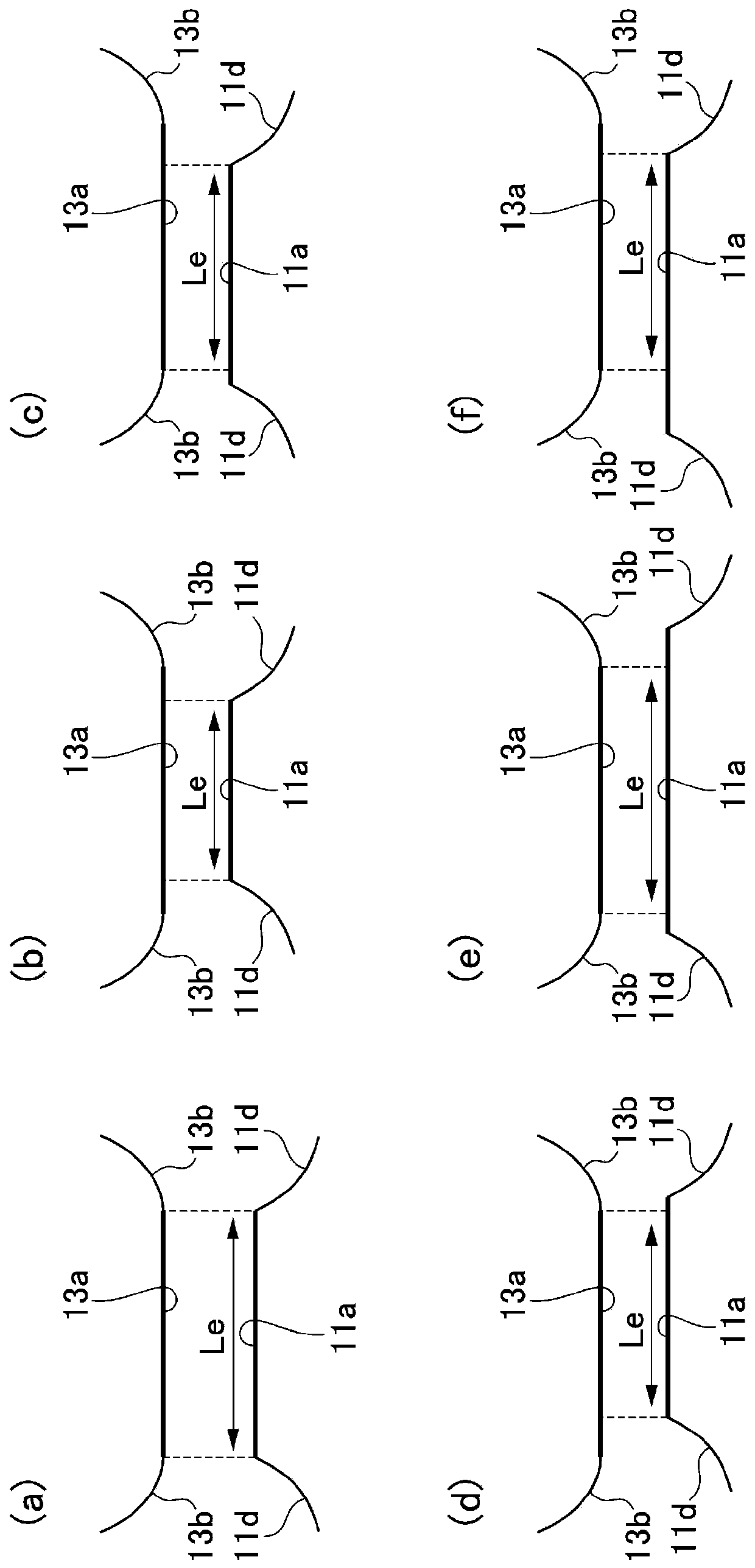

Supersonic welding method and device for welding reinforced belt chip to zipper belt

InactiveCN1235733CAvoid residueAvoid separationSlide fastenersDomestic slide fastenersSynthetic resinElectrical and Electronics engineering

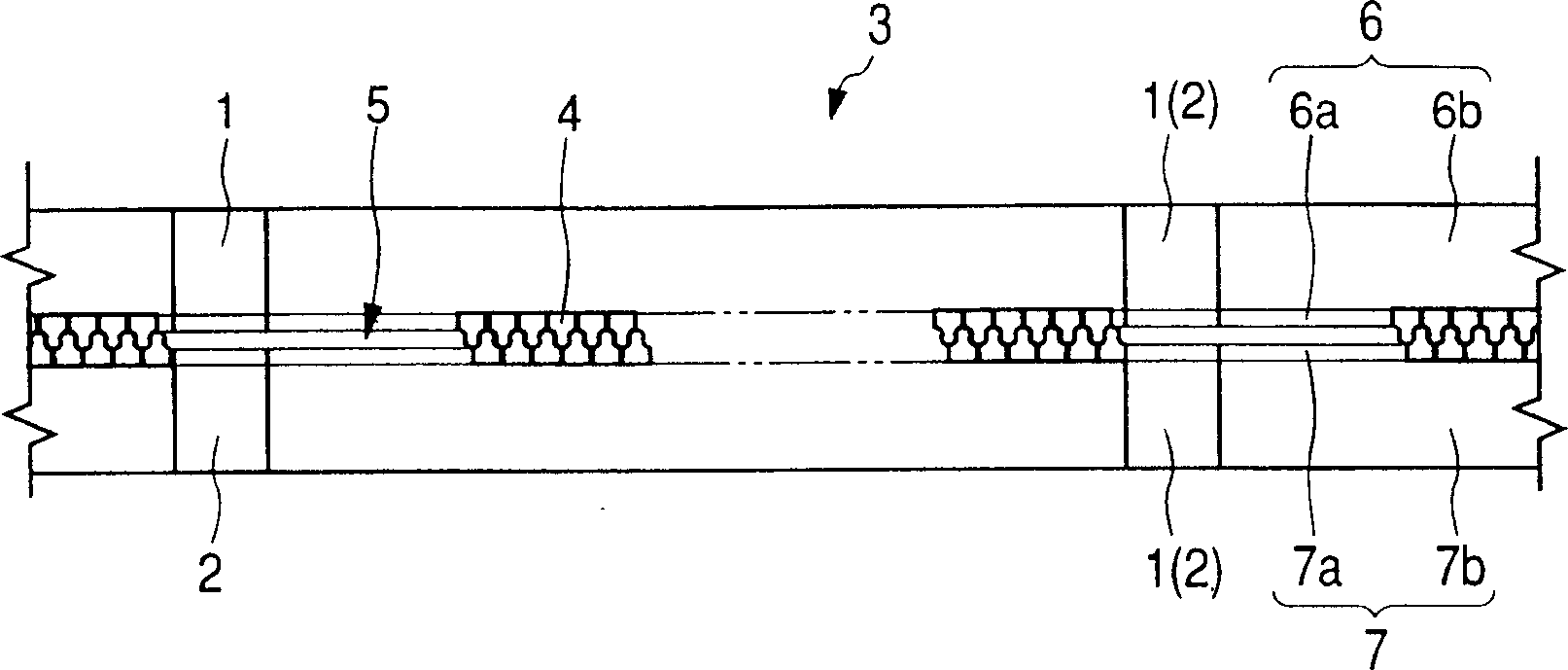

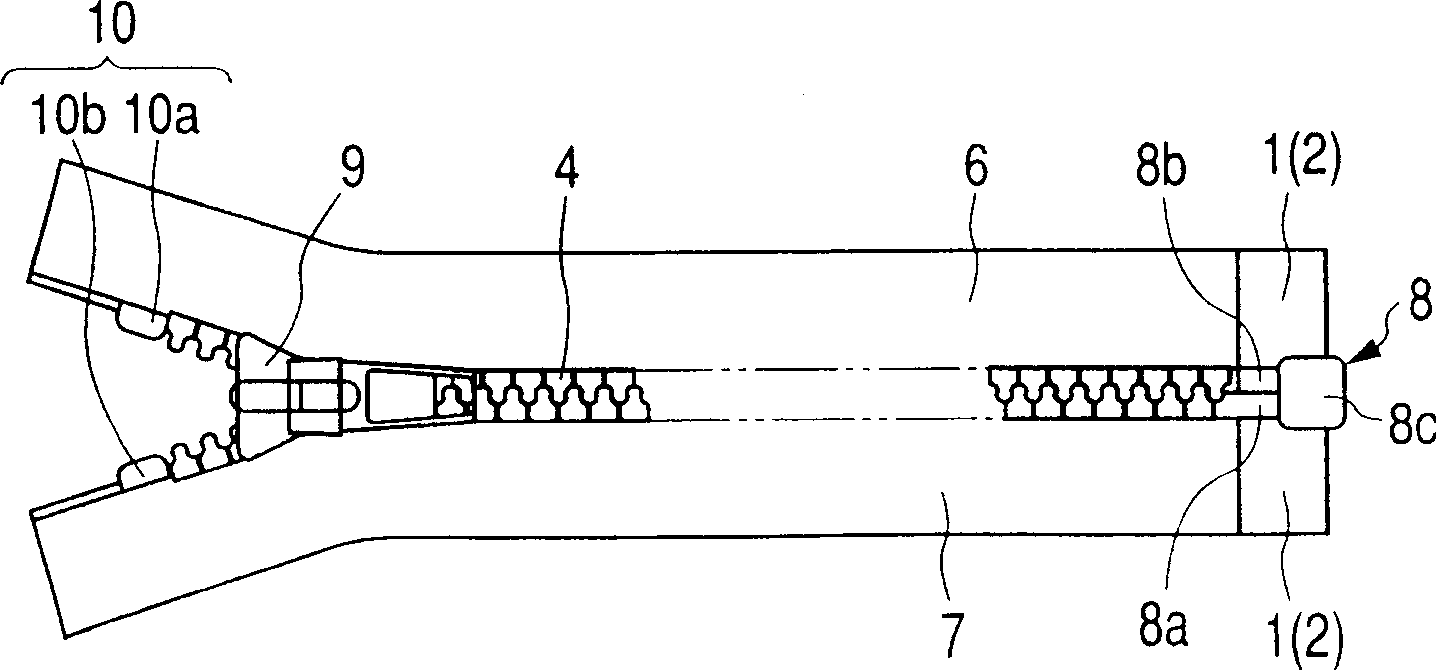

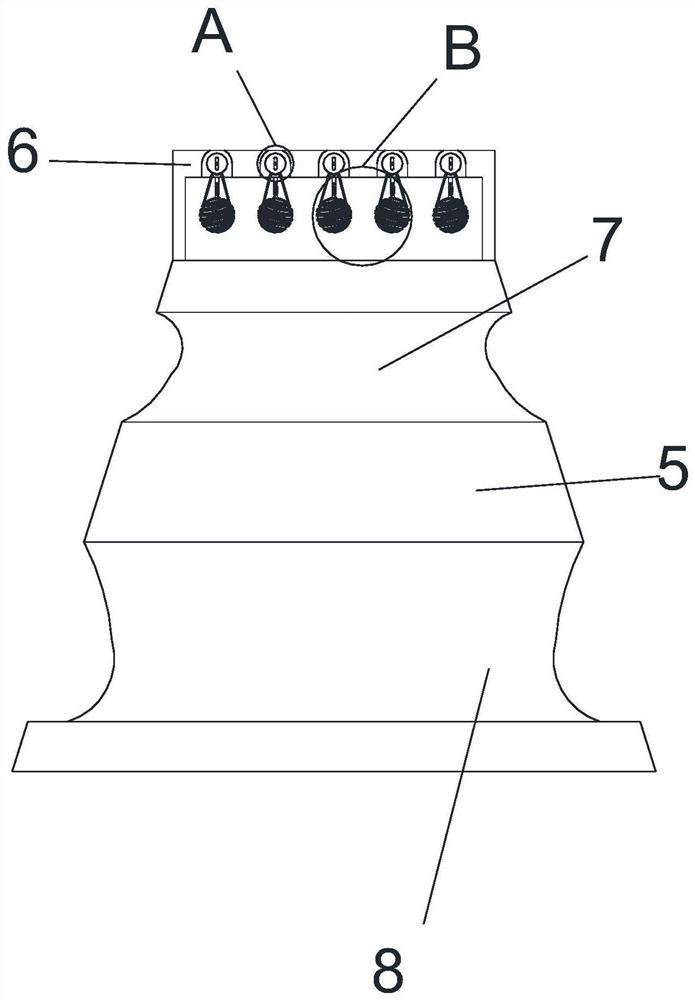

In order to weld a reinforcing tape piece (1, 2) formed of a synthetic resin to a separable bottom stop a separable bottom stop attachment portion of a slide fastener chain (3) by ultrasonic heating over a core portion (6a, 7a) and a main tape portion (6b, 7b) in a fastener tape (6, 7), a welding time and / or an amplitude which are / is suitable for welding the reinforcing tape piece (1, 2) to the core portion (6a, 7a) and the vicinity of the core portion, and a welding time and / or an amplitude which are / is suitable for welding the reinforcing tape piece (1, 2) to the main tape portion (6b, 7b) are preset respectively. The welding of the reinforcing tape piece (1, 2) to the core portion (6a, 7a) and the vicinity of the core portion and the welding of the reinforcing tape piece to the main tape portion (6b, 7b) are carried out in two stages in accordance with the welding time or the amplitude which is set.

Owner:YKK CORP

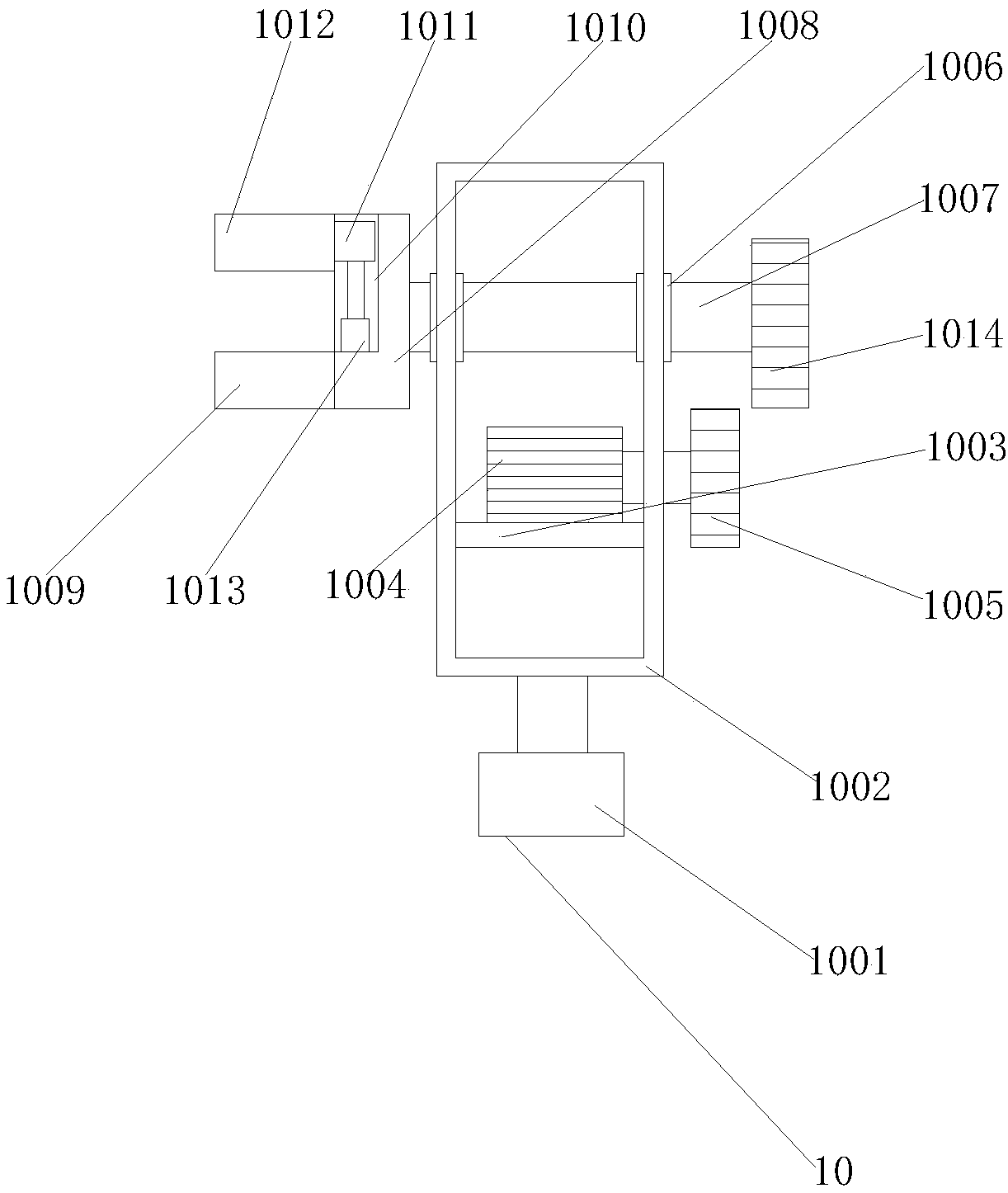

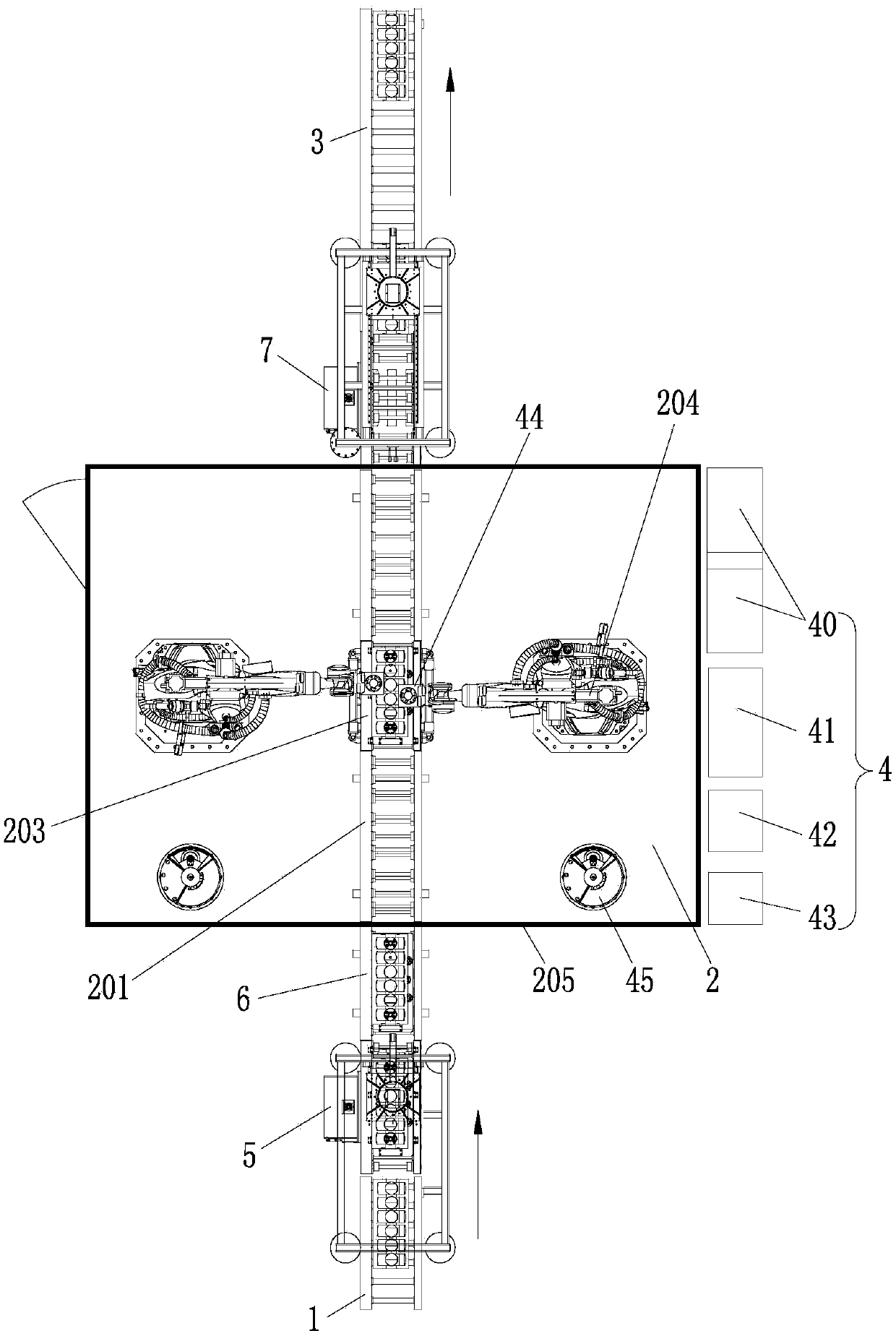

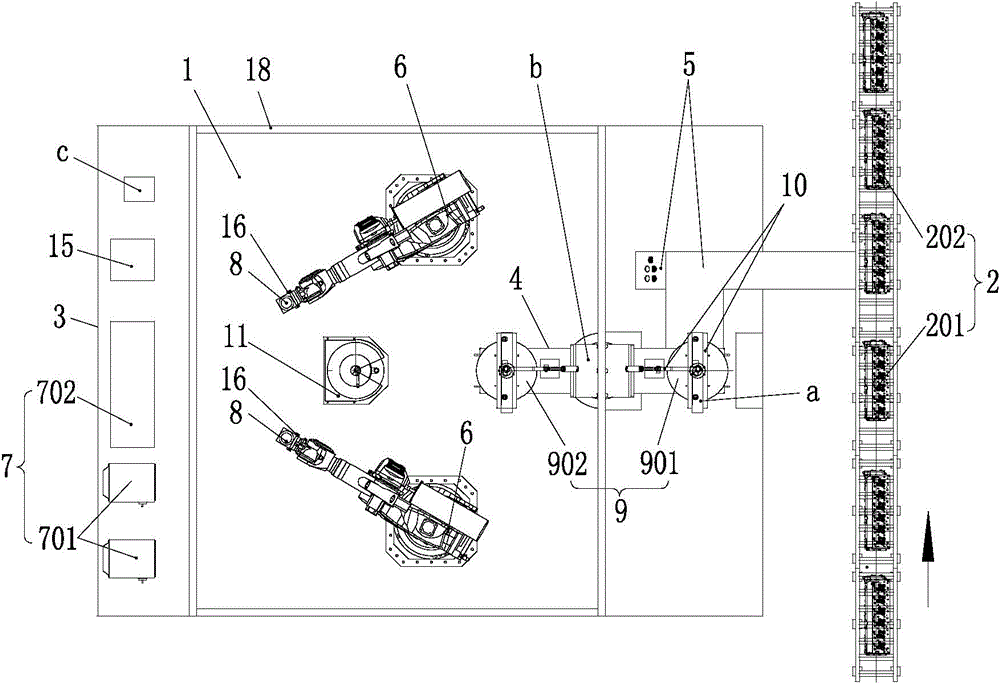

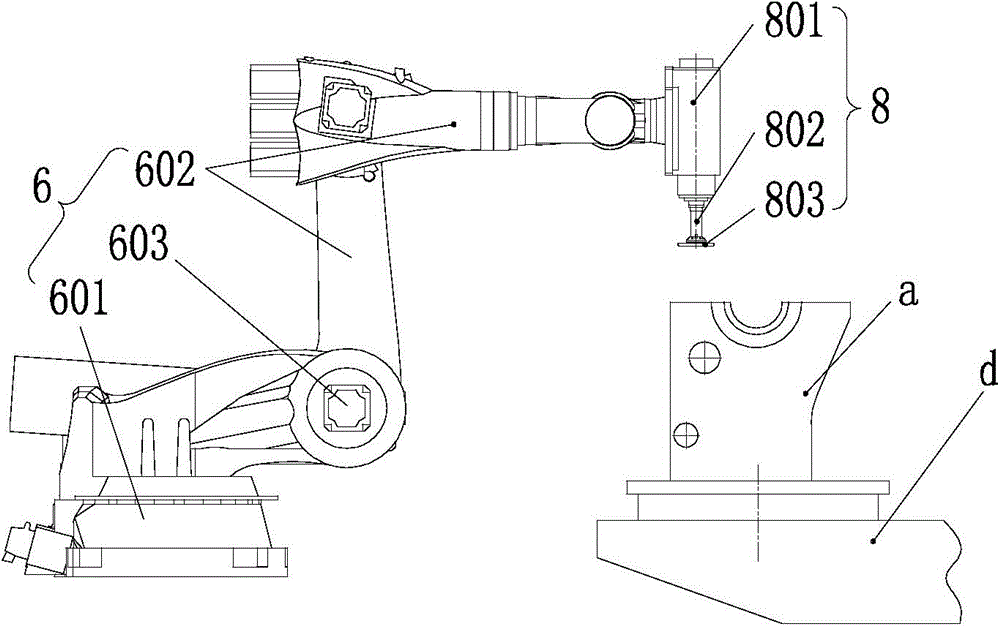

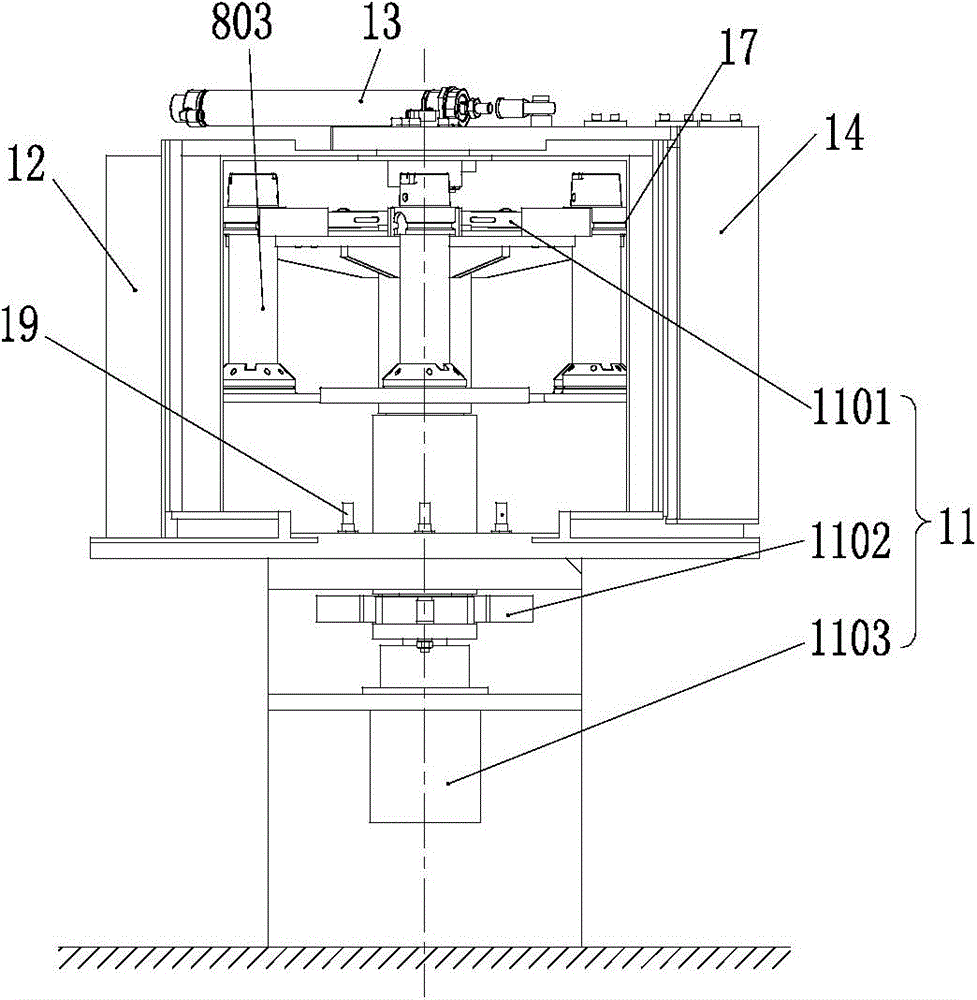

Workstation for finishing iron castings and finishing method for iron castings

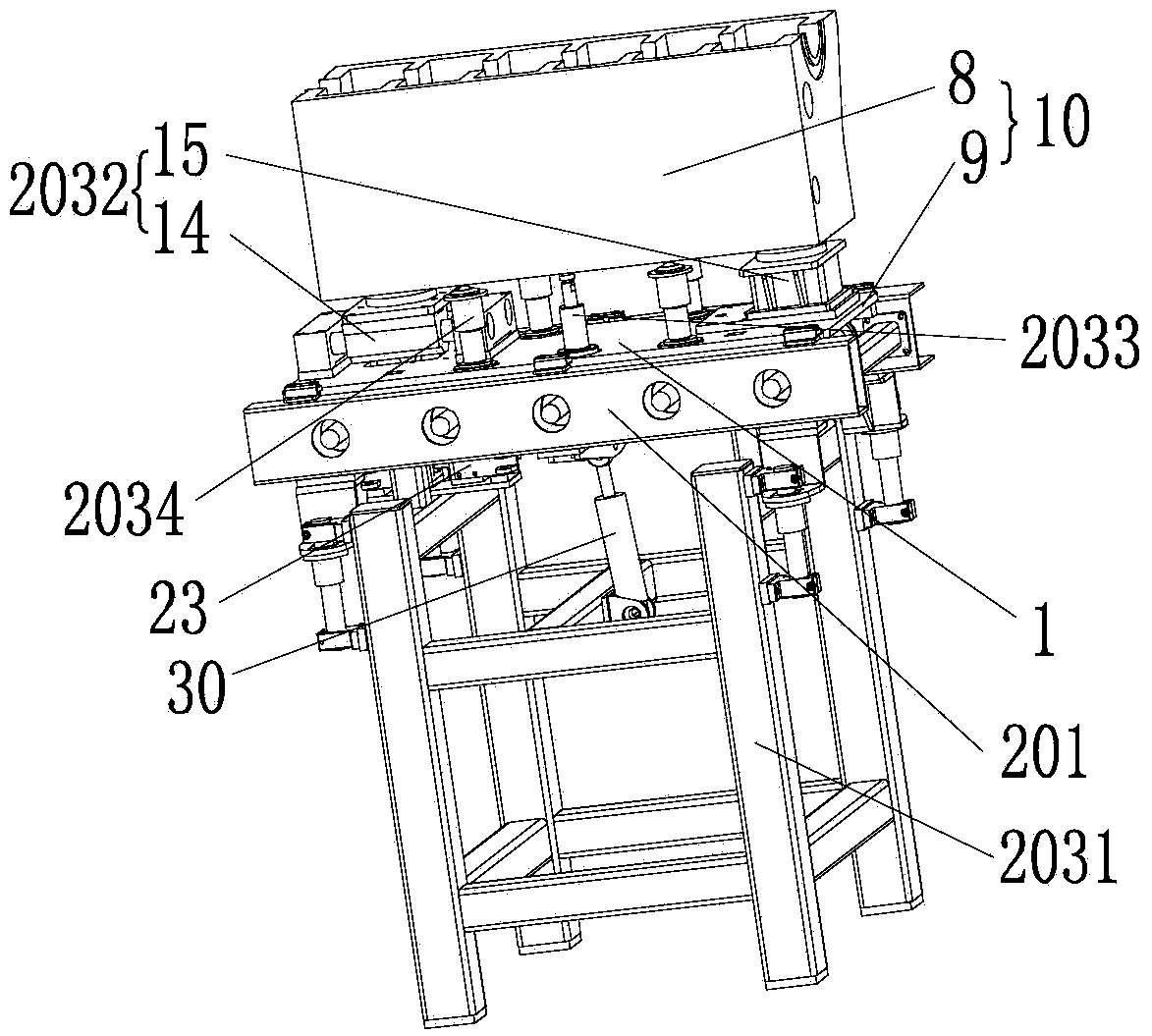

The invention discloses a working station for finishing an iron casting. The working station comprises a base, a conveying mechanism for conveying the iron casting and a finishing mechanism for machining the iron casting, wherein the conveying mechanism and / or the finishing mechanism are / is mounted on the base; the working station further comprises a working table for fixedly positioning the iron casting, a transferring mechanism for transferring the iron casting to be machined from the conveying mechanism to the working table, and a control mechanism for controlling the conveying mechanism to run and / or the finishing mechanism to run; the finishing mechanism comprises machining components for finishing the iron casting to be machined and robots for adjusting the machining orientations of the machining components; the machining components are mounted at the movable ends of the robots. A mechanical finishing machining device is arranged in a transferring, fixedly positioning and finishing machining structural mode and is used for automatic and assembly line production work of iron casting finishing, so that complete suspended production of the casting is realized, and the production efficiency and the workpiece cleaning quality are greatly improved.

Owner:CHANGSHA CTR ROBOTICS

a spraying device

ActiveCN113404261BImprove spray strengthImprove adhesionBuilding constructionsPressure transmissionEngineering

Owner:东台市高科技术创业园有限公司

Method for preparing flame-retardant textiles by electron radiation technology

ActiveCN104818607BLower reaction energyIncrease profitPhysical treatmentFire-retardant fabricTemperature resistance

A method of producing flame retardant textile by the electronic radiation technology is characterized in that after textile is pad-rolled or coated with flame retardant finishing liquid, and drying or baking is performed after electronic beam radiation to obtain the flame retardant textile; the flame retardant fishing liquid comprises resin cross-linking agent and organophosphorus flame retardant. The method has the advantages that the technical operation is simple and the flame retardant textile has performances such as durability, high temperature resistance and non-flammability.

Owner:JIANGNAN UNIV

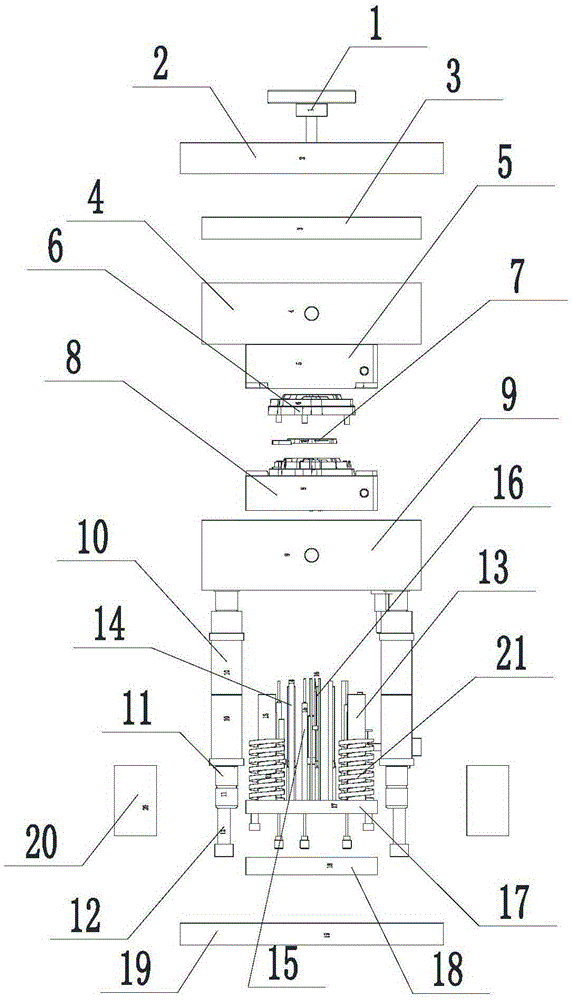

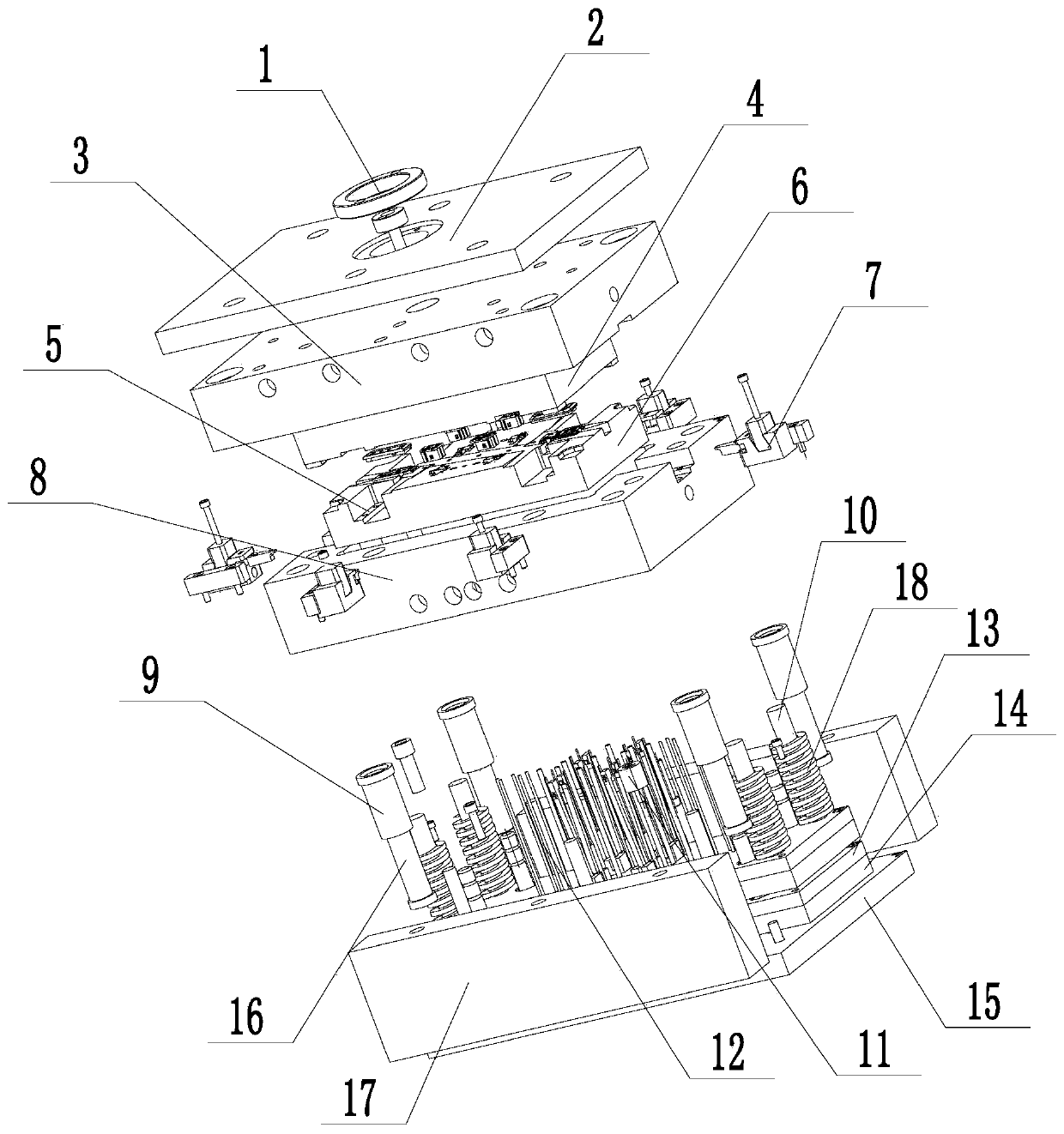

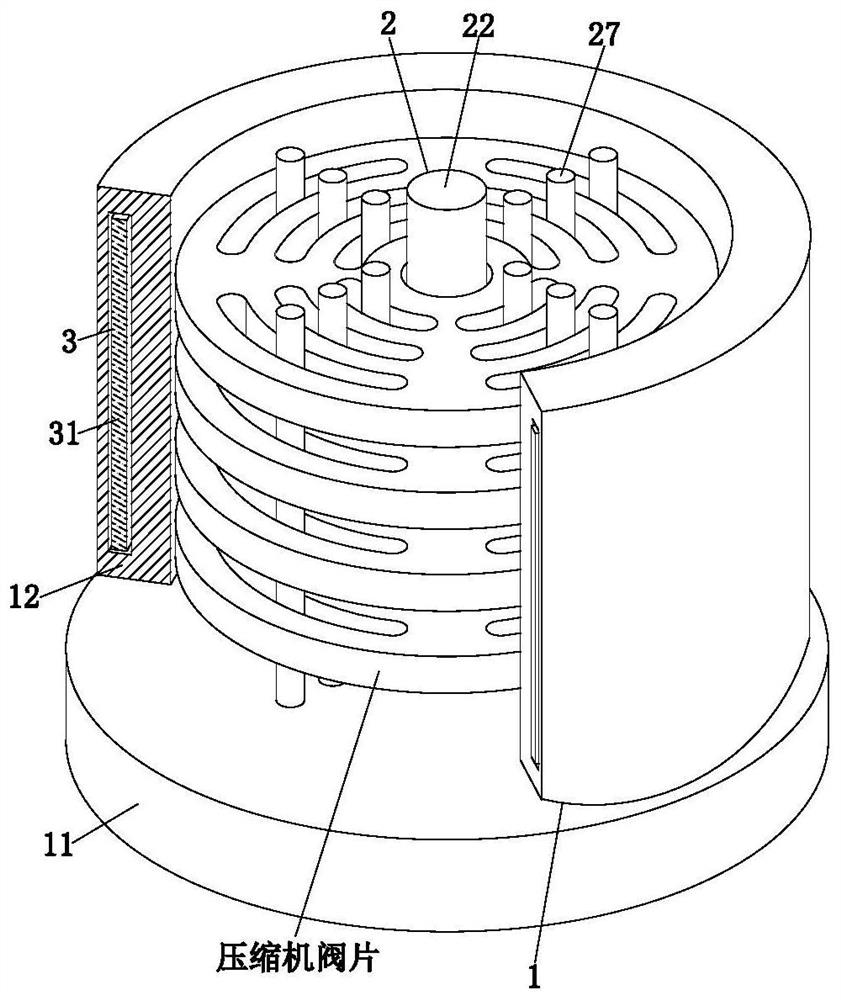

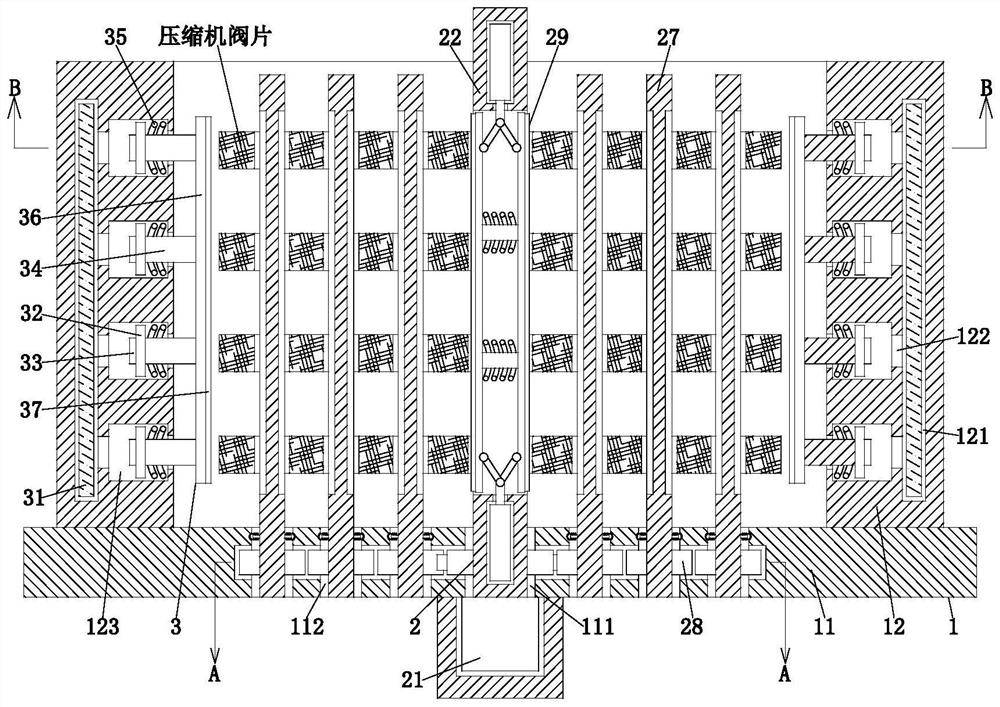

Refrigeration compressor valve plate manufacturing and finishing system

InactiveCN112757103AEasy finishingRealize batch processingGrinding drivesGrinding machinesManufacturing engineeringMachining system

The invention provides a refrigeration compressor valve plate manufacturing and finishing system. The system comprises a base frame, a finishing unit and an auxiliary unit. The finishing unit is installed on the inner wall of the lower end of the base frame, and the auxiliary unit is arranged in the circumferential direction of the inner side wall of the base frame. The refrigeration compressor valve plate manufacturing and finishing system can solve the problems that most compressor valve plates are finished one by one during finishing at present, and batch machining cannot be achieved, so that the working efficiency is affected; and when finishing machining is carried out on a common compressor valve plate, secondary finishing machining needs to be carried out on the outer wall of the compressor valve plate after finishing machining of a notch of the compressor valve plate is completed, so that unnecessary workloads are increased, and working hours are consumed.

Owner:马彬彬

A kind of conveying equipment for automatic production workshop

ActiveCN109607090BUniform moving speedConstant speedConveyor partsMechanical conveyorsSocial benefitsElectric machinery

The invention discloses a conveying device for an automated production workshop, comprising a conveying table and a supporting seat, wherein the supporting seat is arranged below the conveying table, and both ends of the conveying table are provided with rolling trays. A rolling belt is sleeved on the rolling feed plate. The beneficial effects of the present invention are: the motors at both ends of the side frame are transported by dragging the upper support plate and the movable seat by the rolling belt, and at the same time of moving, the motor 3 at the bottom of the fixed seat is rolled in the rail groove of the inner rail through the rollers , to drive the moving base to move synchronously, to ensure that the moving base takes the objects for moving and conveying more stable and reliable, and cooperate with the side partitions to prevent the objects from falling from the equipment. A moving seat is used to transport objects synchronously, which not only ensures the high efficiency of transportation, but also makes the installation and disassembly of the moving seat more convenient. The device has good social benefits and is suitable for popularization.

Owner:合睿达智能科技(烟台)有限公司

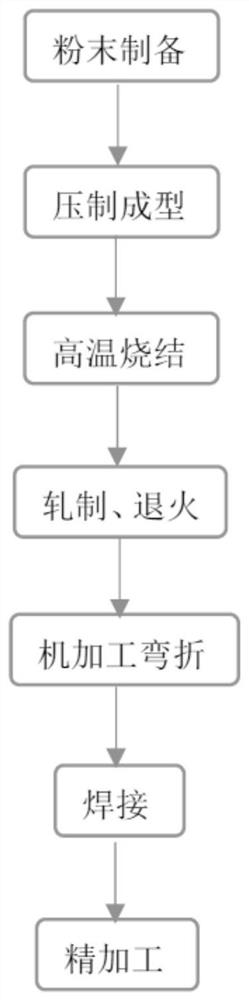

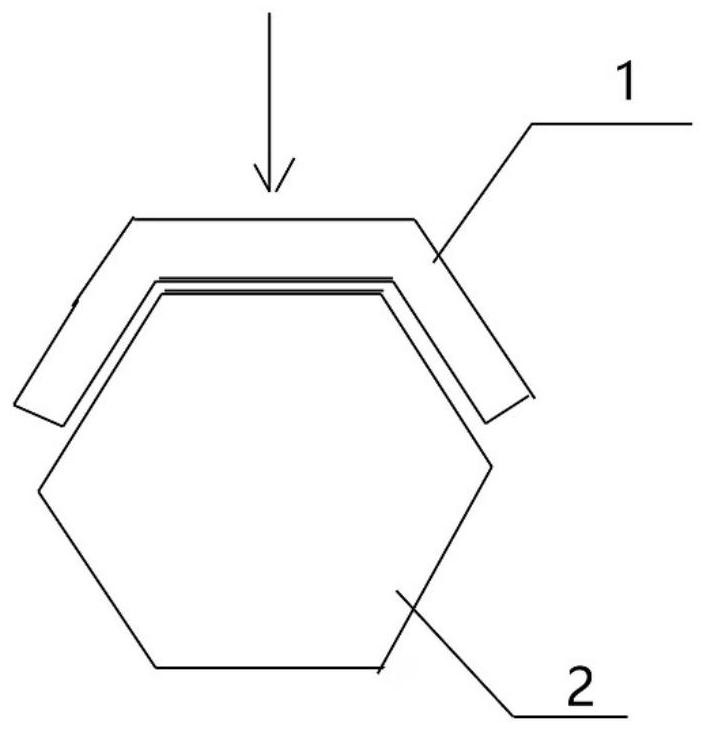

A kind of preparation method of molybdenum-rhenium alloy barrel

The invention relates to a method for preparing a molybdenum-rhenium alloy cylinder. The method sequentially comprises: the preparation step of molybdenum-rhenium alloy powder: uniformly mixing molybdenum powder and rhenium powder to obtain molybdenum-rhenium alloy powder; loading the molybdenum-rhenium alloy powder into a pressing mold, performing pressing molding treatment, and obtaining a compact; Sintering the compact to obtain a sintered slab; rolling the sintered slab to obtain a molybdenum-rhenium rolled plate; annealing the molybdenum-rhenium rolled plate; The processing is trimmed and bent into shape; the billets obtained through the machining steps are butt-welded to obtain a complete molybdenum-rhenium alloy cylinder. The method can be used to prepare round and / or polygonal molybdenum-rhenium alloy cylinders in a targeted manner according to the requirements of different components and different pipe sizes. The prepared molybdenum-rhenium alloy cylinders have good comprehensive mechanical properties and can meet different requirements. industry requirements.

Owner:安泰天龙钨钼科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com