Supersonic welding method and device for welding reinforced belt chip to zipper belt

A welding method and technology of a welding device, which are applied in applications, household appliances, and other household appliances, and can solve problems such as hardening, melting, and brittleness of the core rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

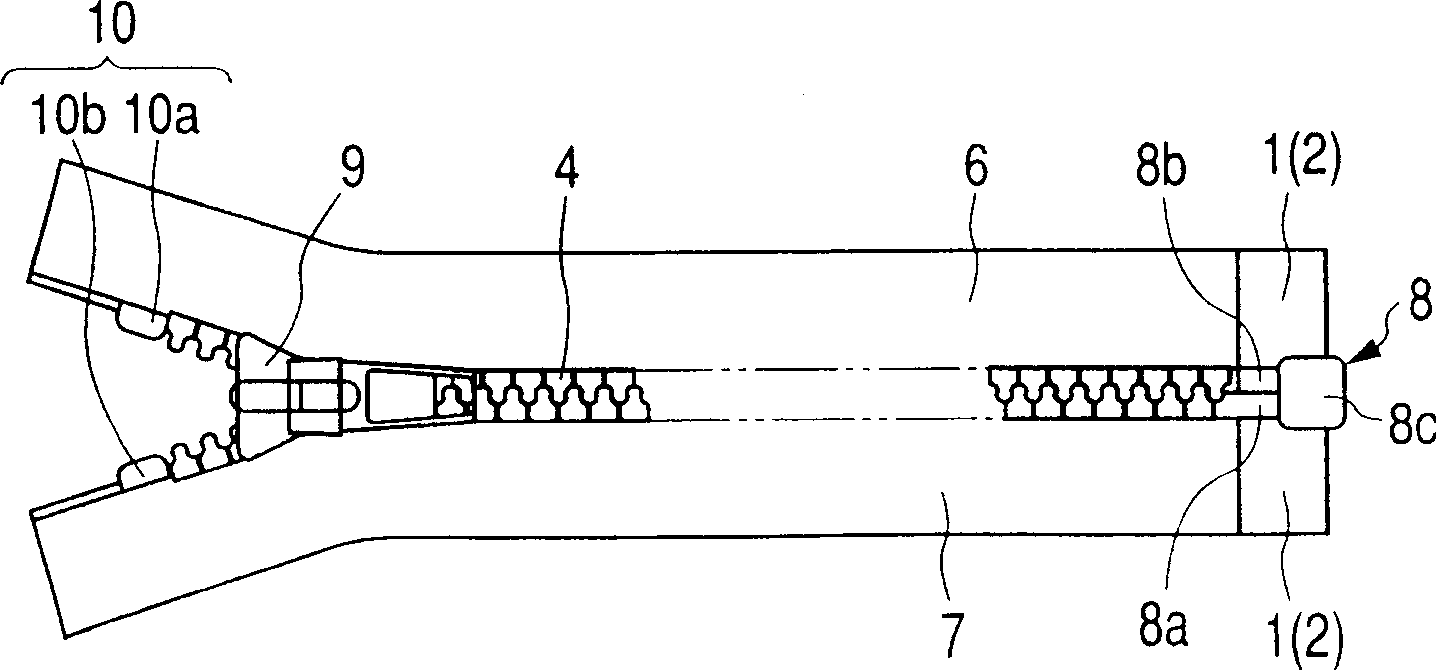

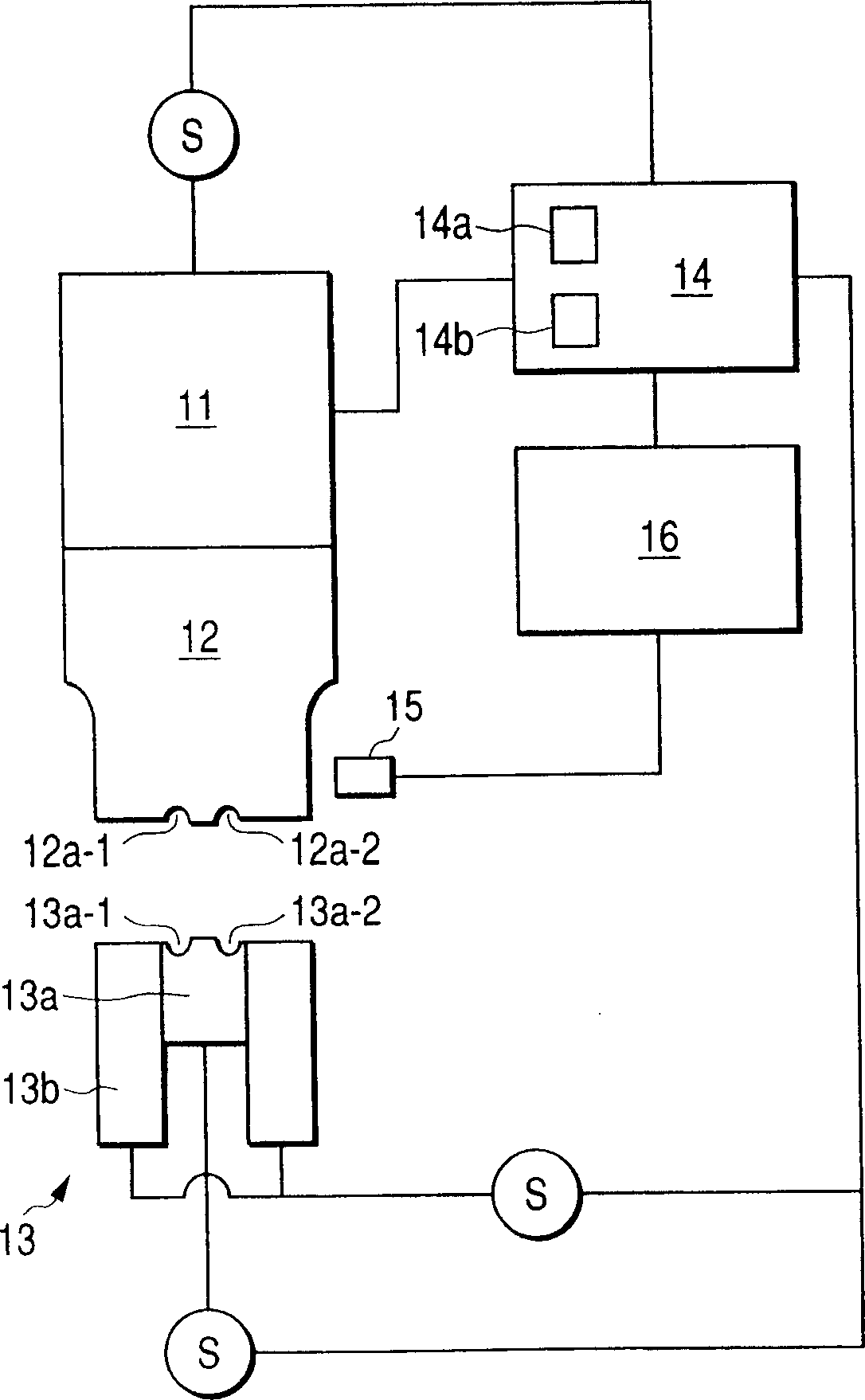

[0036] Exemplary embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

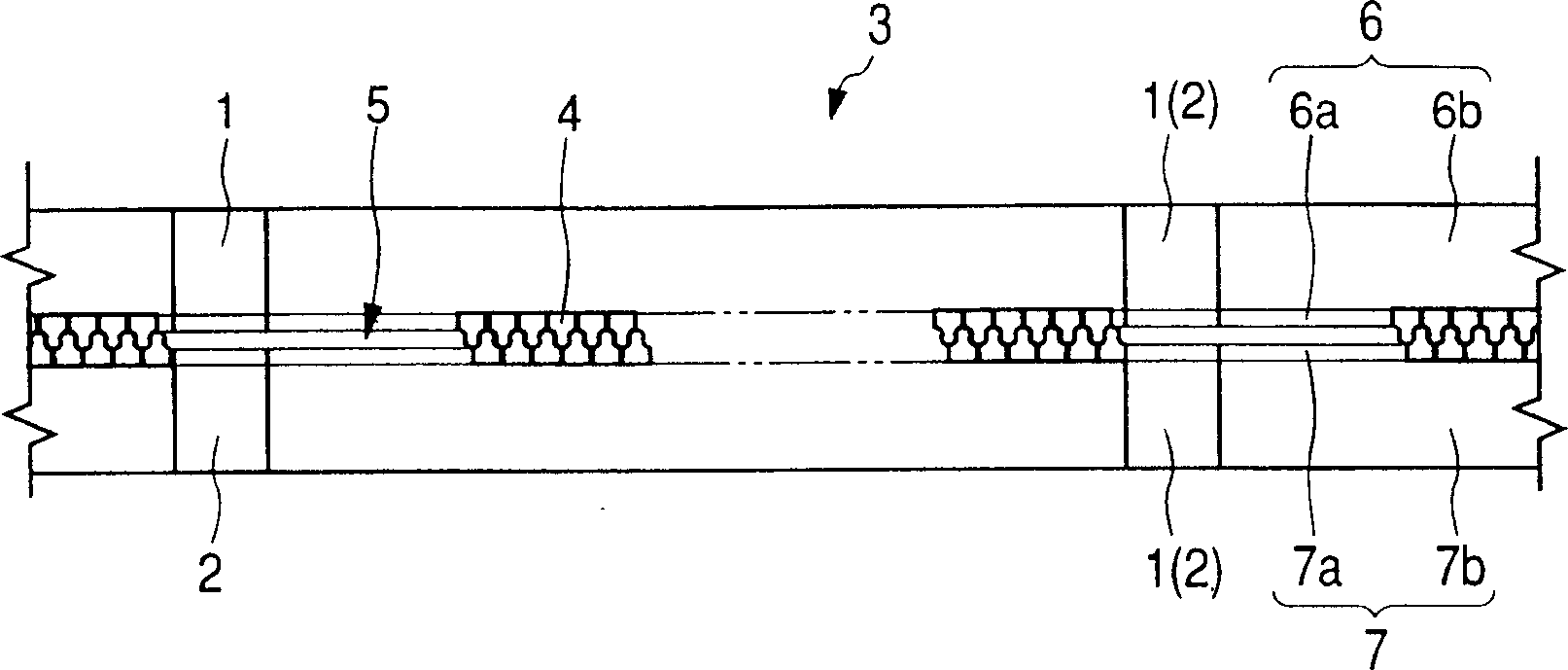

[0037] figure 1 Shown is a zipper chain 3 to which reinforcing tape pieces 1 and 2 are bonded by the welding method of the present invention. The void portion 5 from which the tooth 4 has been removed is formed in the zipper unit along the length direction of the zipper chain 3, such as figure 1 shown. Reinforcing tape pieces 1 and 2 enclose the peripheries of core portions 6a and 7a formed along opposite tape side edges of the fastener tapes 6 and 7 exposed in the void portion 5, and the reinforcing tape pieces 1 and 2 are welded and bonded to the back of each main body belt portion 6b and 7b over the entire surface.

[0038] In this embodiment, the reinforcing tape sheets 1 and 2 are of a laminated structure in which a relatively low-melting synthetic resin layer is provided or coated on the welding surface side of a braided tape or a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com