Method for preparing water-repellent textile

A textile and water-repellent technology, applied in the field of textile production and processing, can solve the problems of water consumption, complicated equipment operation, harsh reaction conditions, etc., and achieve the effects of reducing wastewater treatment costs, reducing environmental pollution, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

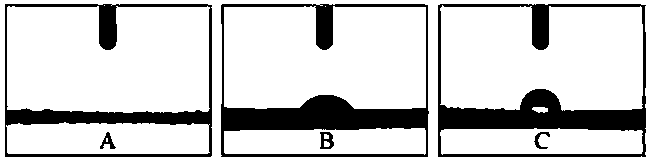

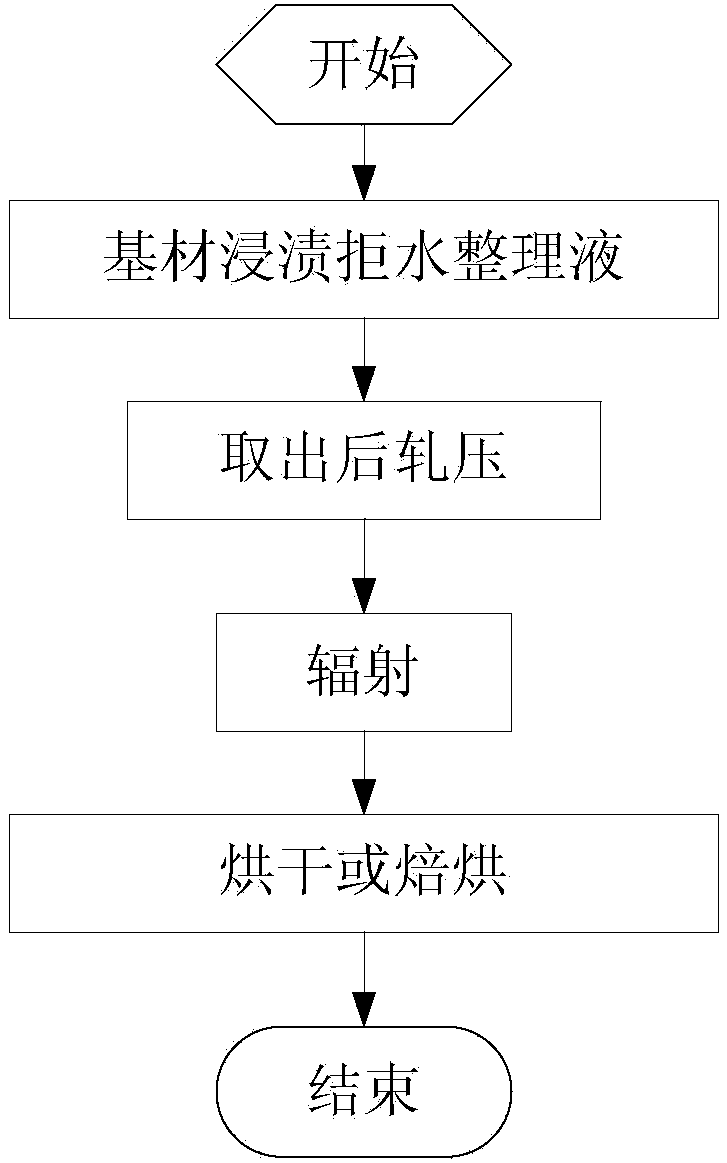

[0028] Specific implementation mode one, such as figure 1 In the preparation method of the water-repellent textiles shown in the present invention, the textile base material is soaked in the water-repellent finishing solution, taken out and then rolled, and the excess rate is 70% to 120%. Then, under the condition of normal temperature and inert gas, it is irradiated, then dried or baked, and finished to make water-repellent textiles. The water-repellent finishing solution is a solution in which a water-repellent agent and a nonionic surfactant are added to a solvent.

specific Embodiment approach 2

[0029] Specific implementation mode two, such as figure 2 As shown, the textile substrate is coated with a water repellent agent, and the coating thickness is 1-30um. Then, under the condition of normal temperature and inert gas, it is irradiated, then dried or baked, and finished to make water-repellent textiles.

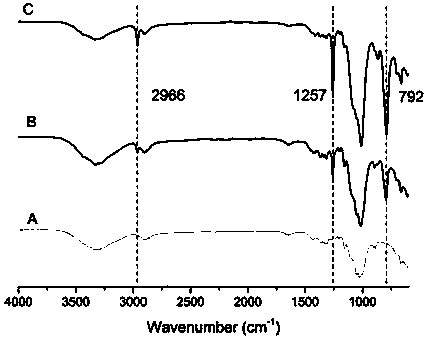

[0030] In Embodiment 1 and Embodiment 2 above, in the process of padding water-repellent finishing liquid or coating water-repellent agent, the range of electron radiation is greater than 0KGy and less than or equal to 300KGy. The water-repellent agent is a monomer or oligomer of reactive silicone, and the viscosity of the oligomer water-repellent agent is less than 5000mPa.s (25°C) or the molecular weight is less than 30000. The water-repellent agent can be used alone or in combination.

[0031] Drying or baking, the drying temperature range is 50-100°C, and the time is 5-60 minutes; the baking temperature range is 100-180°C, and the time is 10-180s.

[0032] ...

Embodiment 1

[0034] Immerse the cotton fabric in the water-repellent finishing solution containing 4% blocked vinyl silicone oil, take it out and roll it, the rolling rate is 80%, after being irradiated by 65KGy electrons, put it in a dryer at 50°C for 30 minutes. After drying, it is soaped, washed with water and then dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com