Method for grinding helical burr on soft rubber roller and processing device

A grinding process and processing device technology, applied in the direction of thread cutting device, metal processing equipment, tangential feeding device, etc., can solve the problems of difficult thread turning, large elastic recovery, low thermal conductivity, etc., and achieve good processing quality and good resilience The effect of small size and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

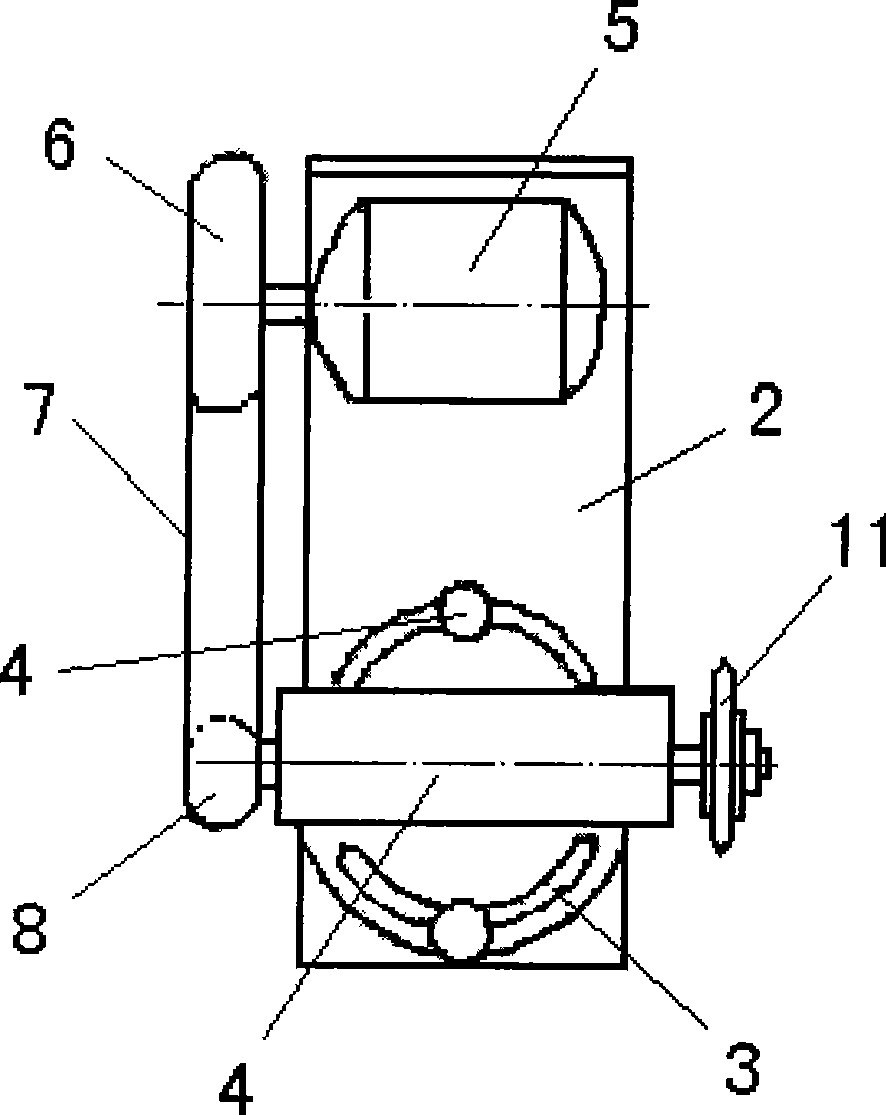

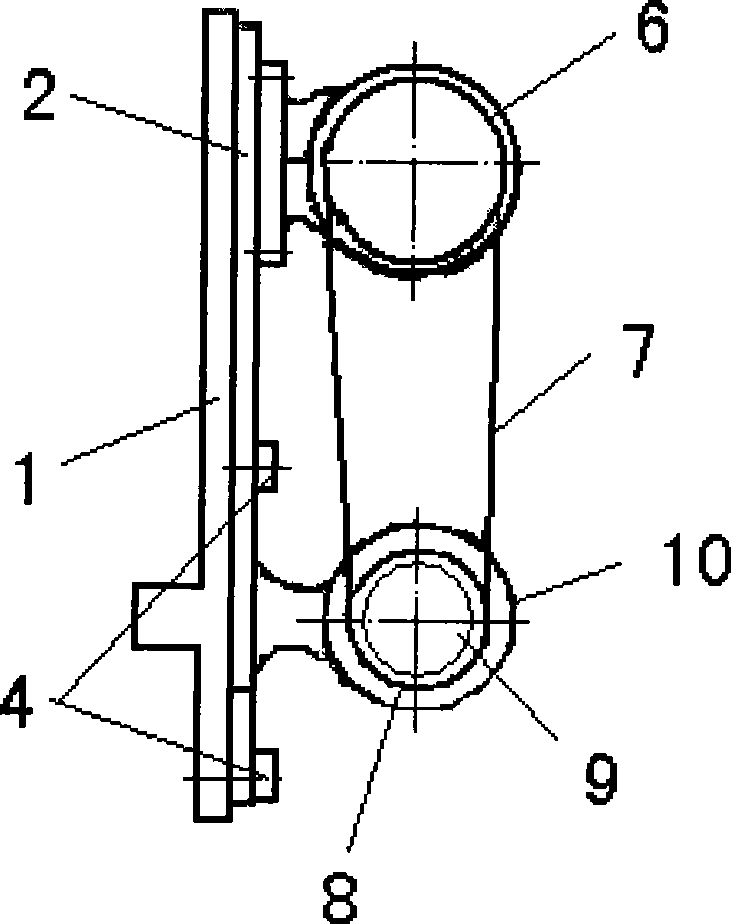

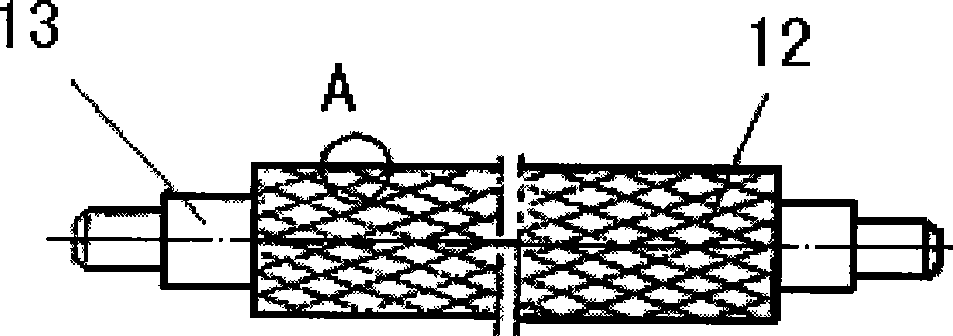

[0027] like image 3 , Figure 4 As shown, the present embodiment is to process positive and negative 20 threads on a soft rubber roller 12, so that the positive and negative threads of the soft rubber roller 12 are formed on the surface. Before grinding, connect the soft rubber roller 12 to the main shaft of the lathe through the mandrel 13, select the grinding wheel 11 that is the same as the thread profile 14 on the soft rubber roller 12, and install it, and press the handle on the tool box of the lathe to press the soft rubber roller 12 When the thread pitch is set properly, the machine can be driven for grinding. When grinding, the workpiece speed should be reasonably selected according to the diameter of the workpiece and the size of the thread lead. For example: when the thread lead of the workpiece is > 300mm, in order to facilitate the operation and the safety of the lathe mechanism, the lathe spindle should be decelerated to 2~5r / min, if the thread profile height o...

Embodiment 2

[0029] like Figure 5 , Image 6 As shown, in the present embodiment, the tooth profile 15, 16 of the thread on the soft rubber roller 12 is a shape in which the two ends are symmetrically inclined to the middle. Thread profile 15 (or 16) is corresponding, and then the handle on the lathe feed box is pulled by the requirement of pitch on soft rubber roller 12, can drive and grind. After the thread grinding at one end is completed, by adjusting the rotating plate 2 in reverse, adjust the deflection angle of the emery wheel 11 to the symmetrically inclined thread profile 16 (or 15) at the other end, and continue grinding.

Embodiment 3

[0031] like Figure 7 As shown, the present embodiment is to grind and process multiple (such as three but not limited to this) threads on a soft rubber roller 12 with a mandrel 13 ( Figure 7 It is a simplified diagram of a multi-start thread), and its installation and operation process are similar to those of the above-mentioned embodiments, so no further details are given.

[0032] Except that the present invention can be installed on the lathe to grind the thread on the soft rubber roller 12, it can also be installed on a thread grinder or a shovel lathe to perform the thread grinding operation. In the grinding operation of the present invention, an oil-free water-based cutting fluid can be used as a cooling fluid to prevent rubber from deforming due to oil, and generally dry grinding can be adopted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com