A kind of preparation method of molybdenum-rhenium alloy barrel

A technology of molybdenum-rhenium alloy and tube parts, which is applied in the field of preparation of molybdenum-rhenium alloy tube parts, can solve the problems of cracking, sintering deformation, material waste, etc., achieve high mechanical properties, high density and mechanical properties, and solve the problems of difficult preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

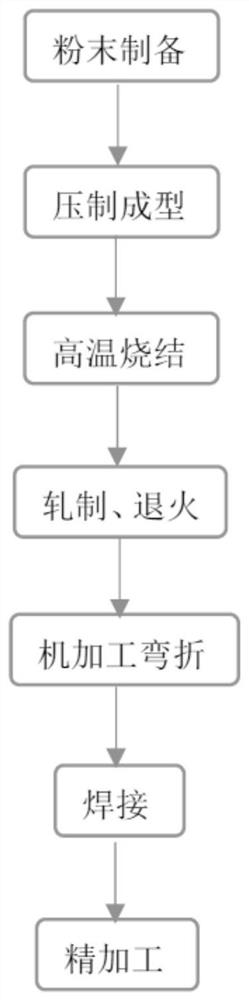

Method used

Image

Examples

Embodiment 1

[0039] (1) Alloy powder preparation: According to the Mo:Re ratio of 95:5, put 9500g of molybdenum powder and 500g of rhenium powder into a three-dimensional mixer for mixing to obtain MoRe5 alloy powder. The speed of the mixer is 30r / min, and the mixing time is 4h; wherein, the Fischer particle size of the molybdenum powder is 3.0 μm, and the purity is 99.95%; the particle size of the rhenium powder is -250 mesh, and the purity is 99.99%.

[0040] (2) Compression molding: put 10Kg of molybdenum-rhenium alloy powder obtained in step (1) into a mold, hold the pressure for 15 minutes under a pressure of 150MPa to obtain a plate-shaped compact with a relative density of 70%.

[0041] (3) High-temperature sintering: Put the green compact in step (2) into an intermediate frequency high-temperature hydrogen sintering furnace for sintering. The maximum sintering temperature is 2100°C, and the maximum temperature is kept for 6 hours to obtain a sintering with a relative density of 93% ...

Embodiment 2

[0049] (1) Alloy powder preparation: according to the ratio of Mo:Re 86:14, put 8.6Kg of molybdenum powder and 1.4Kg of rhenium powder into a three-dimensional mixer for mixing to obtain MoRe14 alloy powder, the speed of the mixer is 40r / min, mix The feeding time is 5 hours; wherein, the Fischer particle size of the molybdenum powder is 3.4 μm, and the purity is 99.95%; the particle size of the rhenium powder is -350 mesh, and the purity is 99.99%.

[0050] (2) Compression molding: put 10Kg of the molybdenum-rhenium alloy powder obtained in step (1) into a mold, hold the pressure for 5 minutes under a pressure of 200 MPa to obtain a plate-shaped green compact with a relative relative density of 75%.

[0051] (3) High-temperature sintering: Put the green compact in step (2) into an intermediate frequency high-temperature hydrogen sintering furnace for sintering. The maximum sintering temperature is 2200 ° C, and the maximum temperature is kept for 5 hours to obtain a sintering w...

Embodiment 3

[0059] (1) Alloy powder preparation: according to the ratio of Mo:Re 65:35, put 5.2Kg of molybdenum powder and 2.8Kg rhenium powder into a three-dimensional mixer for mixing to obtain MoRe35 alloy powder, the speed of the mixer is 30r / min, and mix The feeding time is 8 hours; wherein, the Fischer particle size of the molybdenum powder is 3.2 μm, and the purity is 99.95%; the particle size of the rhenium powder is -200 mesh, and the purity is 99.99%.

[0060] (2) Compression molding: put 8Kg of the molybdenum-rhenium alloy powder obtained in step (1) into a mold, hold the pressure for 10 minutes under a pressure of 200 MPa to obtain a plate-shaped compact with a relative density of 65%.

[0061] (3) High-temperature sintering: Put the green compact in step (2) into an intermediate frequency high-temperature hydrogen sintering furnace for sintering. The maximum sintering temperature is 2200°C, and the temperature is kept at the highest temperature for 6 hours to obtain a sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com