Tapered roller bearing

A tapered roller bearing and roller technology, applied in the direction of bearings, rolling contact bearings, bearing components, etc., can solve the problems of increasing, or the grinding stone is in contact with the flange, and it is not easy to obtain surface roughness, and achieves easy finishing. , suppress the effect of equipment modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

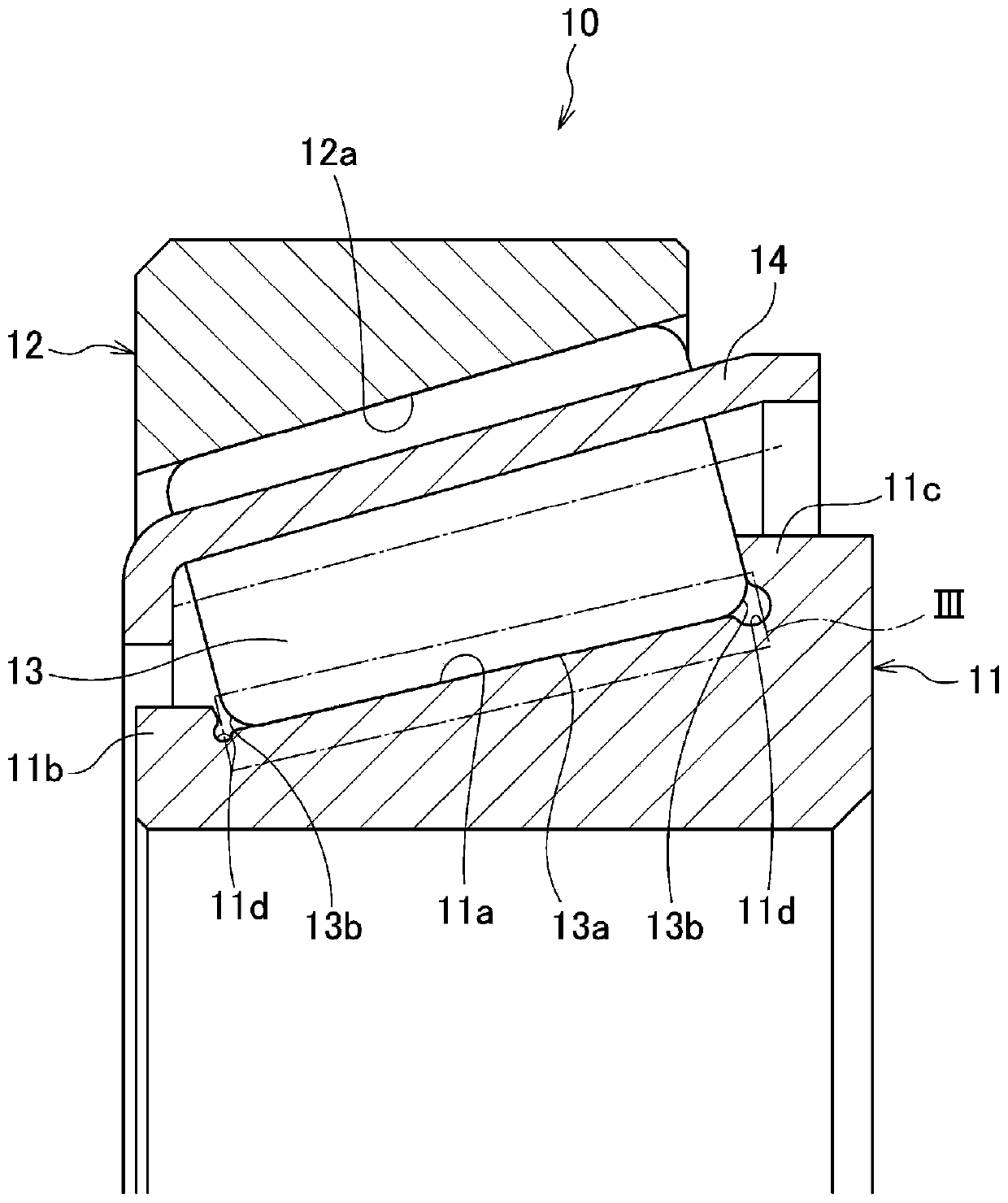

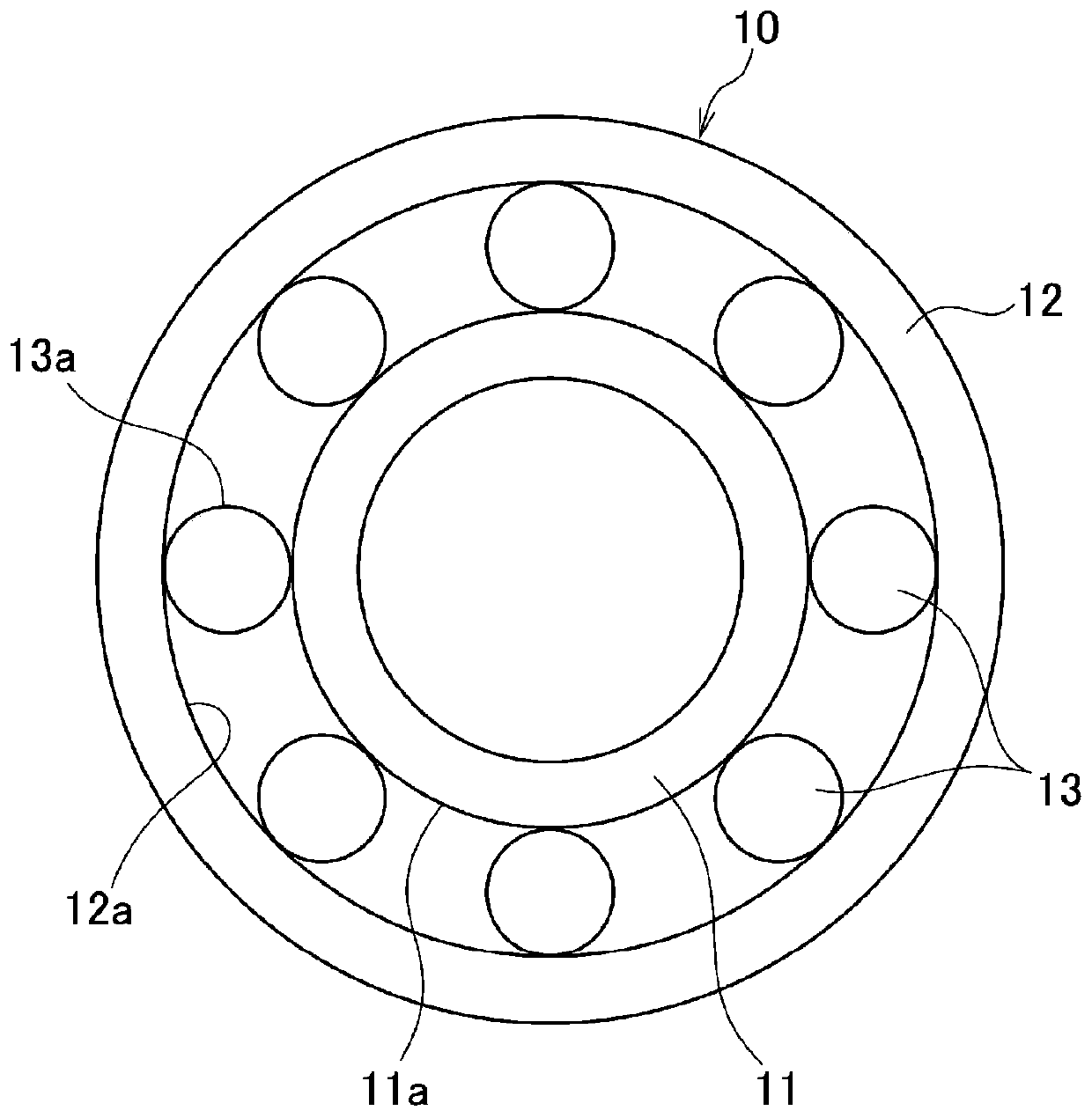

[0056] Such as figure 1 and figure 2 As shown, the tapered roller bearing 10 of this embodiment includes: an inner ring 11, which is provided with an inner ring raceway surface 11a on the outer peripheral surface; an outer ring 12, which is provided with an outer ring raceway surface 12a on the inner peripheral surface; The body is a plurality of tapered rollers 13 (hereinafter, also simply referred to as "rollers 13"), which are arranged between the inner ring raceway surface 11a and the outer ring raceway surface 12a; and the cage 14, which holds a plurality of The rollers 13 are held at predetermined intervals in the circumferential direction.

[0057] The inner ring 11 includes a small-diameter flange portion 11 b and a large-diameter flange portion 11 c at the small-diameter side axial end portion and the large-diameter side axial end portion of the inner ring raceway surface 11 a.

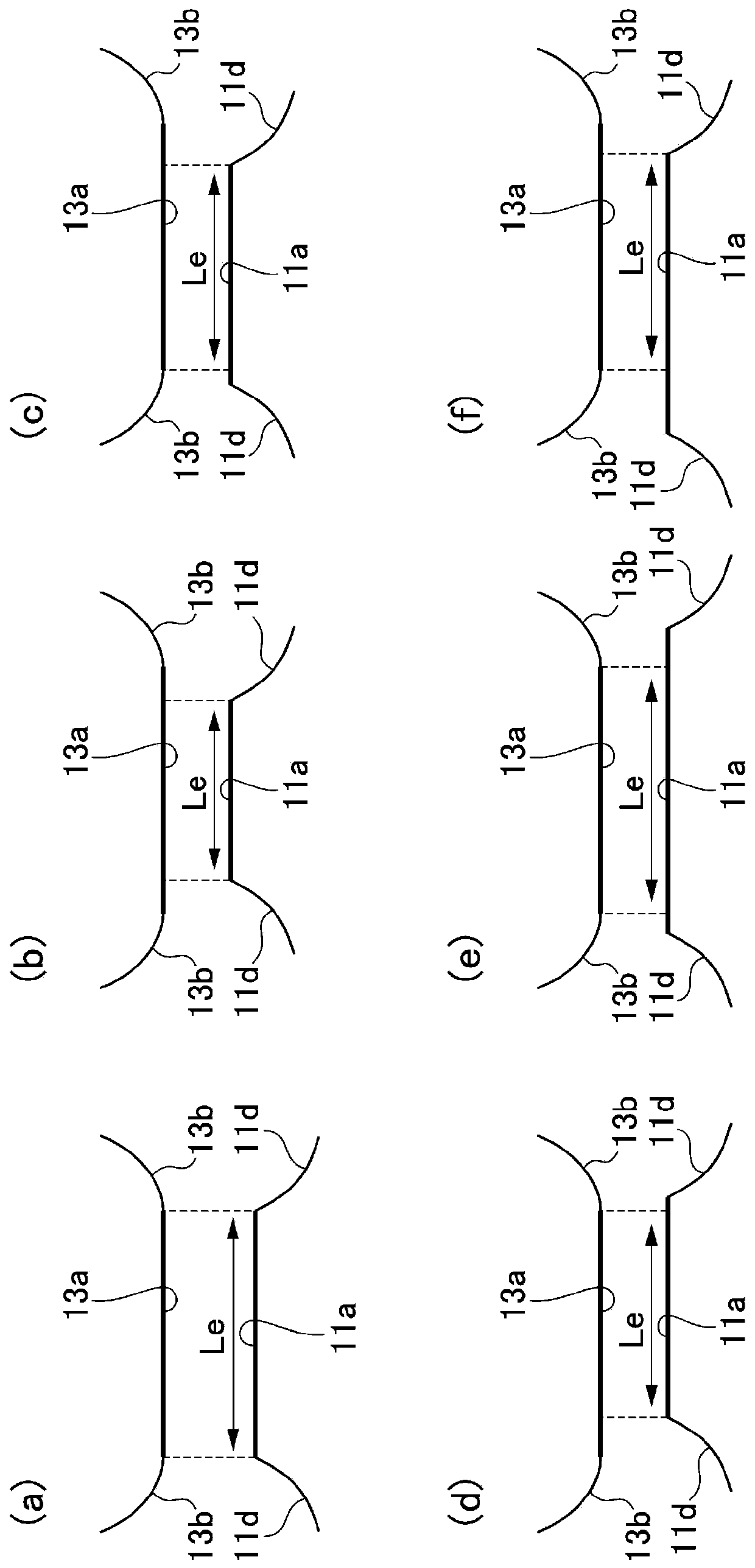

[0058]Furthermore, in this embodiment, in order to suppress the occurrence of edge lo...

no. 2 Embodiment approach

[0097] Next, refer to Figure 7 A tapered roller bearing according to a second embodiment of the present invention will be described. In addition, in this embodiment, the convex shape of the raceway surface of an inner ring and an outer ring, and the rolling surface of a roller differs from 1st Embodiment. Other configurations are the same as those of the first embodiment.

[0098] That is, in the present embodiment, the raceway surface 11a of the inner ring 11 is provided as Figure 7 The shown logarithmic convex surface with a small drop is used instead of the single arc convex surface of the first embodiment. Also in this case, the rolling surface 13a of the roller 13 is formed by subtracting the drop amount of the logarithmic convexity of the inner ring raceway surface 11a from the sum δ of the logarithmic convexity given by the above formula (i). convex shape.

[0099] In addition, in this case, for the crown of the inner ring, the crown drop of the raceway surface 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com