Method for preparing flame-retardant textiles by electron radiation technology

A technology of flame-retardant textiles and electronic radiation, applied in the field of flame-retardant textiles, can solve the problems of increased finishing and wastewater treatment costs, uncontrollable factors and side reactions, and difficult product quality control, etc. Baking or drying temperature, the effect of increasing the utilization rate of flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

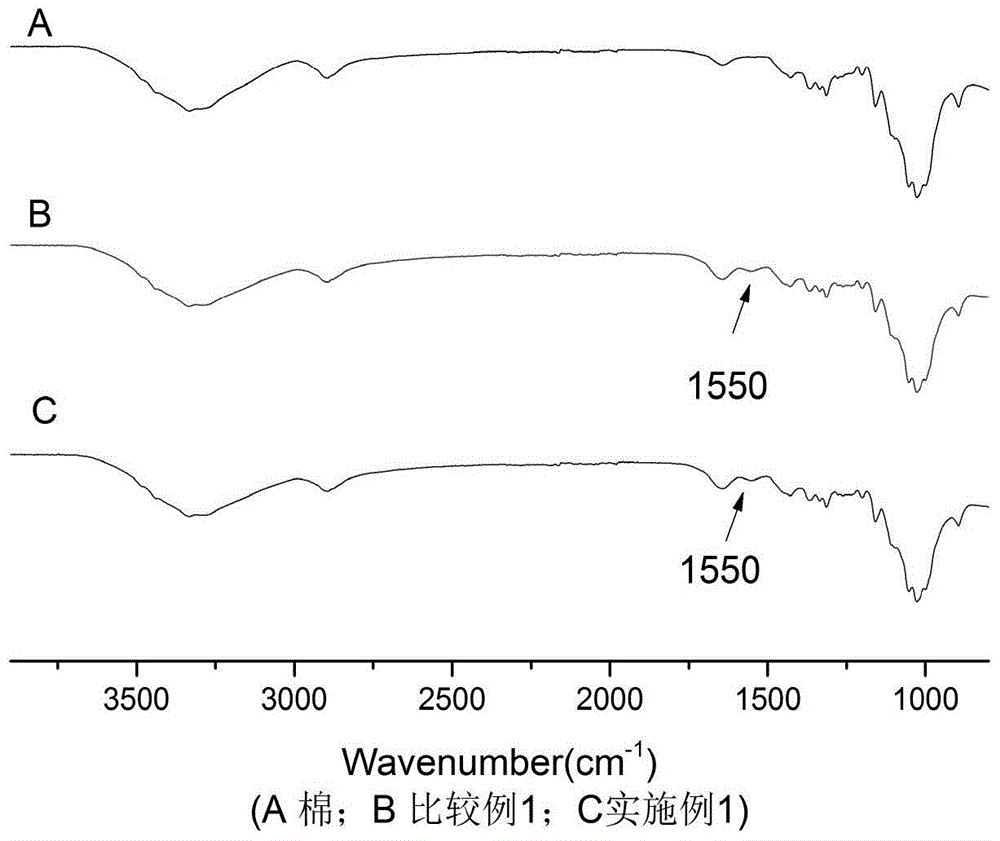

Embodiment 1

[0032] Cotton fabric is padded with flame retardant finishing solution containing 450g / L durable flame retardant DM3070 (reactive organic phosphorus flame retardant), 100g / L crosslinking agent DM-3522 (resin crosslinking agent), and the remaining The efficiency is 100%. After taking it out, it is irradiated with 43KGy electron beams and dried at 100°C for 120s. After washing with water and drying, a flame-retardant pure cotton fabric is obtained.

Embodiment 2

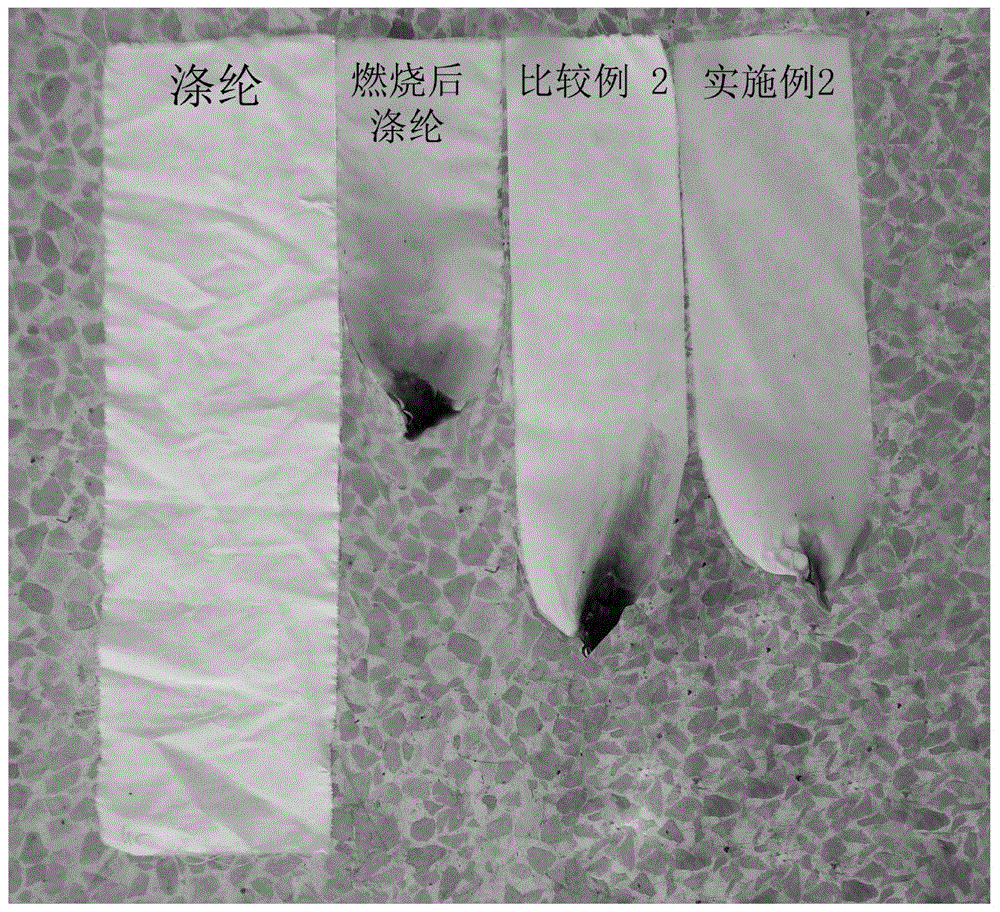

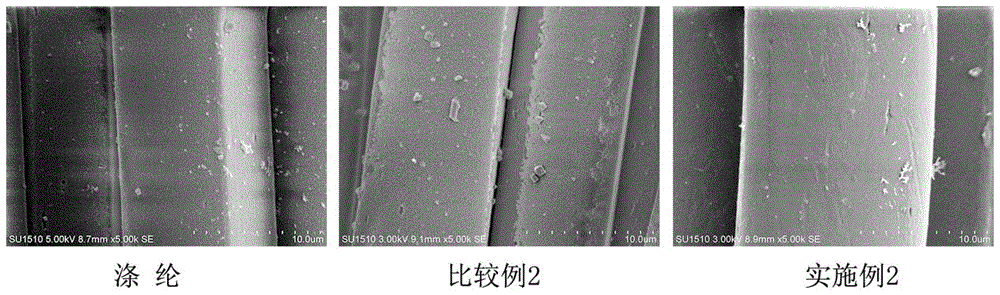

[0039] Pad polyester fabric with flame retardant finishing solution containing 200g / L durable flame retardant DM3070 and 60g / L crosslinking agent DM-3522, take it out, irradiate it with 32KGy electron beam, and dry it at 100℃ for 120s. After washing with water and drying, a flame-retardant polyester fabric is obtained.

Embodiment 3

[0046] Flame retardant finishing of pure cotton fabric by padding containing 400g / L flame retardant DM3074 (composite flame retardant of phosphate ester and various flame retardant components) and 20g / L FM-2 crosslinking agent (resin crosslinking agent) After taking out the solution, it was irradiated with 23KGy electron beam and dried at 100°C for 120s. After washing with water and drying, a flame-retardant polyester fabric is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com