Mirror surface insert mold and preparation technology thereof

A preparation process and mold technology, applied in the field of mirror insert mold and its preparation process, can solve the problem that the mirror insert mold cannot meet the requirements, and achieve the effect of ensuring processing accuracy, high product precision, and meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

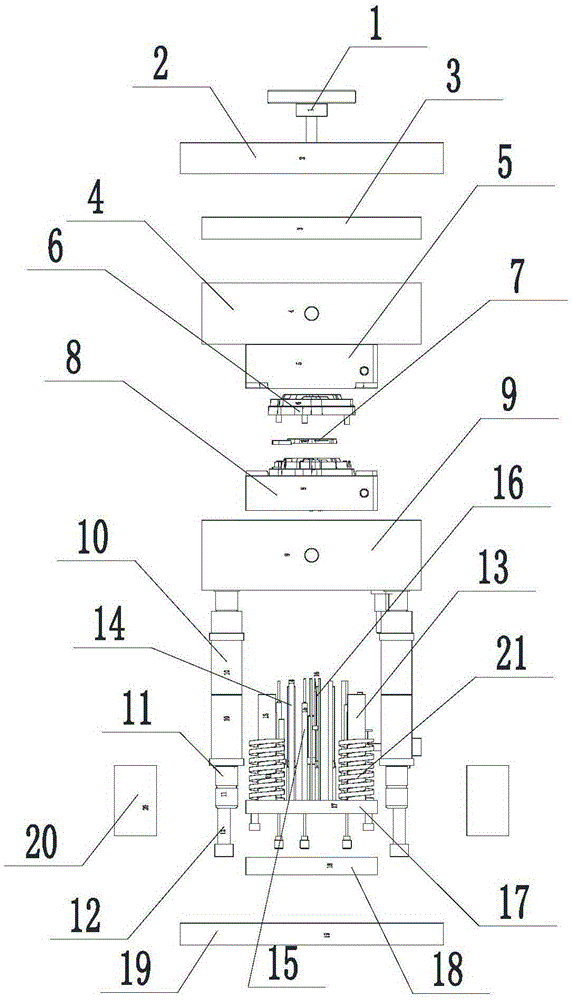

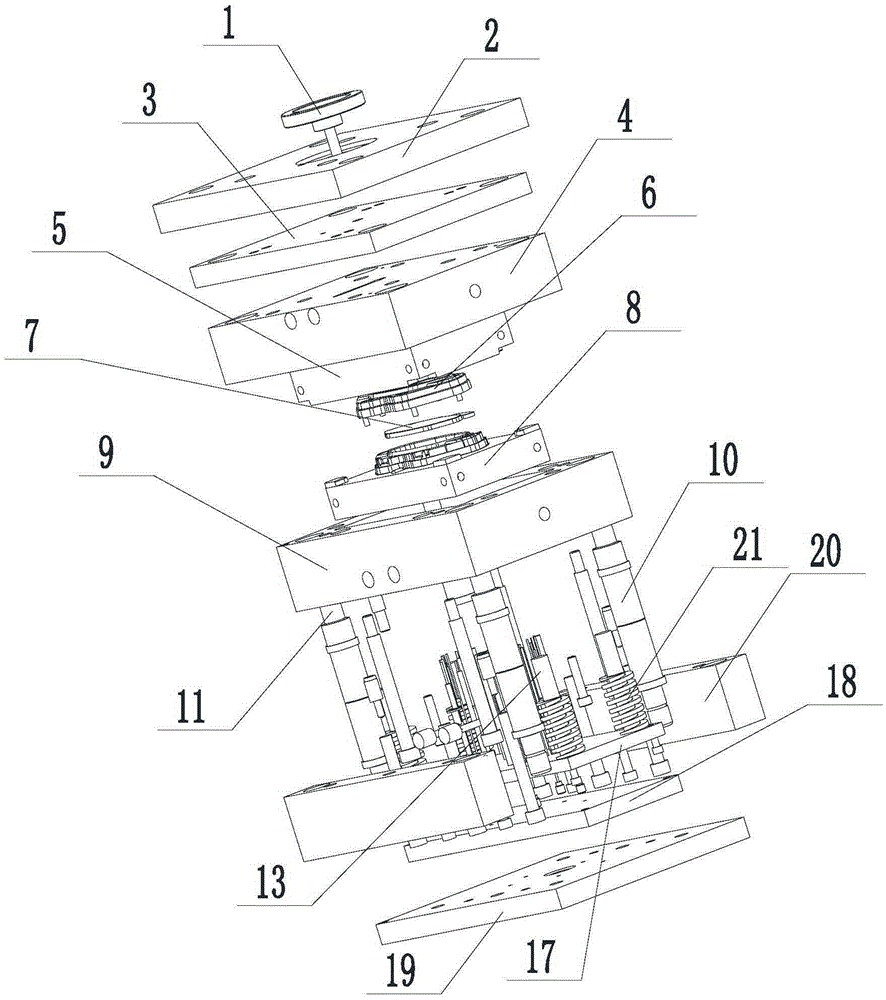

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] like figure 1 As shown, a mirror insert mold includes a bottom plate 19 and a thimble fixing assembly composed of a thimble bottom plate 18 and a thimble panel 17 arranged on the upper surface of the bottom plate 19. The four corners of the upper surface of the thimble fixing assembly are respectively provided with return A needle 13, a spring 21 is tacked on the return needle 13, and several thimbles 14, a cylinder 15 and a flat thimble 16 which pass through two groups of thimble fixing assemblies and are fixed in the middle part of the upper surface of the thimble fixing assembly are provided respectively. The upper surface of the base plate 19 is provided with plug screws 12 near the position of the thimble base plate 18, and two square irons 20 are symmetrically arranged on the upper surface of the base plate 19 close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com