Flexible passivating processing method for superhard cutting tool and flexible passivating processing device thereof

A technology of superhard materials and knives, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., to achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

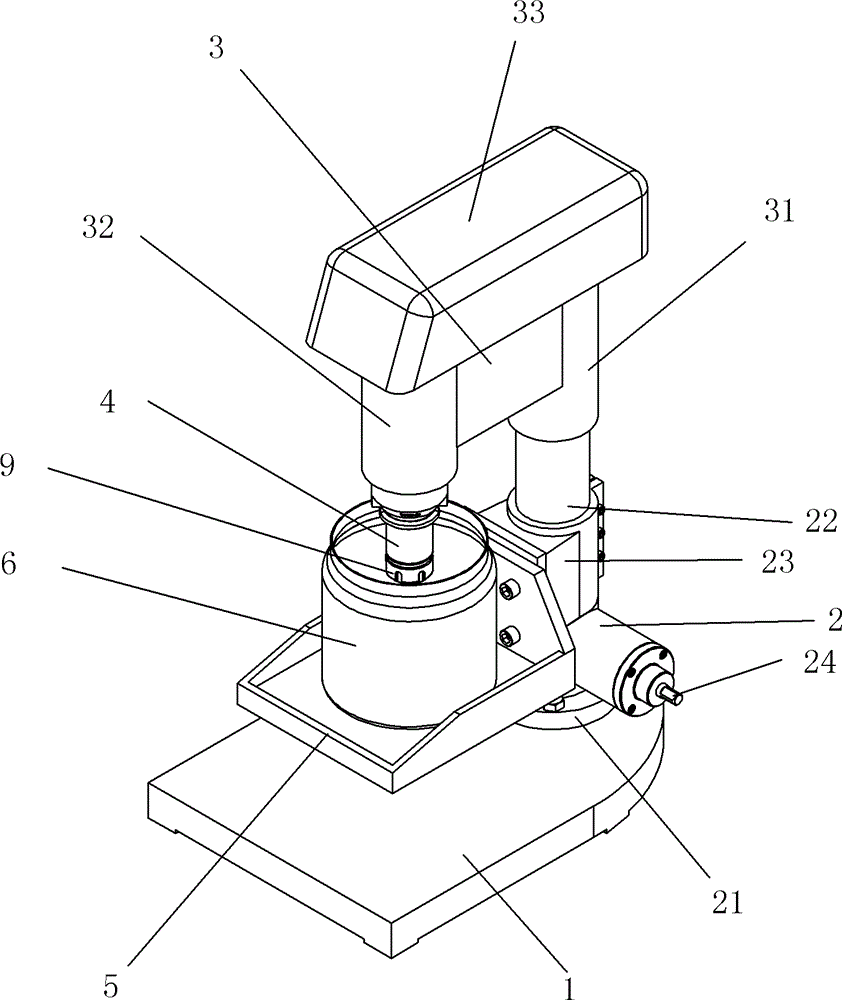

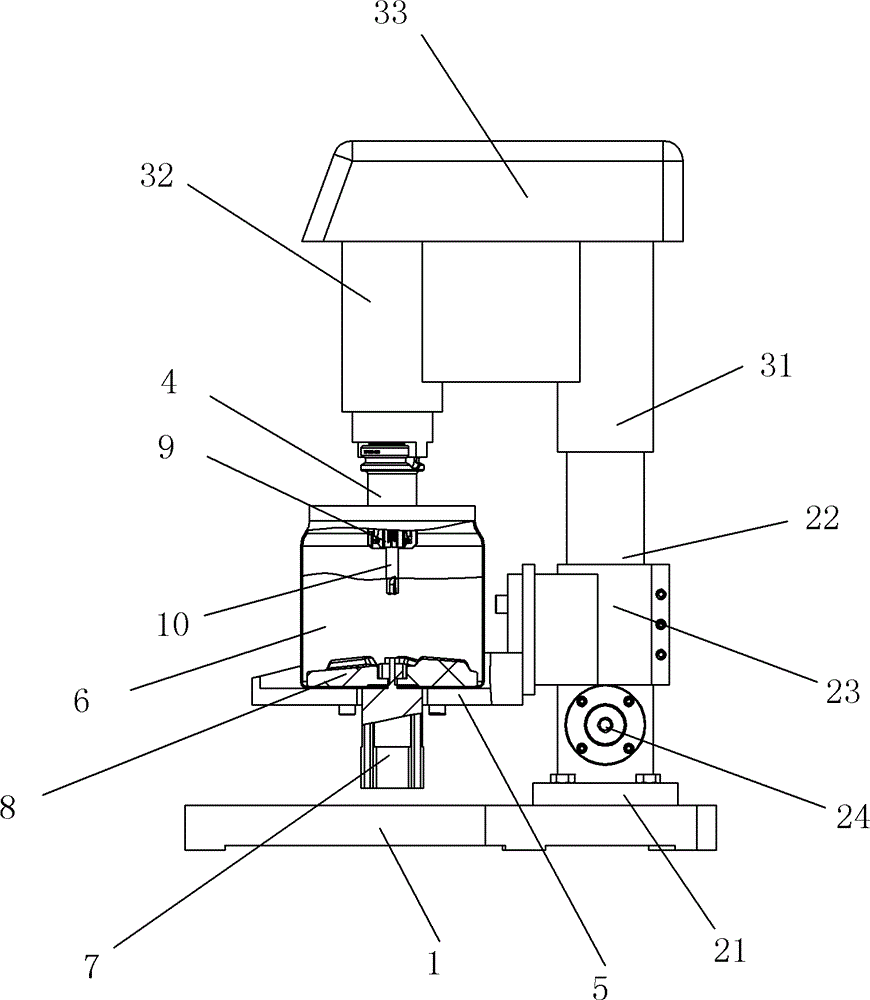

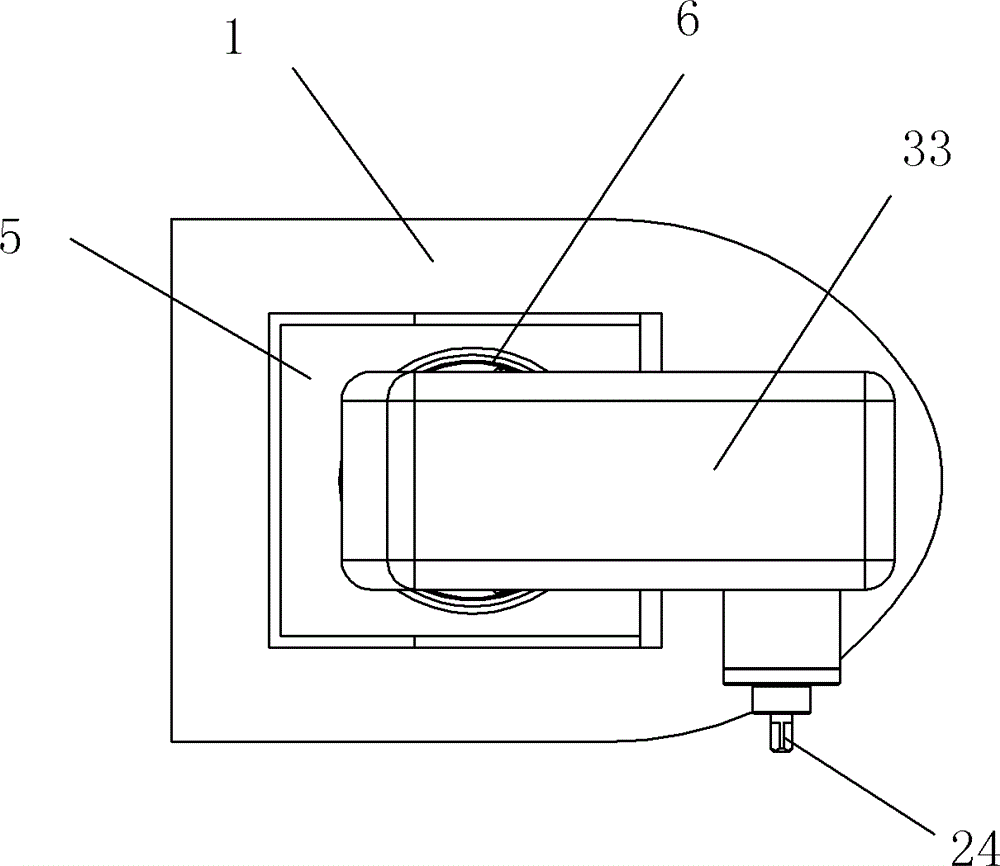

[0031]Embodiment, the flexible passivation treatment method of a kind of superhard material cutting tool of the present invention is to mix superhardness or high hardness abrasive with water according to the preset ratio to form water-based passivation medium; the water-based passivation medium The medium is placed in a container, and a turbine paddle is installed in the container, and the water-based passivation medium in the container is driven by the turbine paddle to rotate in one direction; the superhard material tool is clamped with a clamp, and the superhard material The cutting edge of the tool is immersed in the water-based passivation medium of the container, and at the same time, the fixture drives the superhard material tool to rotate in the water-based passivation medium, and the rotation direction of the fixture and the superhard material tool is the same as that of the water-based passivation medium. On the contrary, the flexible passivation treatment of the supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com