Clutch sleeve of bicycle mini-sized transmission

A clutch sleeve and transmission technology, applied in the field of ratchets, can solve the problems of easily broken teeth and affect the clutch effect, etc., achieve the effect of easy finishing, solve frequent broken teeth, and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

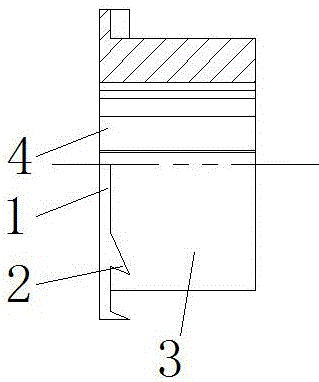

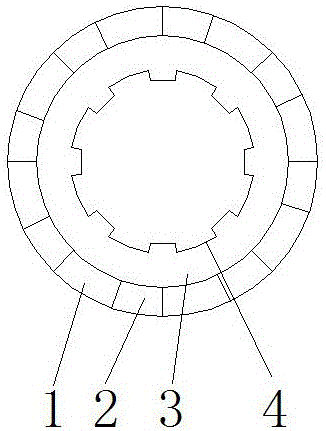

[0014] refer to figure 1 , figure 2 , a clutch sleeve of a bicycle miniature gearbox, a clutch ratchet base ring 1 is provided at one end of the sleeve 3, a clutch ratchet 2 is provided on the clutch ratchet base ring 1, and in the inner hole of the sleeve 3 A spline groove 4 is provided; the clutch ratchet 2 is located inside the clutch ratchet base ring 1, the clutch ratchet 2 has 6-12 teeth, and the clutch ratchet 2 is evenly distributed on the clutch ratchet base ring 1 , the outer diameter of the sleeve 3 is 26 mm, the outer diameter of the clutch ratchet base ring 1 is 32 mm, the total length of the sleeve 3 and the clutch ratchet base ring 1 is 16-18 mm, and the clutch ratchet 2 The tooth height is 2 mm; the spline groove 4 is 8 key grooves.

Embodiment 2

[0016] refer to figure 1 , figure 2 , a clutch sleeve of a bicycle miniature gearbox, a clutch ratchet base ring 1 is provided at one end of the sleeve 3, a clutch ratchet 2 is provided on the clutch ratchet base ring 1, and in the inner hole of the sleeve 3 A spline groove 4 is provided; the clutch sleeve of the bicycle miniature gearbox, the clutch ratchet 2 can also be located on the outside of the clutch ratchet base ring 1, and the clutch ratchet 2 is 6-12 teeth , the clutch ratchet 2 is evenly distributed on the clutch ratchet base ring 1, the outer diameter of the sleeve 3 is 26 mm, the outer diameter of the clutch ratchet base ring 1 is 32 mm, the sleeve 3 and the clutch ratchet base The total length of the ring 1 is 16-18 mm, and the tooth height of the clutch ratchet 2 is 2 mm; the spline groove 4 is 12 key grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com