Dry spraying decorative paper and manufacturing technology thereof

A manufacturing process and decorative paper technology, applied in coating, papermaking, paper coating, etc., can solve the problems of inability to grasp the distribution situation intuitively, uneven distribution of powder particles, insufficient stability of wear resistance, etc., and achieve clear and realistic decorative effects , Finishing processing is convenient, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

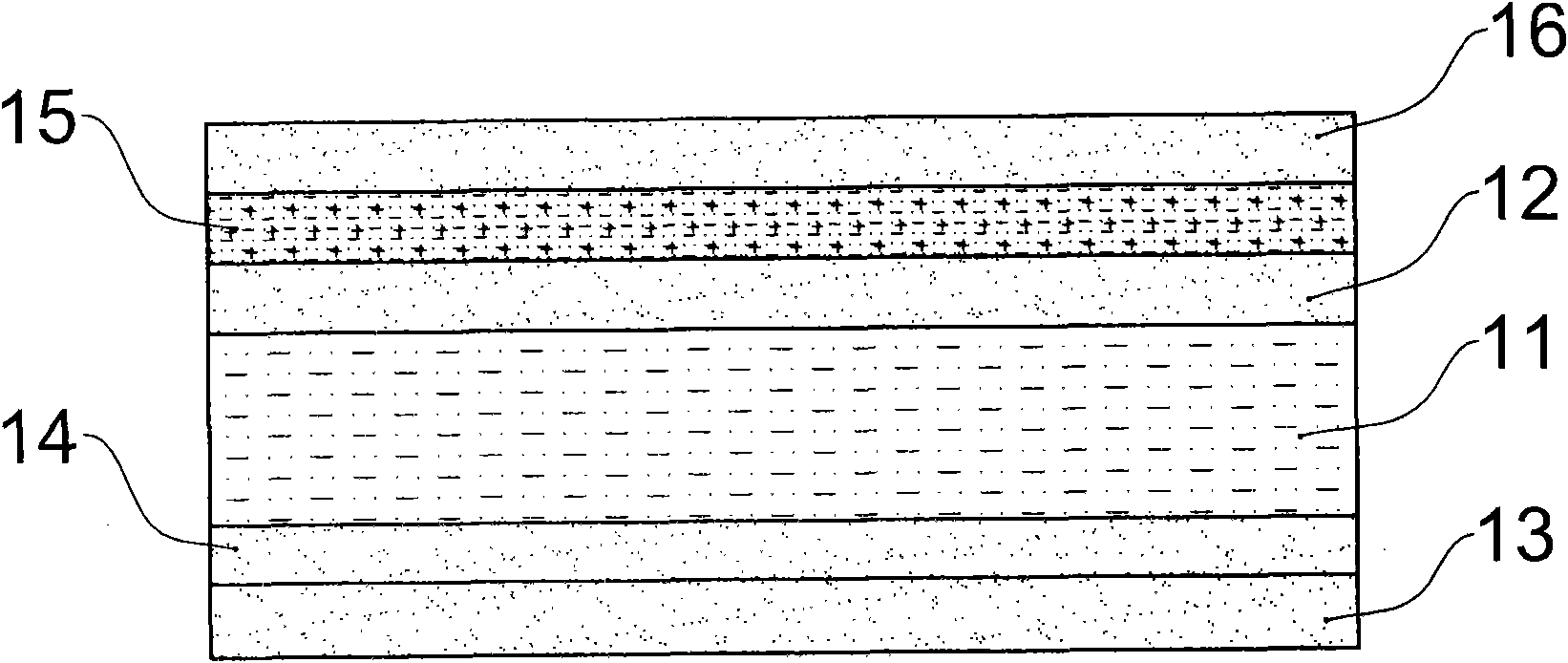

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

[0026] see image 3 The dry-process spraying decorative paper of the present invention comprises a printing base paper 11 printed with decorative patterns on the upper surface, an adhesive layer 12 is coated on the upper surface of the printing base paper 11, and an adhesive layer 12 is coated on the lower surface of the printing base paper 11. The bonding adhesive layer 13 of the base material layer of the ground plate. In order to extrude the air in the printing base paper 11, increase the adhesion of the adhesive adhesive layer 13 to the printing base paper 11, and apply the bonding adhesive layer 13 to the printing base paper 11. Before the lower surface, preferably the lower surface of the printing base paper 11 is first coated with a back glue layer 14 with melamine formaldehyde resin. The upper surface of the adhesive layer 12 is formed by dry powder spraying an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com