Automatic lifting scaffold

An automatic lifting and scaffolding technology, which is applied to the accessories of scaffolding, the scaffolding supported by the building structure, the supporting structure of the building, etc., can solve the problems of the complexity of the electric hoist and the pulley block, the difficulty of moving the lifting scaffold, and the mutual interference of the wire ropes, etc., so as to facilitate construction , reduce the chance of damage, prevent the effect of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

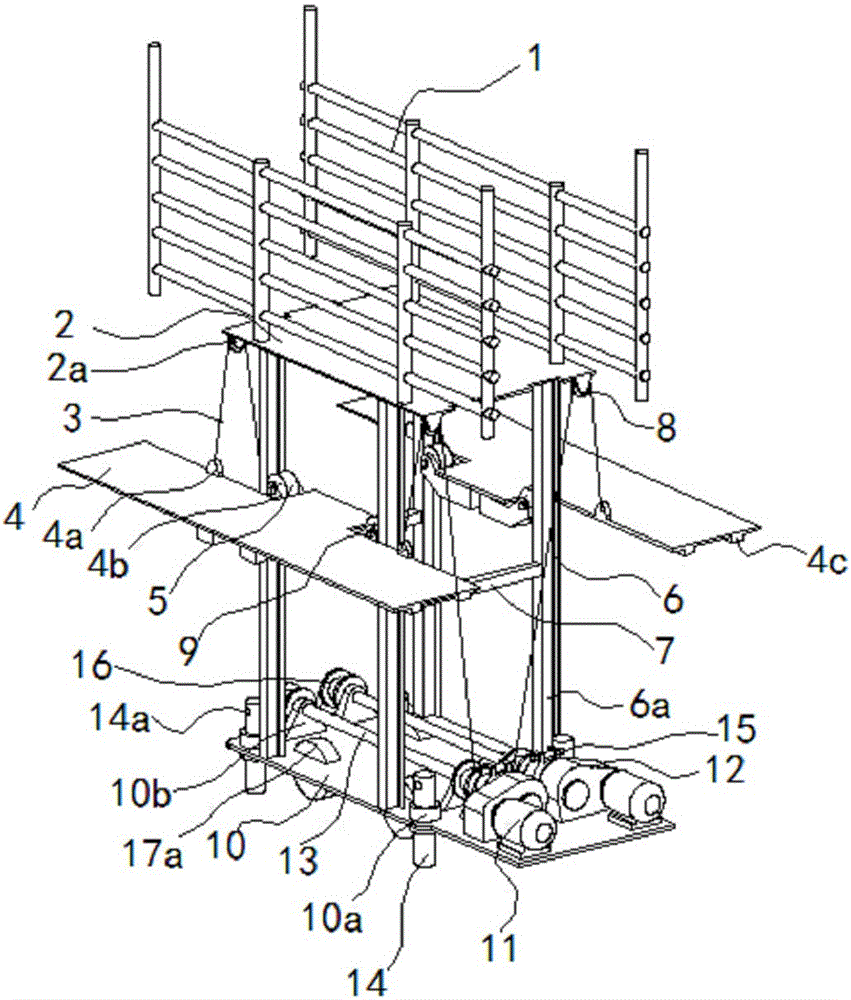

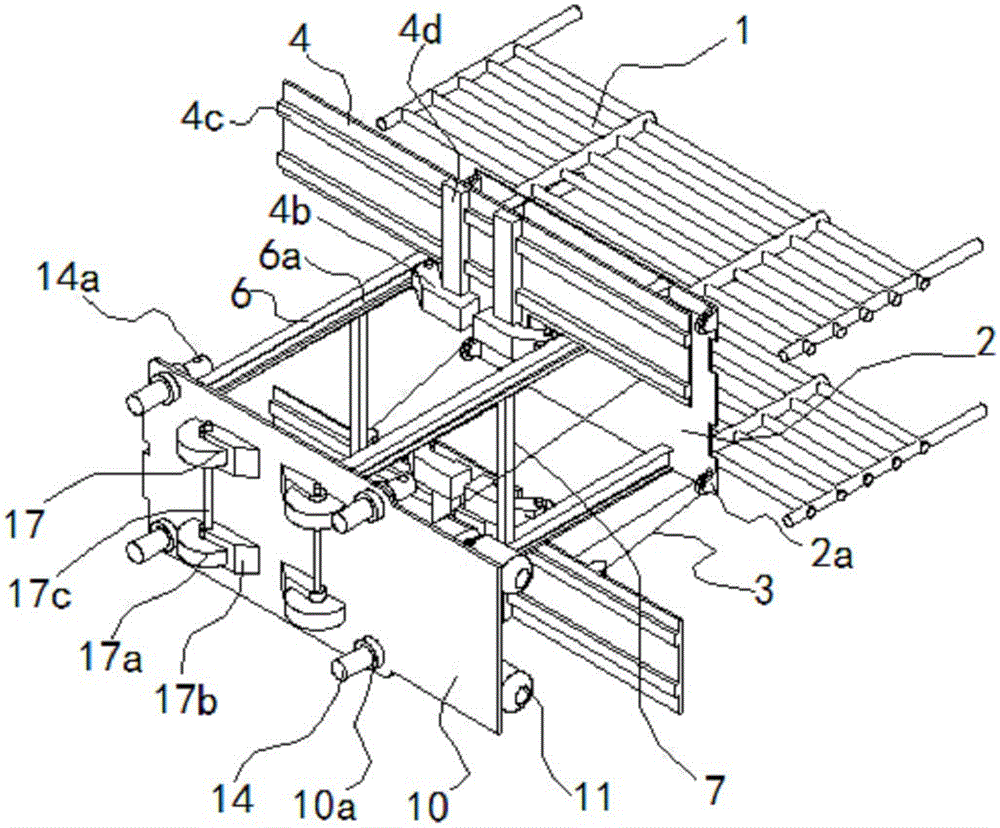

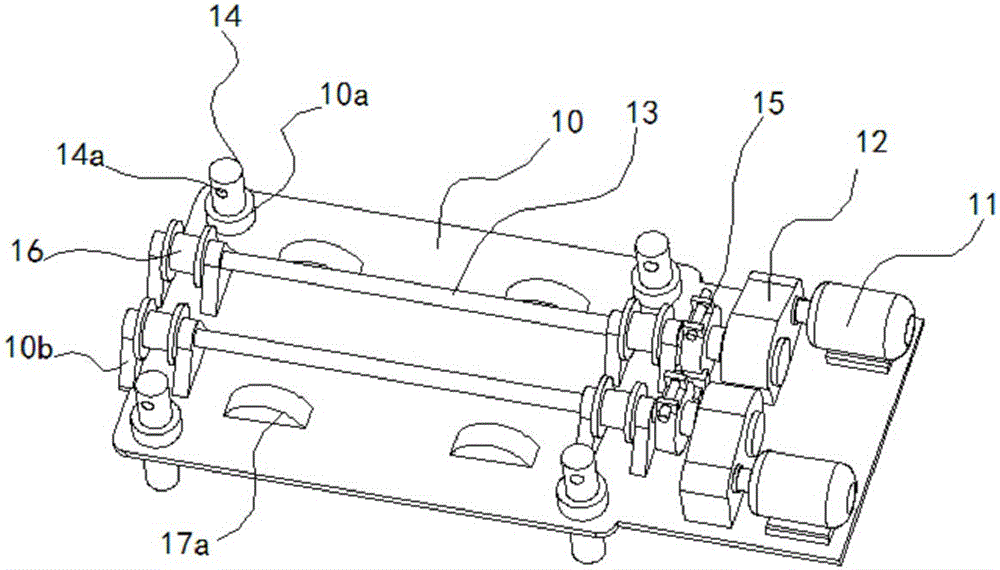

[0055] A kind of automatic lifting type scaffold of the present invention is described in detail below in conjunction with accompanying drawing.

[0056] As shown in the accompanying drawings, a kind of automatic lifting type scaffold of the present invention is made up of safety handrail 1, pull-up plate platform 2, steel wire rope 3, platform 4, guide wheel 5, standing column 6, reinforcing beam 7, fixed pulley 8, Guide wheel bearing pin 9, base 10, motor 11, speed reducer 12, axle 13, adjusting screw mandrel 14, electromagnetic brake 15, rotating bucket 16 and adjusting axle 17 etc. are formed. Wherein, the main structure of scaffolding is the cuboid structure that is made of pull-up plate platform 2, four vertical columns 6 and base 10, safety handrail 1 is installed on the pull-up plate platform 2, and platform 4 is installed on the vertical phase column 6, Power unit is installed on the base 10, and the elevating structure of scaffold is made up of motor 11, rotating buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com