Titanium nitride/copper-titanium intermetallic compound reinforced coating for surface of red copper

A technology of intermetallic compounds and titanium nitride, which is applied in the coating process and coating of metal materials, can solve the problems of poor surface mechanical properties and wear resistance, and achieve the goal of improving the wear resistance and hardness of copper surfaces and high practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

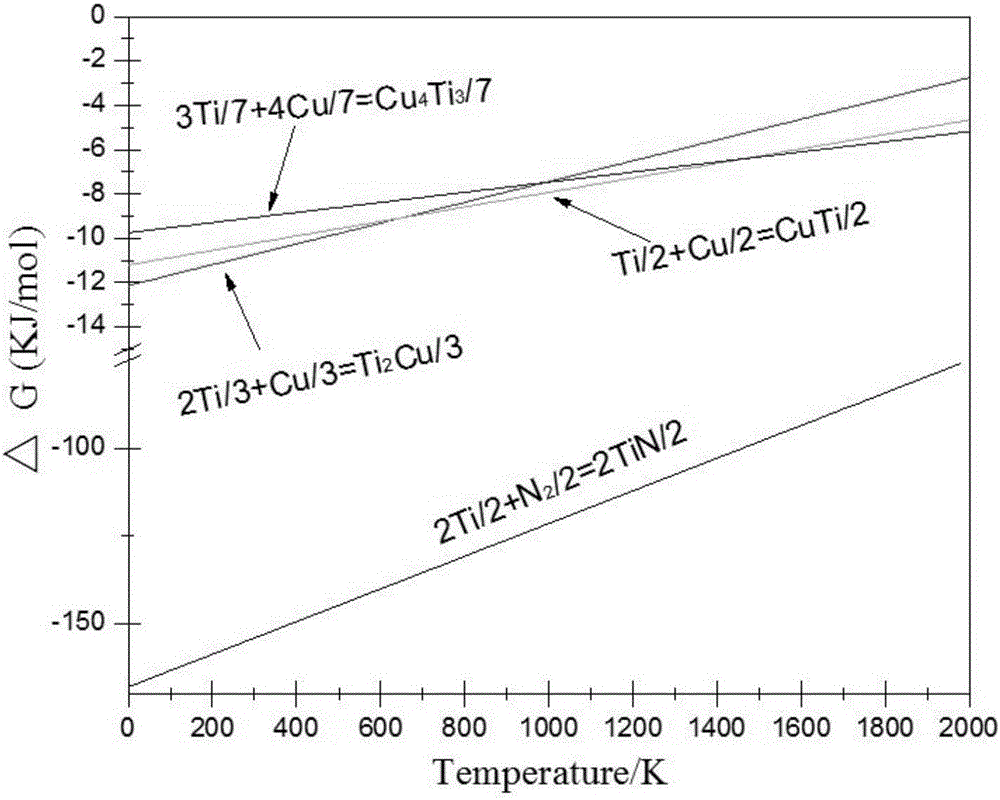

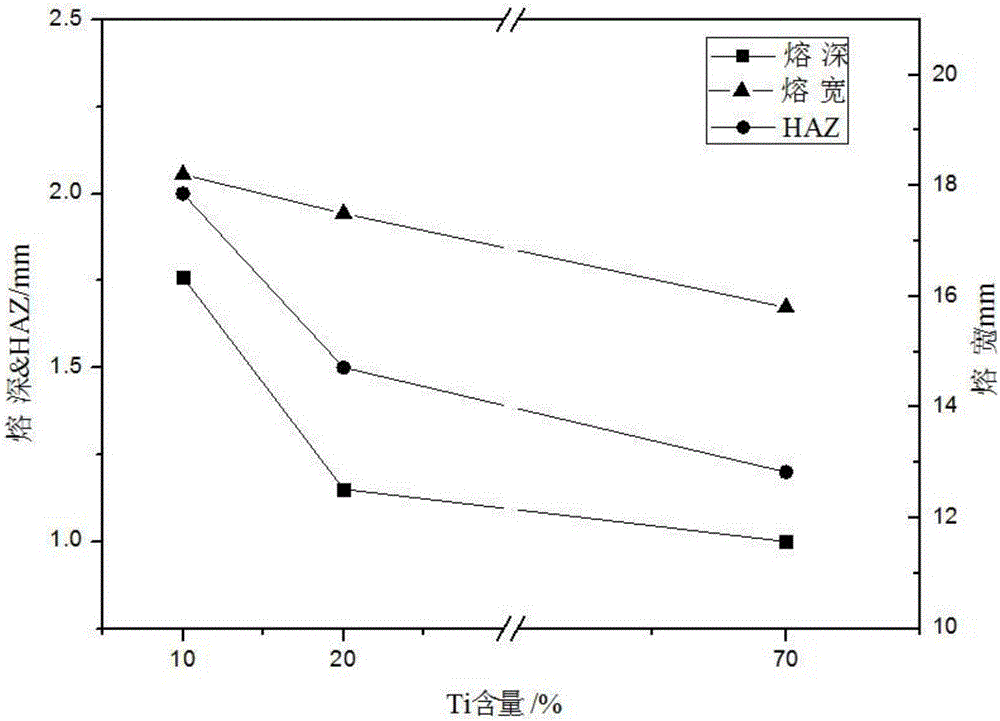

[0048] When the titanium powder in the pre-coating powder is 10%, the cladding layer is two phases of TiN and α-Cu:

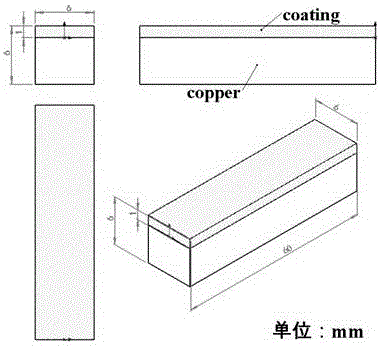

[0049] In this example, a wear-resistant coating with TiN as the reinforcing phase was prepared on the surface of a copper specimen of 100mm×50mm×10mm.

[0050] (1) Mix pure copper powder with a purity of 99.9% and 150 meshes and titanium powder with a purity of 99.99% and 200 meshes according to the ratio of 9:1. The total weight of the powder is 5g. Planetary ball mill, grind for 30 minutes, set aside.

[0051] (2) Mix 150-mesh low-carbon ferromanganese powder and 150-mesh ferrosilicon powder in a ratio of 1:1, the total weight of the powder is 2g, place the mixed powder in a planetary ball mill protected by an argon atmosphere, and grind for 10 minutes Mix powder and set aside. The low-carbon ferromanganese powder includes 0.2% carbon, 85%-92% manganese, 5%-13% iron, and the remainder is impurities. The ferrosilicon powder includes 74%-80% of silicon, 14%...

Embodiment 2

[0060] When the titanium powder in the pre-coated powder is 20%, the cladding layer is Ti 2 Three phases of Cu·TiN, TiN and α-Cu:

[0061] In this example, Ti was prepared on the surface of a copper specimen of 100mm×50mm×10mm 2 Cu · TiN-TiN enhanced copper-based wear-resistant coating.

[0062] (1) Mix pure copper powder with a purity of 99.9%, 150 mesh and titanium powder with a purity of 99.99%, 200 mesh according to the ratio of 8:2. The total weight of the powder is 5g. Planetary ball mill, grind for 35 minutes, set aside.

[0063] (2) Mix 150-mesh low-carbon ferromanganese powder and 150-mesh ferrosilicon powder in a ratio of 1:1, the total weight of the powder is 2g, place the mixed powder in a planetary ball mill protected by an argon atmosphere, and grind for 10 minutes Mix powder and set aside. The low-carbon ferromanganese powder includes 0.2% carbon, 85%-92% manganese, 5%-13% iron, and the remainder is impurities. The ferrosilicon powder includes 74%-80% of si...

Embodiment 3

[0072] When the titanium powder in the pre-coated powder is 70%, the cladding layer is TiN, Ti 2 Cu·TiN, CuTi, Cu 4 Ti 3 Four-phase and matrix α-Cu.

[0073] In this example, Ti was prepared on the surface of a copper specimen of 100mm×50mm×10mm 2 Cu·TiN, TiN and copper-titanium compound CuTi, Cu 4 Ti 3 Enhanced copper-based wear-resistant coatings.

[0074] (1) Mix pure copper powder with a purity of 99.9%, 150 mesh and titanium powder with a purity of 99.99%, 200 mesh according to the ratio of 3:7, the total weight of the powder is 5g, and place the mixed powder in an argon atmosphere protection Planetary ball mill, grind for 45 minutes, set aside.

[0075] (2) Mix low-carbon ferromanganese powder with a purity of 90% and 150 meshes and ferrosilicon powder with a purity of 75% and 150 meshes in a ratio of 1:1. The total weight of the powders is 2g. Place the mixed powders in an argon atmosphere Protected planetary ball mill, mixed powder for 10 minutes, stand-by. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com