Nickel-free weather-resistant steel and method for preparing hot rolled plate thereof

A technology of weathering steel and manufacturing method, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of high cold crack index and poor welding performance, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

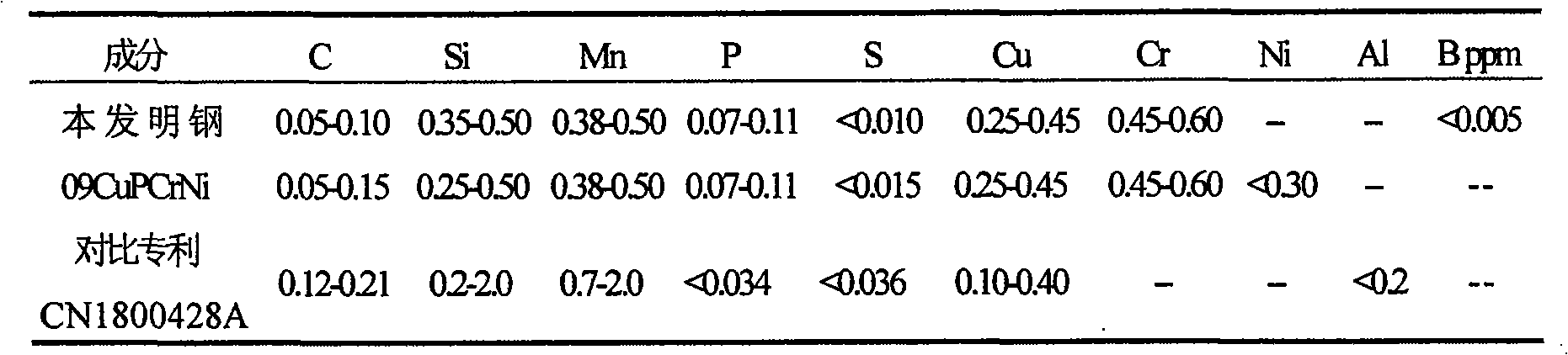

[0022] The preparation method of the low-cost weather-resistant steel adopts electric furnace or converter conventional smelting, and controls the content of key alloy elements and the heating process. From the actual rolling results of hot rolling, the edge and surface quality of the example are better, and the mechanical properties of the example are equivalent to 09CuPCrNi.

[0023] Table 3 embodiment heating system

[0024]

Embodiment and 09

[0025] The mechanical property of table 4 embodiment and 09CuPCrNi

[0026]

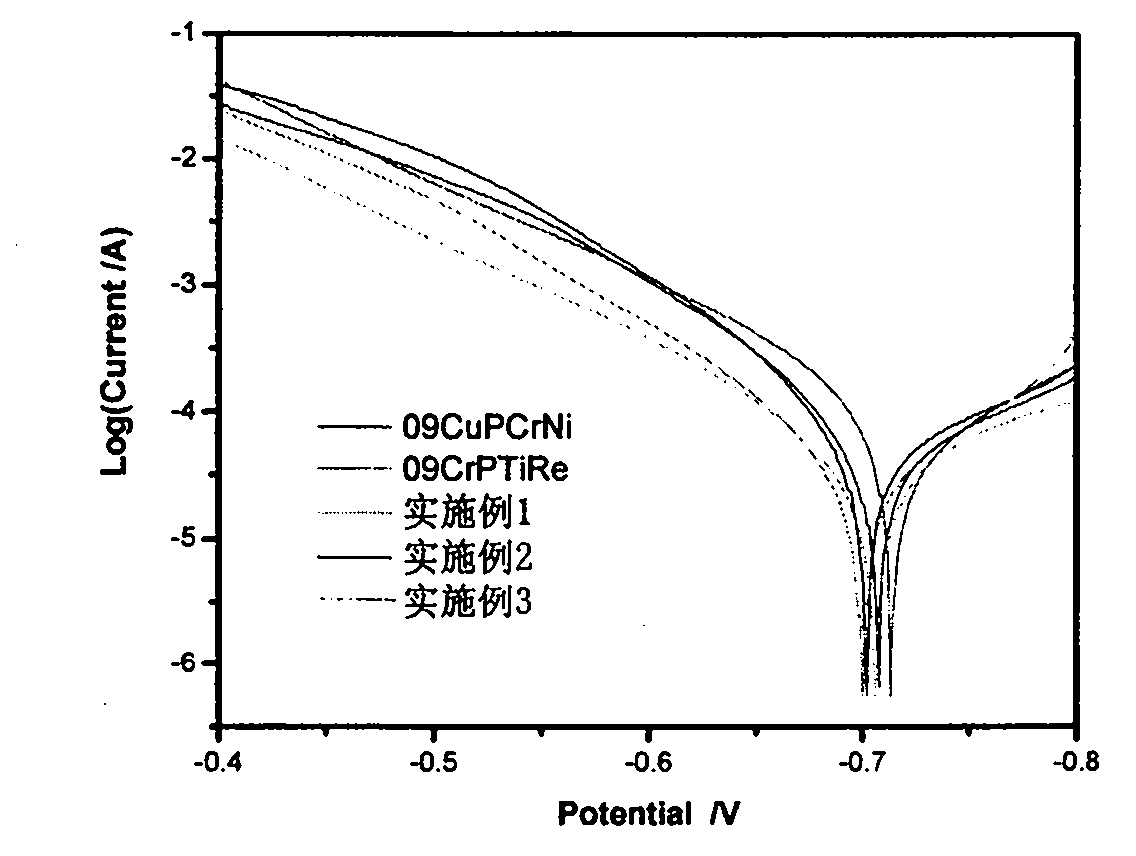

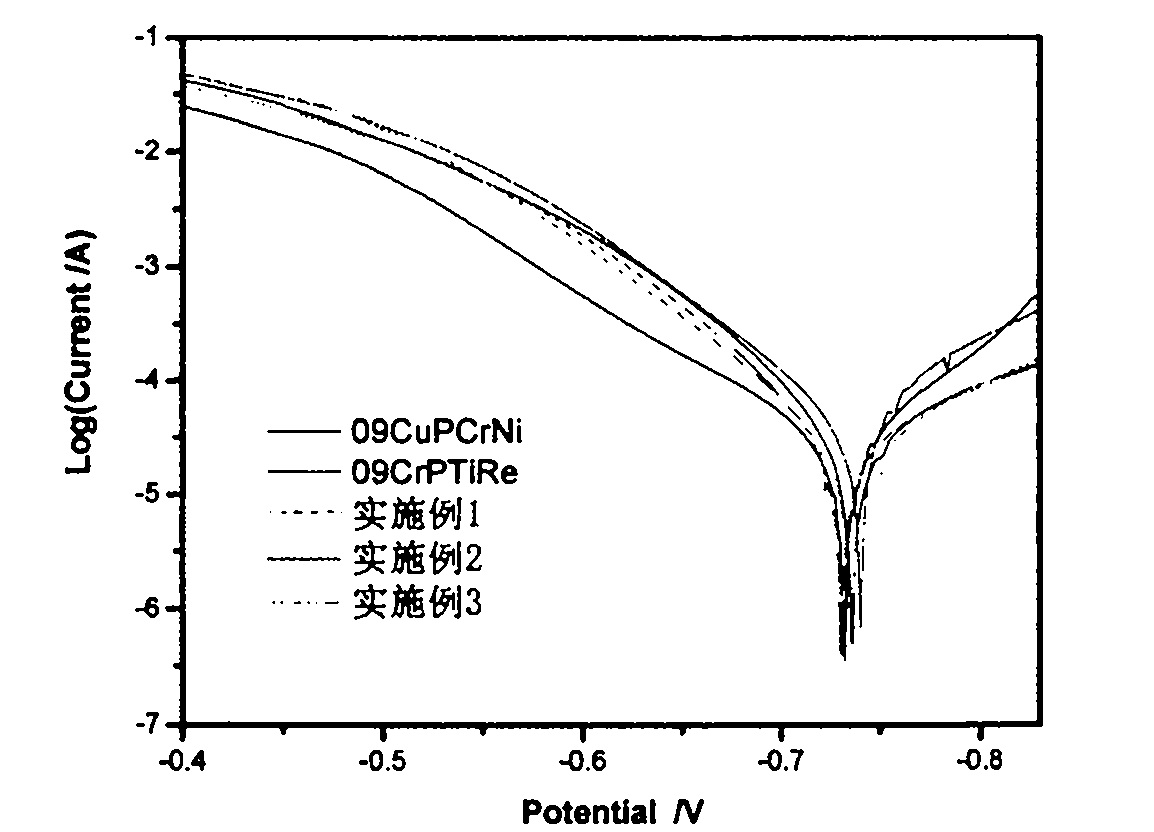

[0027] figure 1 , 2 The analysis results of the polarization curves are shown in Table 5. It can be seen that by reducing the C, S elements and Si-increasing elements in the example, the corrosion resistance under the two corrosion times is significantly better than that of the comparative example 09CuPTiRe, and the corrosion rate drops by nearly 50%, which is basically similar to 09CuPCrNi, or even slightly higher .

[0028] The polarization curve calculation result of table 5 embodiment and comparative example

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com