Production method of nickel-titanium alloy surface nickel-free layer

A technology of nickel-titanium alloy and nickel layer, which is applied in the field of surface engineering technology and biomaterials, can solve the problems of not being able to remove nickel and leave titanium, and achieve the effects of low cost, improved corrosion resistance, and improved coagulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0032] 1. The preparation method of the nickel-free layer on the surface of the nickel-titanium alloy is:

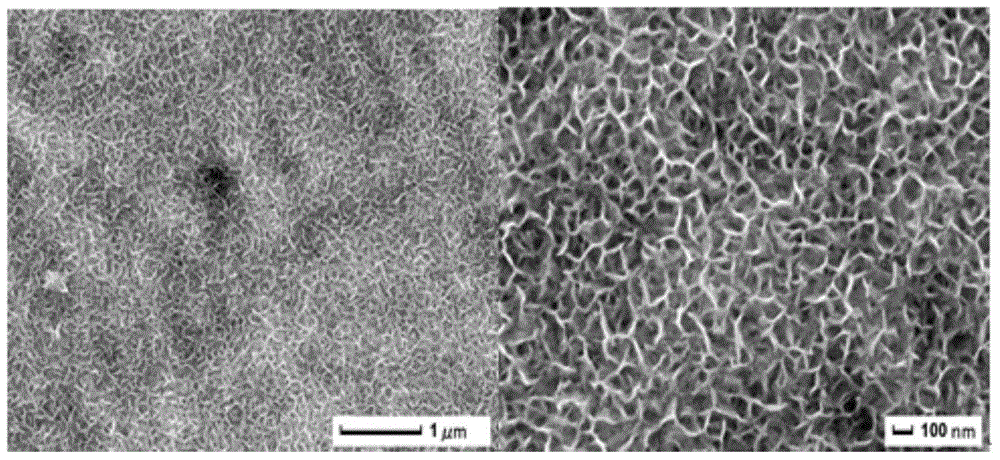

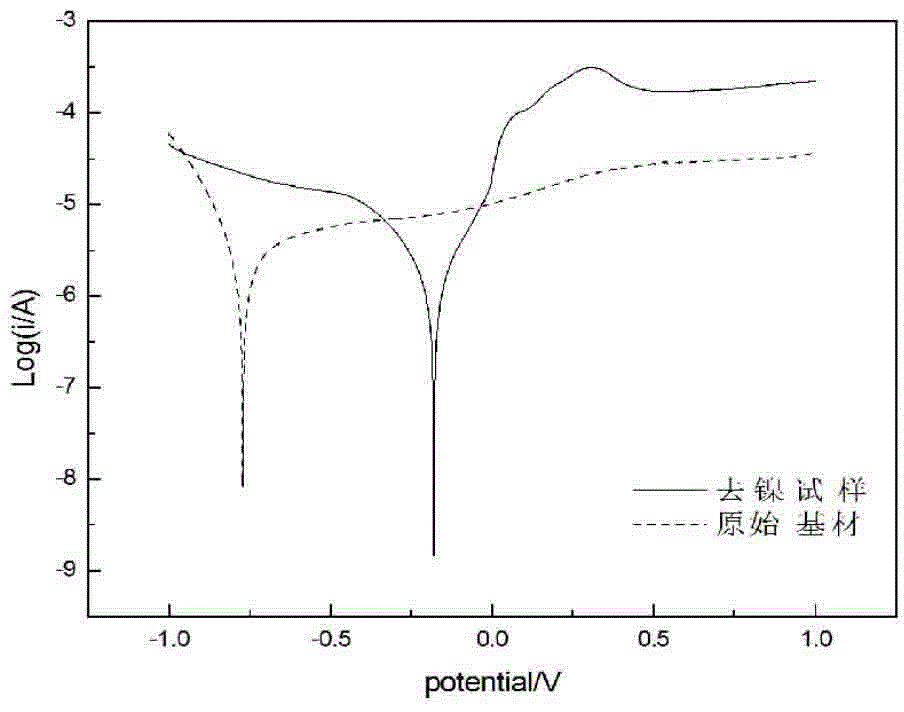

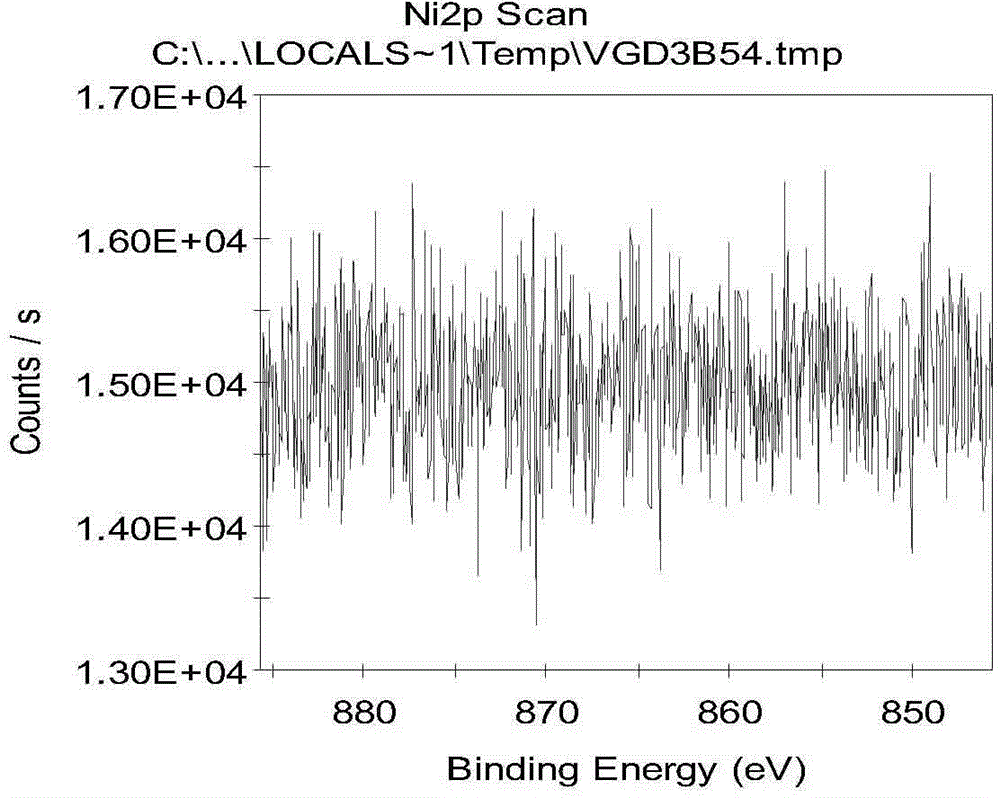

[0033] Ni: 56.3wt% and Ti: 43.599wt% in nickel-titanium alloy were selected, and the NiTi alloy plate was processed into a rectangular sample of 10mm×10mm×2mm by wire cutting method.

[0034] (1) Substrate pretreatment

[0035] Use metallographic paper 280#, 400#, 600#, 800#, 1000# to grind and polish the nickel-titanium alloy to be treated step by step; put the nickel-titanium alloy to be treated into acetone, absolute ethanol and distilled water respectively Ultrasonic cleaning for 10 minutes, then activation treatment with hydrofluoric acid and nitric acid solution (formulation: H2O:HF:HNO3=5:1:4) for 60s, cleaning and drying for later use;

[0036] (2) Surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com