Trivalent-nickel-doped nickel-based hydrotalcite nanometer sheet, preparation method thereof, and application of nano-sheet to supercapacitor

A technology of hydrotalcite and trivalent nickel, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of limited application, low specific surface area of catalyst, harsh synthesis conditions, etc., and achieve good results The effects of electrochemical capacity and stability, ease of large-scale production, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of trivalent nickel-doped NiMn-LDH hydrotalcite nanosheets by microemulsion:

[0033] Configure microemulsion: Based on a 100ml three-necked flask, add 50ml of isopropanol, 1.1ml of deionized water, and 1.88g of surfactant sodium lauryl sulfate into the three-necked flask, stir; slowly add 2ml of 1-butanol, Stir until clear. 0.004mol of Ni(NO 3 ) 2 ·6H 2 O was added to the microemulsion prepared above, and after the salt was dissolved, 0.001molMn(NO 3 ) 3 4H 2 O, after dissolving, add 1.2 g of precipitant urea, crystallize and reflux at 100°C for 27 hours.

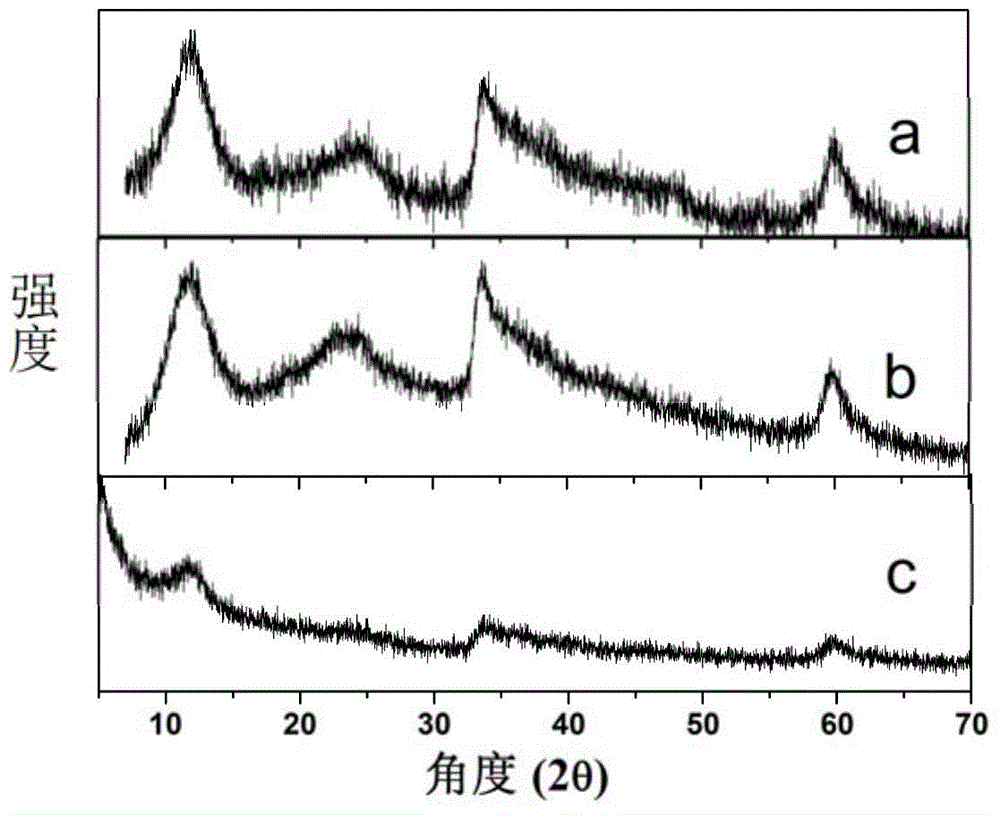

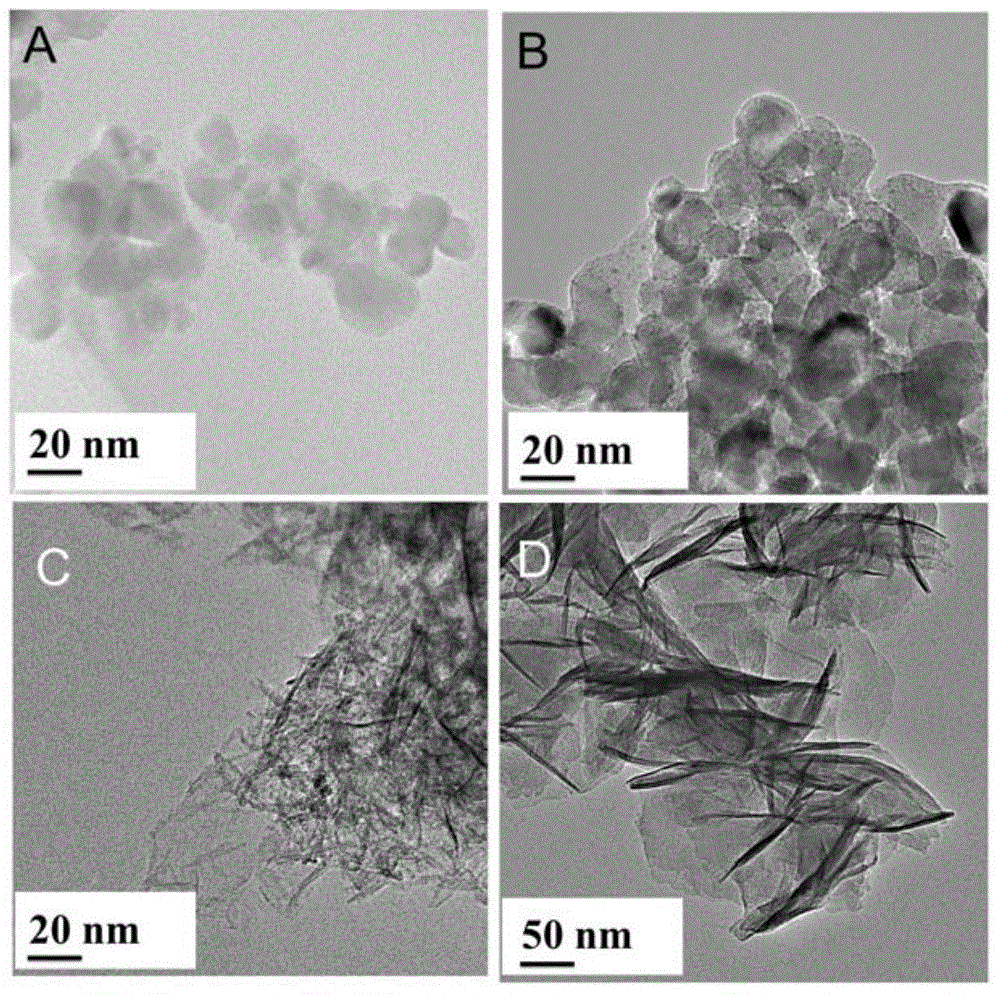

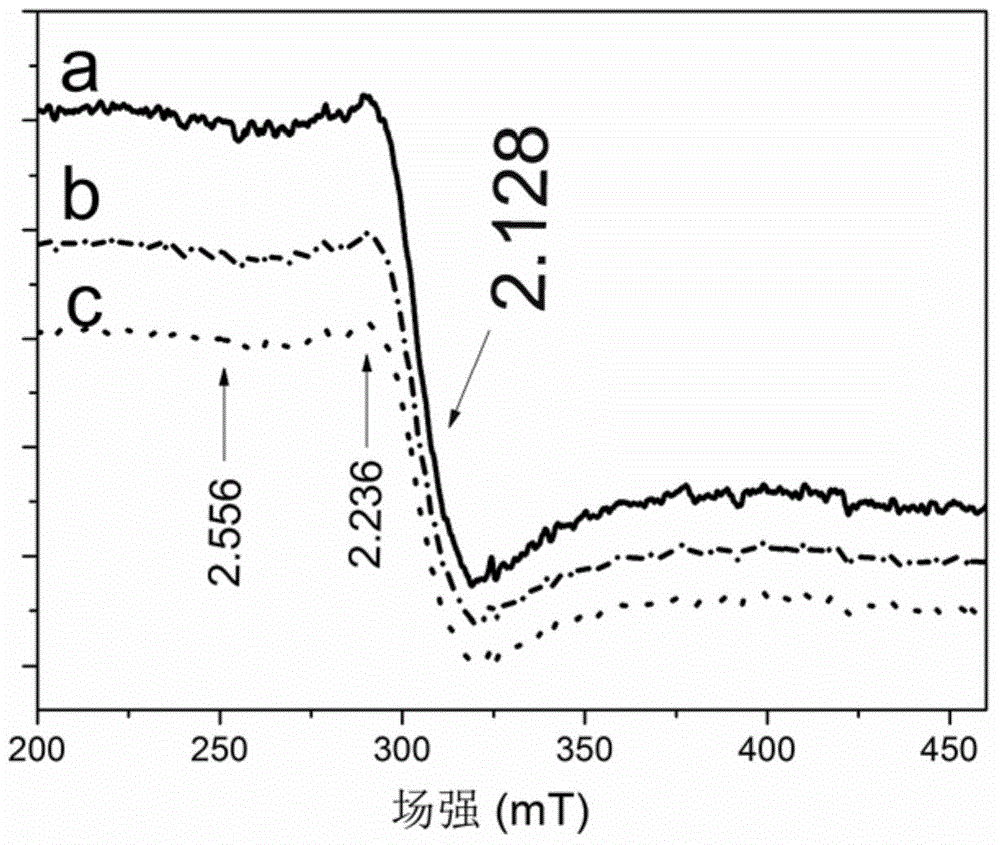

[0034] 2. After the reaction is completed, the product is suction-filtered, centrifuged and washed 3 times with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and then washed once with absolute ethanol, and the filter cake is dried in an oven at 60°C for 12 hours. Trivalent nickel-doped NiMn hydrotalcite nanosheets were obtained. The chemical formula of the NiMn hydr...

Embodiment 2

[0038] Trivalent Ni-doped NiTi-LDH hydrotalcite nanosheets prepared by microemulsion:

[0039] 1) Configure microemulsion: Based on a 100ml three-necked flask, add 80ml of isopropanol, 2.0ml of deionized water, and 2.00g of surfactant sodium lauryl sulfate into the three-necked flask, stir; slowly add 1-butanol 1.5ml, stir until clear. 0.008mol of Ni(NO 3 ) 2 ·6H 2 O was added to the microemulsion prepared above, and after the salt was dissolved, TiCl was added in a closed environment. 4 The solution is 0.002mol, and after the smoke disappears, add 1.500g of urea, crystallize and reflux at 130°C for 27h.

[0040] 2) After the reaction is completed, the product is suction-filtered, centrifuged and washed three times with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and then washed once with absolute ethanol, and the filter cake is dried in an oven at 90°C for 16 hours, namely NiTi hydrotalcite nanosheets doped with trivalent nickel were obtai...

Embodiment 3

[0045] Trivalent Ni-doped NiCo-LDH hydrotalcite nanosheets prepared by microemulsion:

[0046] 1) Configure microemulsion: Based on a 100ml three-necked flask, add 20ml of isopropanol, 0.2ml of deionized water, and 0.48g of surfactant sodium lauryl sulfate into the three-necked flask, stir; slowly add 1-butanol 0.5ml, stir until clear. 0.002mol of Ni(NO 3 ) 2 ·6H 2 O was added to the microemulsion prepared above, and after the salt was dissolved, 0.001mol Co(NO 3 ) 3 ·6H 2 O, after dissolving, add 1.0 g of precipitant urea, crystallize and reflux at 80°C for 48 hours.

[0047] 2) After the reaction is completed, the product is suction-filtered, centrifuged and washed three times with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and then washed once with absolute ethanol, and the filter cake is dried in an oven at 90°C for 10 hours, namely NiCo hydrotalcite nanosheets doped with trivalent nickel were obtained.

[0048] The chemical formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com