Nickel-free hole sealing agent for aluminum alloy and hole sealing treatment process of agent

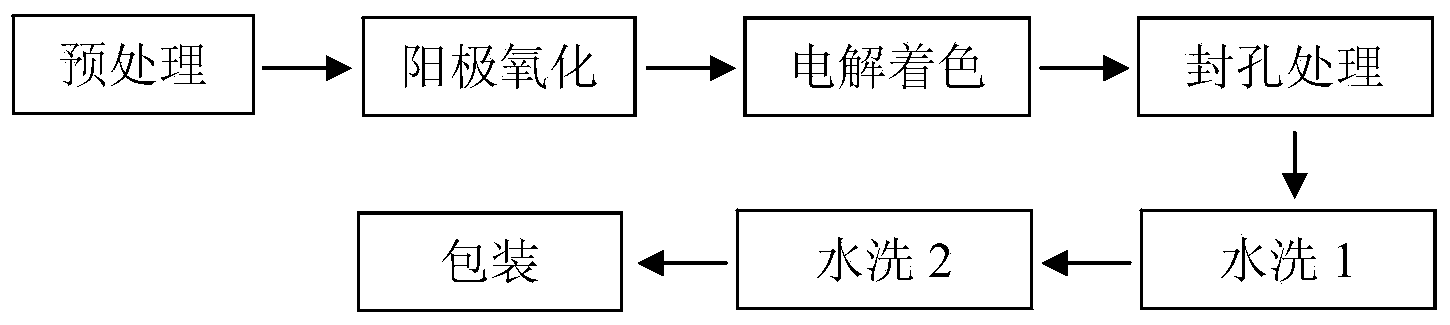

A treatment process and aluminum alloy technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve problems such as nickel pollution, achieve energy saving, eliminate pollution, and reduce the amount of dissolved aluminum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

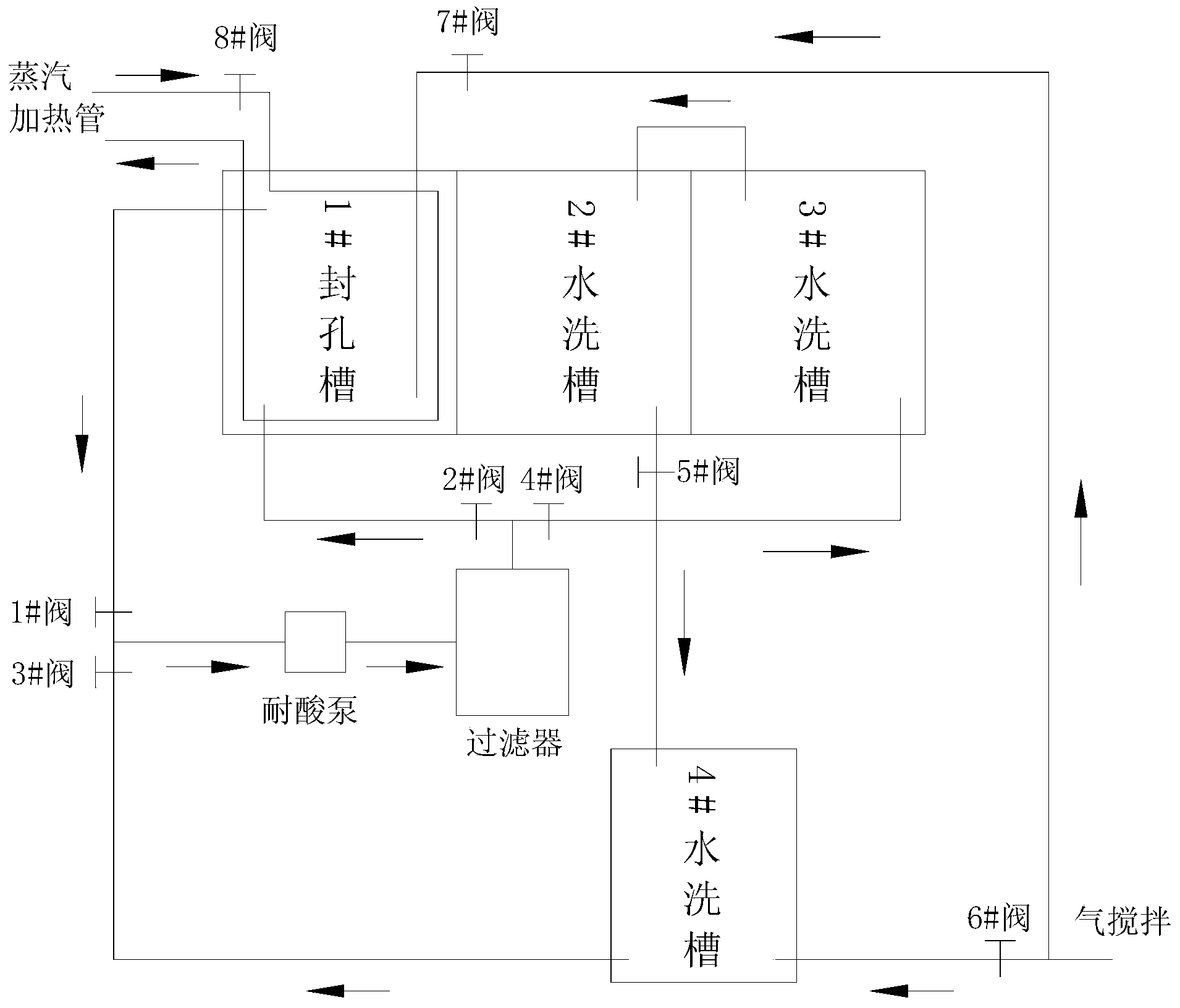

Method used

Image

Examples

Embodiment 1

[0068] Fluotitanic acid (50wt.%) 7.5g / L was selected as the sealing component; ethylene glycol 2.0g / L was used as the corrosion inhibitor, sodium tripolyphosphate 2.0g / L was used as the chelating component, and the working temperature was 25°C. The pH value is 3.5, and the sealing speed is 1 μm / min.

Embodiment 2

[0070] Fluotitanic acid (50wt.%) 7.5g / L was selected as the sealing component; glycerol 2.0g / L was used as the corrosion inhibitor, sodium tripolyphosphate 2.0g / L was used as the chelating component, the working temperature was 25°C, pH The value is 3.5, and the sealing speed is 1 μm / min.

Embodiment 3

[0072] Fluotitanic acid (50wt.%) 7.5g / L was selected as the sealing component; sorbitol 2.0g / L was used as the corrosion inhibitor, sodium tripolyphosphate 2.0g / L was used as the chelating component, the working temperature was 25°C, and the pH value 3.5, sealing speed 1μm / min;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com