Nodular cast iron roller of hot rolled seamless steel tube tandem mill and preparation method thereof

A technology of seamless steel pipe and ductile iron, which is applied in the field of roll manufacturing, and can solve problems such as difficulty in austempering and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the hot-rolled seamless steel pipe continuous rolling mill nodular cast iron roll of the present invention has the following steps:

[0022] Mold design: According to the structural shape of the roll, choose a circular cross-section variable-diameter type or a round cross-section nearly equal-thickness pure sand or composite sand mold; the mold runner is an independent runner. The round section of the mold is made of a round sand box instead of the traditional square sand box, so that the thickness of the sand mold in each part is the same, and the cooling conditions are consistent.

[0023] The diameter-reducing type of round section of the casting mold is to divide the sand mold into three parts according to the shape of the continuous rolling roll: the upper short axis, the middle roll ring and the lower long axis. The diameter of each part of the round sand box is determined according to the diameter of the continuous rolling roll. The overa...

Embodiment 1

[0030] Embodiment 1 is to manufacture Φ460 hot-rolled seamless steel pipe continuous rolling mill rolls, and the chemical composition of the rolls is shown in Table 1 by weight percentage (%Wt).

[0031] Table 1

[0032] C

Si

mn

Cu

Mo

Ti

Al

Bi

Mg

P

S

3.2

2.3

0.20

0.23

0.22

0.05

0.02

0.002

0.05

0.03

0.02

[0033] The balance is Fe.

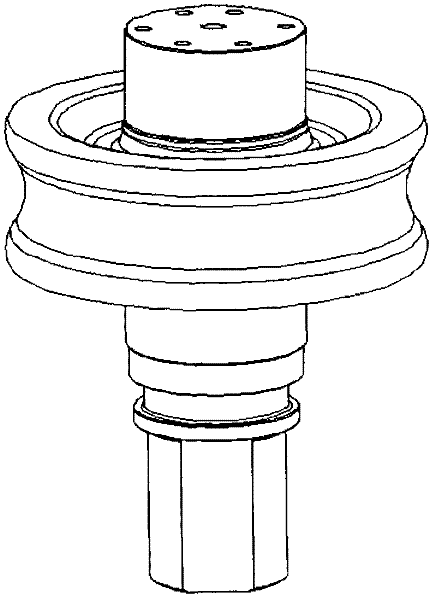

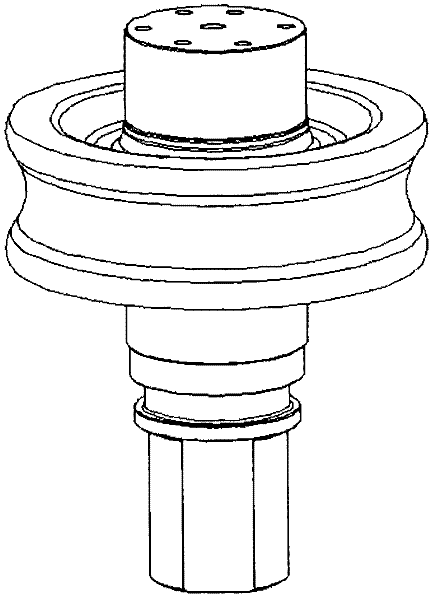

[0034] refer to figure 1 , the upper short axis diameter of the roll is Φ300mm, the shaft length is 147mm, the middle roll ring diameter is Φ803.9mm, the scrapped diameter is Φ740mm, the roll ring thickness is 320mm, the lower long axis diameter is Φ280-300mm, the shaft length is 700mm, and the weight of the finished product is 1310kg / piece.

[0035] Process requirements: tensile strength ≥ 800MPa, hardness 270-330HB, hardness should be ≥ 270HB when it is scrapped.

[0036] The casting ...

Embodiment 2

[0043] Example 2 is to manufacture Φ180 hot-rolled seamless steel pipe continuous rolling mill rolls, and the chemical composition of the rolls is shown in Table 2 by weight percentage (%Wt).

[0044] Table 2

[0045]

C

Si

mn

Cu

Mo

Ti

Al

Bi

Mg

P

S

3.6

2.61

0.20

0.39

0.30

0.07

0.04

0.003

0.04

0.03

0.02

[0046] The balance is Fe.

[0047] refer to figure 1 , the diameter of the upper short axis of the roll is Φ275mm, the shaft length is 140mm, the diameter of the middle roll ring is Φ623.1mm, the diameter when scrapped is Φ573mm, the thickness of the roll ring is 220mm, the diameter of the lower long axis is Φ260-275mm, the shaft length is 500mm, and the weight of the finished product is 623kg / piece.

[0048] Process requirements: the tensile strength is ≥850MPa, the hardness is 420-450HB, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com