High-nitrogen nickel-free austenite antibacterial stainless steel (HNSAg) and manufacturing method thereof

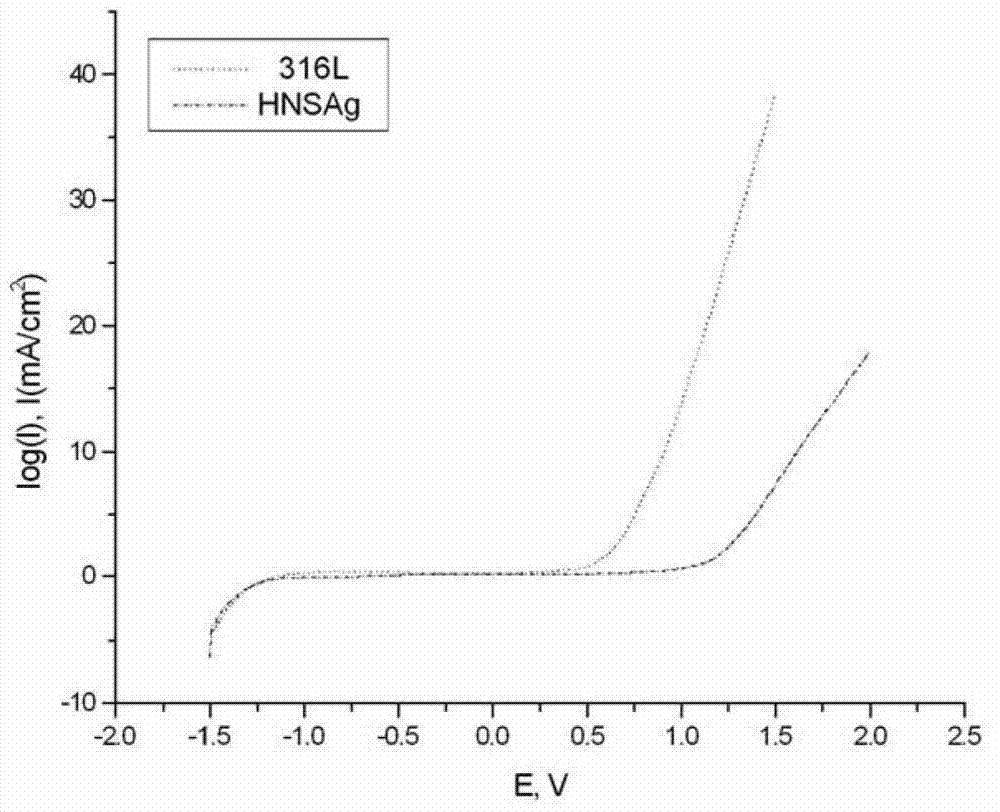

An antibacterial stainless steel and austenite technology, applied in the field of alloys, can solve the problems that chromium-nickel stainless steel does not have antibacterial properties, increases the risk of nickel sensitization, and has strong work hardening ability, and achieves good anti-microbial corrosion performance and excellent resistance to spots. corrosion resistance, good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention also discloses a preparation method of high-nitrogen nickel-free austenitic antibacterial stainless steel (HNSAg), comprising the following steps:

[0036] a. Smelting in a magnesia crucible: clean the crucible before smelting to avoid carburization during smelting, and then use raw materials YT0 pure iron, FeCr69 micro-carbon ferrochrome, MnN8.28 manganese nitride, FeMo60 ferromolybdenum, FeSi75 silicon Iron, electrolytic manganese, pure copper, CuAg30 copper-silver alloy, FeNb50A ferroniobium are put into the crucible and filled tightly, then close the crucible lid;

[0037] b. Vacuumize the crucible to below 5Pa, then fill the crucible melting chamber with nitrogen to 6-9atm and heat and melt to a temperature of 1600-1620°C, then pour the molten metal into the metal ingot mold to make an ingot; The ingot is hot-rolled into a slab at a temperature of 1050-1100°C, and finally solution-treated at a temperature of 1080-1150°C; high-nitrogen nickel-free aus...

Embodiment 1

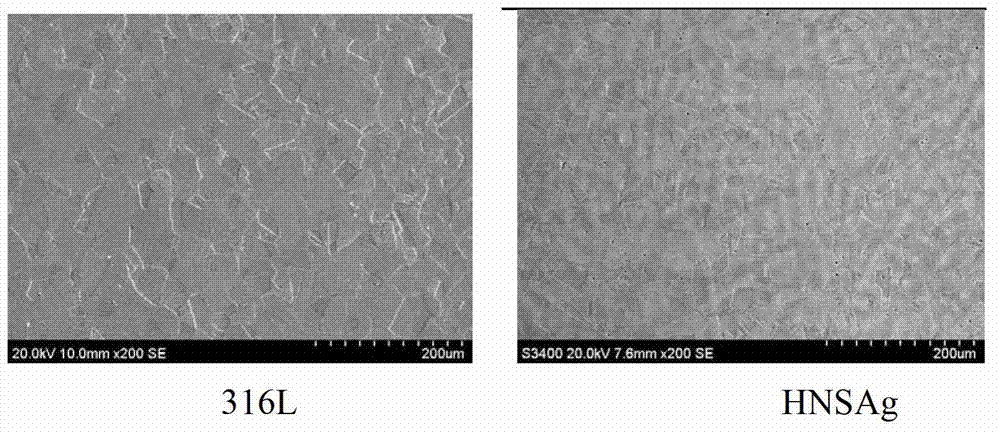

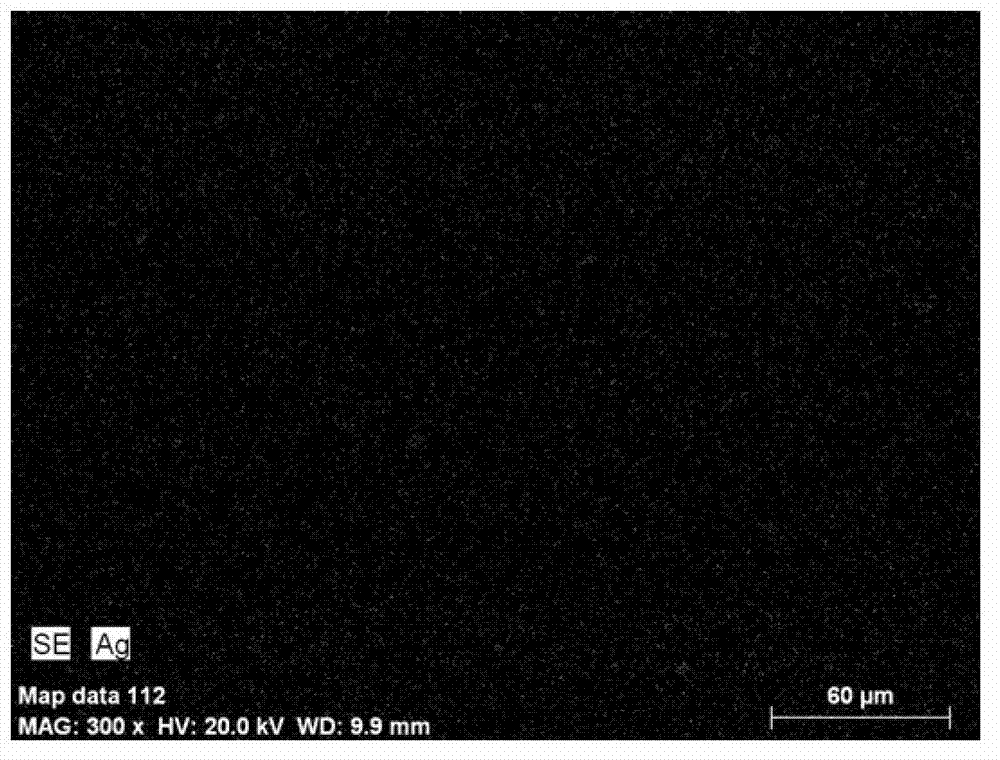

[0042] The high-nitrogen nickel-free austenitic antibacterial stainless steel (HNSAg) of the present embodiment, the stainless steel composition comprises the following components by weight percentage:

[0043] Carbon 0.024%, silicon 0.48%, manganese 18.42%, chromium 18.05%, molybdenum 1.96%, copper 0.48%, phosphorus 0.011%, sulfur 0.006%, nitrogen 0.55%, niobium 0.10%, silver 0.13%, and the balance is iron.

[0044] The preparation method of the high-nitrogen nickel-free austenitic antibacterial stainless steel (HNSAg) in this embodiment includes the following steps: (The weight of the raw materials in this embodiment and the following embodiments is: weight percentage×10KG.)

[0045] a. Smelting in a magnesia crucible: clean the crucible before smelting to avoid carburization during smelting, and then put YT0 pure iron, FeCr69 micro-carbon ferrochrome, MnN8.28 manganese nitride, FeMo60 ferromolybdenum, FeSi75 silicon Iron, electrolytic manganese, pure copper, CuAg30 copper s...

Embodiment 2

[0049] The high-nitrogen nickel-free austenitic antibacterial stainless steel (HNSAg) of the present embodiment, the stainless steel composition comprises the following components by weight percentage:

[0050] Carbon 0.023%, silicon 0.53%, manganese 18.04%, chromium 18.10%, molybdenum 1.92%, copper 0.49%, phosphorus 0.013%, sulfur 0.008%, nitrogen 0.52%, niobium 0.10%, silver 0.19%, and the balance is iron.

[0051] The preparation method of the high-nitrogen nickel-free austenitic antibacterial stainless steel (HNSAg) of the present embodiment comprises the following steps: a. melting in a magnesia crucible: before melting, the crucible is cleaned up to avoid carburization during smelting, and then YT0 pure iron, FeCr69 micro-carbon ferrochromium, MnN8.28 manganese nitride, FeMo60 ferromolybdenum, FeSi75 ferrosilicon, electrolytic manganese, pure copper, CuAg30 copper silver, FeNb50A ferro-niobium into the crucible and close the crucible cover after filling densely ; Among t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com