High-resistance electrophoretic aluminum profile being resistant to cracking caused by bending and preparation method of aluminum profile

An aluminum profile and bending-resistant technology, applied in the field of aluminum alloy materials, can solve the problems of poor resistance to bending cracking, the qualified rate of finished products needs to be further improved, and cracks are easy to occur, so as to improve plasticity and strength, uniform chemical composition distribution, and cracking. The effect of reducing the phenomenon of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

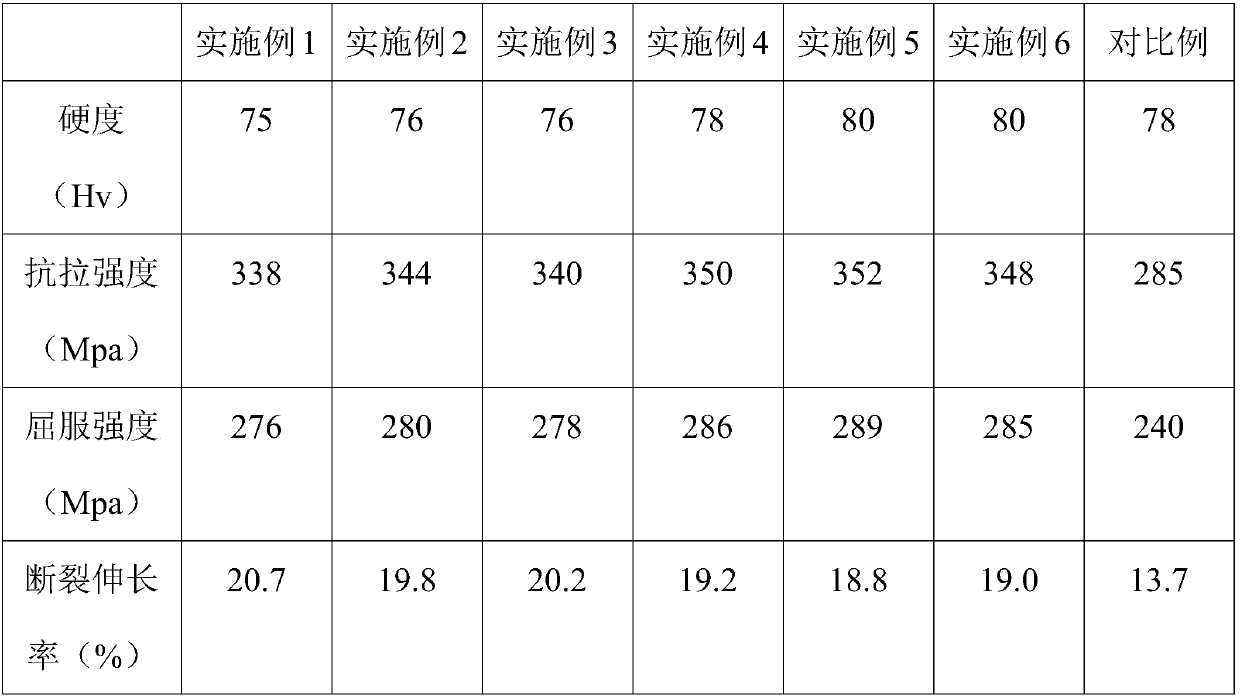

Examples

Embodiment 1

[0021] The invention proposes an electrophoretic aluminum profile with high resistance to bending and cracking. The base material of the aluminum profile includes, by weight percentage: 0.47% Si, 0.68% Mg, 0.25% Fe, 0.12% Mo, 0.30% Mn, Cr 0.05%, Cu0.03%, Zn 0.10%, the balance is Al and unavoidable impurities, single impurity ≤ 0.05%, total impurity 0.15%.

[0022] The present invention also proposes a method for preparing the above-mentioned electrophoretic aluminum profiles with high resistance to bending and cracking, which includes the following steps:

[0023] S1. Melting: batching is carried out according to the composition of the base material of the aluminum profile, smelting, the melting temperature is 745-755°C, refining and slag casting, and casting to obtain blanks;

[0024] S2. Homogenization treatment: heat the blank at 550°C for 6 hours for homogenization treatment, and air-cool;

[0025] S3. Primary extrusion: heat the homogenized billet to 440° C., extrude it ...

Embodiment 2

[0031] An electrophoretic aluminum profile with high resistance to bending and cracking proposed by the present invention, the base material of the aluminum profile includes by weight percentage: Si 0.49%, Mg 0.78%, Fe 0.33%, Mo 0.18%, Mn 0.22%, Cr 0.03%, Cu0.05%, Zn 0.07%, the balance is Al and unavoidable impurities, single impurity ≤ 0.05%, total impurity 0.12%.

[0032] The present invention also proposes a method for preparing the above-mentioned electrophoretic aluminum profiles with high resistance to bending and cracking, which includes the following steps:

[0033] S1. Smelting: batching is carried out according to the composition of the base material of the aluminum profile, and the melting temperature is 750-760°C. Refining and slag casting are carried out to obtain blanks;

[0034] S2. Homogenization treatment: heat the blank at 560°C for 8 hours for homogenization treatment, and air-cool;

[0035] S3. One-time extrusion: heat the homogenized billet to 450° C., ex...

Embodiment 3

[0041] The invention proposes an electrophoretic aluminum profile with high resistance to bending and cracking. The base material of the aluminum profile includes, by weight percentage: 0.55% Si, 0.78% Mg, 0.27% Fe, 0.15% Mo, 0.25% Mn, Cr 0.04%, Cu0.03%, Zn 0.05%, the balance is Al and unavoidable impurities, single impurity ≤ 0.04%, total impurity 0.10%.

[0042] The present invention also proposes a method for preparing the above-mentioned electrophoretic aluminum profiles with high resistance to bending and cracking, which includes the following steps:

[0043] S1. Smelting: batching is carried out according to the composition of the base material of the aluminum profile, smelting, the melting temperature is 745-750°C, refining and slag casting, and casting to obtain blanks;

[0044] S2. Homogenization treatment: heat the blank at 550°C for 6.5 hours for homogenization treatment, and air-cool;

[0045]S3. Primary extrusion: heat the homogenized billet to 440°C, extrude it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com