Rubber-coating roll with composite rubber-coating layer and method for preparing same

A composite material layer and composite material technology, applied in the field of rubber-coated rollers and their preparation, can solve problems such as poor impact resistance, and achieve the effects of good wear resistance, not easy to fall off, and high bonding strength

Inactive Publication Date: 2010-08-25

SHANDONG UNIV

View PDF10 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Wear-resistant alloys have high hardness and exhibit good wear resistance. For example, high-chromium cast iron alloys are materials with excellent abrasive wear resistance, but their impact resistance is poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

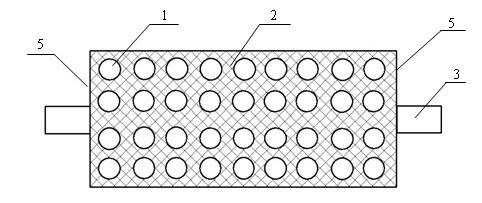

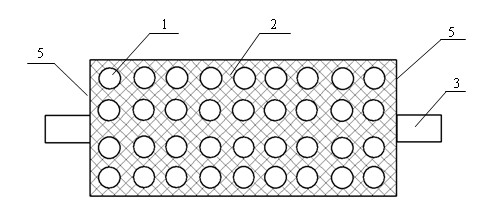

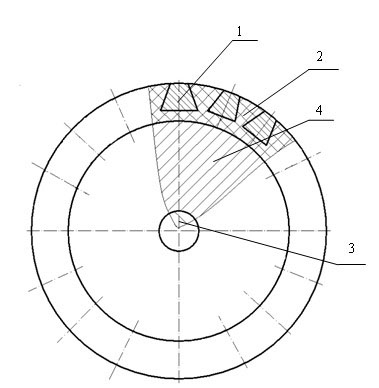

The invention discloses a rubber-coating roll with a composite rubber-coating layer. The rubber-coating roll comprises a cylindrical rotary body made of a metallic material; the rubber composite material layer is coated on the rotary body; and the rubber composite material layer is made of a composite material formed by embedding wear resistant alloy blocks in rubber. The rubber-coating roll has the advantages of high toughness and plasticity and impact resistance of rubber materials and high hardness and wear resistance of wearing resistant alloy; and the rubber-coating roll can be used under working conditions of bearing a bigger impact load, and overcomes the defect that the impact resistance of the wearing resistant alloy materials is low.

Description

Covering roller with composite material covering layer and preparation method thereof technical field The invention relates to a rubber-coated roller with a composite material rubber-coated layer and a preparation method thereof. Background technique Covered rollers are widely used in metallurgy, mining, electric power, chemical industry, printing, textile, printing and dyeing and other industries, and are divided into conveying rollers, tension rollers, steering rollers, squeezing rollers, support rollers, etc. Rubber-covered rollers are also called rubber-coated rollers, which use metal materials to make a cylindrical rotating body, and then cover a layer of rubber material on the surface of the cylindrical rotating body. Most of the currently used cylindrical revolving bodies are made of seamless steel pipes, and the revolving bodies of some small rubber-covered rollers also use solid shaft structures. The covering layer is made of wear-resistant rubber. The structure ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B1/08B32B15/06B32B3/16B32B3/30

Inventor 孙俊生孙逸群

Owner SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com