Magnetic core of low conductive magnet, manufacturing method and application thereof

A manufacturing method and low magnetic permeability technology, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor magnetic core, magnetic material, etc., to achieve the effect of simple process, low residual magnetic flux density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

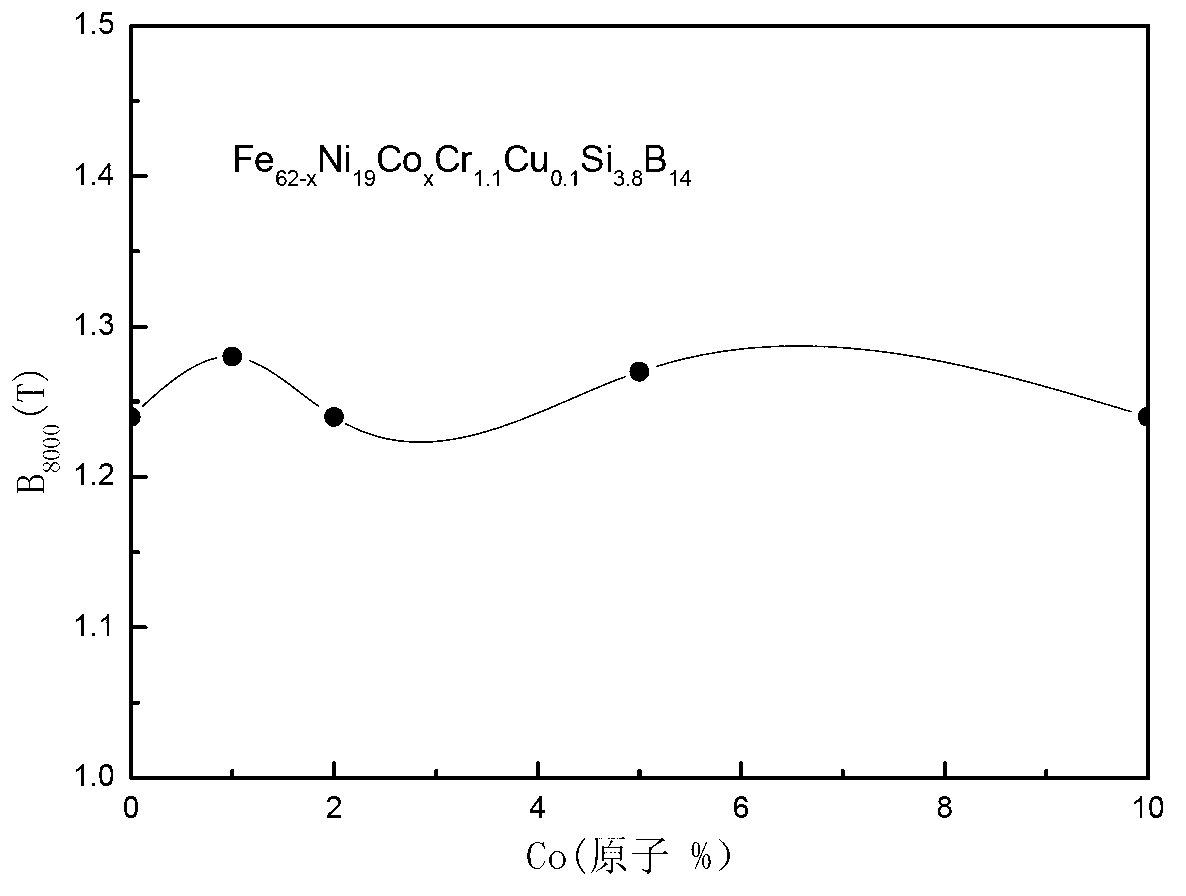

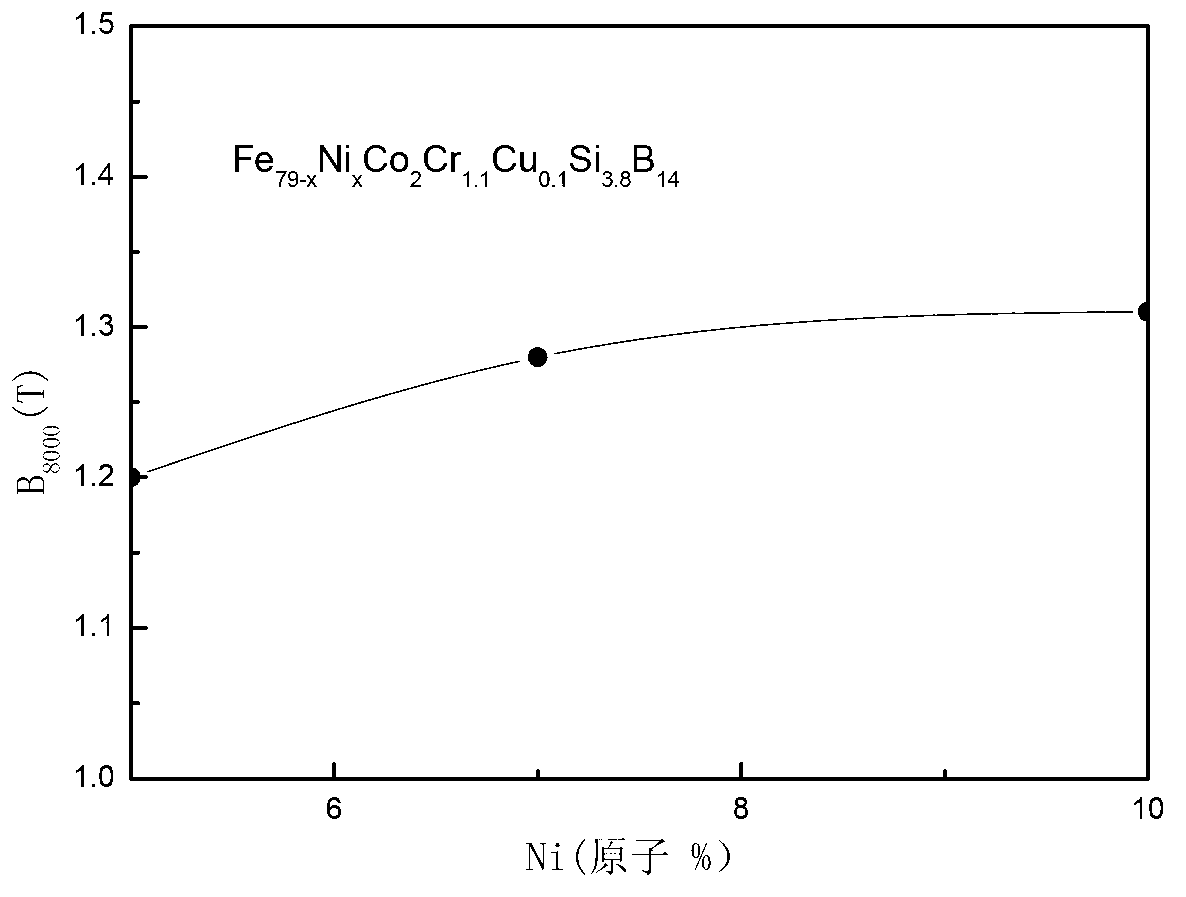

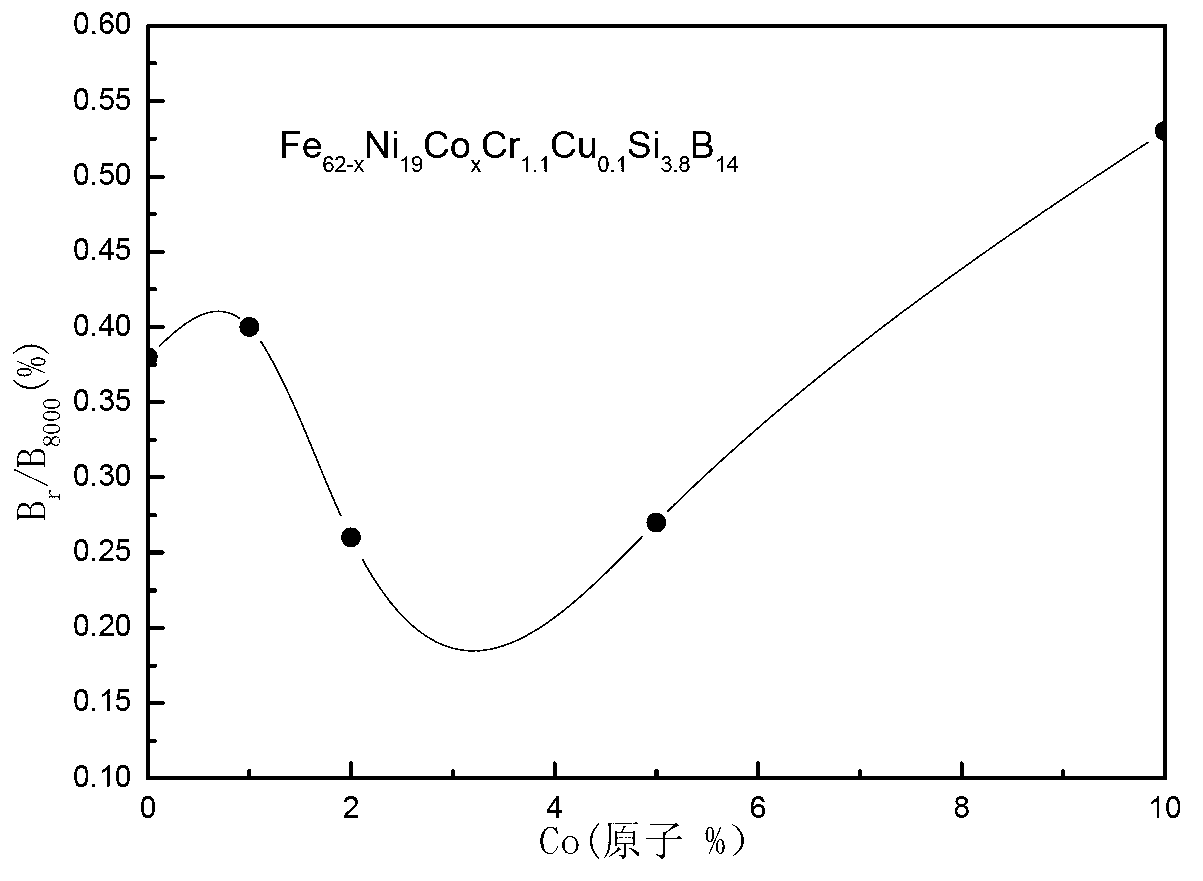

[0061] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. The present invention is not limited to the following examples.

[0062] Composition of low permeability magnetic core

[0063] The low magnetic permeability magnetic core with low magnetic permeability and high anti-saturation performance and high modulability for AC and DC components of the present invention is made of Fe-based amorphous alloy, wherein the alloy can be represented by the general formula as Fe a m b Cu c Si d B e M' f x g (atomic %), wherein, M is Ni and / or Co, M' is at least one element selected from V, Ti, Zr, Nb, Mo, Cr, Hf, Ta, W, X represents P, Ge , C and common impurities on the market, the values of a, b, c, d, e, f, g, h, i are given in atomic %, a, b, c, d, e, f, g Satisfy the following conditions respectively: 5≤b≤40, 0.05≤c≤1, 1≤d≤8, 10≤e≤20, 0.5≤f≤5, 0≤g≤0.5, 10≤d+e≤25, a =100-b-c-d-e-f-g....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com