Micro-alloy chemical die steel and thermal treatment method thereof

A heat treatment method and technology of tool and die steel, applied in the field of new tool and die steel and its heat treatment, can solve the problems of low quenching heating temperature, limited hardenability, and insufficient use of V, so as to reduce carbon emissions and simplify the heat treatment process , good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

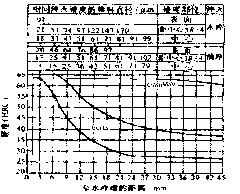

[0039] Such as Figure 1 ~ Figure 3shown. A microalloy chemical mold steel and a heat treatment method thereof. The chemical composition characteristics of this type of steel are: adding 0.2% V or Nb for microalloying; the carbon content is reduced from hypereutectoid to eutectoid composition, that is, reduced to 0.7-0.9%; the content of alloying elements is reduced to about 1.5%. The content of O, N, S, P and other harmful elements can be divided into two categories, one is ordinary steel, the content is the same as the current standard, and the other is clean steel, the total content of O, N, S, P, etc. should be 50ppm the following. The specific heat treatment process of this type of steel is as follows: After hot rolling, heat to a temperature of 1050-1150°C where vanadium carbide and niobium carbide can fully dissolve into austenite, and perform solid solution treatment to dissolve carbon and all alloy elements into austenite , quickly cool to 600°C, transfer to a furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com