Martensite wear resistant steel and manufacturing method thereof

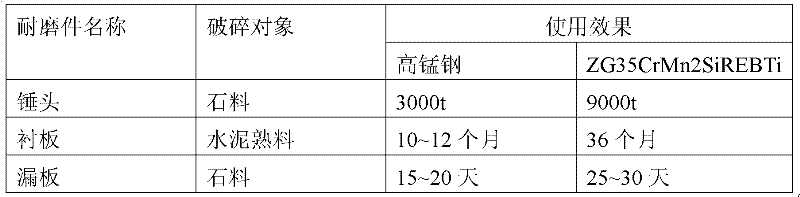

A martensitic and wear-resistant steel technology, applied in the field of martensitic wear-resistant steel and its manufacture, and wear-resistant castings, can solve the problem of unsatisfactory wear resistance of high-manganese steel, effective hardening of high-manganese steel, and low hardness and other problems, to achieve the effect of excellent toughness and wear resistance, low manufacturing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment, the present invention will be further described, and following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

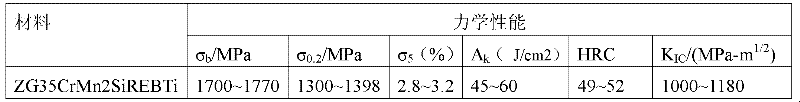

[0012] A martensitic wear-resistant steel, according to chemical composition (mass percentage): C 0.30-0.35, Si 0.6-1.2, Mn 1.0-1.5, Cr 2.5-3.5, B 0.003-0.007, Ti 0.03-0.06, RE 0.1- 0.15, Al 0.01~0.03, S≤0.035, P≤0.035, and the rest is Fe.

[0013] Its manufacturing method includes smelting process and heat treatment process:

[0014] (1) Melting process:

[0015] The first step of microalloying treatment: Melting in an intermediate frequency induction furnace, adding Cr, Mn, and Si at 1550-1600 ° C, and putting the melted steel into a ladle;

[0016] The second step of microalloying treatment: put RESiFe into the ladle, the temperature is 1600°C during pouring, and then cool down to obtain the rough casting;

[0017] Put the rough casting int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com