Steel for super-high-strength and super-high-toughness petroleum casing, petroleum casing and manufacturing method of petroleum casing

A technology of oil casing and ultra-high toughness, which is applied in the direction of casing, manufacturing tools, drilling pipes, etc., to achieve the effect of easy production and implementation and simple heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

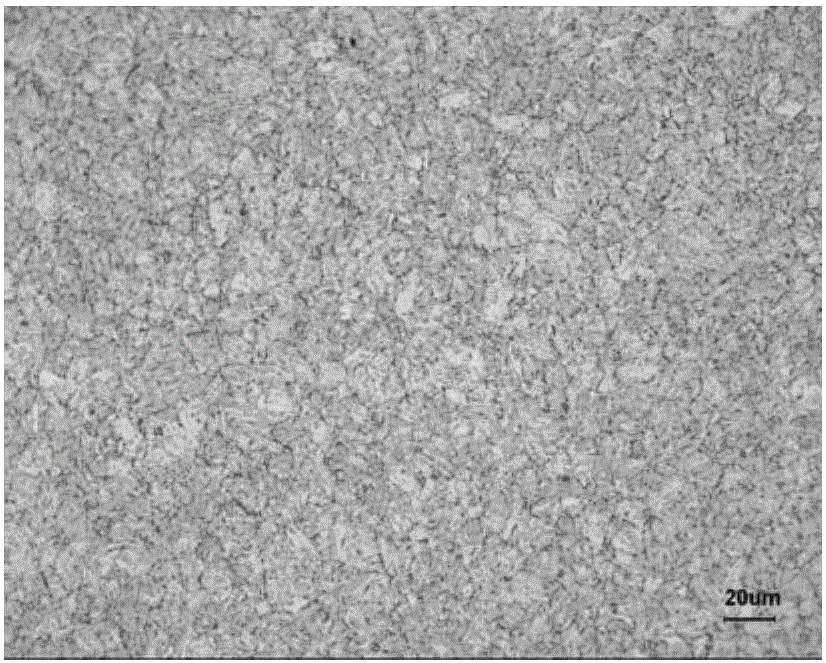

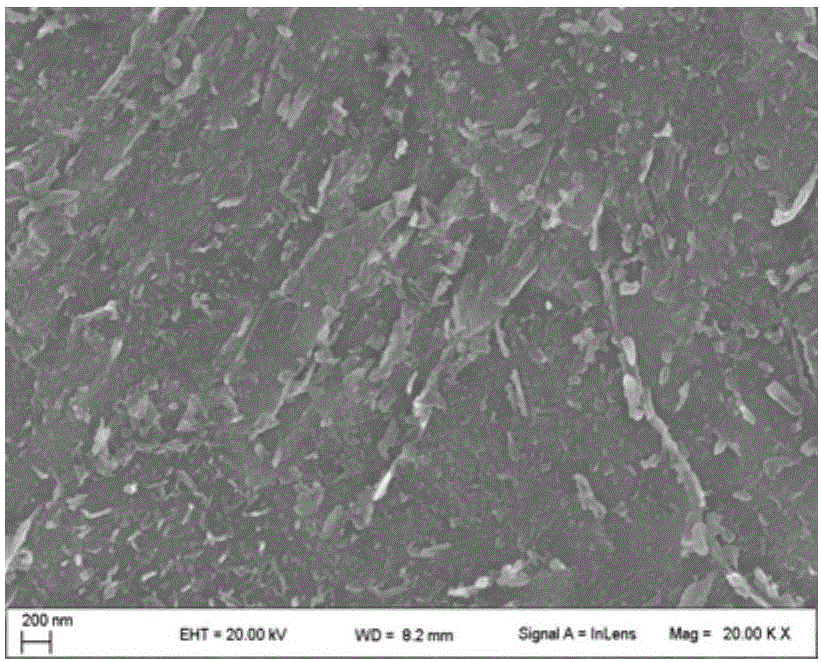

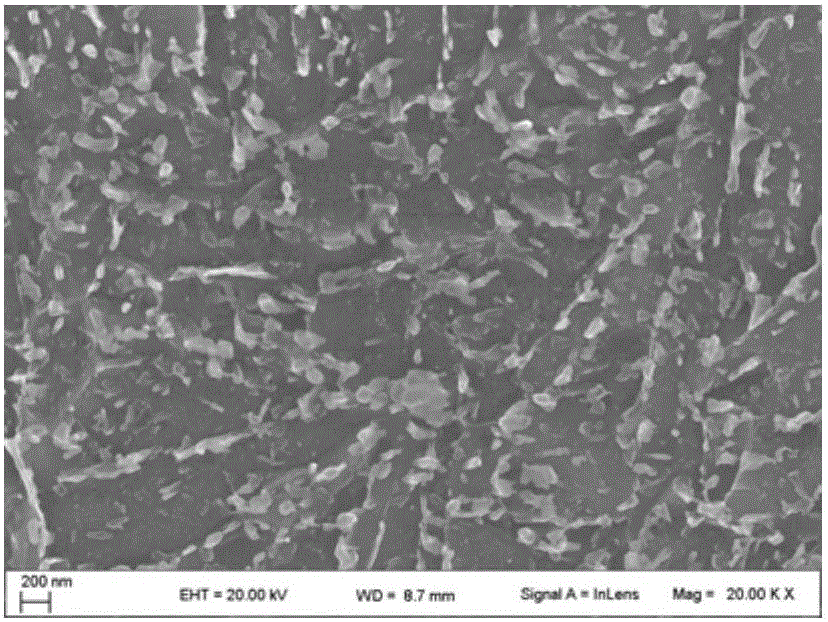

Image

Examples

Embodiment 1-5 and comparative example 1-3

[0055] According to the following steps, the oil casing pipes in the examples 1-5 of the present invention and the oil casing pipes in the comparative examples 1-3 (the element ratio in each embodiment and the comparative examples are shown in Table 1, each embodiment and the comparative examples Concrete process parameter in the as shown in table 2):

[0056] (1) Smelting: The molten steel is smelted in an electric furnace, refined outside the furnace, vacuum degassed and stirred with argon, and then treated with Ca to denature the inclusions to reduce the O and H content;

[0057] (2) Casting tube blank: control the superheat of molten steel below 30°C during the casting process;

[0058] (3) Piercing and continuous rolling of steel pipes: After the continuous casting slab is cooled, it is heated in an annular heating furnace and soaked at 1200-1240°C, the piercing temperature is 1180-1240°C, and the final rolling temperature is 900°C-950°C;

[0059] (4) Heat treatment: con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com