Inorganic/organic composite solid electrolyte and preparation method and application thereof

A solid electrolyte and organic technology, applied in the field of inorganic/organic composite solid electrolyte and its preparation, can solve the problems of low room temperature ionic conductivity and poor electrochemical performance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

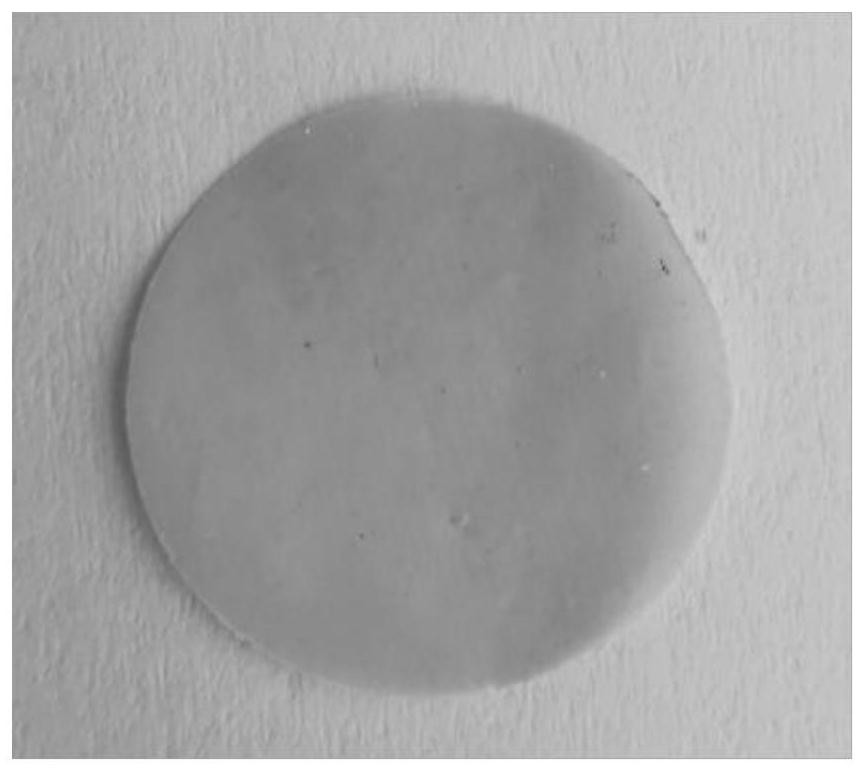

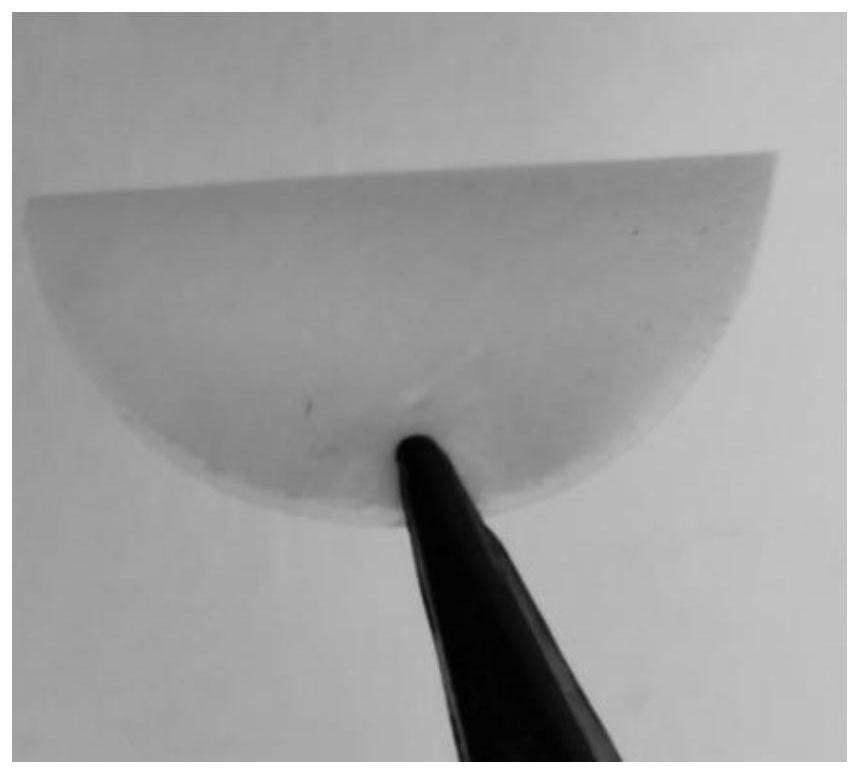

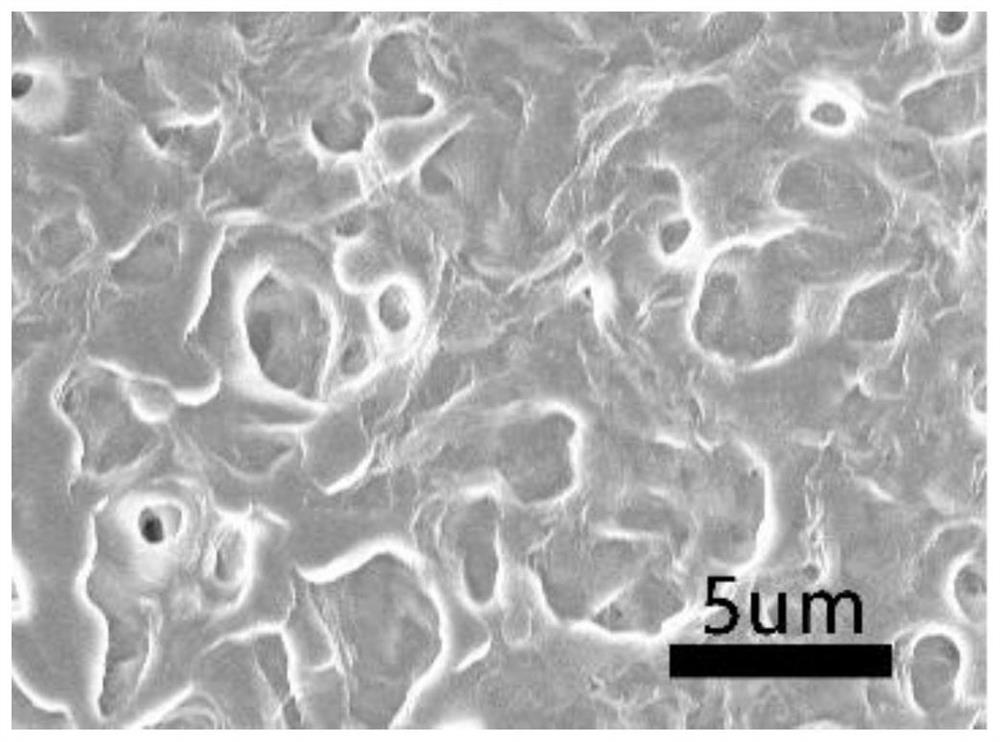

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of an inorganic / organic composite solid electrolyte, comprising the following steps:

[0032] (1) Mix polyethylene oxide, polyvinylidene fluoride-hexafluoropropylene copolymer, sodium salt, the first filler and an organic solvent to obtain the first slurry; the first filler is P2 modified by a silane coupling agent type layered oxide fast ion conductor; the particle size of the first filler is 500nm~1.5μm;

[0033] (2) Mix polyethylene oxide, polyvinylidene fluoride-hexafluoropropylene copolymer, sodium salt, and a second filler with an organic solvent to obtain a second slurry; the second filler is P2 modified by a silane coupling agent Type layered oxide fast ion conductor; the particle size of the second filler is less than 500nm;

[0034] (3) coating the first slurry obtained in the step (1) on the substrate, and drying to obtain a layer of solid electrolyte;

[0035] (4) coating the second slurry obtained in the step (2...

Embodiment 1

[0071] (1) Add the silane coupling agent to 20% ethanol solution under stirring to obtain a mixed solution; the concentration of the silane coupling agent in the mixed solution is 2%;

[0072] (2) P2-type layered oxide fast ion conductor Na 2 Ni 2 TeO 6 Add it into the mixed solution obtained in step (1) under stirring, filter it after stirring for 20 minutes, and dry it at 80°C, and ball mill it to a particle size of 900nm-1.2μm to obtain the first filler; wherein, the silane coupling agent 1.5% of the mass of the P2-type layered oxide fast ion conductor;

[0073] (3) Disperse polyethylene oxide with a viscosity-average molecular weight of 600,000 in dimethylformamide at 1.6 wt%, and stir at 60°C to obtain a uniform polymer slurry liquid; The filler is added under the condition of stirring at 60°C, after mixing evenly, sodium hexafluorophosphate and PVDF-HFP copolymer are added under the condition of stirring at 60°C, and the first slurry is obtained after mixing evenly; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com