Preparation method of conductive polymer modified lithium ion battery positive pole piece

A technology of lithium-ion batteries and conductive polymers, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficulty in large-scale production, cumbersome preparation process of lithium-ion battery composite electrode materials, etc., and achieve excellent rate performance and Cycling performance, reduction of interface side reactions, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the conductive polymer modified lithium-ion battery cathode sheet of the present embodiment comprises the following steps:

[0041] 1) Pour 0.05g polyvinylcarbazole into a 5mL small beaker, add 2mL N-methylpyrrolidone, and stir at 500r / min until dissolved to obtain solution A;

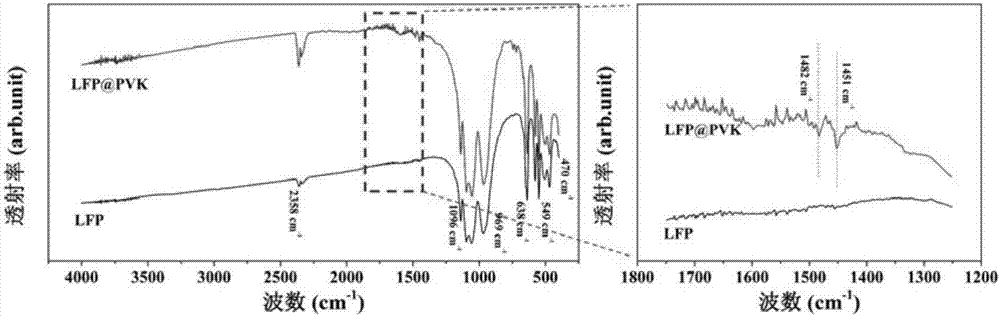

[0042] 2) 2g LiFePO 4 The powder was slowly added to the solution A obtained in step 1), and then heated and stirred at 60°C for 4 hours, and mixed evenly to obtain the dispersion B;

[0043] 3) Centrifuge the dispersion B obtained in step 2) to remove N-methylpyrrolidone; then add distilled water to disperse, centrifuge, pour off the liquid, and repeat 2 times; then add ethanol to disperse, centrifuge, pour off the liquid, and repeat 2 more times times; during centrifugation, the speed of the centrifuge was 3000r / min; finally, it was dried at 110°C for 12 hours to obtain a conductive polymer-coated positive electrode material;

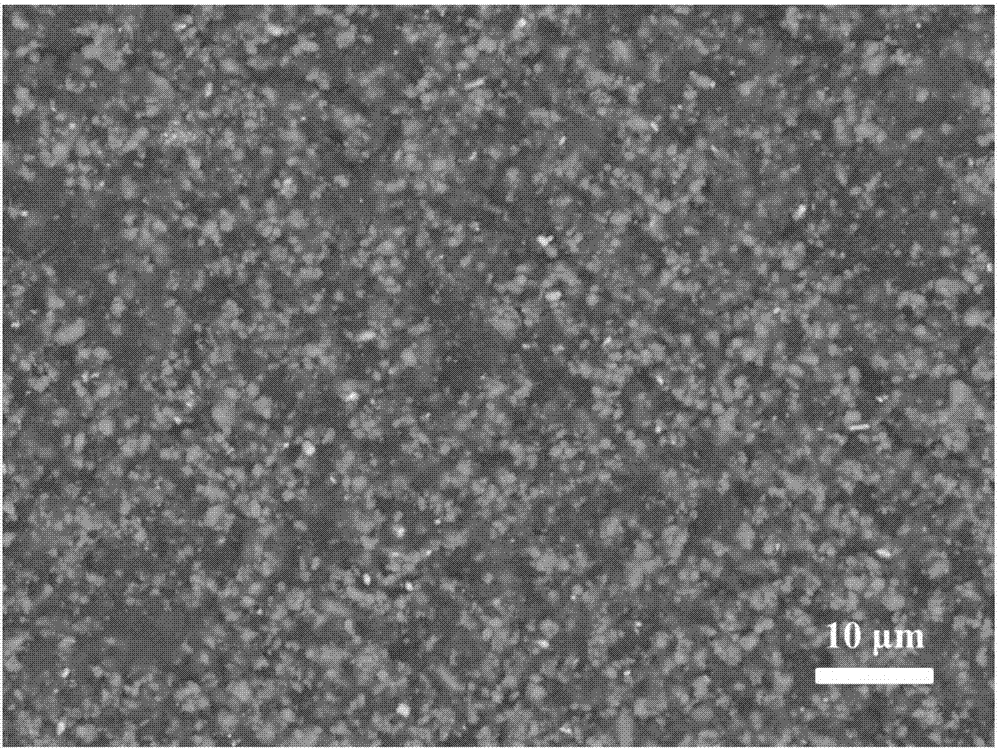

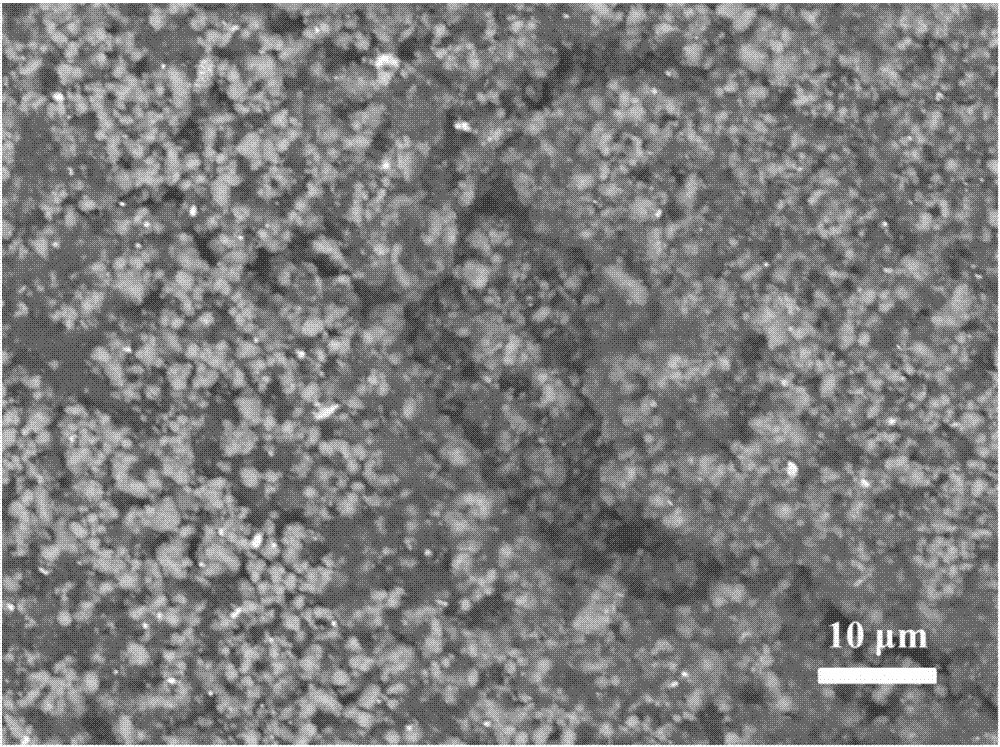

[0044] 4) Mix the conductive polymer-c...

Embodiment 2

[0046] The preparation method of the conductive polymer modified lithium-ion battery cathode sheet of the present embodiment comprises the following steps:

[0047] 1) Pour 0.025g polyvinylcarbazole into a 5mL small beaker, add 2mL N-methylpyrrolidone, stir at 300r / min until dissolved, and obtain solution A;

[0048] 2) 2g LiCoO 2 The powder was slowly added to the solution A obtained in step 1), and then heated and stirred at 70°C for 4 hours, and mixed evenly to obtain the dispersion B;

[0049] 3) Centrifuge the dispersion B obtained in step 2) to remove N-methylpyrrolidone; then add distilled water to disperse, centrifuge, pour off the liquid, and repeat 2 times; then add ethanol to disperse, centrifuge, pour off the liquid, and repeat 2 more times times; during centrifugation, the speed of the centrifuge was 3500r / min; finally, it was dried at 110°C for 10 hours to obtain a conductive polymer-coated positive electrode material;

[0050] 4) Mix the conductive polymer-coa...

Embodiment 3

[0052] The preparation method of the conductive polymer modified lithium-ion battery cathode sheet of the present embodiment comprises the following steps:

[0053] 1) Pour 0.075g polyvinylcarbazole into a 5mL small beaker, add 2mL N-methylpyrrolidone, stir at 700r / min until dissolved, and obtain solution A;

[0054] 2) 2g LiNiO 2 The powder is slowly added to the solution A obtained in step 1), and then heated and stirred at 70°C for 8 hours, and mixed evenly to obtain the dispersion B;

[0055] 3) Centrifuge the dispersion B obtained in step 2) to remove N-methylpyrrolidone; then add distilled water to disperse, centrifuge, pour off the liquid, and repeat 2 times; then add ethanol to disperse, centrifuge, pour off the liquid, and repeat 2 more times times; during centrifugation, the speed of the centrifuge was 4500r / min; finally, it was dried at 120°C for 10 hours to obtain a conductive polymer-coated positive electrode material;

[0056] 4) Mix the conductive polymer-coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com