Method for modifying surface of lithium cobalt oxide positive electrode material by phosphorus-containing compound and lithium cobalt oxide positive electrode material

A cathode material and surface modification technology, applied in battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of complex and difficult process control, and achieve the effect of simple and easy control of the process and obvious modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

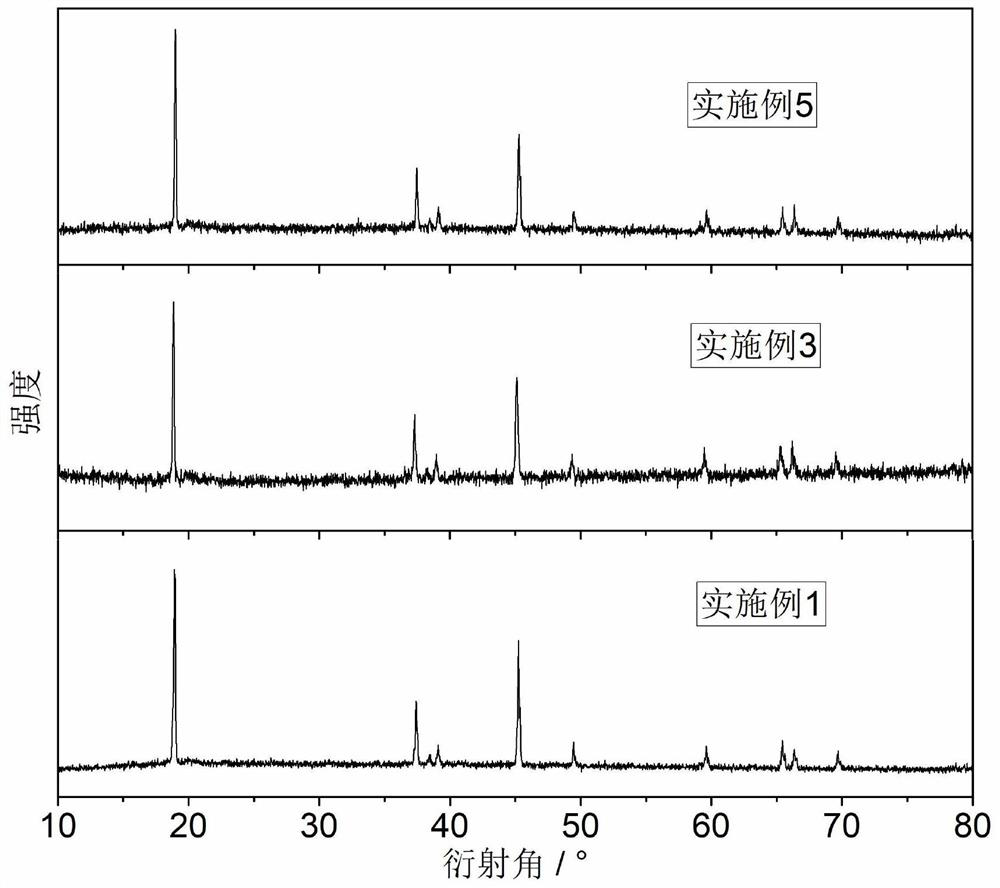

Embodiment 1

[0052] Mix 0.1g of sodium phosphate and 10g of lithium cobaltate in a ball mill, mill for 2 hours, heat at 400°C in air for 5-6 hours, and cool naturally to obtain a surface-modified lithium cobaltate material.

Embodiment 2

[0054] 0.2 g of sodium hypophosphite and 10 g of lithium cobaltate were ball-milled for 2 hours, heated at 200° C. in argon for 1 hour, and naturally cooled to obtain a surface-modified lithium cobaltate material.

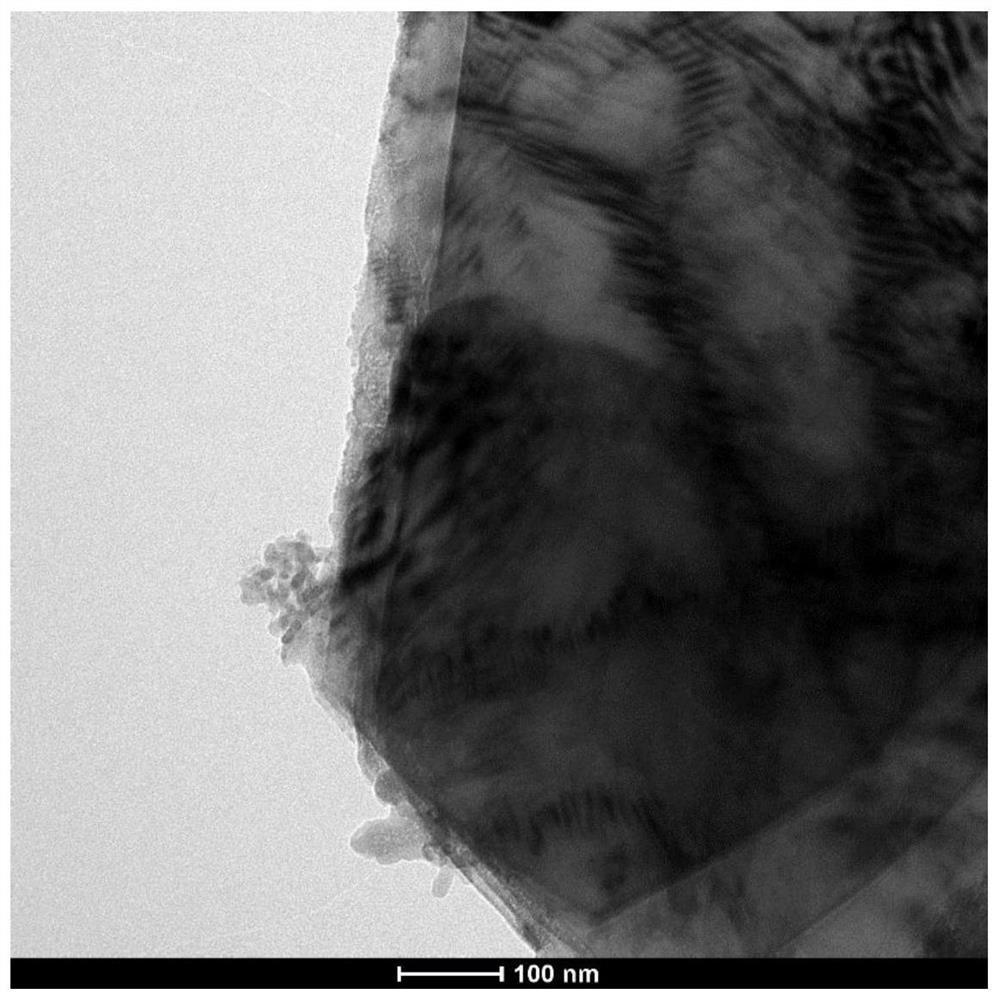

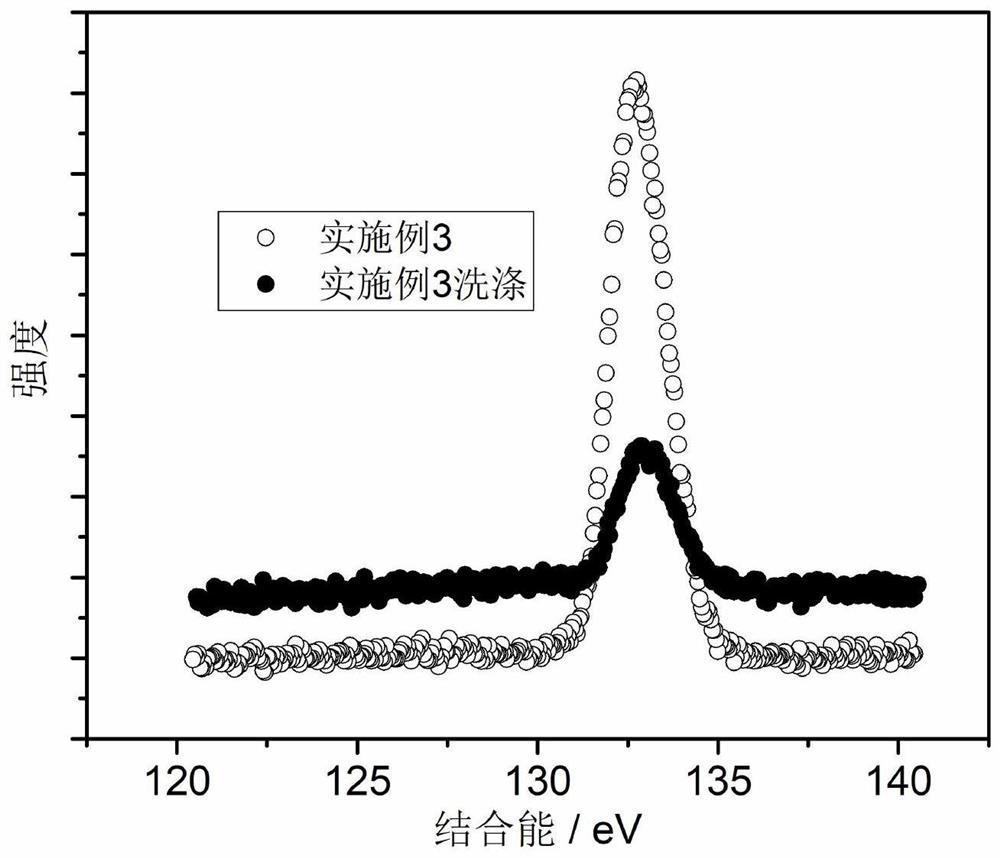

Embodiment 3

[0056] 0.5 g of sodium hypophosphite and 10 g of lithium cobaltate were mixed and ball-milled for 2 hours, heated at 500° C. in air for 2 hours, and naturally cooled to obtain a surface-modified lithium cobaltate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com